Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

338results about How to "Penetrating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

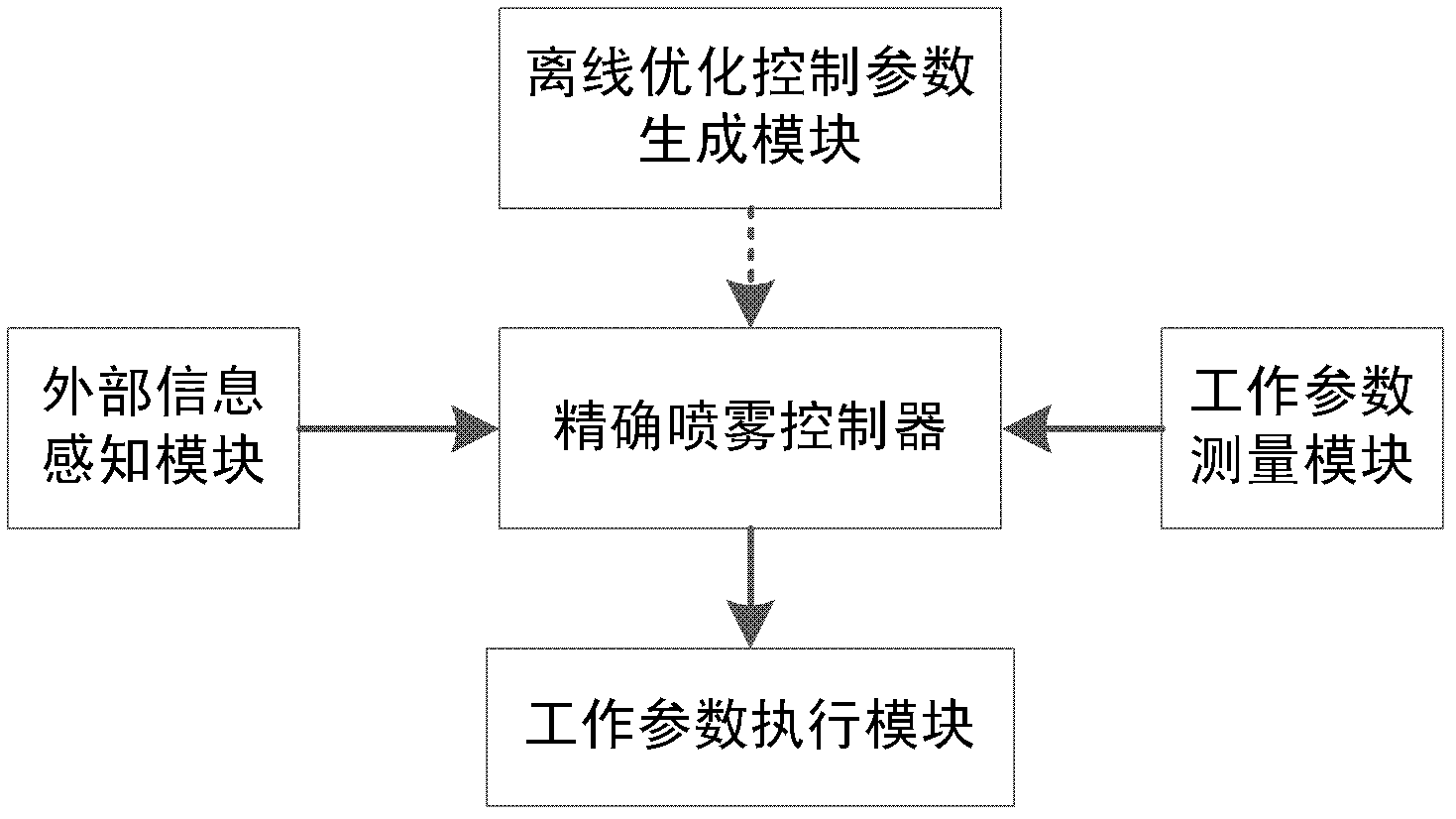

Operating environment sensing based active control system for boom sprayer

ActiveCN102599138AReduce power consumptionReduce droplet driftControllers with particular characteristicsInsect catchers and killersPesticidePlant

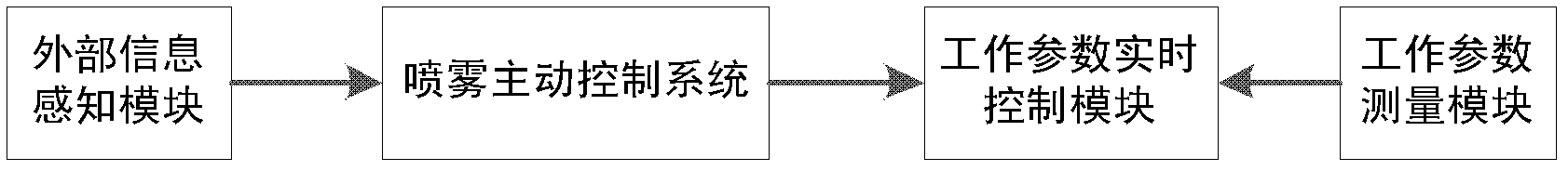

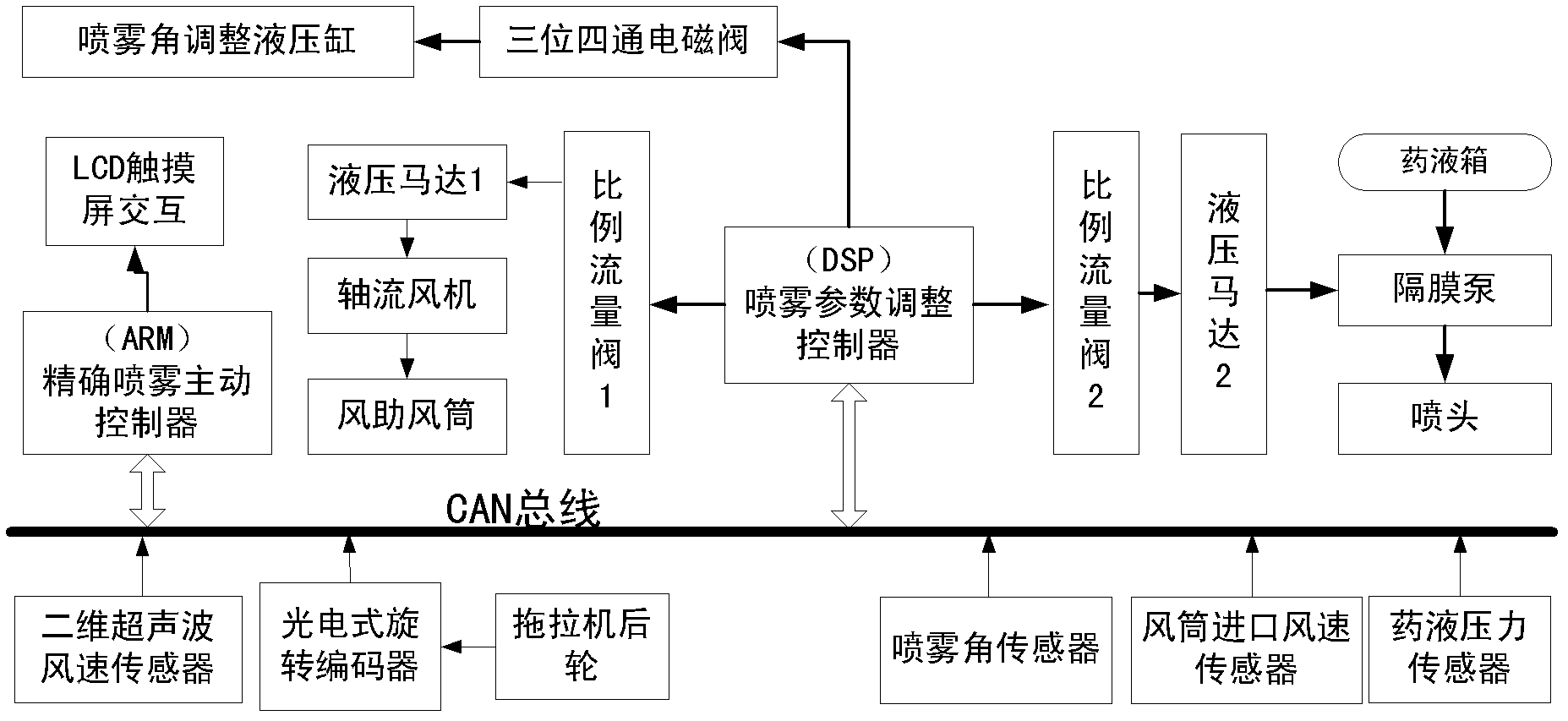

The invention relates to an operating environment sensing based active control system for a boom sprayer, which comprises an outside information sensing module, a running parameter measuring module, an active spray control system module and a running parameter real-time control module. CAN (controlled area network) bus communication of field-operation natural wind speed measured with a two-dimensional ultrasonic wind speed sensor and advancing speed of the boom sprayer measured with a rotary encoder is realized, and spray parameters are calculated through a precision active spray controller. A spray parameter regulating controller is used for acquiring pesticide pressure, fan air volume and spray angle information in real time so as to complete respective PID (proportion integration differentiation) control, and accordingly, the spray volume is guaranteed, drift-reduced spray and fine droplet penetrability are realized, and the effect of settling droplets on plant leaves is improved. The spray system based on external environment sensing and automatic active operating parameter control is high in practical value, simple in structure, convenient in operation and convenient in application.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

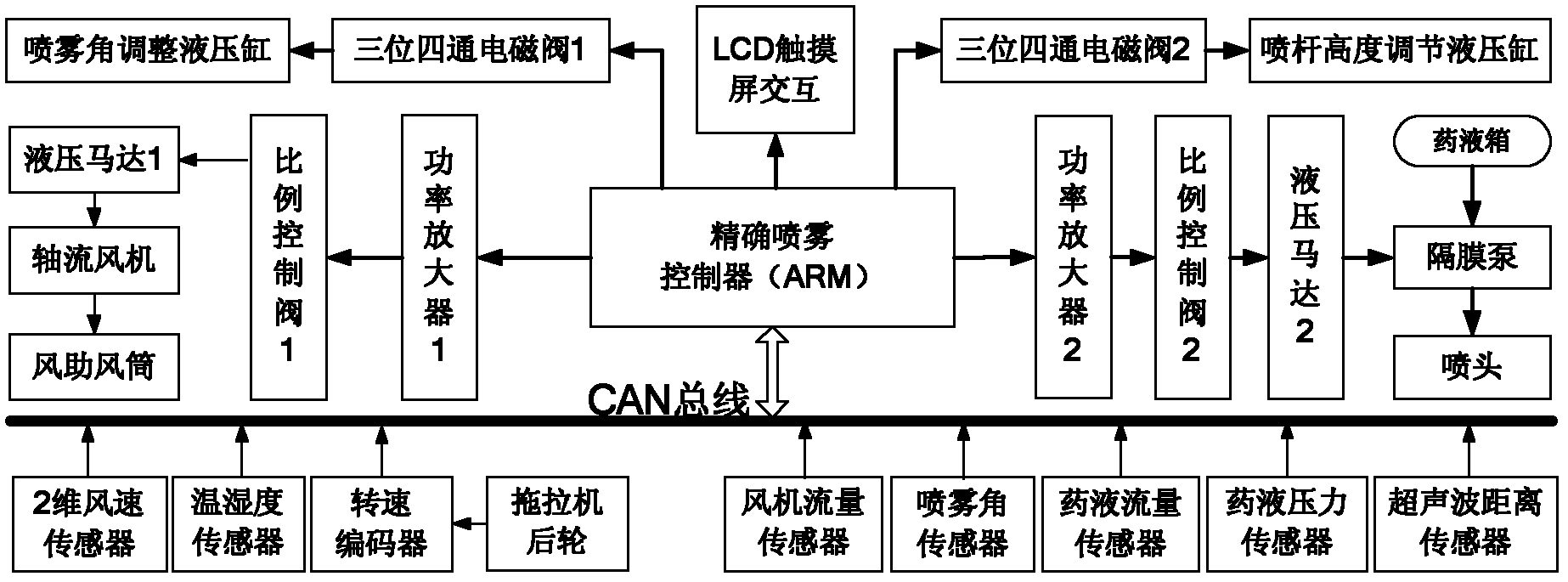

Control system for boom sprayer and spraying compensation control method

InactiveCN102613161AReal-time control of working parametersPenetratingInsect catchers and killersSolenoid valveOptimal control

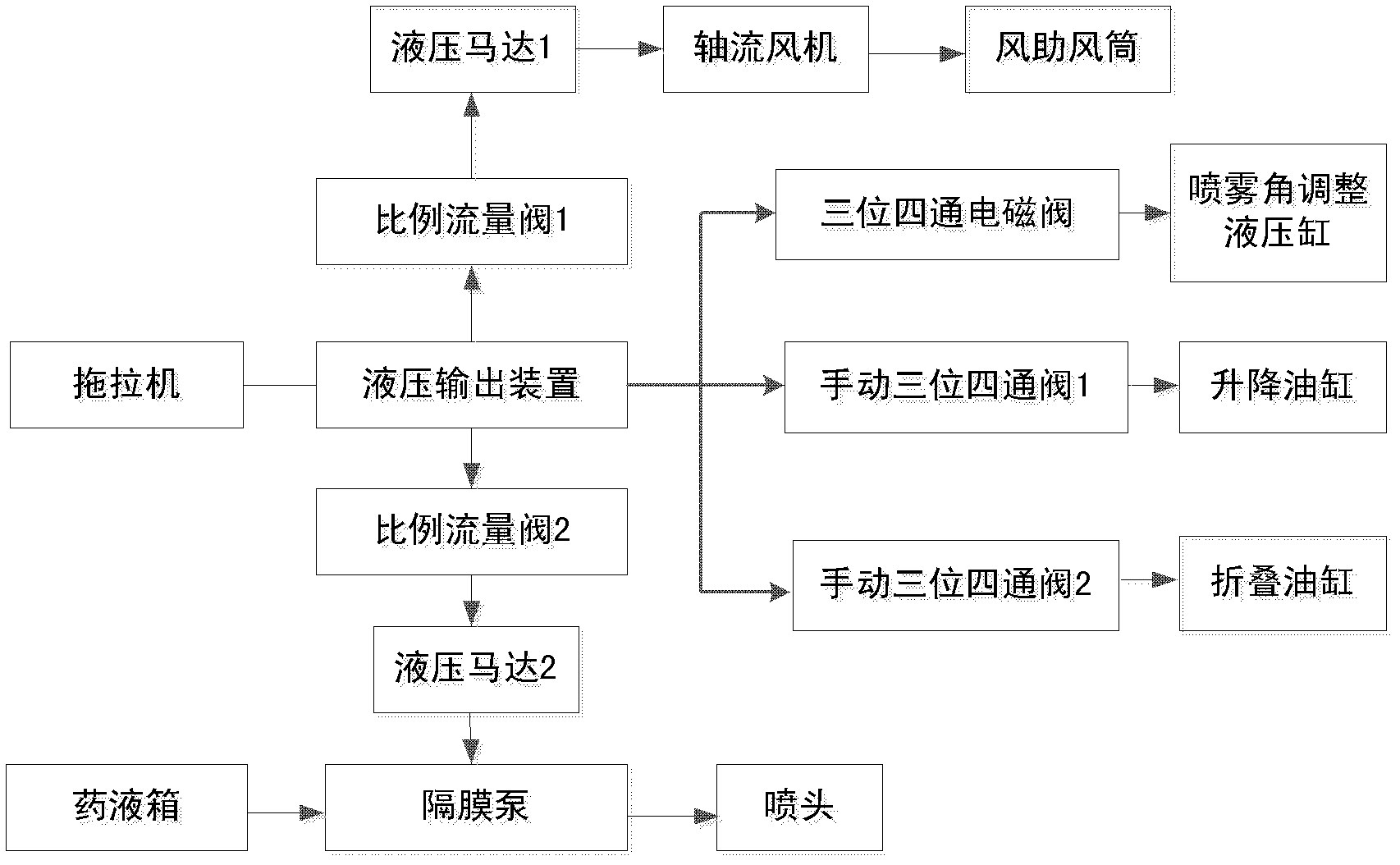

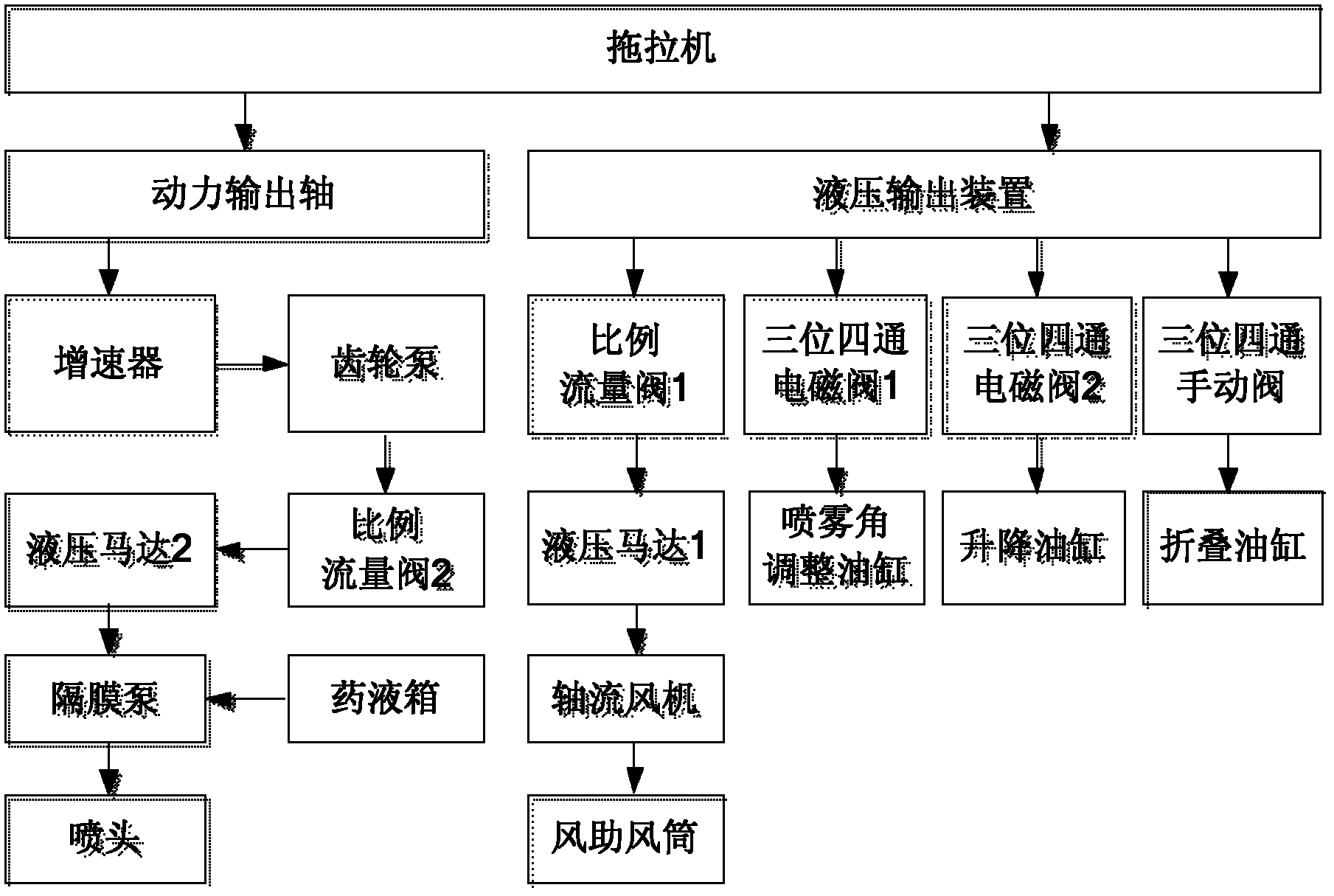

The invention relates to a control system for a boom sprayer and a spraying compensation control method. The control system comprises a hydraulic and mechanical driving part and an electric control part, wherein the hydraulic and mechanical driving part provides a proportional flow valve and a three-position four-way solenoid valve to control working parameters of the sprayer, such as the liquid pesticide pressure, fan delivery, spraying angle and distance from a spraying head to a crop canopy; the electric control part searches parameters in an optimal control index parameter table to work out the best spraying control parameters in the state according to acquired external information such as two-dimensional natural wind speed, environmental humiture and tool traveling speed; and then PID (Proportion, Integration and Differentiation) feedback control is performed on each parameter; further, an intelligent control method for the optimal control index is provided; a support vector machine is used for nonlinear characteristic modeling of spraying under a dynamic environment, and the optimal control parameter index table is established by using multi-objective optimization and storedin an SD (Secure Digital) card for reading by a spraying master control system; with the adoption of the above spraying control considering the dynamic variation of the natural environment and based on the optimal control parameter index table, the stability of a spraying system is effectively improved, and the spraying effect is ensured.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

