Afterburner and turbine engine

A technology of afterburner and combustion chamber, which is applied in the direction of combustion chamber, deflagration combustion chamber, gas turbine device, etc. It can solve the problems of unstable combustion, limiting the working time and performance of afterburner, and the decline of working ability. , to achieve the effect of solving unstable combustion, improving work ability and improving thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The afterburner and turbine engine according to the present invention will be described in detail below with reference to the accompanying drawings.

[0036] First, the afterburner according to the first aspect of the present invention will be explained.

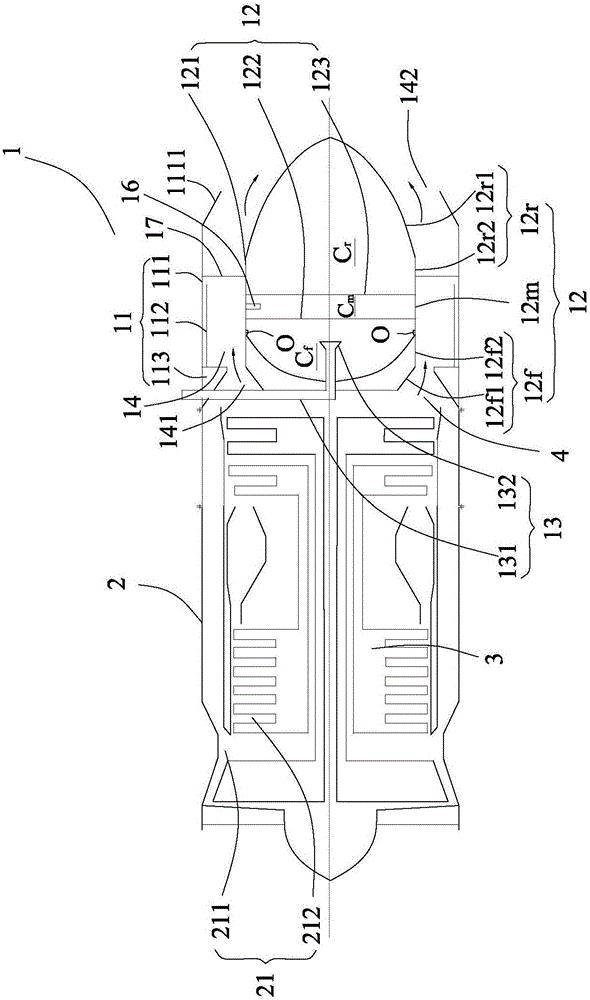

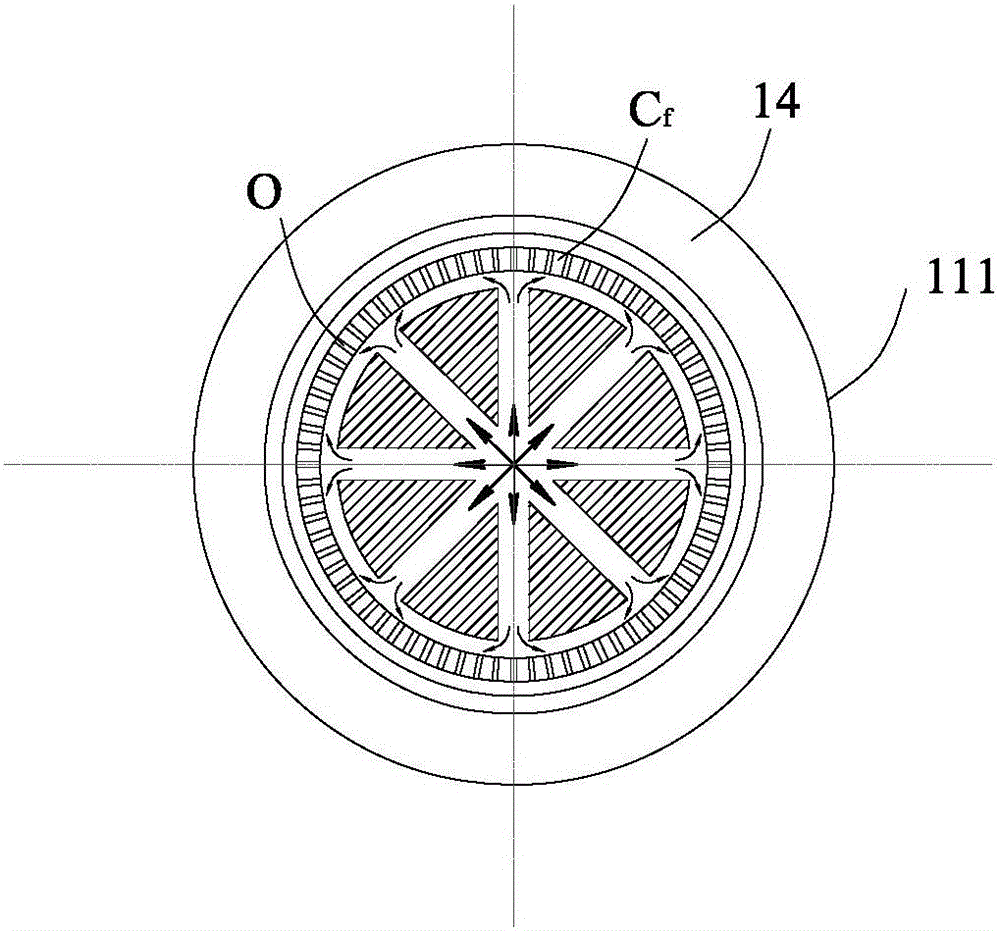

[0037] refer to Figure 1 to Figure 4 , The afterburner 1 according to the present invention includes: an outer cylinder assembly 11 ; a central body assembly 12 , an oil passage assembly 13 , an annular combustion chamber 14 and an igniter 16 .

[0038] The central body assembly 12 is accommodated in the outer cylinder assembly 11 and forms an annular combustion chamber 14 with the outer cylinder assembly 11 . The oil circuit assembly 13 is controlled to communicate with the annular combustion chamber 14 to provide fuel (ie fuel oil) to the annular combustion chamber 14 . Among them, the center body assembly 12 includes: a front body 12f, which is located at the axial front end of the afterburner 1 and forms an ann...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com