Display panel of transflective transparent display and sub-pixel structure thereof

A semi-transmissive, semi-reflective and transparent display technology, applied in instruments, nonlinear optics, optics, etc., can solve the problems of the panel not having transparent characteristics and increasing the cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-A

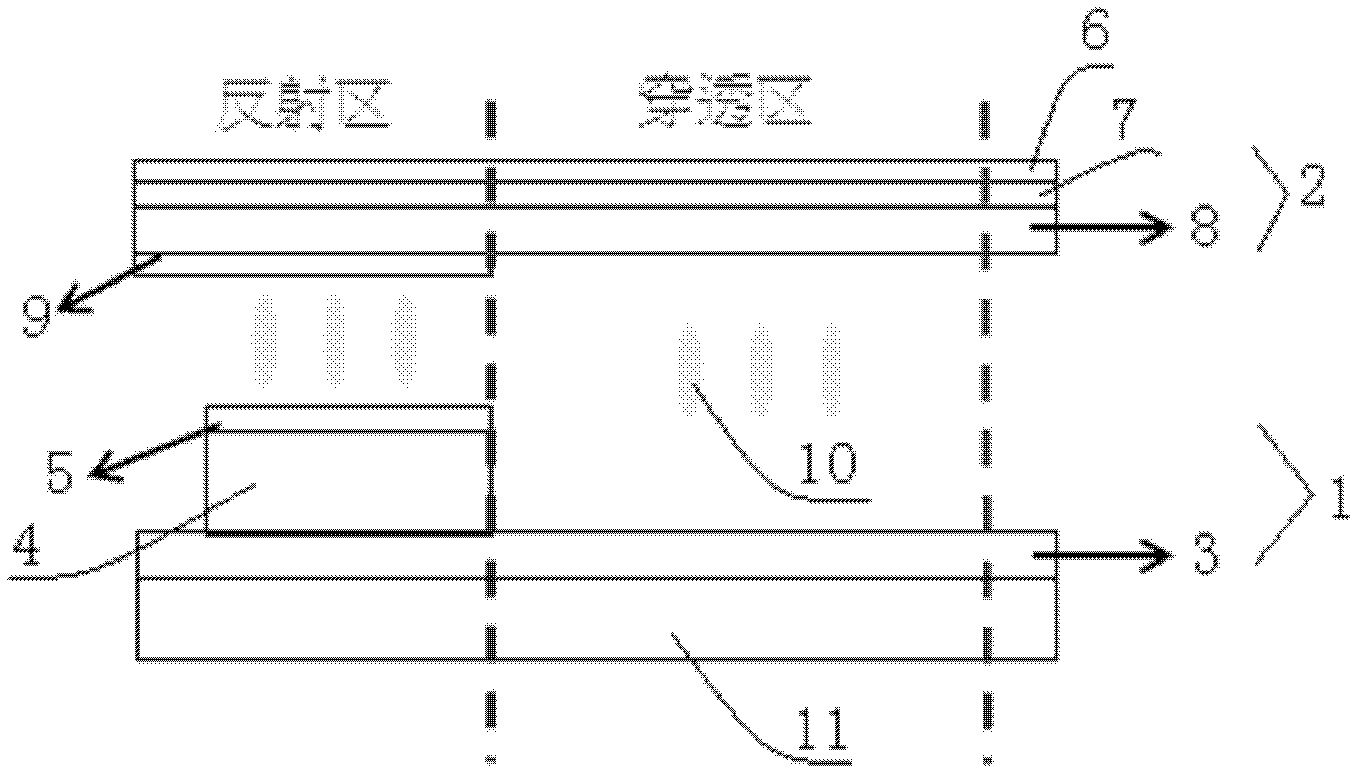

[0027] Such as figure 1 As shown, the pixel structure of the present embodiment includes a first substrate 1 and a second substrate 2 oppositely arranged. The left area of the two substrates is the reflection area of the sub-pixel, the right area is the penetration area of the sub-pixel, and the first substrate 1 includes a first glass 3, a reflective layer 4 provided on the reflective area of the first glass 3, and a sub-pixel electrode 5 provided on the reflective layer 4. The second substrate 2 includes a polarizing plate 6 arranged in sequence, a quarter wave Sheet 7, second glass 8, and ITO layer 9 on the reflective area of second glass 8, without color filters; multiple sub-pixel structures and a liquid crystal layer arranged between the first substrate 1 and the second substrate 2 10 constitutes a display panel. Compared with the prior art, the first substrate has no backlight, polarizer and quarter-wave plate, and the second glass does not have pixel electrod...

Embodiment 1-B

[0029] Such as figure 2 As shown, the difference between this embodiment and embodiment 1-A is that the outer side of the first glass 3 is also provided with an LED backlight source 11, and the LED backlight source is used to strengthen the light source under the dark room, so that the panel can display content more clearly. Suitable for darkroom environment.

Embodiment 2-A

[0031] Such as image 3 As shown, the difference between this embodiment and embodiment 1-A is that the second glass 8 is located between the reflective area and the ITO layer 9 and is also provided with a color filter 12 to realize color image display, and the design in the penetrating area There is no color filter to increase the transparency of the panel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com