High-efficiency and high-strength composite material with far infrared radiation heating and preparation method thereof

A technology of far-infrared radiation and composite materials, applied in the field of high-efficiency and high-strength far-infrared radiation heating composite materials and its preparation, can solve the problems of slow heat transfer, high cost, and large energy consumption, and achieve the effect of metabolism and health care

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

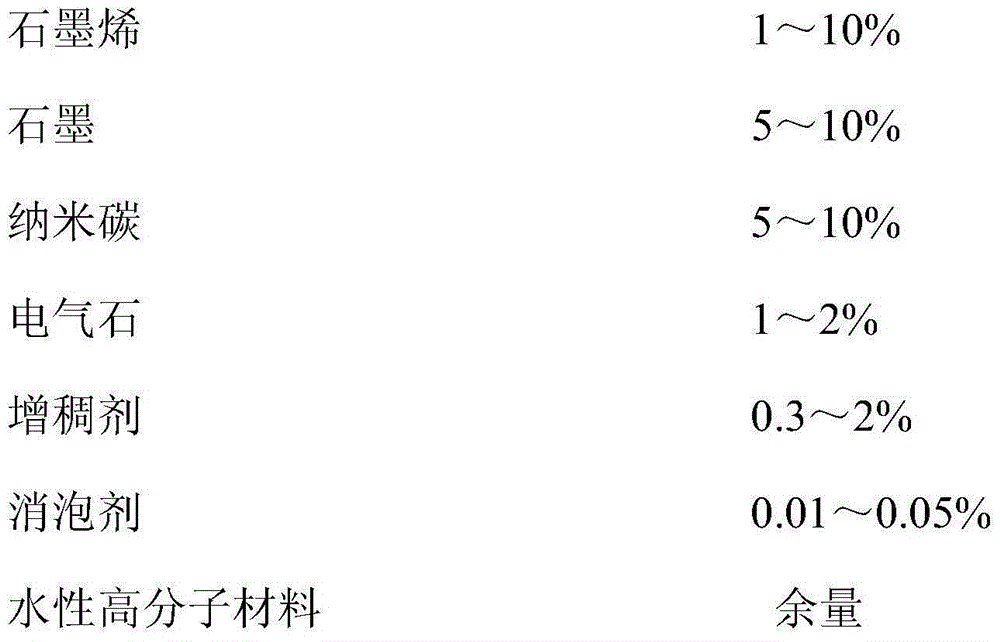

[0035] Water-based polyacrylate is used as the polymer material, and its mass percentage ratio is as follows:

[0036]

[0037] After modifying the above powder, use a high-speed mixer to mix evenly, and then add it to the water-based polymer coating. During the addition process, keep stirring at a high speed, and the stirring temperature is 50°C. After all the powders are uniformly dispersed, add the solubilizer and defoamer and continue stirring for 30 minutes.

[0038] Adding a defoamer during the stirring process helps to prevent the generation of air bubbles in the composite material, so that pores appear during the coating process, which affects the infrared radiation performance and thermal conductivity of the product. The far-infrared composite material prepared by this method is evenly coated on a dust-free and flat non-woven fabric carrier with a thickness of 1 μm. The coated product was dried in a vacuum oven at a drying temperature of 100° C. and a drying time ...

Embodiment 2

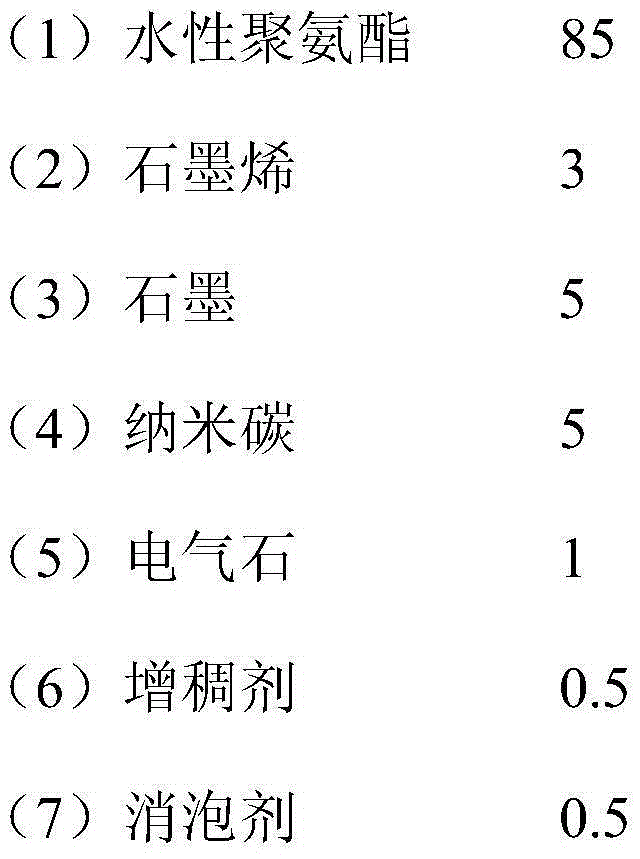

[0040] Water-based polyurethane is used as the polymer material, and its mass percentage ratio is as follows:

[0041]

[0042] After modifying the above powder, use a high-speed mixer to mix evenly, and then add it to the water-based polymer coating. During the addition process, keep stirring at a high speed, and the stirring temperature is 40°C. After all the powders are dispersed evenly, add the solubilizer and defoamer and continue stirring for 40 minutes.

[0043] Adding a defoamer during the stirring process helps to prevent the generation of air bubbles in the composite material, so that pores appear during the coating process, which affects the infrared radiation performance and thermal conductivity of the product. The far-infrared composite material prepared by this method is uniformly coated on a dust-free flat gauze carrier with a thickness of 1 μm. The prepared samples were dried in a vacuum oven at 120°C for 5 min to obtain the final samples. When the tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com