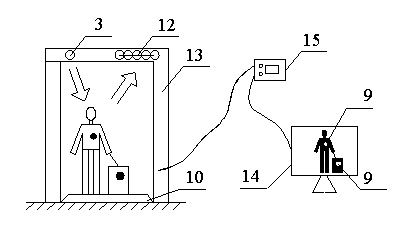

Terahertz imaging passenger luggage rapid security inspection system and dangerous goods detection method thereof

The invention relates to a passenger luggage security inspection system, in particular to a terahertz imaging passenger luggage rapid security inspection system and a dangerous goods detection method of the terahertz imaging passenger luggage rapid security inspection system. Terahertz rays are focused on passenger luggage by controlling a two-dimensional transversely-moving platform through a computer, and are received by a detector after being reflected by passenger luggage and focused by a lens, terahertz signals are converted into voltage signals, and images are output through the computer after noise reduction and amplification are conducted on the voltage signals. The problems that during X-ray detection, hurts are great, formed images are not clear, luggage simultaneous detection signals interfere with one another, and a detection device is complex in structure, large in occupied area, low in detection efficiency and high in cost are solved. The terahertz imaging passenger luggage rapid security inspection system and the dangerous goods detection method are wide in application range, accurate in detection, small and exquisite in structure, and capable of simultaneously conducting security inspection on passenger luggage, and the potential safety hazards of public places are reduced on the premise of efficient security inspection.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

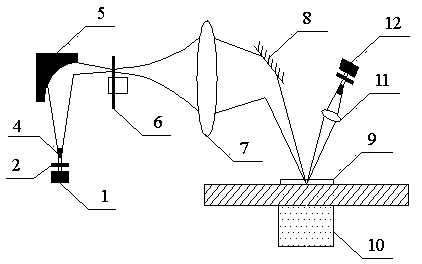

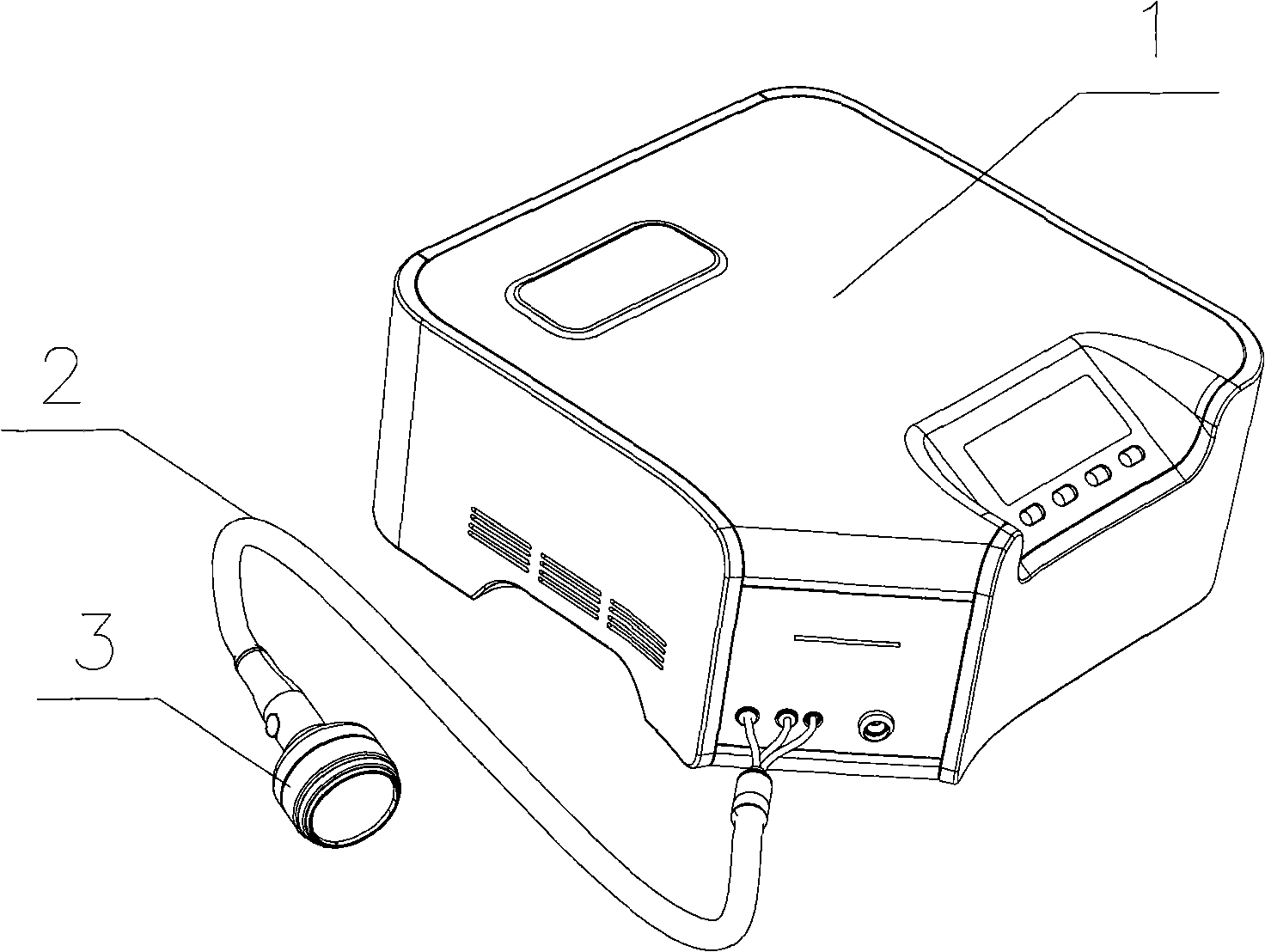

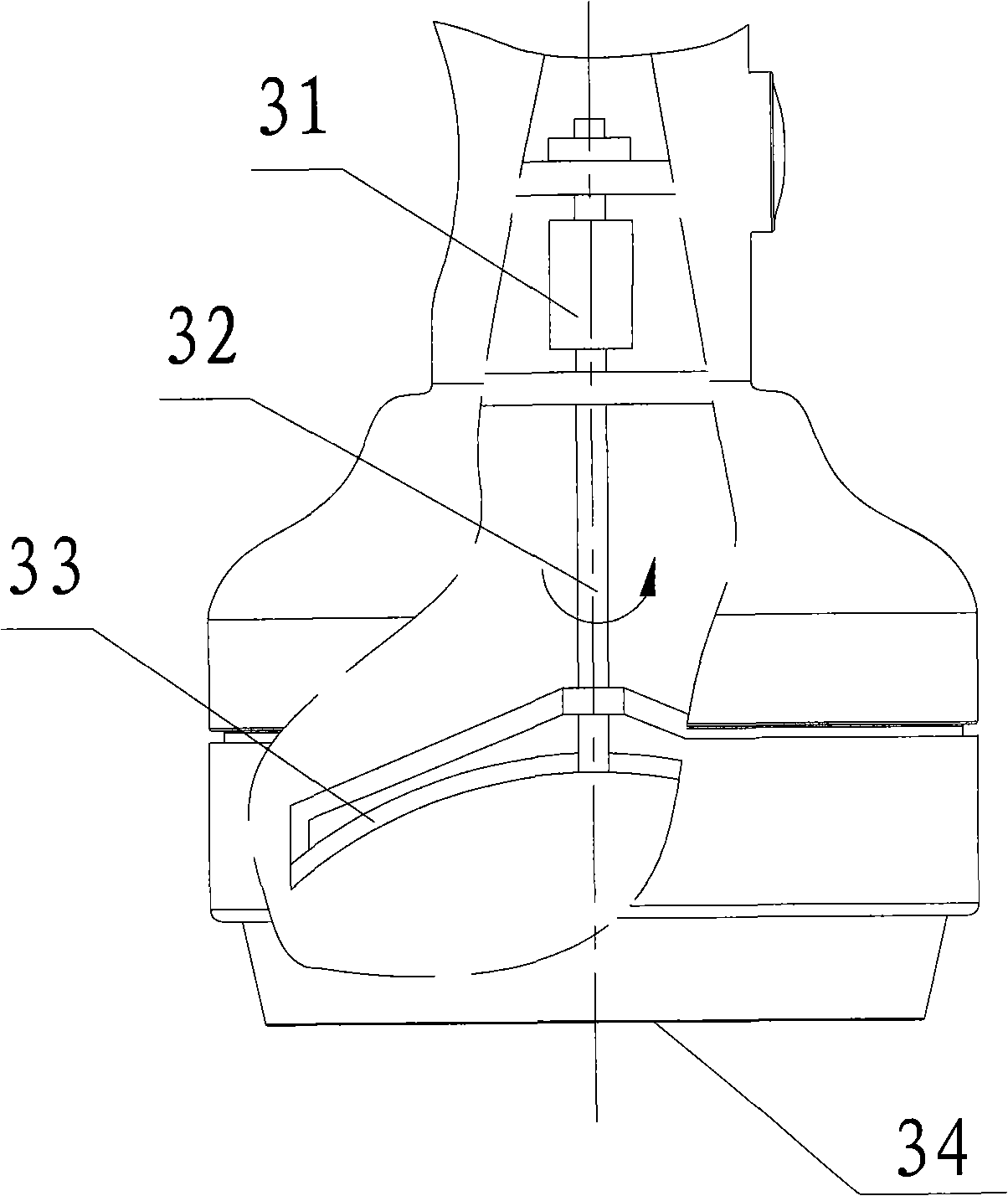

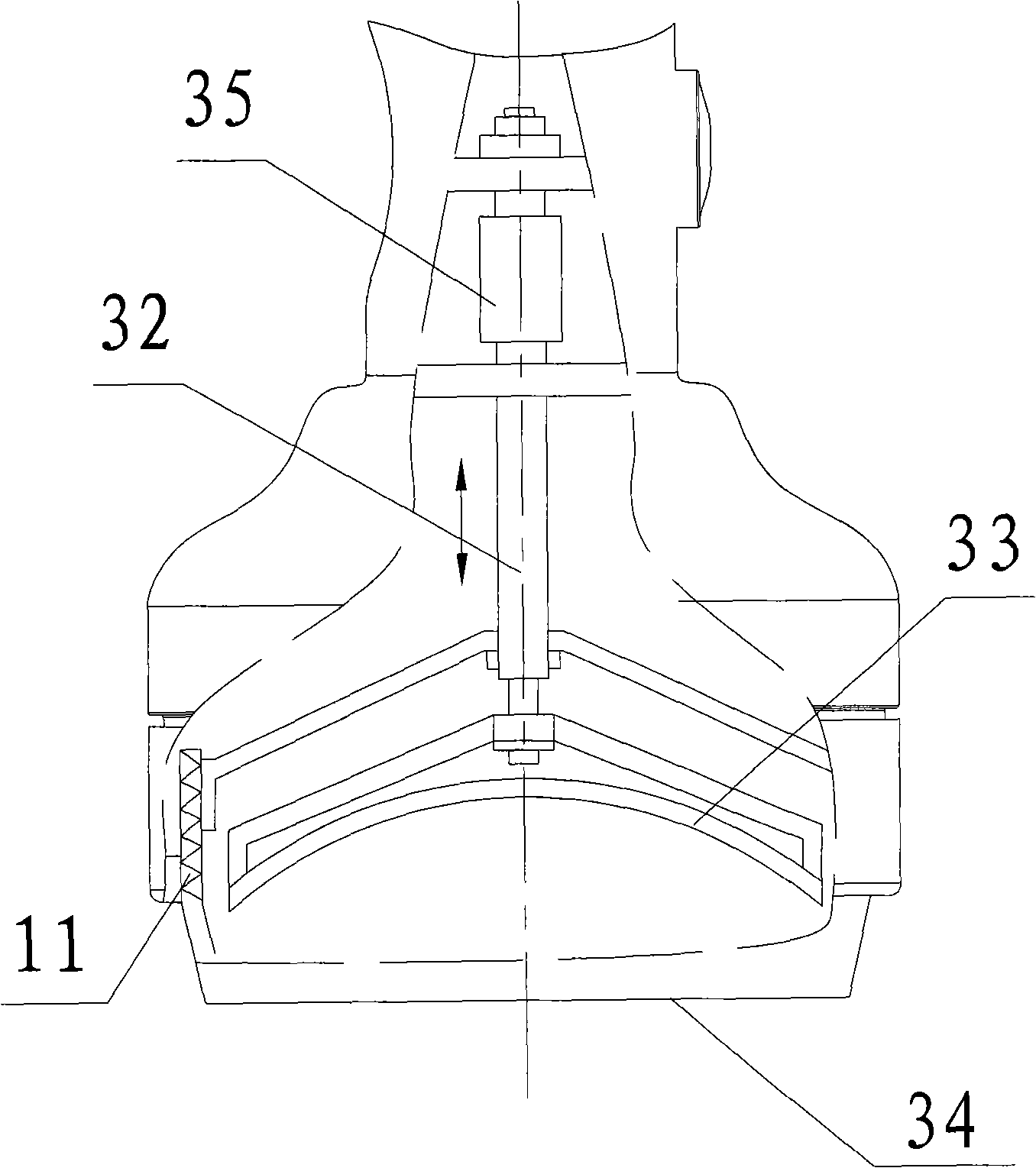

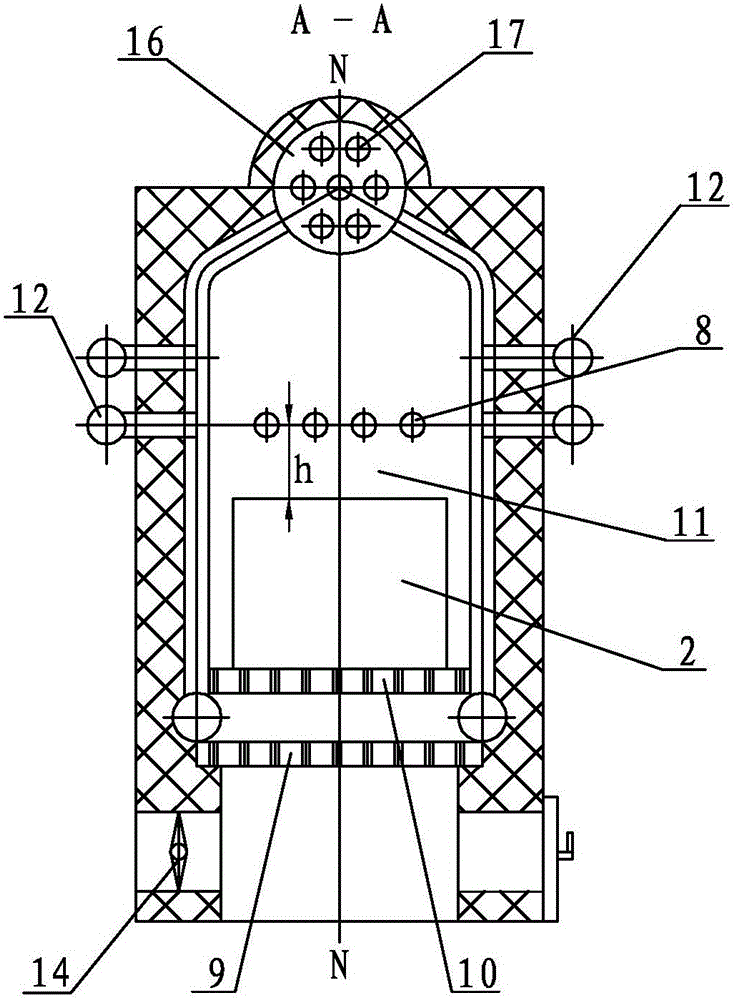

Focused ultrasonic point therapeutic equipment

InactiveCN101284163APenetratingAvoid the risk of infectionUltrasound therapyDevices for heating/cooling reflex pointsUltrasonic sensorCurative effect

The invention discloses a focused ultrasonic-wave point treatment device, comprising a host machine and a treatment gun. The treatment gun is connected with the host machine through a connecting cable; an ultrasonic transducer that can generate focused ultrasonic-waves is arranged inside the treatment gun; an acoustic-field controlling unit that leads the ultrasonic transducer to generate a non-axial symmetry acoustic field is included inside the treatment gun. The focused ultrasonic-wave point treatment device is a noninvasive treatment device, effectively increases the therapeutic safety, and achieves the same curative effect with the traditional acupuncture.

Owner:RONGHAI SUPERSONIC MEDICINE EN

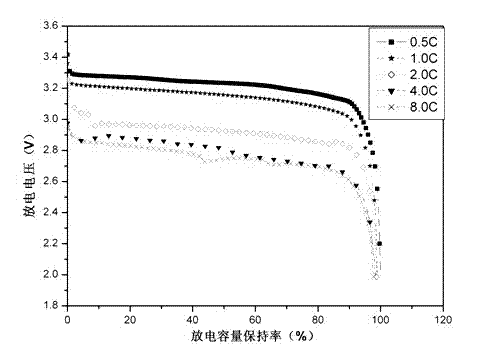

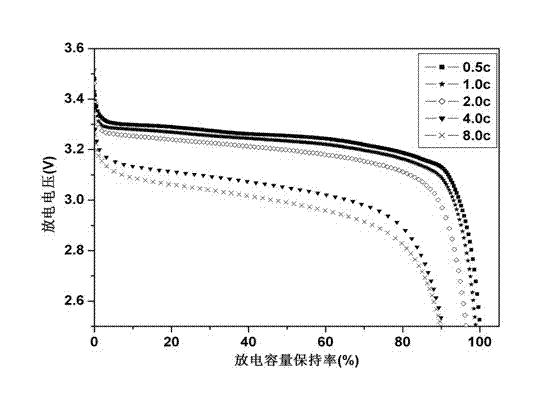

Lithium ion battery negative pole material capable of improving safety performance and preparation method thereof

The invention relates to a preparation method of a lithium ion battery negative pole material capable of improving the safety performance. The method comprises the following steps of: (1) slurry configuration, (2) coating, and (3) roasting and drying. According to the invention, as a negative pole tab is coated with a lithium metaaluminate film, which not only has a good electronic insulation effect, but also can effectively obstruct battery short circuit after a battery diaphragm PP (Polypropylene) or PE (polyethylene) is punctured, and at the same time the lithium metaaluminate has good ionic conductivity, thus increasing the transmission velocity of the lithium ion battery, and reducing the probability that dendritic crystal generated by lithium separation of the lithium ion battery pierces the diaphragm. The composite negative pole tab prepared by the method plays a very important role in improving high-capacity lithium ion batteries.

