Blade skeleton type atomizing sprayer

A technology of atomizing nozzles and blades, applied in the direction of spraying devices, spraying devices, liquid spraying devices, etc., can solve the problems of limited coverage area and uneven atomization, so as to avoid waste and environmental pollution, enhance the atomization effect, Easy atomization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing, the present invention is described in detail:

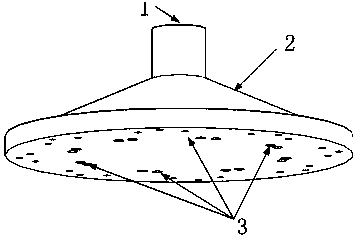

[0020] figure 1 A schematic diagram of the three-dimensional structure of the atomizing nozzle is given. An atomizing nozzle combined with blade venation channels is composed of a main conveying channel 1 , an ultrasonic generator 2 and a liquid outlet 3 . The liquid is transported from the main conveying channel 1 to the veined channel 4 of the forked blade, and is sprayed out from the liquid outlet 3 under the action of the ultrasonic atomizer 2 . The ultrasonic generator 2 is conical, runs through the main conveying channel 1, and is arranged above the branch channel of the nozzle and the water outlet, and atomizes the liquid at the outlet of the channel by generating high-frequency oscillation.

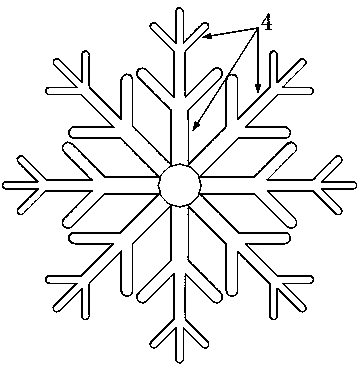

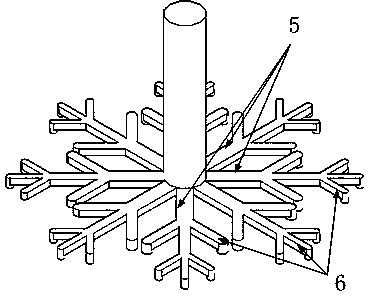

[0021] figure 2 , 3 The top view and three-dimensional stereogram of the veined channel of the blade are given. The forked blade vein channels 4 are arranged in a plane ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com