Atomizing element and electronic cigarette

A technology of components and parts, applied in the field of atomization components and electronic cigarettes, can solve the problems of low atomization speed, small atomization amount, dry burning and overheating, etc. burn effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

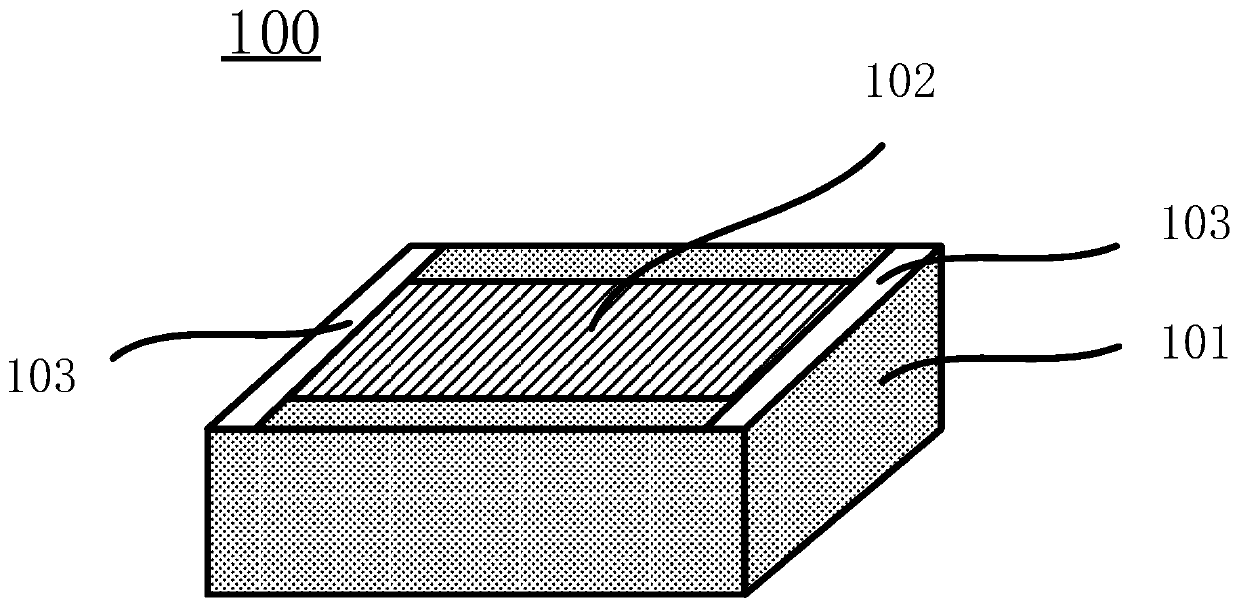

[0051] The structure of the atomizing element of this embodiment is as figure 1 As shown, a porous alumina ceramic is used as the porous ceramic part, the average pore diameter is 27 μm, the porosity is 45%, and the thickness is 2530 μm.

[0052] A nickel-based alloy is used to form a linear porous metal film by screen printing on the upper surface of the porous ceramic part, and then silver paste is printed on both ends of the porous metal film to form a silver electrode covering the porous metal film, and then Sintering to obtain the atomizing element. The average pore diameter of the porous metal membrane is 15 μm, the porosity is 30%, and the thickness is 100 μm. At least part of the pores of the porous metal membrane communicate with the pores of the porous ceramic part.