Owner:JIANGSU LENENG BATTERY INC

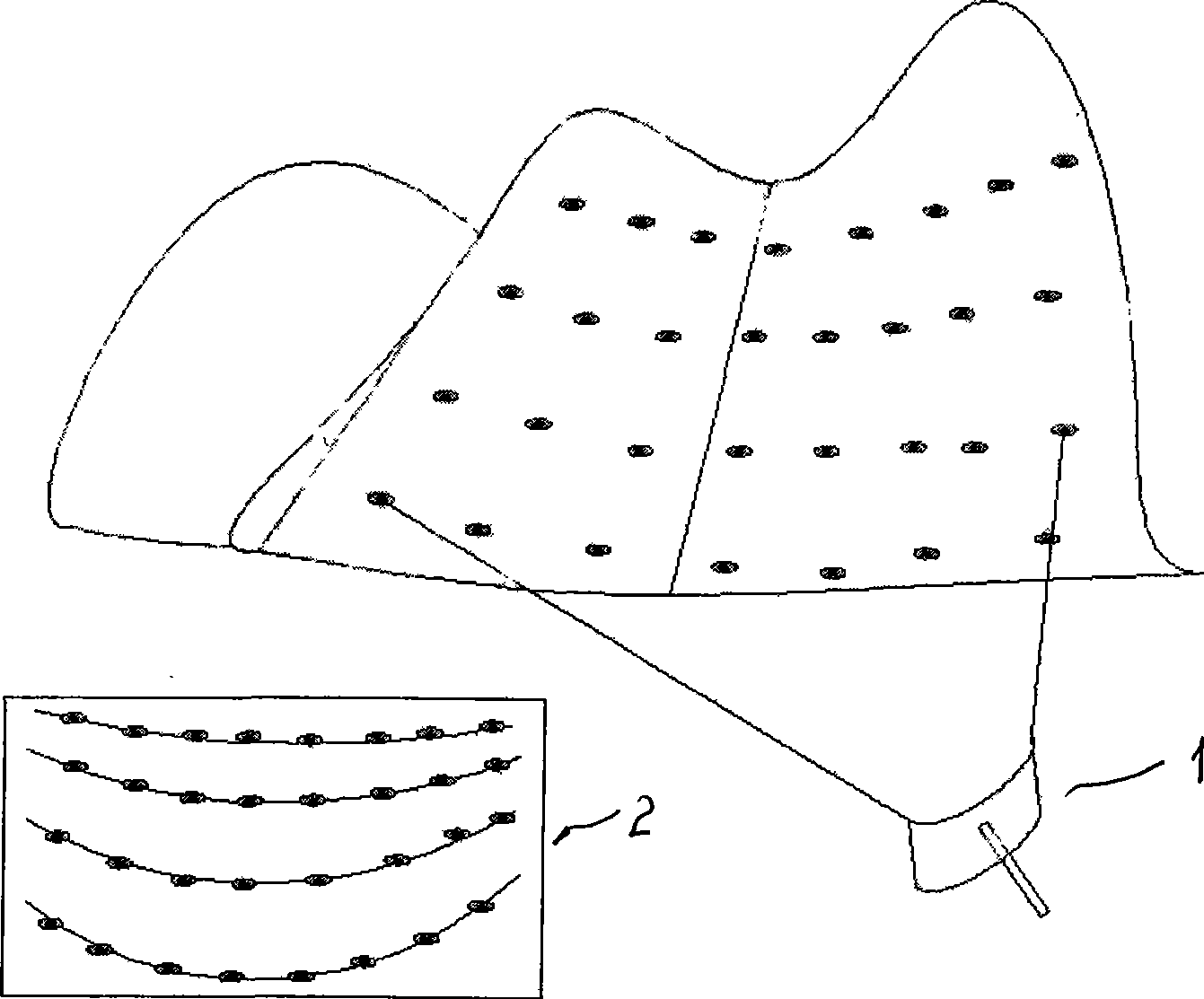

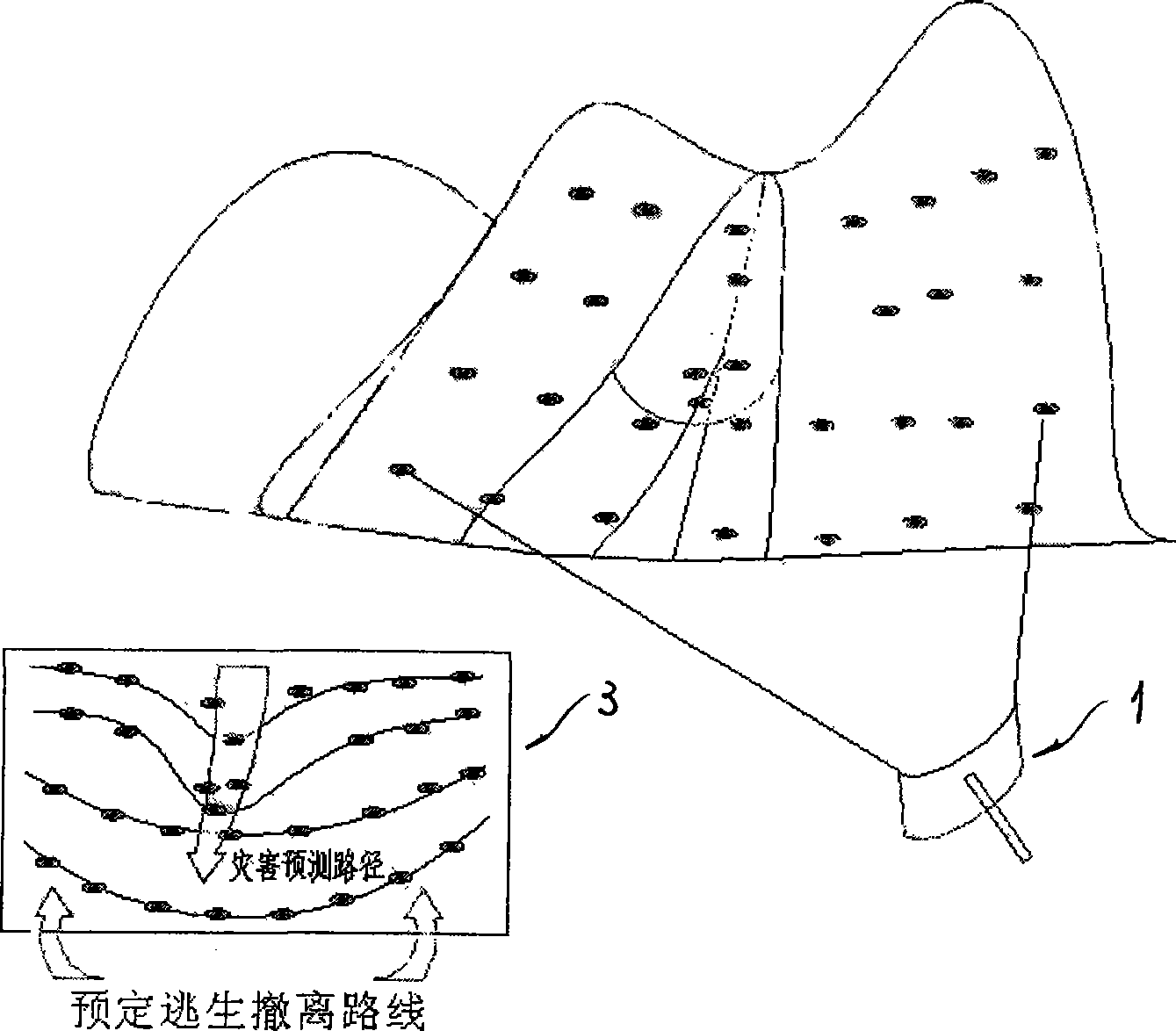

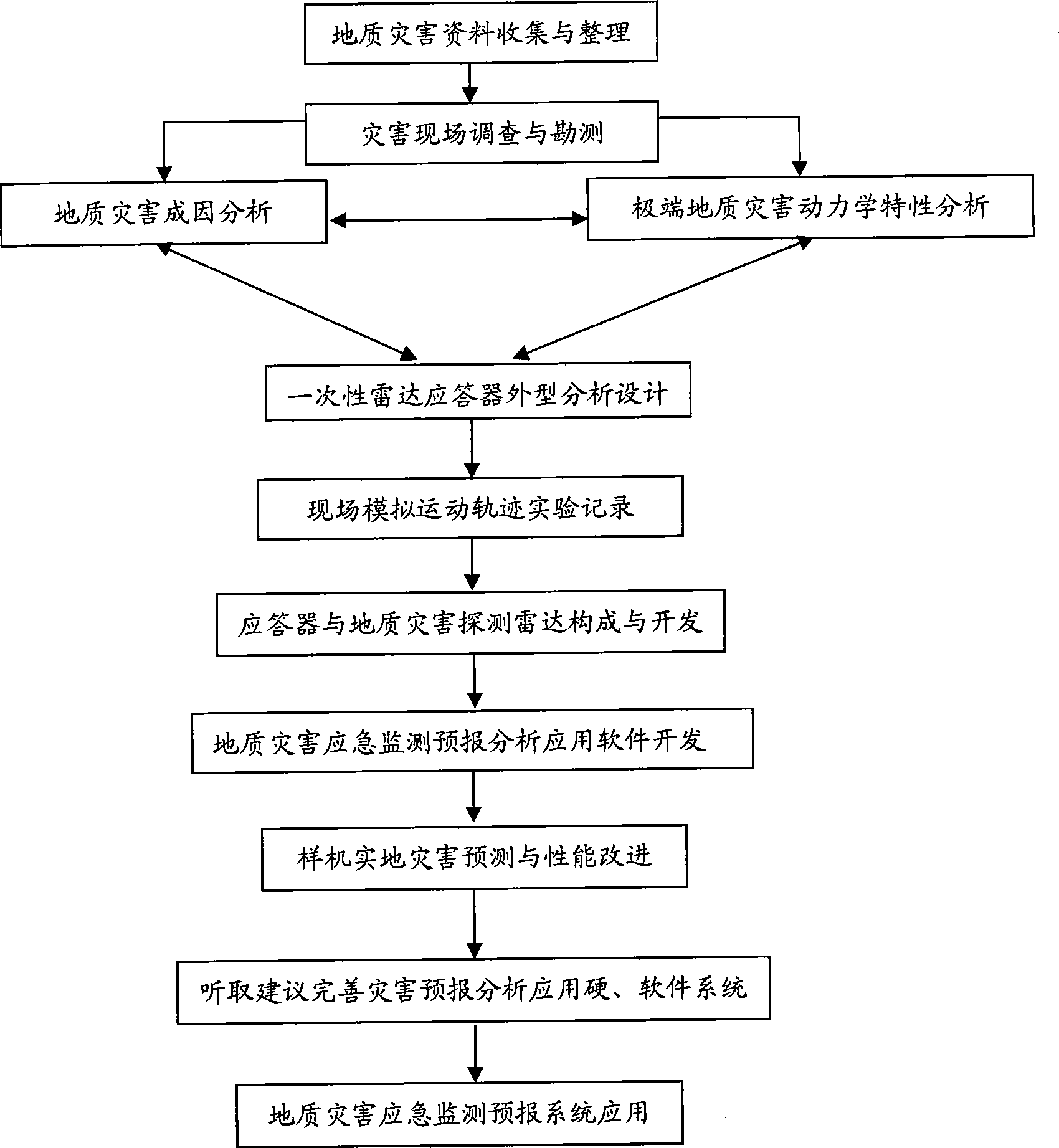

Geological calamity emergency monitoring, predicting and analyzing method

InactiveCN101477206ARich forecasting toolsPenetratingSeismologyRadio wave reradiation/reflectionRadarPredictability

The invention discloses a geologic hazard emergency monitoring forecast system and a method for analyzing the forecast of the system. Disposable radar responders move together with landslide or debris flow, flood and the like on ground surface by irregularly launching the disposal radar responders in a geologic hazard region which is formed or is forecasted to be formed. Through technology of radar scanning, running tracks of the radar responders can be monitored and compared intuitively and quickly; the place and the time formed by the hazard can be further analyzed and determined combining with status of topography and landform; and basic causes and important information, such as a territorial scope which is about to be affected by the hazard, forecasted imminent time slice and safe escape route, and the like, can be acquired assorted with rainfall, earthquake and other information. The system and the method have a standard product structure and low cost, and have incomparable advantages on the forecast of geologic hazard which has clear cause, certain predictability, large scale and short-terming burst under quick response.

Owner:INST OF MOUNTAIN HAZARDS & ENVIRONMENT CHINESE ACADEMY OF SCI

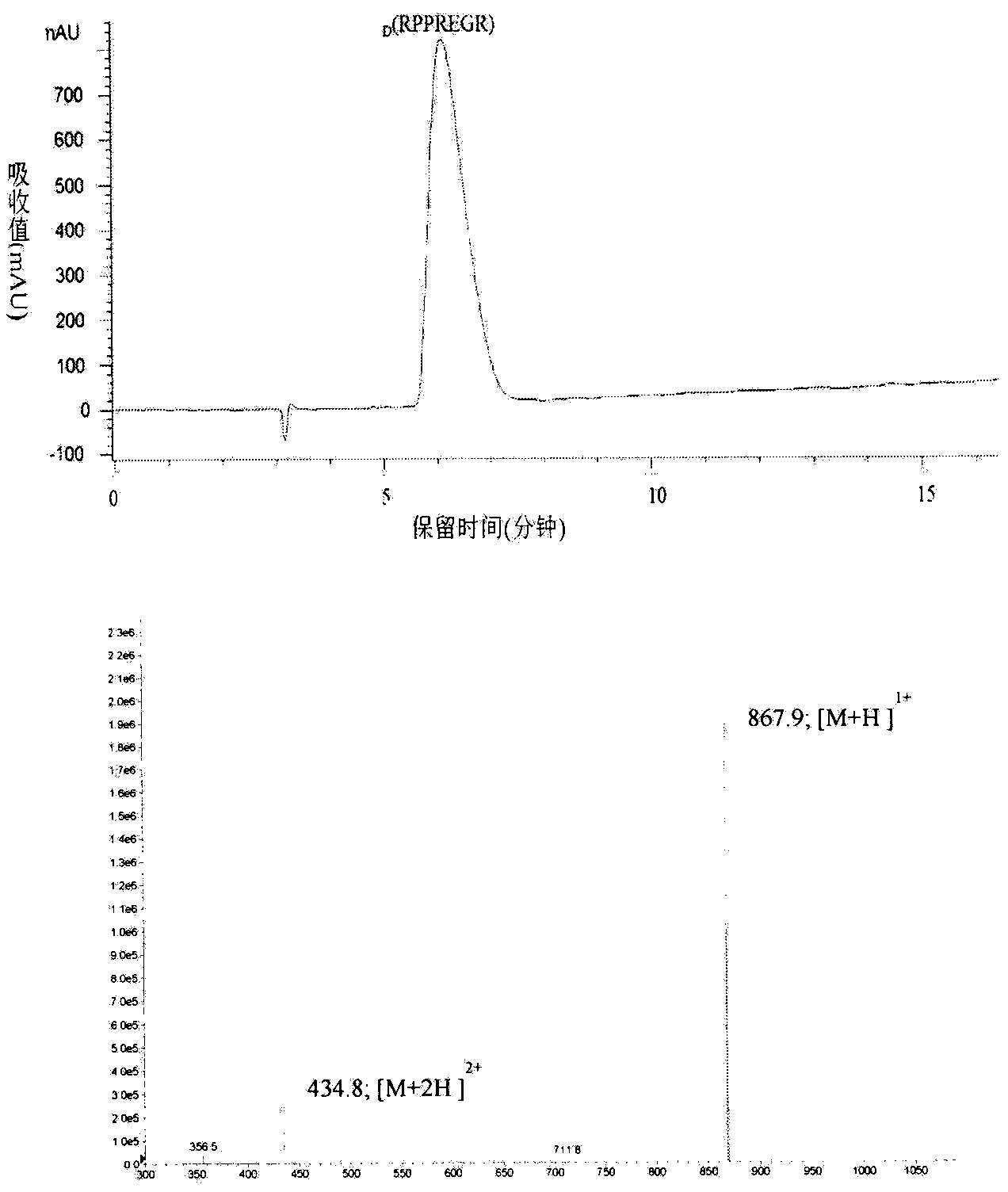

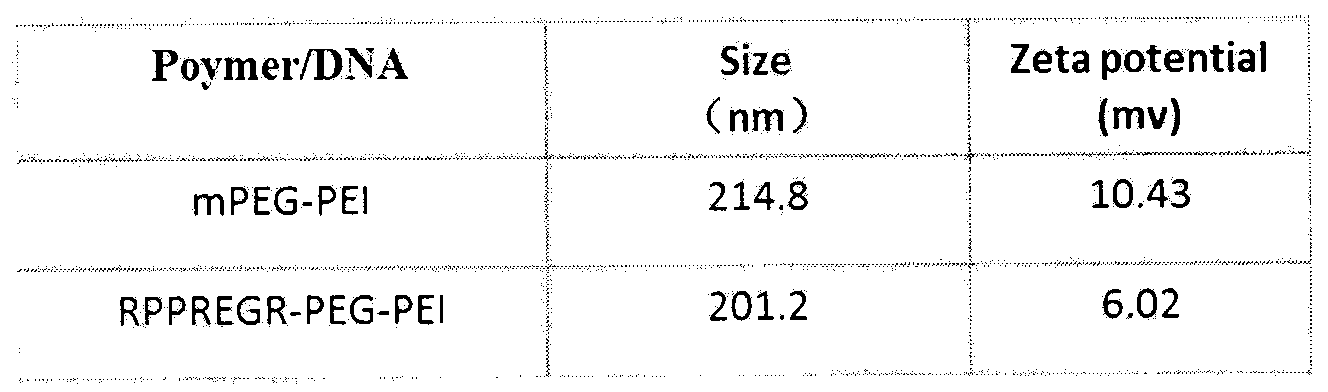

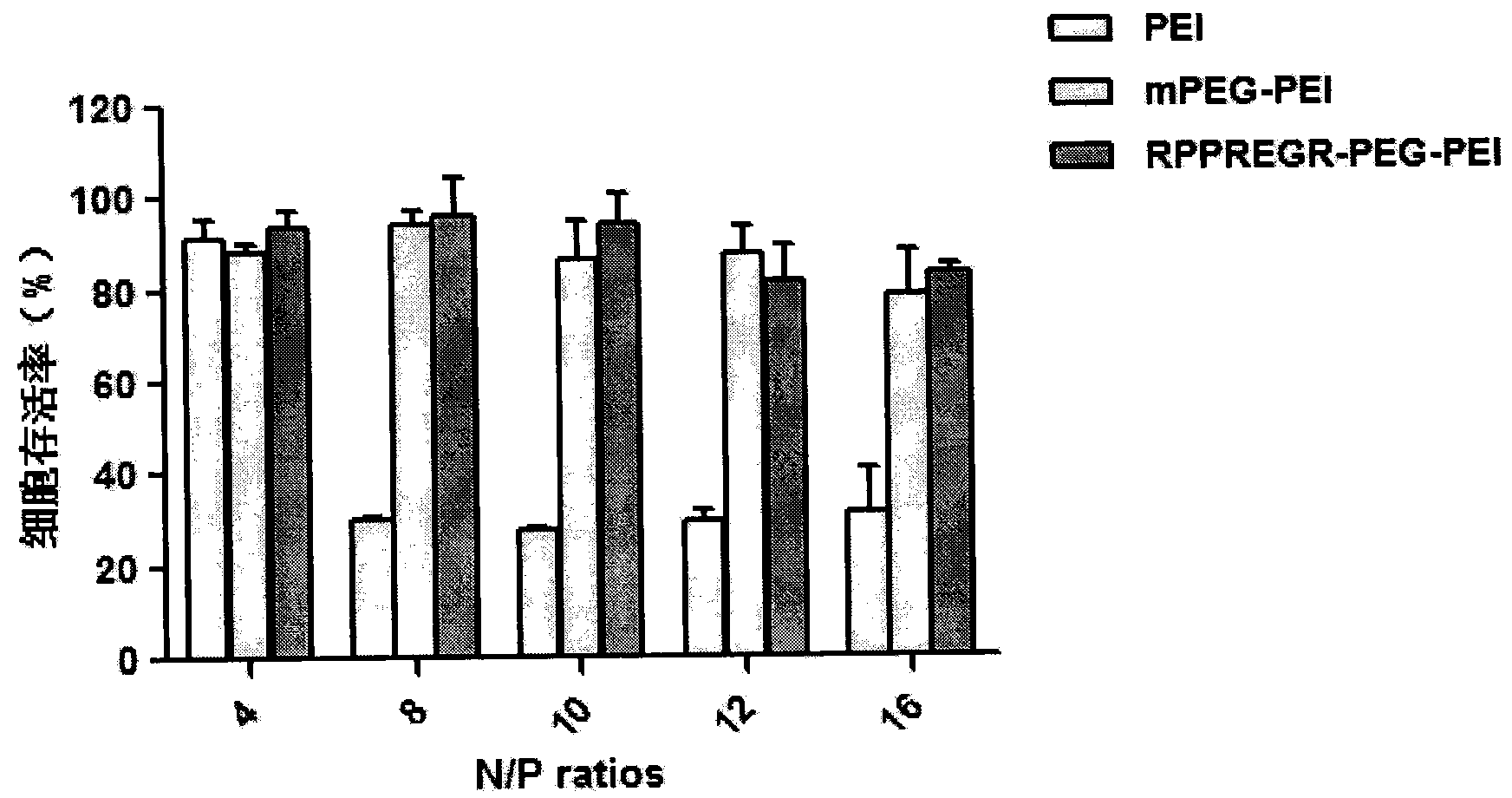

D-configuration polypeptide with brain tumor targeting and tumor tissue penetrating capabilities and gene delivery system thereof

