A deep recovery device for boiler flue gas waste heat

A recovery device and boiler flue gas technology, which is applied in flue gas combustion, greenhouse gas reduction, climate sustainability, etc., can solve combustion instability and other problems, achieve the effects of reducing NOx generation, increasing dew point temperature, and normal flame

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

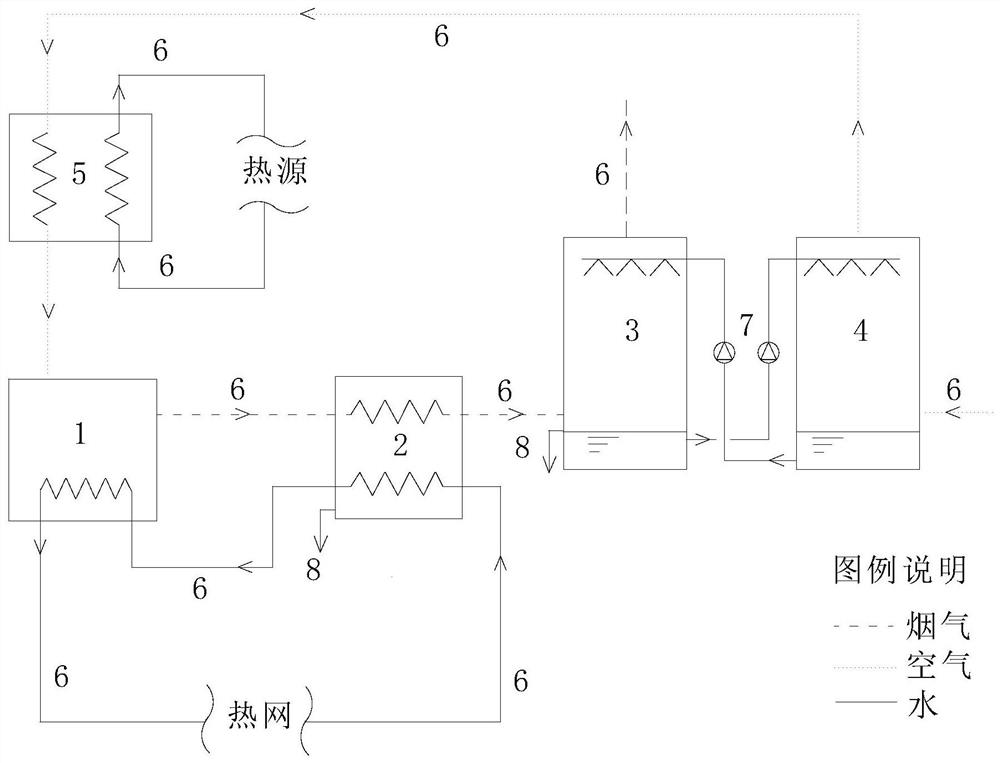

[0024] like figure 1 As shown, the boiler flue gas waste heat deep recovery device of the present invention comprises a boiler 1, a steam-water heat exchanger 2, a flue gas-water heat exchanger 3, an air-water heat exchanger 4, and an air reheater 5 , a number of pipes 6, a number of water pumps 7 and a number of overflow pipes 8.

[0025] figure 2 It is a schematic diagram of the overall structure of the boiler effluent as the heat source of the air reheater in Example 1 of the present invention. in:

[0026] The flue gas outlet of the boiler 1 is connected to the flue gas inlet of the steam-water heat exchanger 2 through the pipe 6a, and the flue gas outlet of the steam-water heat exchanger 2 is connected to the flue gas inlet of the flue gas-water heat exchanger 3 through the pipe 6b. The high-temperature flue gas in the boiler 1 passes through the steam-water heat exchanger 2 and the flue gas-water heat exchanger 3 for heat exchange in turn, and then is discharged into...

Embodiment 2

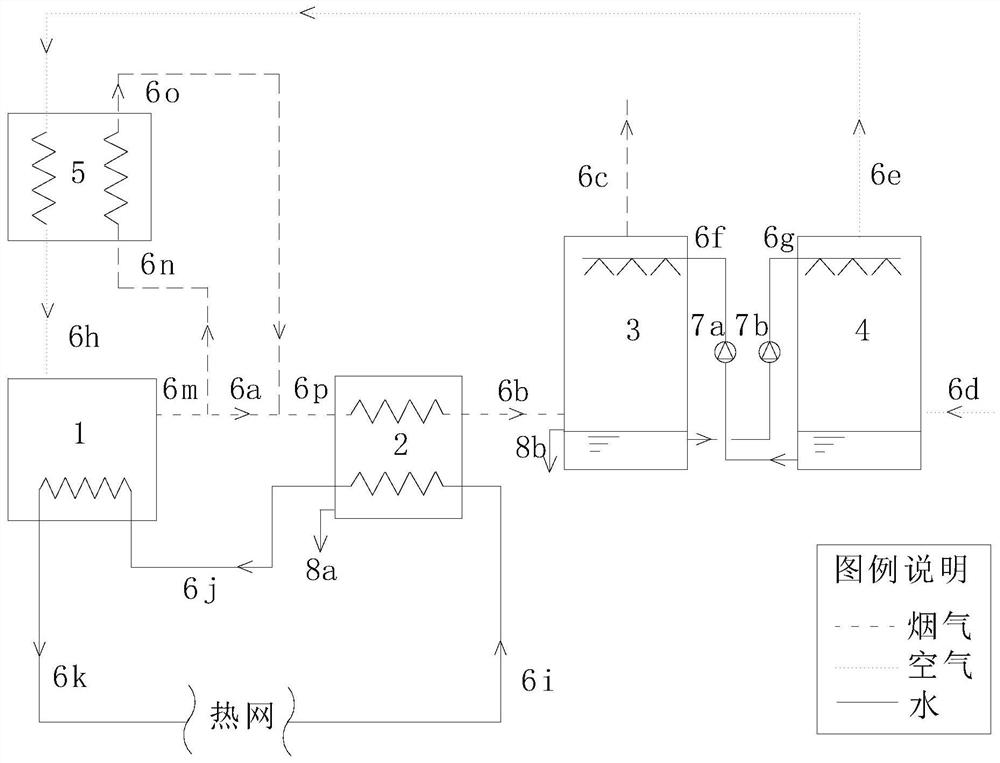

[0041] like Figure 5 As shown, the boiler flue gas waste heat deep recovery device of the present invention comprises a boiler 1, a steam-water heat exchanger 2, a flue gas-water heat exchanger 3, an air-water heat exchanger 4, and an air reheater 5 , a number of pipes 6, a number of water pumps 7 and a number of overflow pipes 8.

[0042] The flue gas outlet 6m of the boiler 1 is divided into two tributaries 6n and 6a, the tributary 6n is connected to the heat source inlet of the air reheater 5, and the flue gas is mixed with air in the air reheater 5, which is a gas mixing device , the air-flue gas mixture is connected to the air inlet of the boiler 1 through the pipeline 6h; the other branch 6a is connected to the flue gas inlet of the steam-water heat exchanger 2, and the flue gas outlet of the steam-water heat exchanger 2 is connected to the flue gas- The flue gas inlet of the water heat exchanger 3. The high-temperature flue gas in the boiler 1 passes through the stea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com