Dual-fuel swirling atomizing nozzle for chemical regenerative cycle

A technology of swirling atomizing nozzle and chemical reheating cycle, which is applied in the direction of combustion chamber, combustion method, combustion equipment, etc., can solve the problem of uneven mixing of pyrolysis gas and air in the head, unsatisfactory atomization effect, and influence on combustion effect and other problems, to achieve the effect of compact head structure, improved adaptability and economy, and easy layout and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

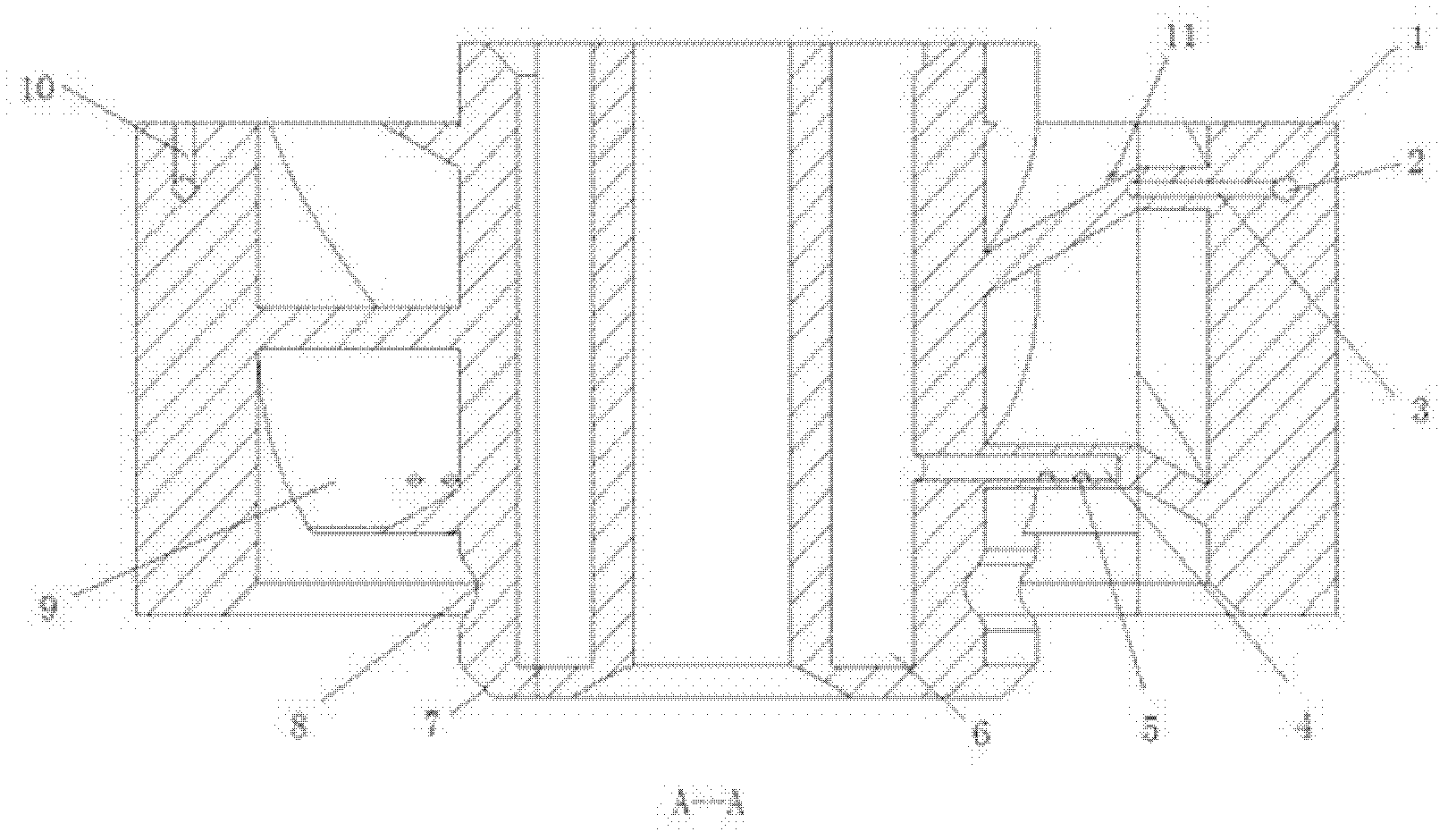

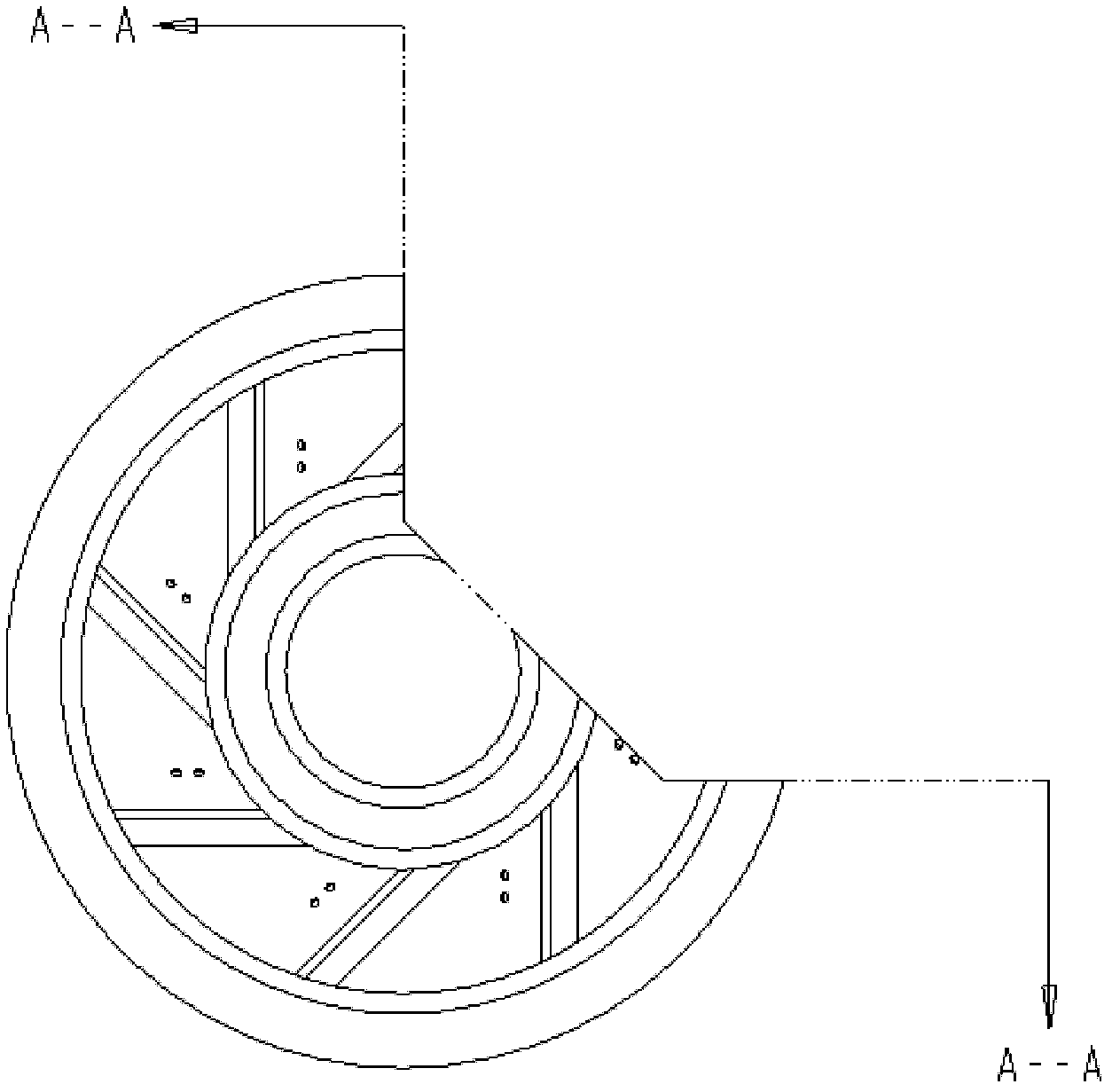

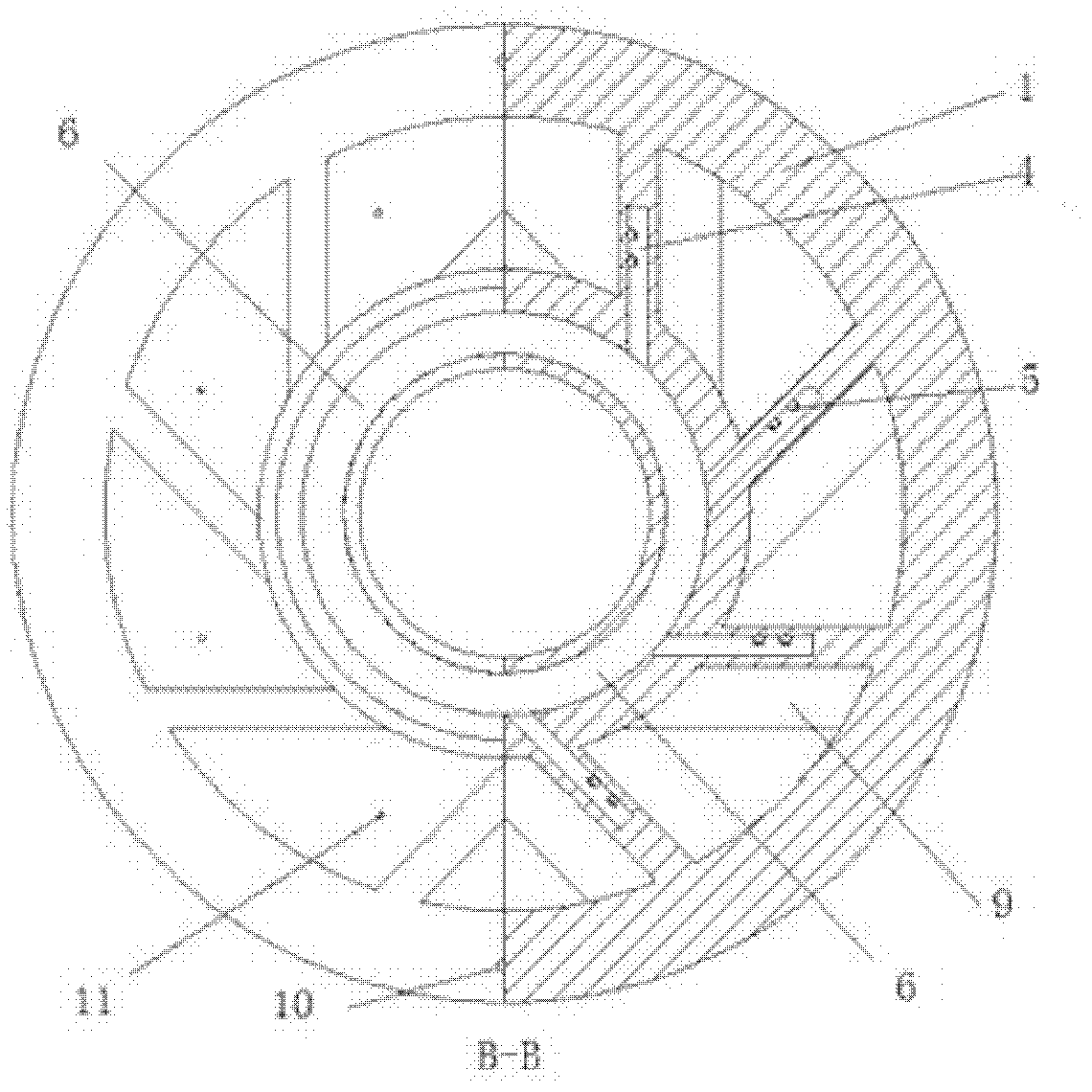

[0022] The present invention is described in more detail below in conjunction with accompanying drawing example:

[0023] to combine Figure 1~5 , when injecting liquid fuel, the liquid fuel is directly injected into the high-speed airflow channel of the swirler, and when the high-speed airflow flows through the horizontally injected liquid column, the pressure on the windward side is higher and the pressure on the leeward side is lower, resulting in The aerodynamic force can squeeze the liquid column, and the liquid column is gradually flattened. Surface fluctuations appear on the windward and leeward sides of the fuel jet. The appearance of these fluctuations intensifies the bending of the jet, and the surface fluctuation increases along the direction of the jet. The jet breaks at the trough of the wave, and the broken fuel jet forms shorter fuel fragments, which are further broken into small particles. The diameter of the droplets produced by surface atomization is better ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com