ActiveCN104072581AHigh transfection efficiencyProlong lifeGenetic material ingredientsPeptidesGene deliveryNeuropilins

The invention belongs to the field of pharmacy and relates to a D-configuration polypeptide and a gene delivery system of the D-configuration polypeptide and particularly relates to the D-configuration polypeptide which has high combining activity with neuropilin NRP-1 and has the brain tumor targeting and tumor tissue penetrating capabilities. The D-configuration polypeptide provided by the invention can mediate a nano delivery system to deliver drugs to tumors in a targeted manner for realizing targeted treatment of brain in-situ glioma. In vivo and in vitro experiments show that the genetic vector modified by the D-configuration polypeptide can remarkably improve the gene transfection efficiency. The genetic vector entrapping the therapeutic gene pORF-hTRAIL can remarkably prolong the lifetime of a nude mouse of brain glioma in-situ mode.

Owner:FUDAN UNIV

Method for processing printed circuit board

InactiveCN101296583ALow costImprove efficiencyMultilayer circuit manufacturePrinted element electric connection formationCopper platingPrinted circuit board

The invention provides a circuit board processing method for a printed wire, which is used for manufacturing a precision printing blind-hole circuit board and is characterized in that: the conventional double-sided printed board technology is applied to the multi-layer blind-hole board manufacturing completed by utilizing mechanical drilling; a mechanical drilling through-hole method is mainly adopted to divide the multi-layer blind hole board into a plurality of conventional double-sided boards for finishing the manufacturing; and the through-hole method solves the problem of the bad copperplating of the bind-holes which occurs in the process of electrodeposition; the procedure of the method differs from the blind-hole board manufactured by laser drilling at a certain extent and is completed by adopting a part-dividing method; the method can be applied to the technique for manufacturing the blind-hole board with over four layers. The method can greatly reduce production cost and prevent quality defects brought by using the laser drilling to manufacture the blind-hole board.

Owner:苏州市惠利华电子有限公司

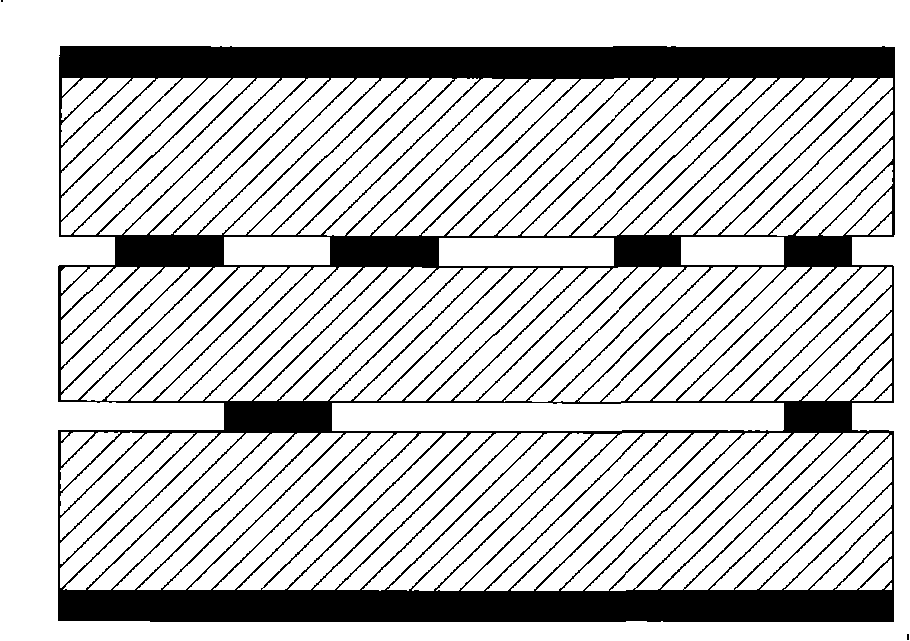

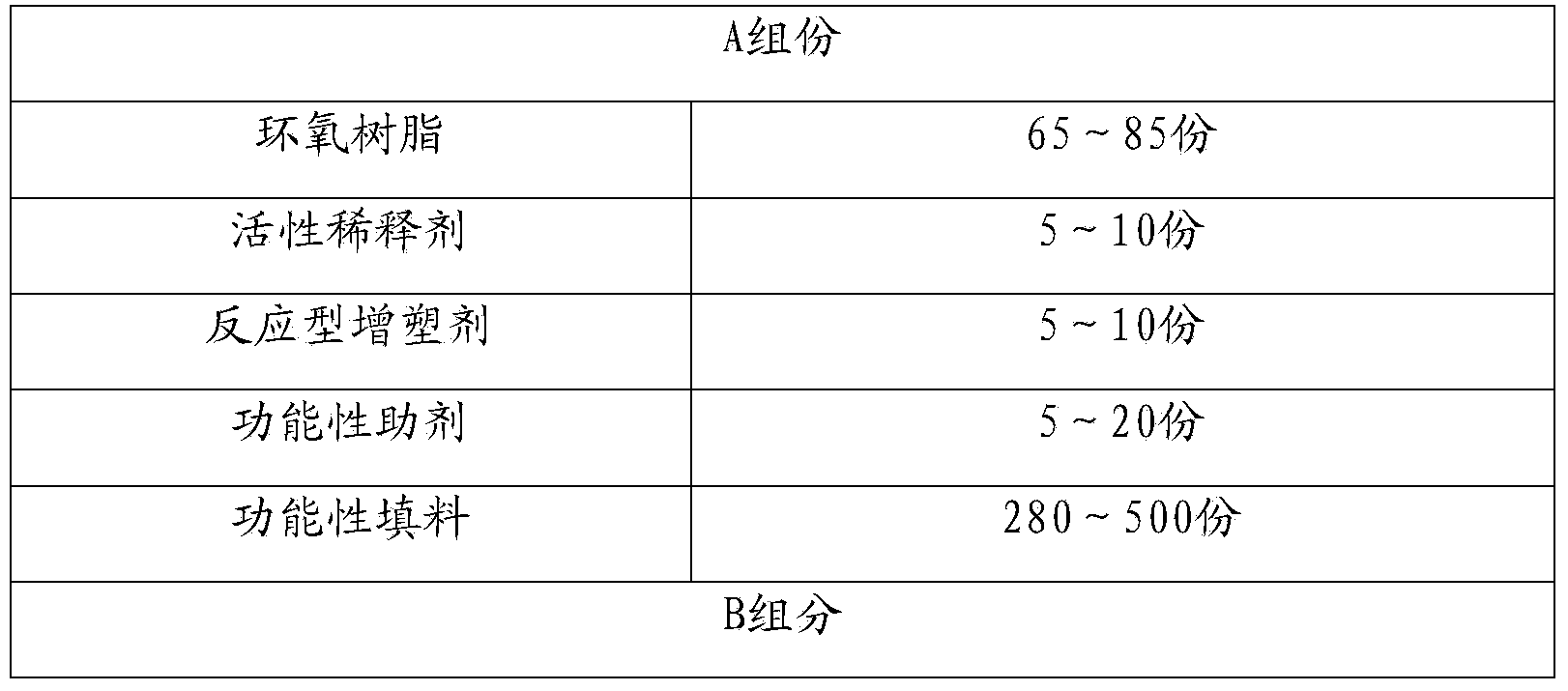

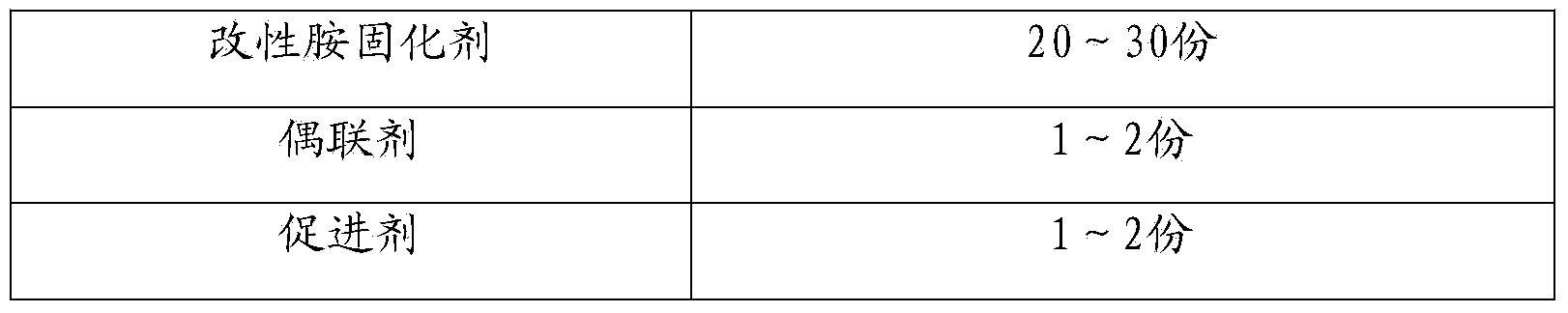

Elastic epoxy resin waterproof coating and preparation method thereof

InactiveCN103849296AGood bond strengthImprove crack resistanceEpoxy resin coatingsChemistryPlasticizer

The invention discloses an elastic epoxy resin waterproof coating which comprises components A and B, wherein the component A comprises the following components in parts by weight: 65-85 parts of epoxy resin, 5-10 parts of activity diluent, 5-10 parts of reaction type plasticizer, 5-20 parts of functional additive and 280-500 parts of functional filling agent; the component B comprises the following components in parts by weight: 20-30 parts of modified amine hardener, 1-2 parts of coupling agent and 1-2 parts of prompting agent. The waterproof coating disclosed by the invention can be directly firmly adhered to the surface of a cement substrate when used on the surface of concrete, and 20% of deformation, cracking and the like on the surface of the cement substrate is overcome.

Owner:BEIJING ORIENTAL YUHONG WATERPROOF TECH CO LTD

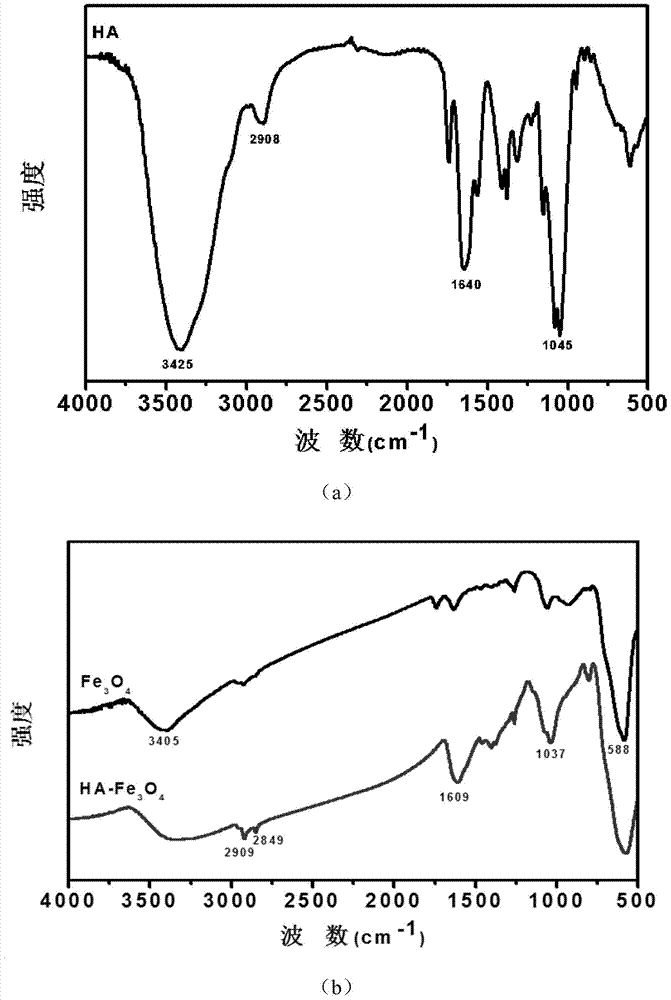

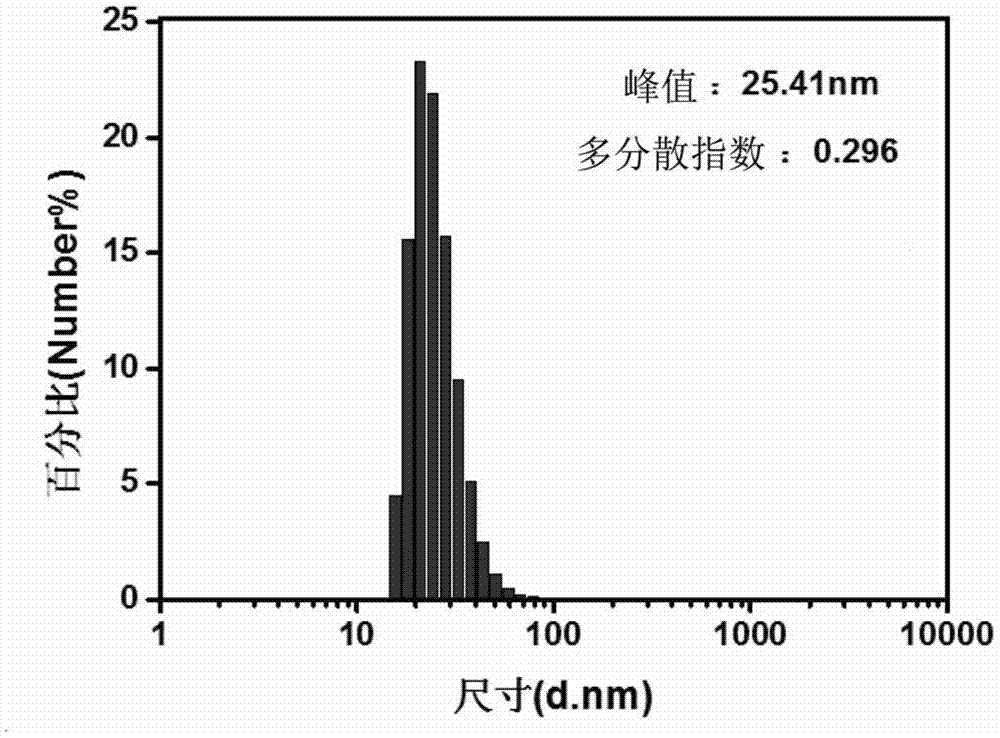

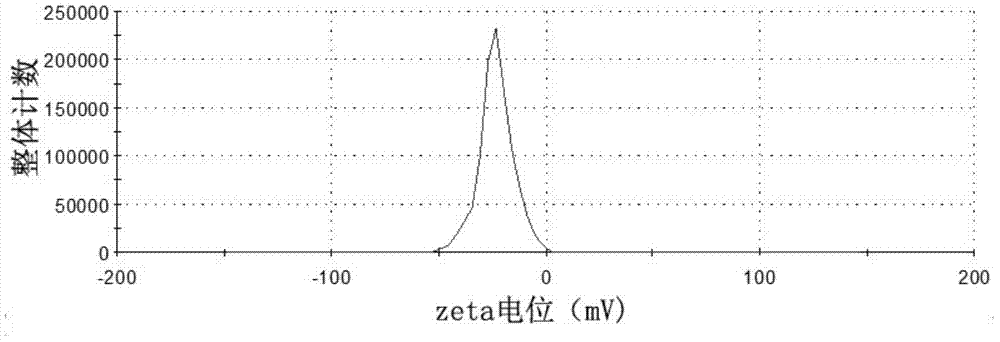

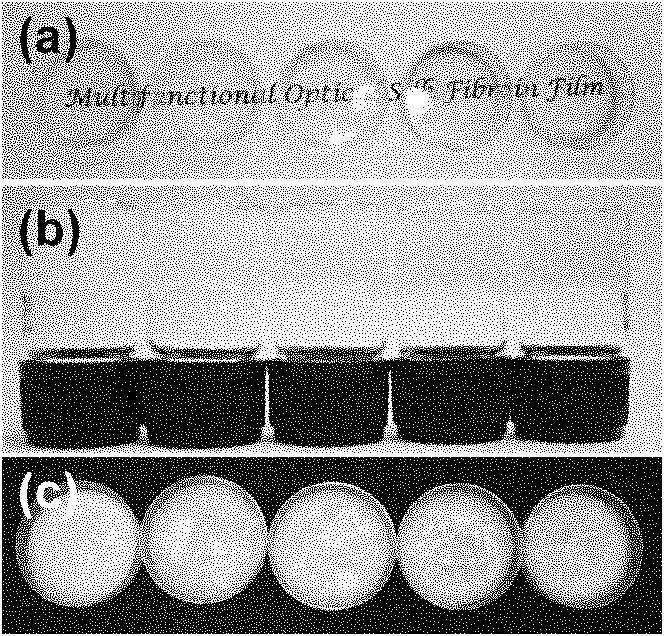

Tumor-targeted T1-T2 double nuclear magnetic resonance imaging contrast agent and preparation method and application thereof

ActiveCN104758956ASuperparamagneticHas a relaxation-enhancing effectEmulsion deliveryIn-vivo testing preparationsTumor targetFerrous salts

The invention relates to a tumor-targeted T1-T2 double nuclear magnetic resonance imaging contrast agent and a preparation method and an application thereof. The contrast agent comprises hyaluronic acid-coated ferroferric oxide composite magnetic nanoparticles, wherein the molecular formula of hyaluronic acid is as shown in the specification; n is an integer of 17-290. The preparation method of the contrast agent comprises the following steps: (1) dissolving hyaluronic acid into deionized water, introducing a gas, and heating to obtain a reaction system A; (2) dissolving ferric salt and ferrous salt into a strong acid to obtain a solution B; (3) injecting the solution B into the reaction system A, adjusting the pH to be alkaline, and then refluxing at a high temperature to obtain a reaction system C; and (4) cooling a reaction system C to a room temperature, and dialyzing to obtain the contrast agent. The invention further provides an application of the contrast agent in T1 and T2 weighted imaging in in-vivo and in-vitro nuclear magnetic resonance. The contrast agent provided by the invention has superparamagnetism and outstanding T1 and T2 relaxation enhancement effects, and is suitable for being used as a T1-T2 double nuclear magnetic resonance imaging contrast agent.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

Nanometer manetic powder for magnetothermical therapy and anti-CEA antibody target medicine

InactiveCN1772300APenetratingGood biocompatibilityPowder deliveryInorganic non-active ingredientsHysteresisSide effect

The present invention relates to target medicine of nanometer magnetic powder and anti-CEA antibody for magentothermical therapy on colon cancer, stomach cancer, liver cancer, etc. The present invention features that nanometer magnetic powder and antibody in the weight ratio of 1 to 0.0001-0.20 are coupled via mixing in solution to prepare the nanometer target medicine. The target medicine has grain size one 5-1000 nm, nanometer magnetic powder with one or several antibodies coupled to the surface, and bioactivity. The target medicine is injection with medicine dispersed into nanometer grains, and is targeted and concentrated to the cancer focus. Under the action of the AC magnetic field of the magentothermical therapy instrument, the target medicine produces hysteresis heat effect of 10-7000 W / gFe to heat the cancer focus to 42-95 deg.c and kill cancer cell. The target medicine has biodegrading function and is used in the magentothermical treatment of cancer without toxic side effect.

