Combustor

A burner and wall technology, applied in the direction of combustion chamber, combustion method, combustion equipment, etc., can solve the problems of large size of burner and unstable combustion, and achieve the effect of solving unstable combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

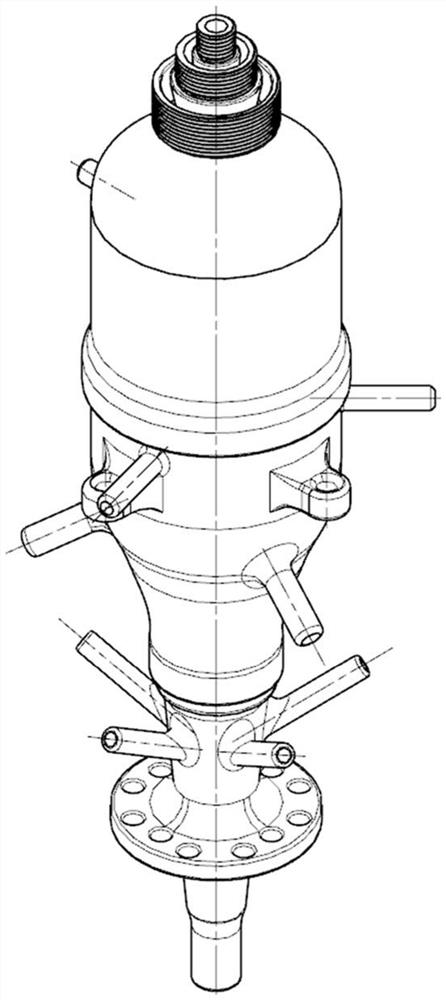

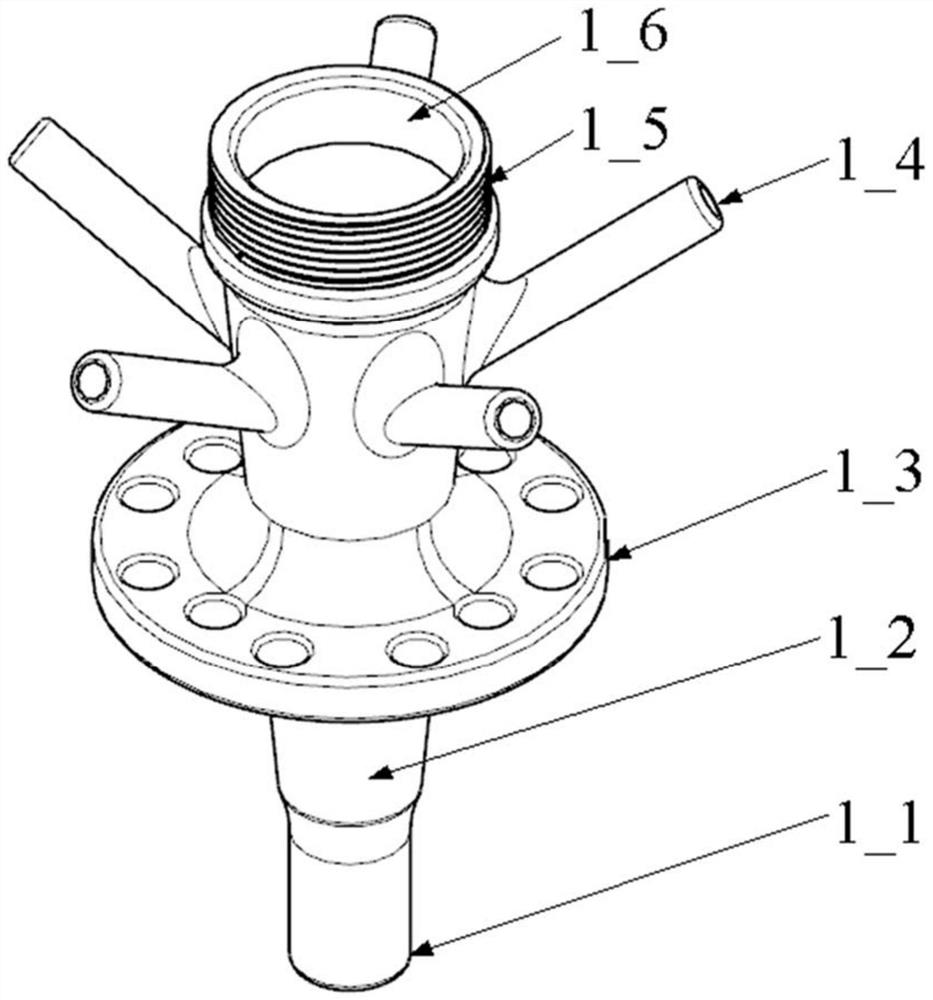

[0064] In order to make the purpose, technical solutions and advantages of the present disclosure clearer, the present disclosure will be further described in detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

[0065] At present, 3D printing processing technology has become more mature and has been applied in engineering. However, due to the process requirements of 3D printing, a large number of support structures must be added inside the printed parts. These support structures will hinder the movement of airflow, increase flow loss, and increase airflow. Disturbance is not conducive to stable combustion. How to take into account the support problem during structural design and avoid adding additional support during 3D printing through optimized design is also a key issue.

[0066] This disclosure applies 3D printing technology to the structural design of the burner. During 3D printing processing, no additional support structur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com