Embodiment 2

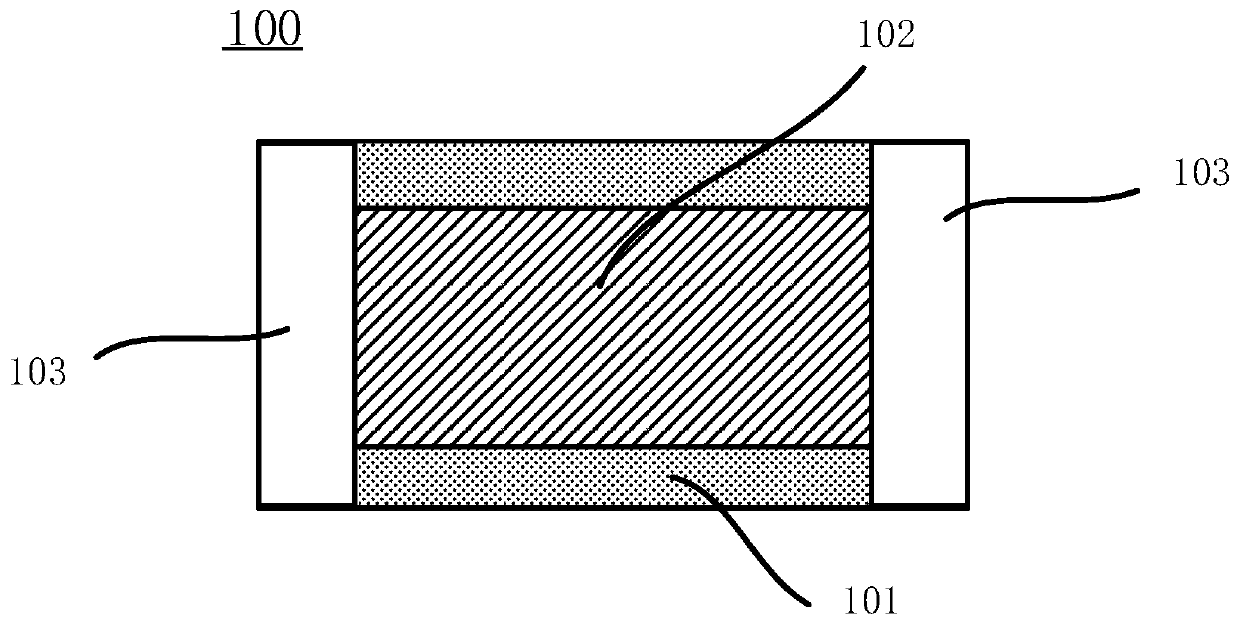

[0054] The structure of the atomizing element of this embodiment is as Figure 8 As shown, the preparation process is roughly the same as that of Example 1, the only difference being that a linear porous metal film is formed by screen printing on the upper surface, left side and right side of the porous ceramic part. The average pore diameter of the porous metal membrane is 25 μm, the porosity is 20%, and the thickness is 80 μm. At least part of the pores of the porous metal membrane communicate with the pores of the porous ceramic part.

Embodiment 3

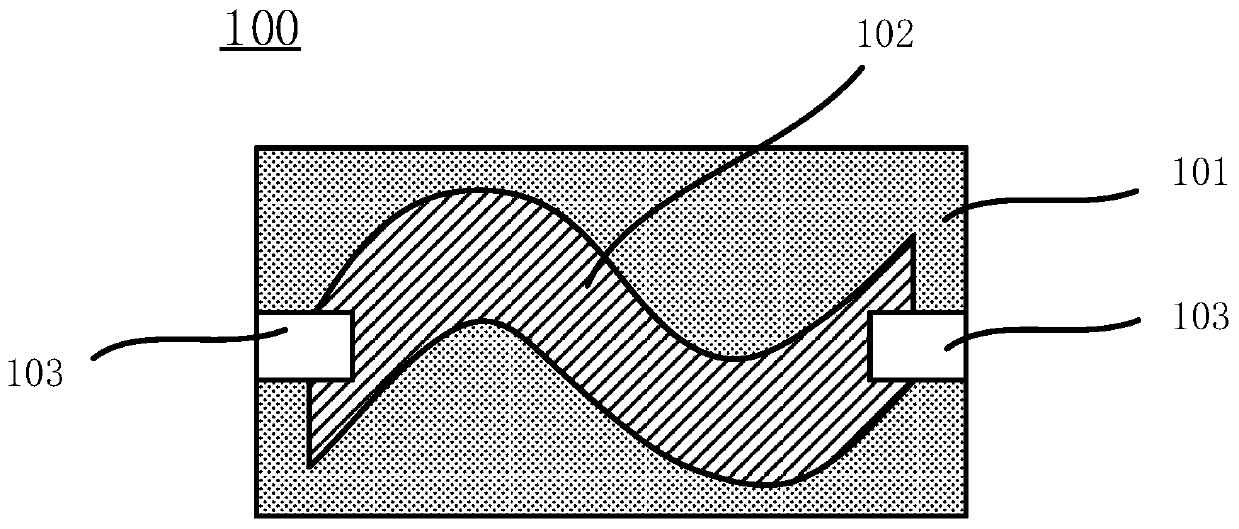

[0056] The structure of the atomizing element of this embodiment is as Figure 9 shown. Porous silica ceramics were used as the porous ceramic part with an average pore diameter of 35 μm, a porosity of 50%, and a thickness of 3000 μm.

[0057] First, a groove with a thickness of 100 μm and a square longitudinal section is dug out on the upper surface of the porous ceramic part, and then a nickel-based alloy is used to form a porous metal film in the groove by screen printing, and then the two sides of the porous metal film are The silver paste is screen-printed at the end to form a silver electrode covered with a porous metal film, and then sintered to obtain an atomized element. The average pore diameter of the porous metal membrane is 43 μm, the porosity is 20%, and the thickness is 98 μm. At least part of the pores of the porous metal membrane communicate with the pores of the porous ceramic part.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com