Owner:南京伍盛纳米科技有限公司

Two-photon fluorescence biological silk material and preparation method thereof

InactiveCN102080271AGood Gemini FluorescenceImprove mechanical propertiesMonocomponent fibroin artificial filamentArtifical filament manufactureBiocompatibility TestingProtein materials

The invention relates to a two-photon fluorescence biological silk material and a preparation method thereof. The material is formed by evenly compounding two-photon inorganic fluorescent substances and biological silk protein materials at a mass ratio of (0.001-50):100. The excitation wavelength of the material is positioned near infrared, and the fluorescence wavelength is shorter than the excitation wavelength. The preparation method comprises the following steps: adding a fibroin solution into a solution containing the two-photon inorganic fluorescent substances; stirring to obtain a mixed solution; and drying, standing or spinning to obtain the two-photon fluorescence biological silk material. Alternatively, the preparation method comprises the following steps: at room temperature, adding pre-processed silk into a fibroin solution containing the two-photon inorganic fluorescent substances, and dipping;, and stirring, washing and drying to obtain the two-photon fluorescence biological silk material. The material provided by the invention has strong two-photon adsorption and adjustable two-photon fluorescence performance under the irradiation of near infrared laser; the wavelength of an excitation light source is bio-optically transparent and does not damage biological tissues; and the material has the advantages of good biocompatibility, strong mechanical property and good economic benefit, is easy to prepare and is suitable for industrial production.

Owner:DONGHUA UNIV

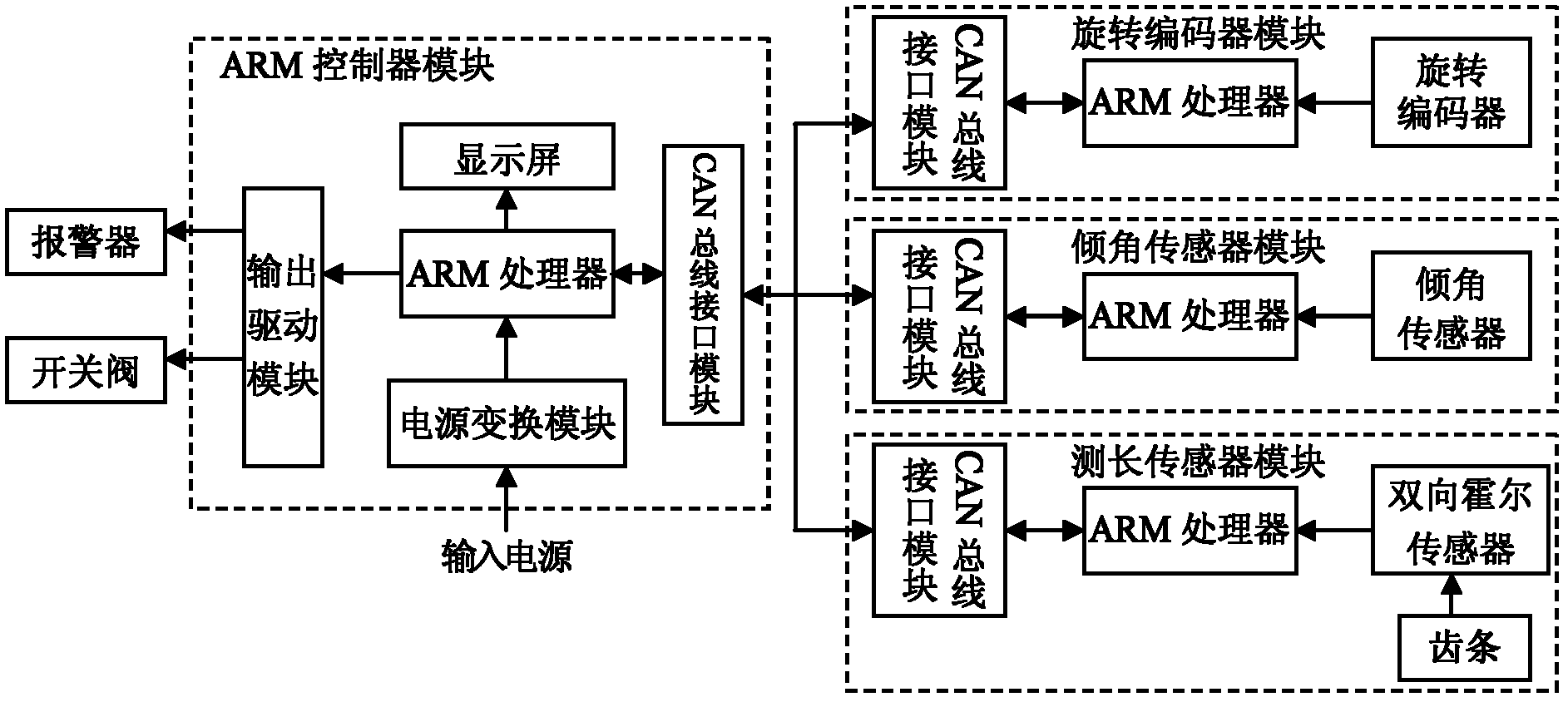

Amplitude limiting device and method

InactiveCN102627231AHigh precisionImprove reliabilitySafety devices for lifting equipmentsCranesEngineeringControl theory

The invention discloses an amplitude limiting device and an amplitude limiting method. The amplitude limiting device is used for calculating and limiting the operating amplitude of a telescopic arm of a telescopic arm frame type construction machinery vehicle, and comprises an ARM (Advanced RISC Machine) controller module, a tilting angle sensor module, a length measurement sensor module and a rotary coder module, which are connected through a CAN (Controller Area Network) bus. The amplitude limiting method comprises the following steps: obtaining the pitching angle of the telescopic arm, the rotary position angle of the telescopic arm and the arm length of the telescopic arm; according to the structural form, the pitching angle and the arm length of the telescopic arm, calculating the operating amplitude of the telescopic arm; according to the rotary position angle, looking up a corresponding amplitude limiting critical value in a pre-stored amplitude limiting critical value corresponding table; and according to the comparison result of the operating amplitude and the amplitude limiting critical value, limiting or warning the operating amplitude of the telescopic arm to guarantee the working safety of the construction machinery vehicle and avoid the roll-over accident.

Owner:INST OF AUTOMATION CHINESE ACAD OF SCI

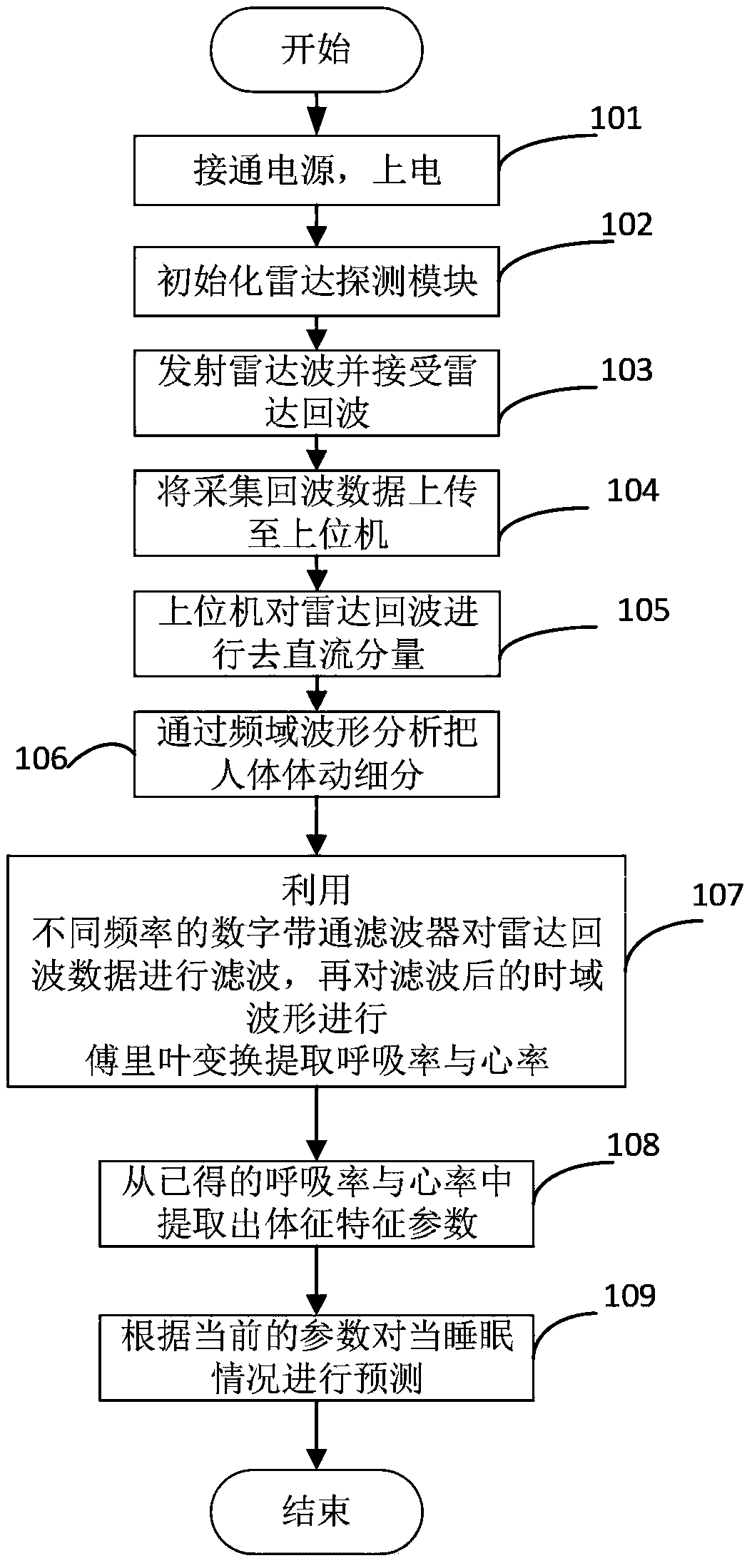

Noncontact sleep monitoring device based no ultrawide-band radar and noncontact sleep staging method based on ultrawide-band radar

ActiveCN109480787AEasy and quick installationReduce power consumptionSensorsMeasuring/recording heart/pulse rateMeteorologyWave shape

The invention provides a noncontact sleep monitoring device based no ultrawide-band radar and a noncontact sleep staging method based on ultrawide-band radar. The noncontact sleep monitoring device based no ultrawide-band radar comprises an ultrawide-band radar module, a data acquisition and transmission module, a power module, a data cable and an upper computer. The noncontact sleep staging method includes: using the noncontact sleep monitoring device to acquire radar echo data of a human body lying down and transmit the same to the upper computer; allowing the upper computer to perform DC component removal and Fourier transform on the radar echo data, and analyzing and distinguishing body movement states through frequency-domain waveform; subjecting the radar echo data to digital filtering and Fourier transform to extract sign characteristic parameters; staging the sleep states according to the analyzed and extracted body movement states and sign characteristic parameters. The noncontact sleep monitoring device based no ultrawide-band radar and the noncontact sleep staging method based on ultrawide-band radar can acquire body movement and sign information in noncontact and interference-free manner and can stage the sleep condition, and good comfort and convenience of use are provided.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

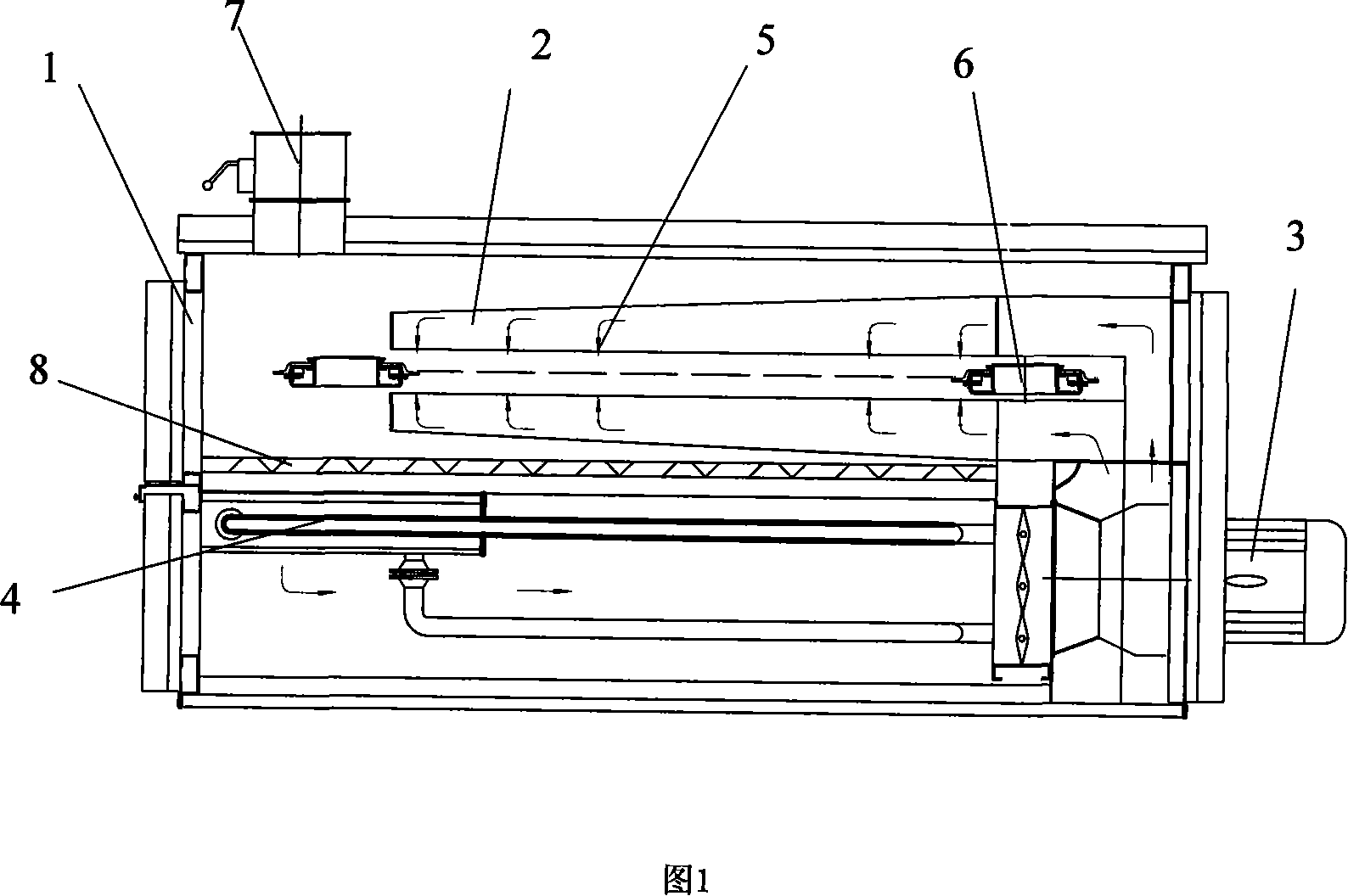

Drying room for tentering boarding machine

InactiveCN101144239AReduce temperature gradient distributionDry evenlyHeating/cooling textile fabricsStretchingPulp and paper industryAir blower

The present invention discloses a drying room of a stenter setting machine, and comprises a drying room box body and a heating device, wherein, a belt conveyor is arranged in the drying room box body, and the heating device is arranged at the upper end and the lower end of the belt conveyor; the heating device comprises a spraying tube, a cycle air blower and a heat sink, the spraying tube is arranged at the upper end and the lower end of the belt conveyor, and the heat quantity emitted from the heat sink is transported to an air jetting tube through the cycle air blower; the heat transfer medium of the heat sink adopts oil or water; the air jetting tube is provided with two air jetting tubes, one air jetting tube is an upper air jetting tube arranged at the upper end of the belt conveyor, the other air jetting tube is a lower air jetting tube arranged at the lower end of the belt conveyor, and a layer of filter mesh is arranged at the lower end of the lower air jetting tube. Compared with the prior art, the present invention has the advantages that the drying is evener, and the drying and the setting effects are good.

Owner:JIANGSU HAIDA DYEING & PRINTING MACHINERY

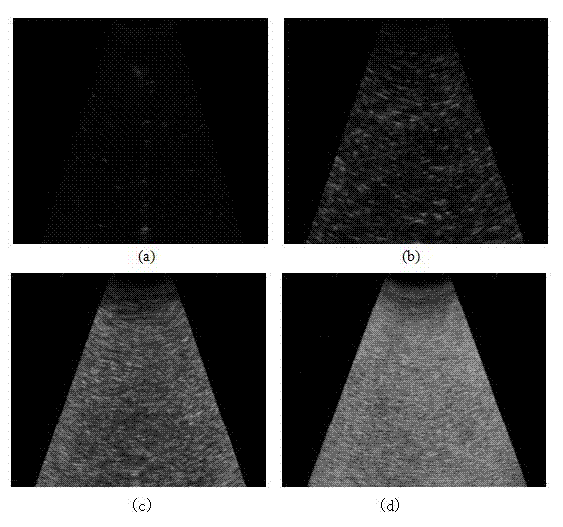

Measurement method for low sand content based on B-type ultrasound imaging technology

InactiveCN103033560AEnables direct imagingPenetratingAnalysing fluids using sonic/ultrasonic/infrasonic wavesUltrasound imagingGrey level

The invention provides a measurement method for a low sand content based on a B-type ultrasound imaging technology. The measurement method comprises the following steps of: directly imaging suspended sand grains in water by virtue of a B-type ultrasound instrument so as to obtain image information of the sand grains in the water at first, and then filtering background noise of images, extracting image areas or grey-level areas occupied by bright specks of the sand grains in the images, calculating the image area concentration or the grey-level area concentration of the sand grains, and finding a corresponding value according to a corresponding relationship between the image area concentration and an actual sand content or a corresponding relationship between the grey-level area concentration and the actual sand content, so as to obtain the to-be-measured sand content. Via the measurement method provided by the invention, the spatial concentration distribution and the dynamic movement process of the sand grains on a section can be reflected and measured in real time, and the intuitive and visible movement images and the concentration distribution rule of the sand grains can be provided for technicians in the related fields; and the measurement method has the advantages of being high in adaptability, good in timeliness, comprehensive in function, as well as convenient and fast to operate.

