Double-rotational-flow single-heat-storage flat flame burner

A flat flame burner, single heat storage technology, applied in heat storage equipment, burners, combustion methods, etc., can solve the problems of inconvenient maintenance and complex structure, and achieve the effect of increasing speed, simple maintenance, and uniform heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

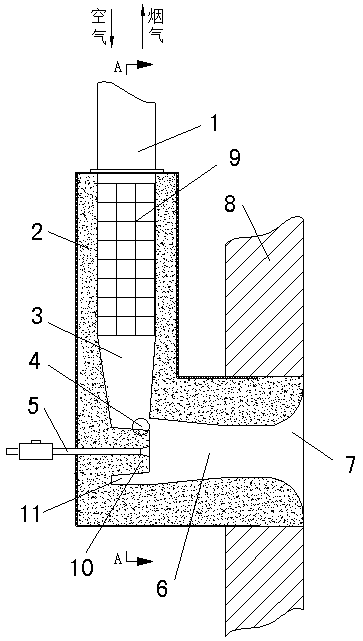

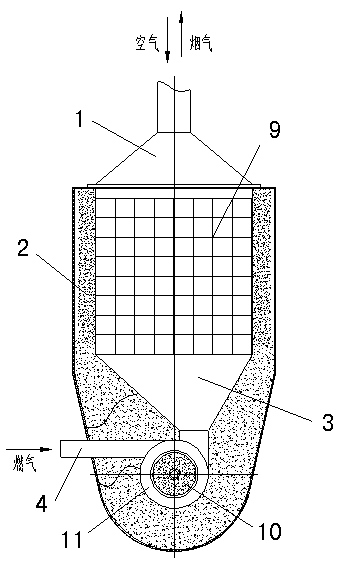

[0021] The double swirl single heat storage flat flame burner of the present invention relies on the internal structure to make the air and gas swirl, and the double swirl flow of air and gas can be realized without adding swirl sheets inside the burner. Its structure is as figure 1 and figure 2 As shown, the housing 2 is included. The casing 2 is provided with a connected air and smoke chamber 3 and a combustion chamber 6 , the air and smoke chamber 3 and the combustion chamber 6 are in a vertical state, the air and smoke chamber 3 is in a vertical direction, and the combustion chamber 6 is in a horizontal direction. An air flue gas pipe 1 is connected to the upper part of the air flue gas chamber 3 . The shell 2 is provided with a circular boss 10 at the inner end of the combustion chamber 6 (at the junction with the air and smoke chamber 3 ), so that the cross section of the inner end of the combustion chamber 6 forms an annular cavity 11 . The outer end of the combusti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com