Owner:WUHAN UNIV

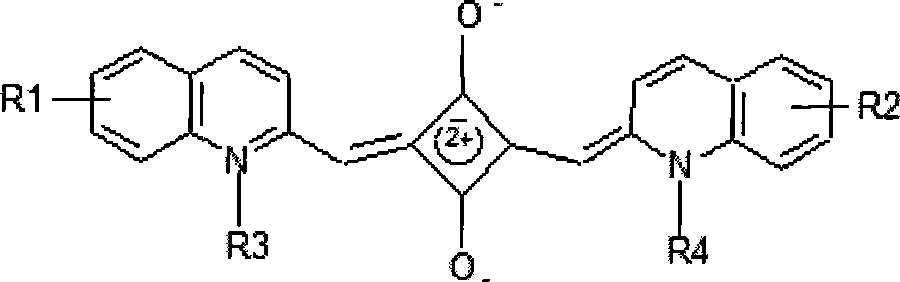

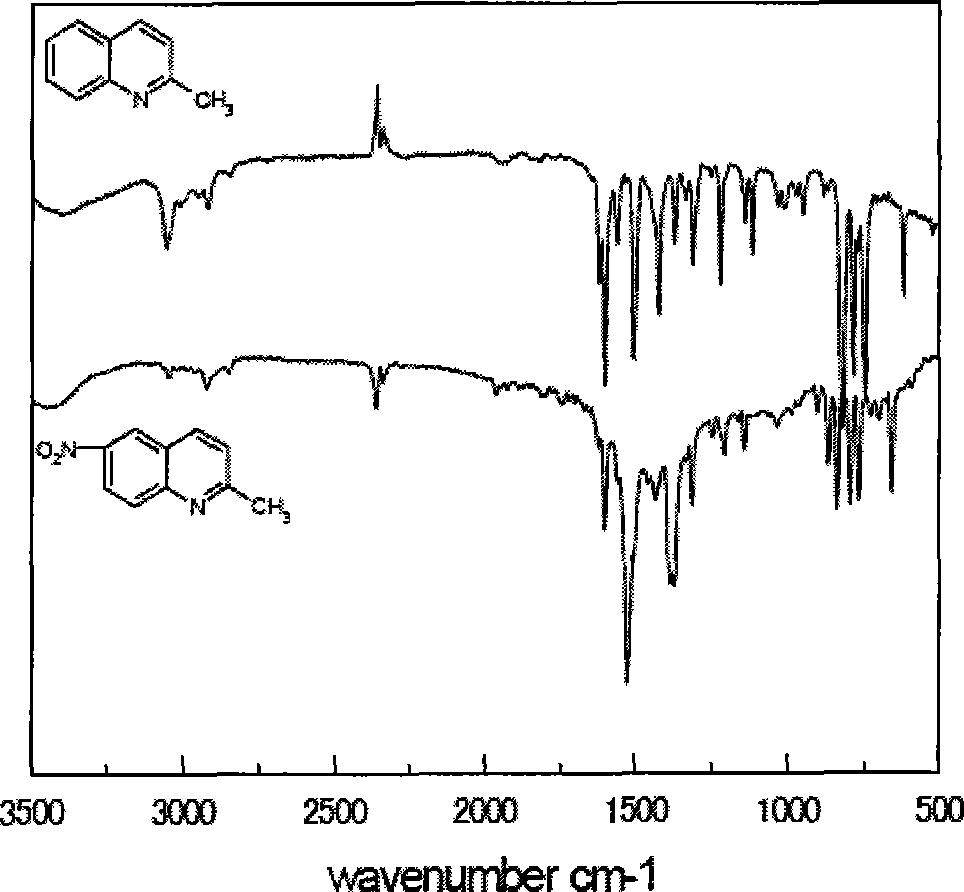

Water-soluble near infrared luminescent quinoline squaraine dye and preparation and application thereof

InactiveCN101544844AImprove stabilityGood compatibilityAzo dyesBiological testingQuinolineWavelength

The invention relates to water-soluble near infrared luminescent quinoline squaraine dye, of which the molecular structural general formula is shown on the figure. The method for preparing the water-soluble near infrared luminescent quinoline squaraine dye comprises that: firstly, 2-methylquinoline is subjected to bromination, sulfonation, nitration and acylation and reacts with acetonitrile and iodo-acid or iodo-ester to generate quinoline quaternary ammonium salt; and secondly, the quinoline quaternary ammonium salt is mixed with squaric acid, and the mixture is subjected to azeotropic distillation and dehydration, vacuum distillation and silica gel column chromatography and recrystallization through ethanol to obtain the water-soluble quinoline squaraine dye. The dye is applied in the fields of development of novel medicines, fluorescence labeling, probes, biological immunoassay, biological immunodetection and the like. The fluorescence-emission wavelength of the water-soluble quinoline squaraine dye is near infrared, so that the water-soluble quinoline squaraine dye has superior penetrability on environments and biological tissues and reduces self absorption and background absorption, and the sensitivity of fluorescence analysis can reach 10<-10> mol / L. The preparation method is simple and easy, has low cost and good economic benefit and is suitable for industrialized production.

Owner:DONGHUA UNIV

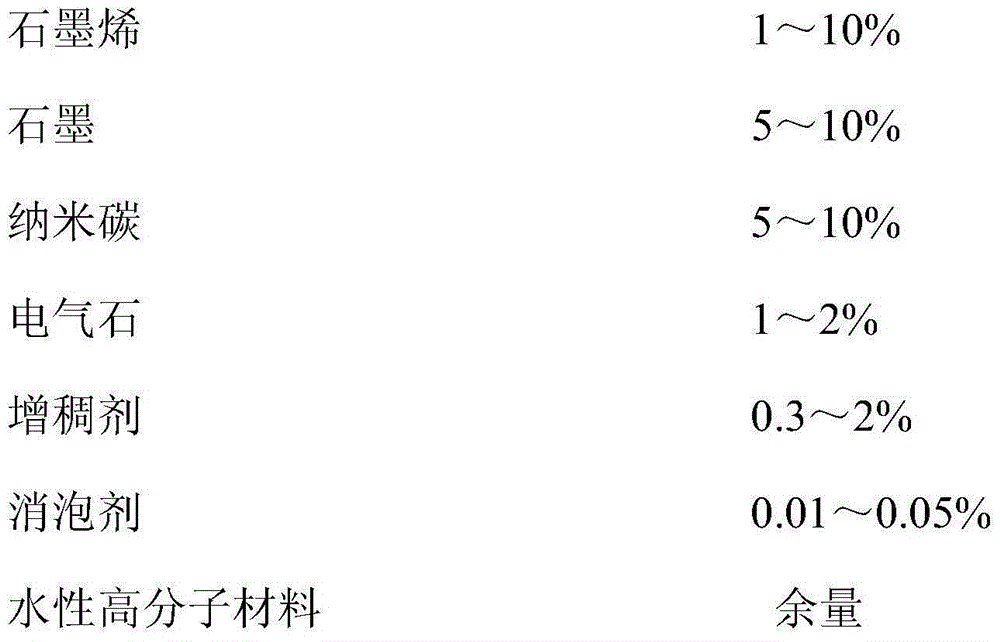

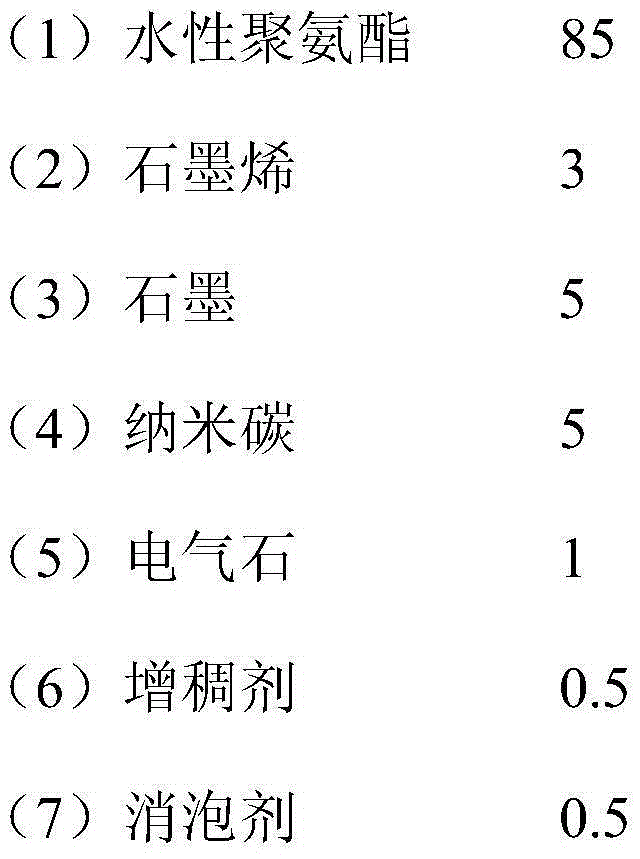

High-efficiency and high-strength composite material with far infrared radiation heating and preparation method thereof

InactiveCN106317728AMetabolism and HealthEfficient and high-strength far-infrared radiant heating energyEnvironmental resistanceElectric heating

The invention relates to a high-efficiency and high-strength composite material with far infrared radiation heating. The material is characterized in that the material comprises the following raw materials in percentages by mass: 1-10% of graphene, 5-10% of graphite, 5-10% of nanocarbon, 1-2% of tourmalinite, 0.3-2% of a thickening agent, 0.01-0.05% of an antifoaming agent, and the balance being an aqueous high-molecular material. The far infrared composite material comprises graphene, graphite, nanocarbon, tourmalinite, and other powder materials with the far infrared radiation heating function. The material can be widely applied to electric heating, electric heating drying, health care, antibiosis, and other aspects. In addition, the composite material comprises the special tourmalinite material, in order to release a certain concentration of negative oxygen ions, and realize the purpose of air purification and environmental protection.

Owner:SHANGHAI WEIXING NOVEL BUILDING MATERIAL

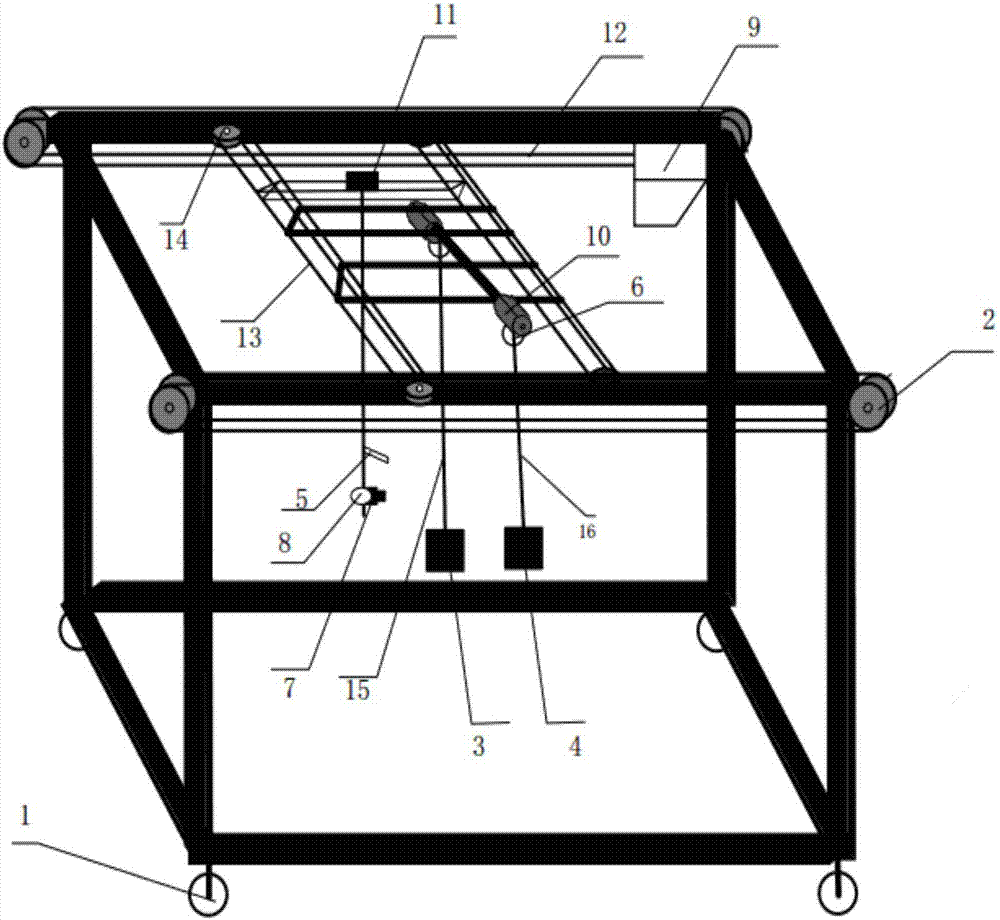

Measurement device for swing angle of multi-sling bridge crane and measurement method adopting device

InactiveCN107055326ADoes not affect measurement accuracySimple structureLoad-engaging elementsMeasurement deviceVideo image processor

The invention discloses a measurement device for the swing angle of a multi-sling bridge crane. The multi-sling bridge crane comprises a bridge crane trolley provided with first lifting ropes. The measurement device for the swing angle of the multi-sling bridge crane is characterized in that the measurement device comprises a swing angle calculation and control computer, a fan-shaped plane infrared light emitter, a swing angle detection camera, lifting rope vertex markers and a video image processor; the fan-shaped plane infrared light emitter is used for emitting fan-shaped infrared light, and the light encounters one or more of the first lifting ropes, so that light spots are left; the swing angle detection camera is used for shooting images of the first lifting ropes; the video image processor is used for receiving the images of the first lifting ropes and finding the positions of the light spots and the lifting rope vertex markers; the swing angle calculation and control computer, the fan-shaped plane infrared light emitter and the video image processor are arranged on a second lifting rope, and the second lifting rope moves along with moving of the bridge crane trolley; and the swing angle calculation and control computer works out the position coordinates of the light spots and the lifting rope vertex markers, and thus a swing angle value is obtained. By adoption of the measurement device for the swing angle of the multi-sling bridge crane, the swing angle of the bridge crane can be detected accurately, and the measurement device has the advantages of being low in cost and high in antijamming capability.

Owner:SHANGHAI MARITIME UNIVERSITY

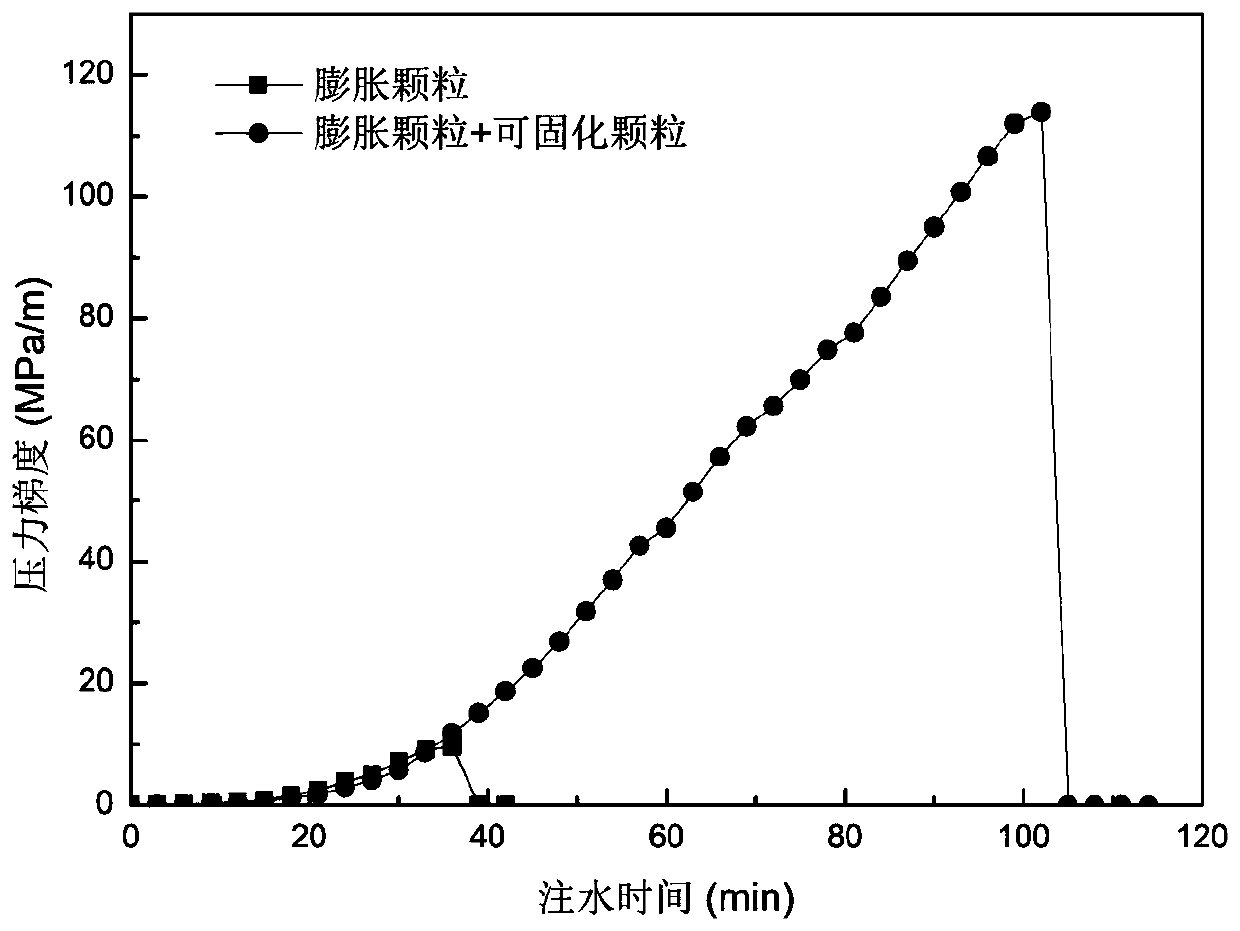

Crack plugging agent based on expansion particles and solidifiable particless

ActiveCN110003869AIncreased breakthrough pressure gradientGood water blocking effectDrilling compositionSealing/packingTemperature resistanceUltimate tensile strength

The invention discloses a crack plugging agent based on expansion particles and solidifiable particles, and belongs to the technical field of profile control and water plugging of an oil field. The crack plugging agent is composed of the expansion particles and the solidifiable particles which are separately stored, the mass ratio of the solidifiable particles to a solidification agent is 100:(5-20), and the content of the expansion particles is indefinite; the solidifiable particles are prepared from a solid core and film-coated resin in a mass ratio of 100:(5-15). The solidifiable particlesare high in strength, high in temperature resistance and salt tolerance and wide in oil reservoir applicability; an immovable plug formed by the solidifiable particles has an interception function ofa screen net, the breakthrough pressure gradient of the expansion particles in cracks can be obviously improved, the expansion particles are forced to remain in the cracks to continue to give play toa water plugging effect, meanwhile, the immovable plug has a penetration capacity, water, a gel breaker and the like are allowed to pass through the immovable plug so as to remove plugging of the expansion particles, and the crack plugging has restorability. The crack plugging agent has a good water plugging effect in water plugging of the oil field.

Owner:SOUTHWEST PETROLEUM UNIV

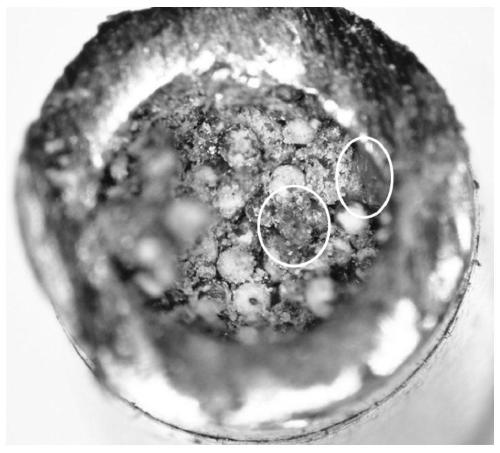

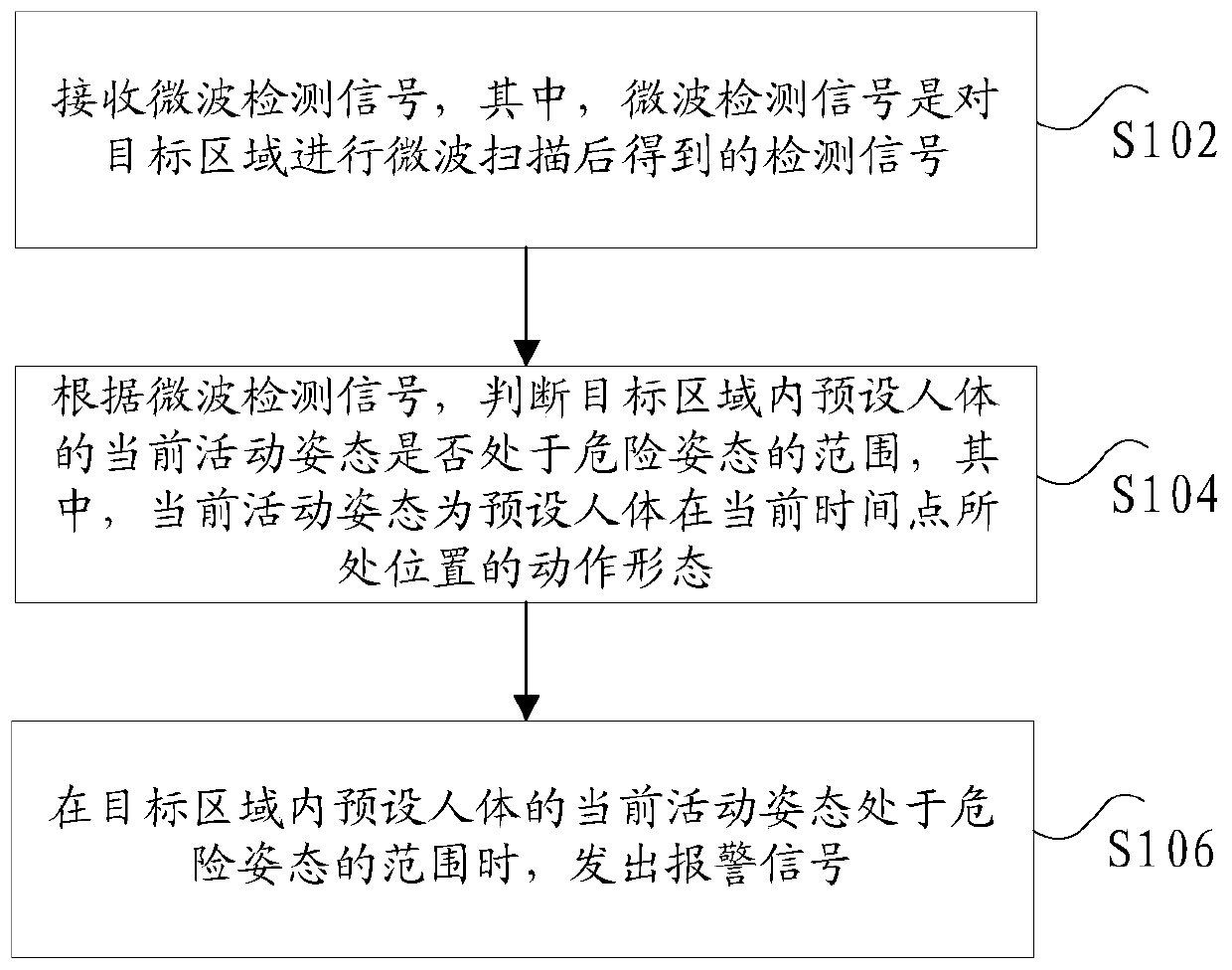

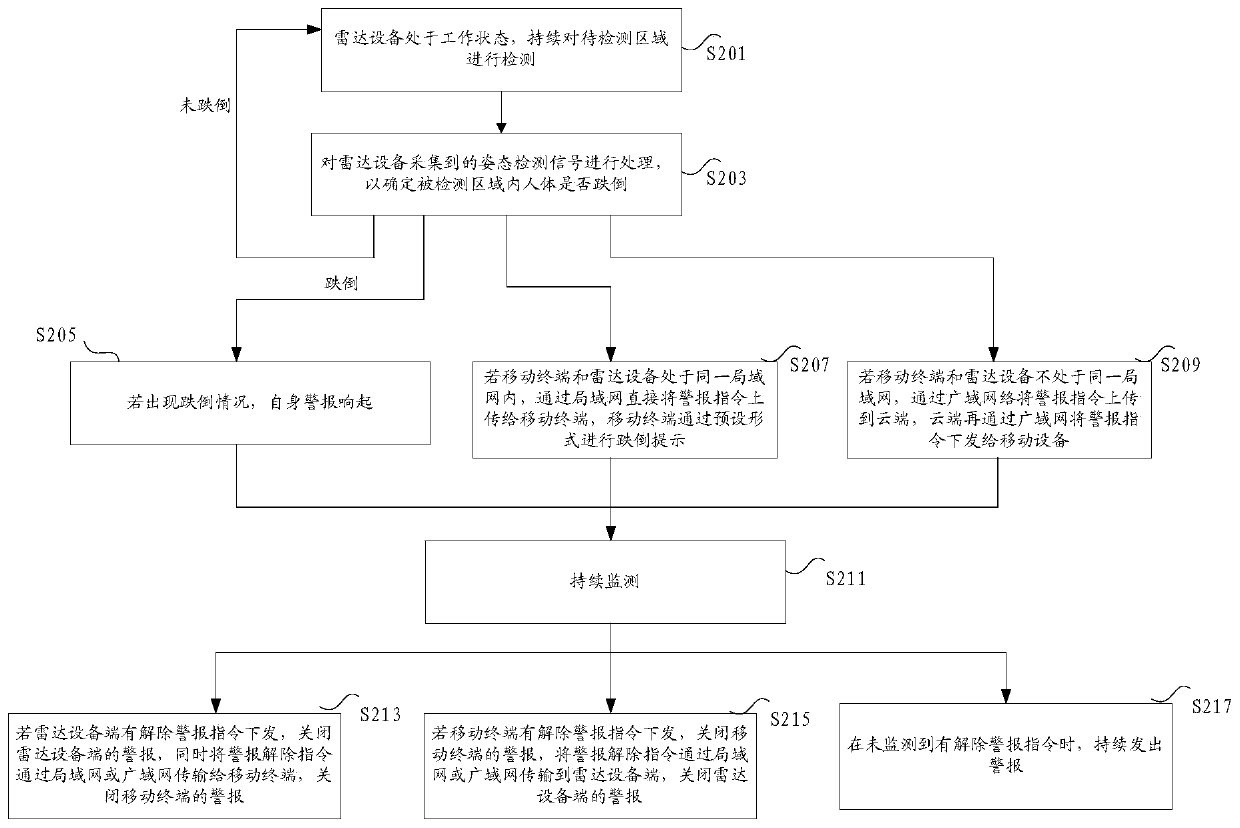

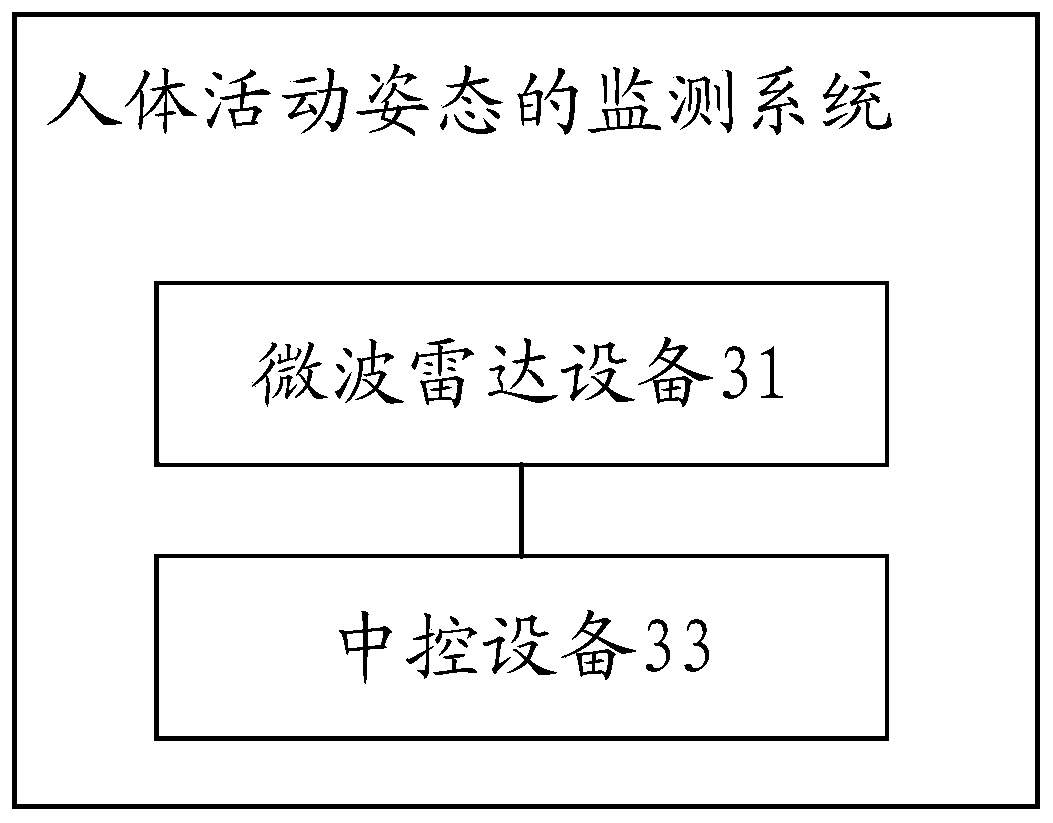

Human body activity posture monitoring method and system, and human body posture monitor

ActiveCN110187341AEnsure safetyPenetratingDiagnostic recording/measuringSensorsHuman bodyMonitoring methods

The invention discloses a human body activity posture monitoring method and system and a human body posture monitor, wherein the method comprises the following steps: receiving a microwave detection signal, wherein the microwave detection signal is a detection signal obtained after performing microwave scanning on a target area; according to the microwave detection signal, judging whether the current activity posture of a preset human body in the target area is in a dangerous posture range, wherein the current activity posture is the action form of the human body at a position at the current time point; and when the current activity posture of the preset human body in the target area is in the dangerous posture range, sending out an alarm signal. According to the human body activity posture monitoring method and system and the human body posture monitor in the invention, the technical problem whether a user is in a dangerous state cannot be determined due to the fact that the activityenvironment with large fog concentration cannot be monitored in the related art is solved.

Owner:GREE ELECTRIC APPLIANCES INC +1

Fixed grate boiler allowing square bundle of stalks to be combusted

ActiveCN105889901AImprove efficiencyAvoid contaminationSolid fuel combustionAir/fuel supply for combustionAir volumeCombustion chamber

The invention relates to a fixed grate boiler allowing a square bundle of stalks to be combusted, and in order to solve the problems that conventional boiler allowing a bundle of stalks to be combusted cannot guarantee that the stalks are sufficiently combusted, slag bonding is easy to occur, discharged pollution is high, and the efficiency of the boiler is low. Square water-cooled jackets are arranged all around a pre-combustion chamber, and a part in front of the pre-combustion chamber communicates with a feed opening; an outlet of the pre-combustion chamber communicates with a step combustion chamber which is divided into two-stage combustion chambers, wherein fixed grates are arranged at the lower part of a first-stage combustion chamber; turnover grates are arranged at the lower part of a second-stage combustion chamber; a first-stage primary air chamber is arranged under the fixed grates, a second-stage primary air chamber is arranged under the turnover grates; the total amount of primary air is adjusted through an air inlet regulating baffle, and the first-stage primary air amount and the second-stage primary air amount are distributed through a middle adjusting baffle; secondary air filling nozzles are arranged on two side walls of the step combustion chamber; secondary air reinforcing nozzles are arranged on the front wall of the step combustion chamber, and an inlet of an after-combustion chamber communicates with an outlet of the step combustion chamber. The fixed grate boiler disclosed by the invention is used for heating by peasant households away from heating sources in winter and is used as heat supply heating sources of agricultural greenhouses.

Owner:哈尔滨哈东新春锅炉有限公司

Method for extracting oil in microalgae

InactiveCN103937604ASimple extraction methodEasy to operateFatty-oils/fats productionSolventChemistry

The invention relates to a method for extracting oil in microalgae. The method comprises the following steps: 1, dissolving microalgae in a mixed alcohol solvent in a sealed reactor, oscillating, heating and extracting to obtain an extracting liquid; 2, centrifugally separating the extracting liquid obtained in the step 1 to obtain supernatant, repeatedly washing and centrifugally separating the residual dregs by using the same mixed alcohol solvent in the step 1, and merging the liquid separated each time and the supernatant to obtain a supernatant merged liquid; and 3, rotating and evaporating the supernatant merged liquid obtained in the step 2 to remove the mixed alcohol solvent so as to obtain crude oil; and 4, dissolving the crude oil obtained in the step 3 in a normal hexane solvent to obtain a crude oil liquid, transferring the crude oil liquid into a separating funnel, adding deionized water or a neutral salt liquid for washing for several times so as to remove water-soluble substances in the crude oil liquid, collecting the upper organic phase in the washed crude oil liquid, and performing rotary evaporation to remove the normal hexane solvent, thus obtaining total oil.

Owner:BEIJING UNIV OF CHEM TECH

Nano target medicine for magnetothermal therapy of malignant tumor

ActiveCN1951495AKill cancer cellsCure cancerInorganic non-active ingredientsAntibody ingredientsMagnetic powderAntibody

The invention relates to a method for preparing the nanometer target drug used to treat cancer. Wherein, it is a nanometer magnetic-antibody / ligand drug and nanometer magnetic target drug used in cancer magnetic thermal treatment, with high specific thermal power; it comprises 1:0.0001-0.20 effective molecule and guide molecule, while the effective molecule is magnetic powder whose diameter is lower than 1000nm, and the specific thermal power SAR is 10-7000W / gFe; the guide molecule comprises antibody or ligand or magnetic powder; the diameter of target drug is 2-1000nm; the preparation comprises that coupling the magnetic powder and guide molecule in water, organic or inorganic mixture. The inventive drug can effective kill cancer cell and treat cancer.

Owner:朱宏

Medicated wine for treating cancer and preparing process thereof

InactiveCN101011426APenetratingPromote rapid playAmphibian material medical ingredientsAlcoholic beverage preparationDrugPit viper

The invention discloses a medicinal liquor for treating cancer and process for preparation, wherein the main constituents include (by weight ratio) Phellinus igniarius 3-15 parts, ganoderma lucidum 3-20 parts, secretio bufonis 3-20 parts, pallas-pit viper spirit 5-50 parts, and yellow rice wine 3000-5000 parts.

Owner:巩庆华

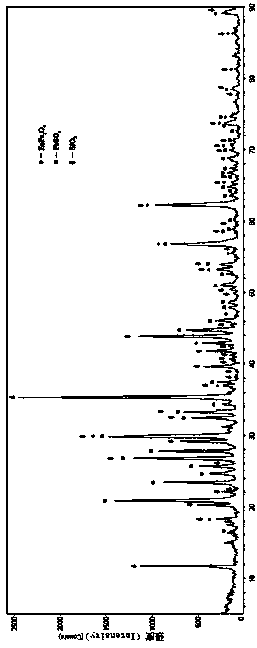

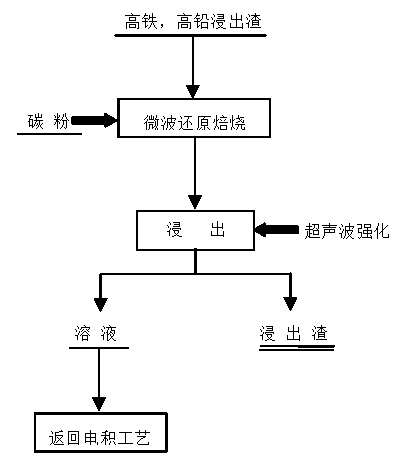

Method for recovering zinc from high iron and high lead leaching residue through microwave-ultrasonic wave combination

ActiveCN103352116APenetratingWith selective heatingProcess efficiency improvementPregnant leach solutionMicrowave

The invention provides a method for recovering zinc from high iron and high lead leaching residue through microwave-ultrasonic wave combination, and belongs to the technical field of microwave and ultrasonic wave applications. The method comprises: taking high iron and high lead leaching residue, adding carbon powder, uniformly mixing, carrying out microwave heating to a temperature of 550-950 DEG C, carrying out constant temperature maintaining for 1-3 h, stopping heating, introducing a N2 protection atmosphere, cooling to a temperature of less than 100 DEG C to obtain after-reduction leaching residue, adding the after-reduction leaching residue to an acid liquid, carrying out ultrasonic wave radiation on the mixed solution at a temperature of 45-85 DEG C to carry out enhancement leaching, carrying out solid-liquid separation to obtain a leaching solution, carrying out subsequent purification on the leaching solution, and recovering metal zinc through electrowinning. Compared to the conventional hot acid leaching, the method of the present invention has the following characteristics that: a leaching time is significantly shortened, a leaching acidity and a leaching temperature are reduced, and 90-98% of zinc can be recovered. With the present invention, the difficult problem of low recovery rate of the high lead and high iron system is overcome, the process is simple, the treatment effect is good, zinc and other valuable metals can be efficiently recovered, and problems of environmental pollution and resource waste caused by stockpiling of a lot of abandoned residue are solved.

Owner:KUNMING UNIV OF SCI & TECH

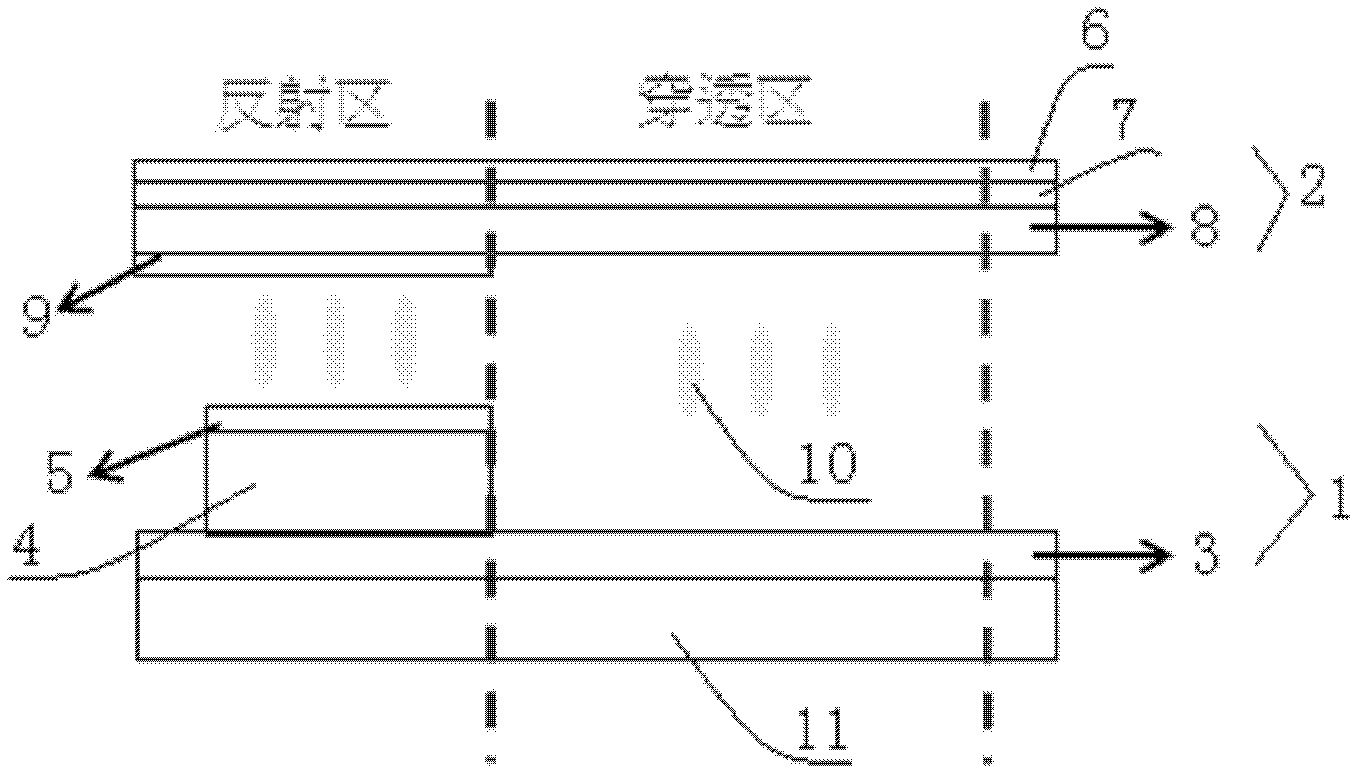

Display panel of transflective transparent display and sub-pixel structure thereof

The invention discloses a sub-pixel structure of a transflective transparent display. The sub-pixel structure comprises a first substrate and a second substrate which are arranged oppositely, wherein the areas corresponding to the first substrate and the second substrate are respectively divided into a reflecting area and a transmitting area; the first substrate comprises first glass, wherein the part of the first glass, which is positioned in the reflecting area, is provided with a reflecting layer at one side relative to the second substrate, and a sub-pixel electrode is arranged on the reflecting layer; and the second substrate comprises a polarizer, wherein the polarizer is provided with a quarter wave plate at the side relative to the first substrate, the quarter wave plate is provided with a second glass, and the part of the second glass, which is positioned in the reflecting area, is provided with an ITO (Indium Tin Oxide) layer. The invention also discloses a display panel comprising the sub-pixel structure. The display area of the display panel disclosed by the invention has a transparent characteristic; and in a condition that a backlight source is arranged, the display panel can also be used in a darkroom environment.

Owner:NANJING CEC PANDA LCD TECH

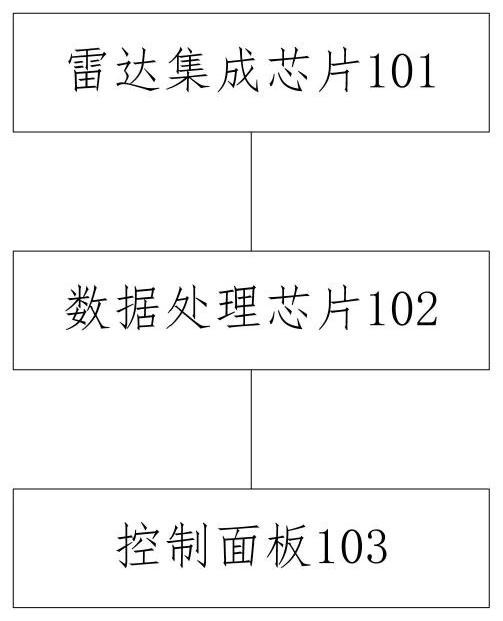

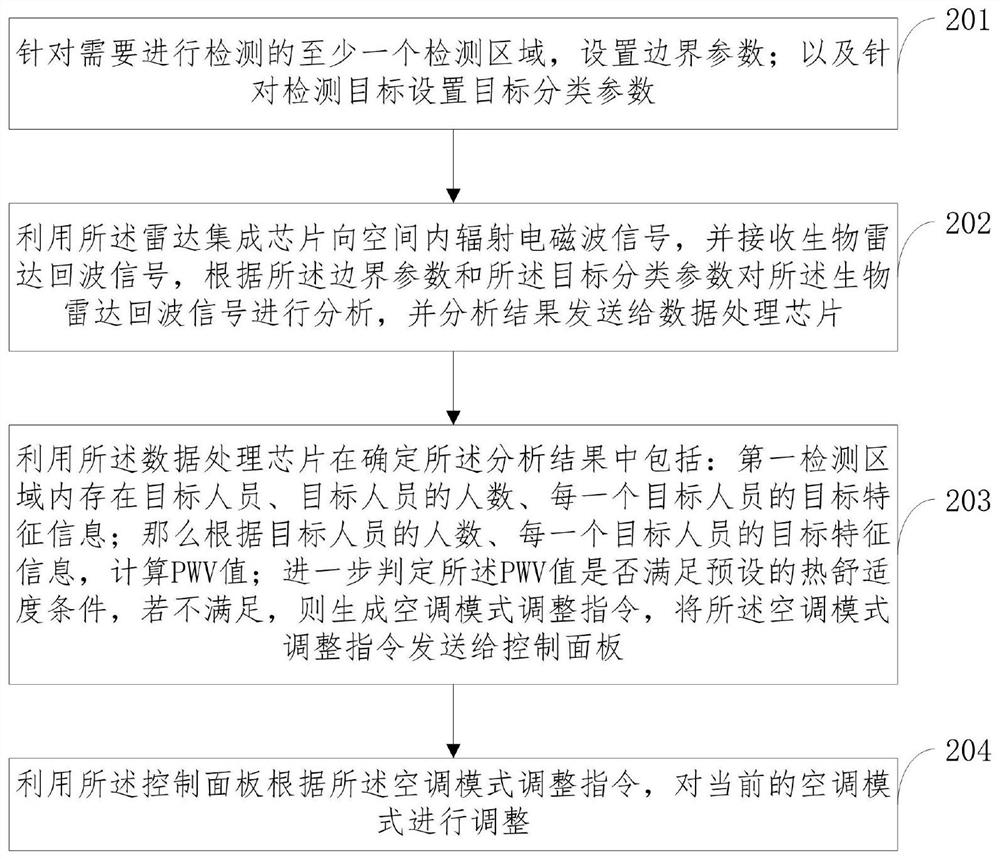

Air conditioner PMV control method and system integrating bioradar detection technique

InactiveCN111664557APenetratingWill not cause privacy leakageMechanical apparatusLighting and heating apparatusRadarThermal comfort

The invention provides an air conditioner PMV control method and system integrating a bioradar detection technique. The method comprises the following steps of setting boundary parameters to determineat least one detection area needed to be detected and setting target sorting parameters to position target personnels; detecting, by a radar integrated chip, the target personnels in the detection areas; processing, by a data processing chip, a detected analysis result; and when the target personnels, the quantity of the target personnels and the target characteristic information of each target personnel exist in the first detection area, carrying out PWV control on an air conditioner by calculating a PWV value and judging whether the PWV value meets a preset thermal comfort degree conditionor not. According to the scheme, by adopting the bioradar detection technique, privacy disclosure of a user as a camera collects images and picture is avoided, and electromagnetic waves not only are of penetrability, but also are not affected by factors such as rays and detection angles. The accuracy is higher when PWV control is carried out on the air conditioner.

Owner:SICHUAN HONGMEI INTELLIGENT TECH CO LTD

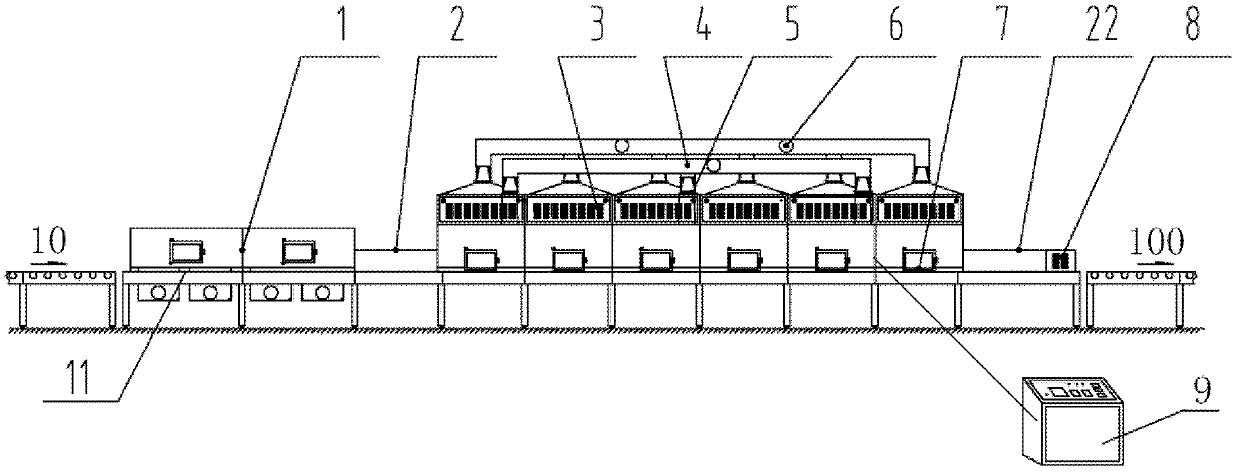

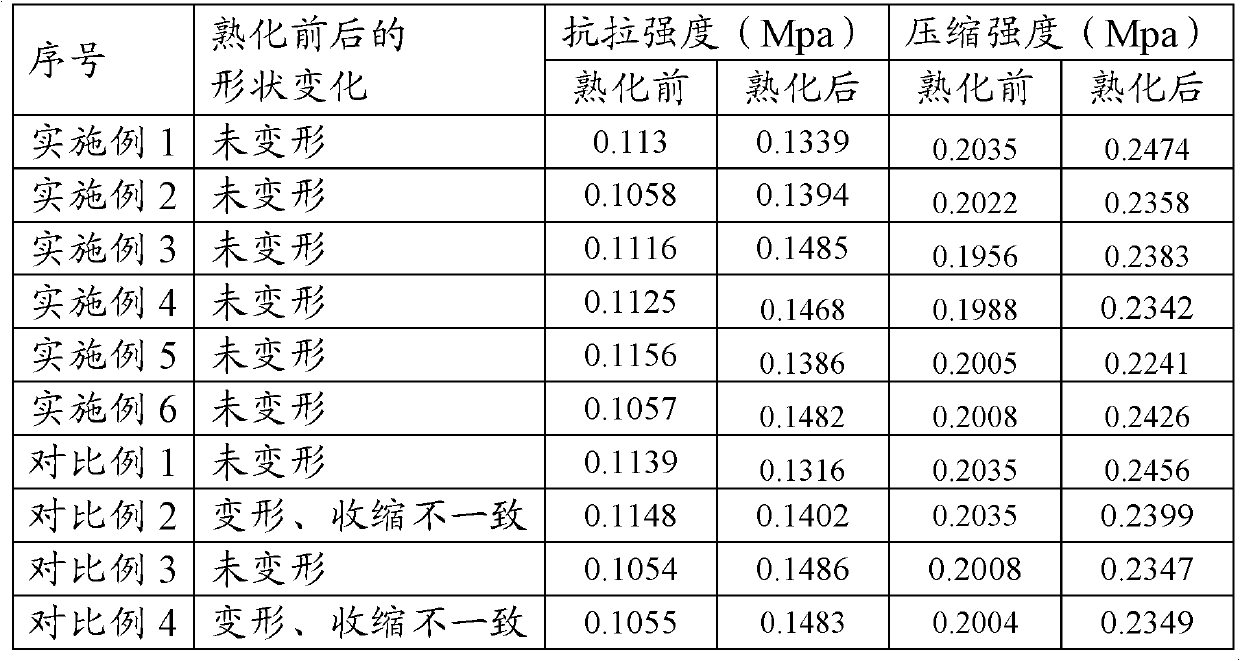

Method and equipment for curing phenolic aldehyde foam material

The invention discloses a method and equipment for curing a phenolic aldehyde foam material. The method for curing the phenolic aldehyde foam material comprises the steps of radiating the phenolic aldehyde foam material to be cured by using microwaves and cooling the phenolic aldehyde foam material. The equipment for curing the phenolic aldehyde foam material has the advantages that moisture, residual foaming agents and formaldehyde inside the phenolic aldehyde foam material are evaporated rapidly, and a chemical reaction inside the phenolic aldehyde foam material is greatly accelerated, so that the curing time is shortened. The microwaves are penetrable, so that the surface and inside of the phenolic aldehyde foam material are subjected to microwave radiation at the same time; and polar molecules absorb the energy of electromagnetic waves and generate uniform heat, so that the product quality is guaranteed, and the phenomenon that the phenolic aldehyde foam material shrinks discordantly, cracks or deforms is avoided.

Owner:JINAN SHENGQUAN GROUP SHARE HLDG

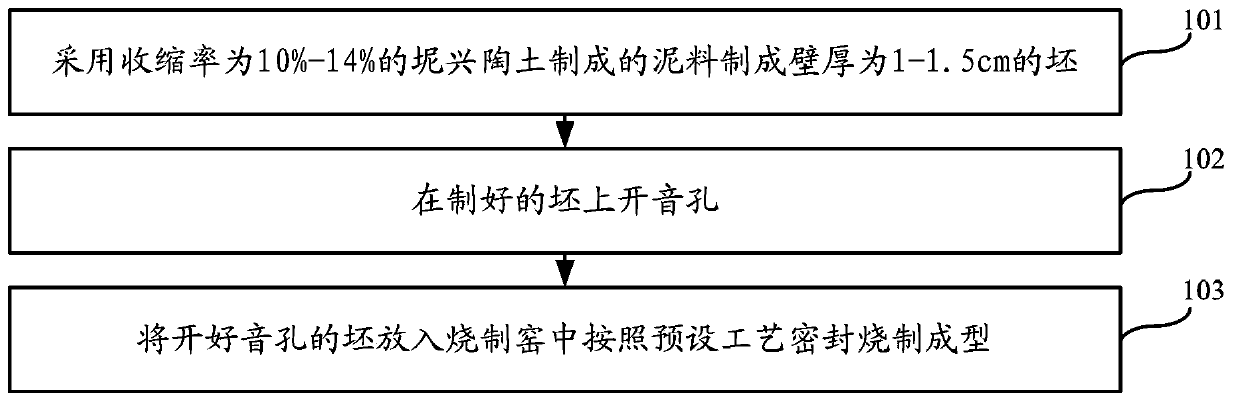

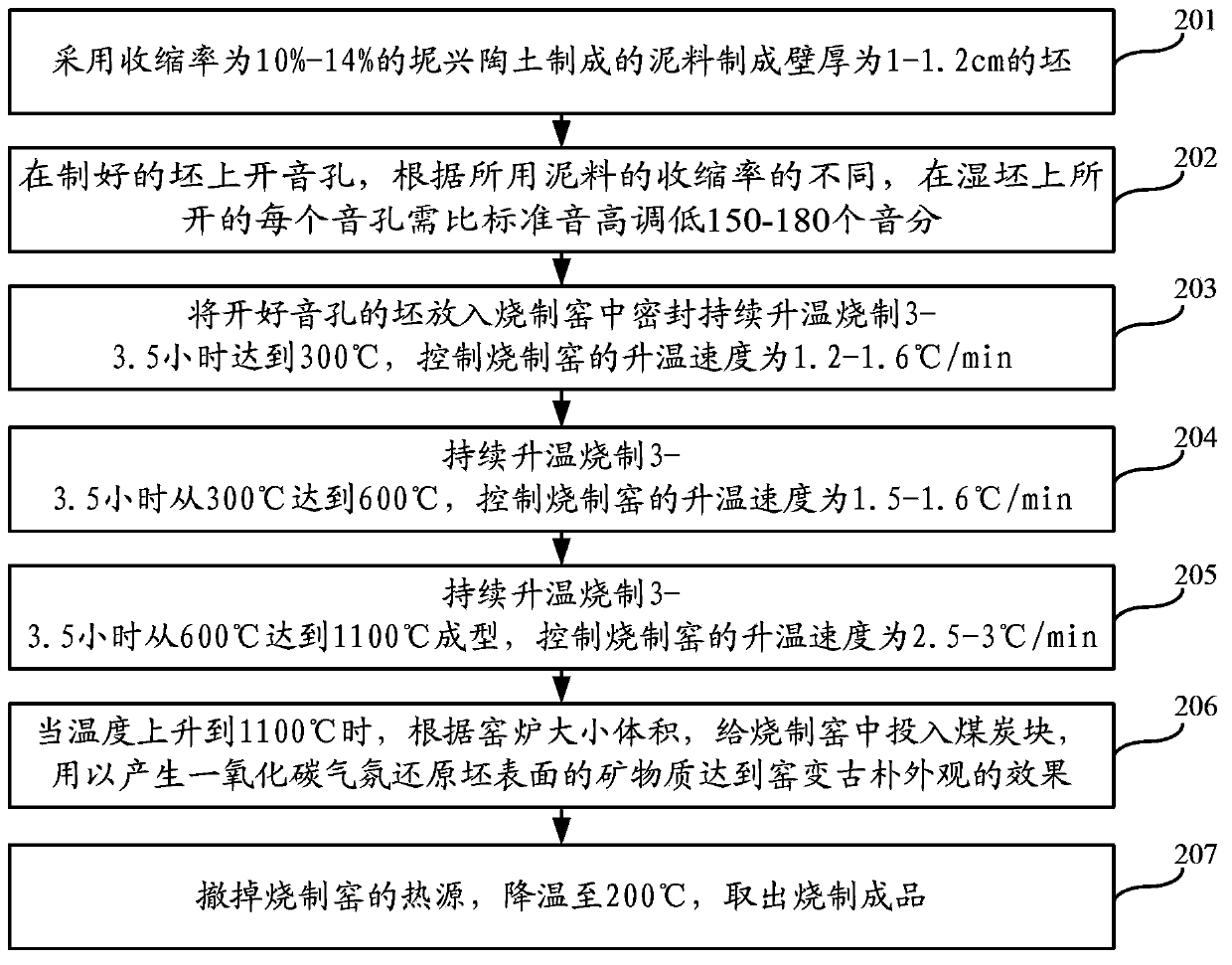

Method for firing Taoxun

ActiveCN103387380AMeet playing requirementsAvoid breakingWind musical instrumentsClaywaresContraction rateKiln

The invention relates to the field of artware processing and in particular relates to a method for firing Taoxun which is a musical instrument. The method specifically comprises the following steps of making a blank with the wall thickness of 1-1.5 cm by Nixing pottery clay with the contraction rate of 10-14 percent, forming tone holes in the blank, putting the blank with the tone holes into a firing kiln, and firing the Taoxun in a sealing manner for forming according to a preset technology. According to the method for firing the Taoxun disclosed by the invention, the finished Taoxun product manufactured by the Nixing pottery clay is hard, firm and unlikely to break and has a thick and turbulent sound; the tone is steady, firm and penetrating; the playing requirement of Taoxun can be met.

Owner:覃雄

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com