Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

34 results about "Main injector" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The NOνA experiment uses, and the MINOS experiment used, Fermilab's NuMI (Neutrinos at the Main Injector) beam, which is an intense beam of neutrinos that travels 455 miles (732 km) through the Earth to the Soudan Mine in Minnesota and the Ash River, Minnesota, site of the NOνA far detector.

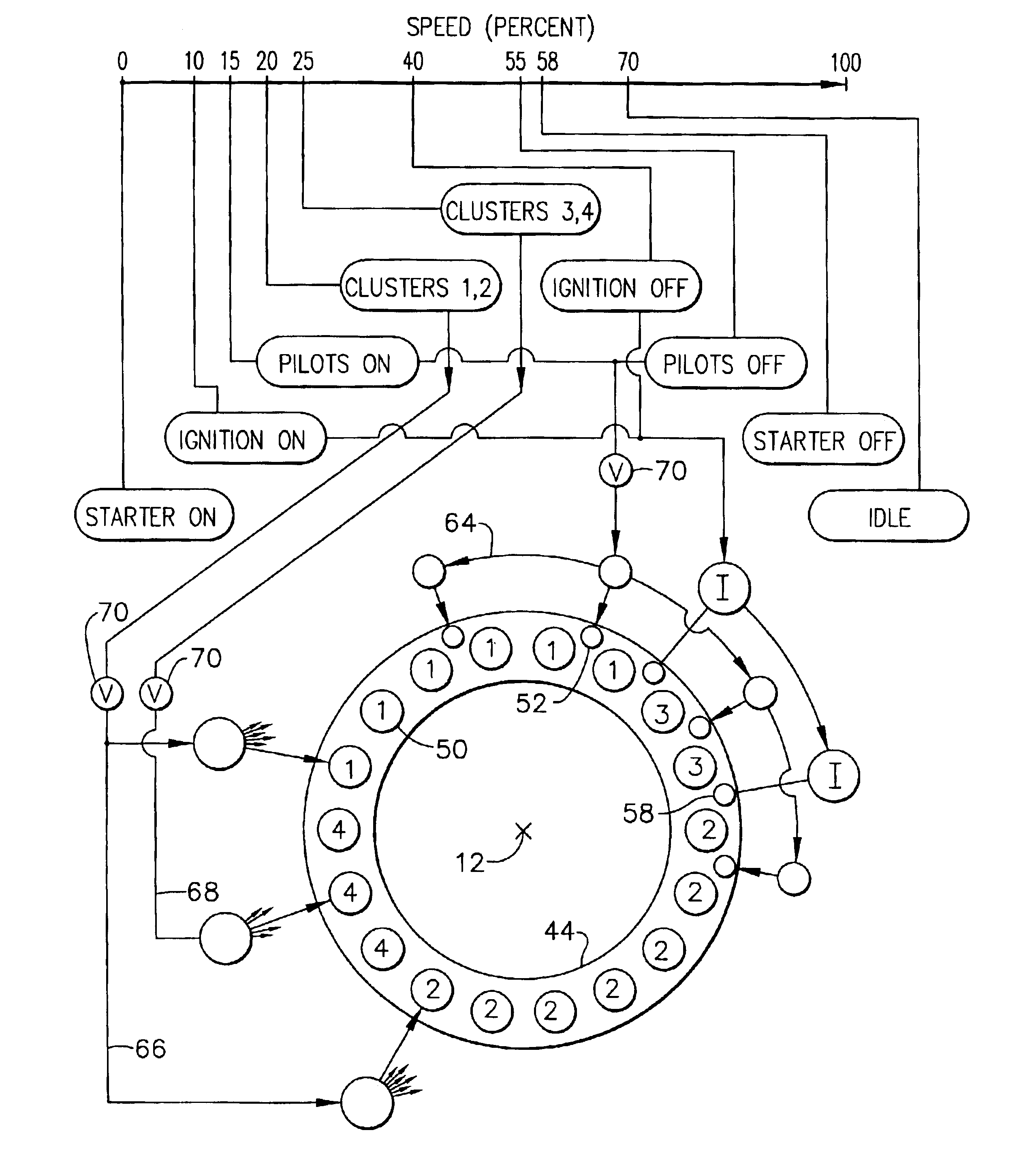

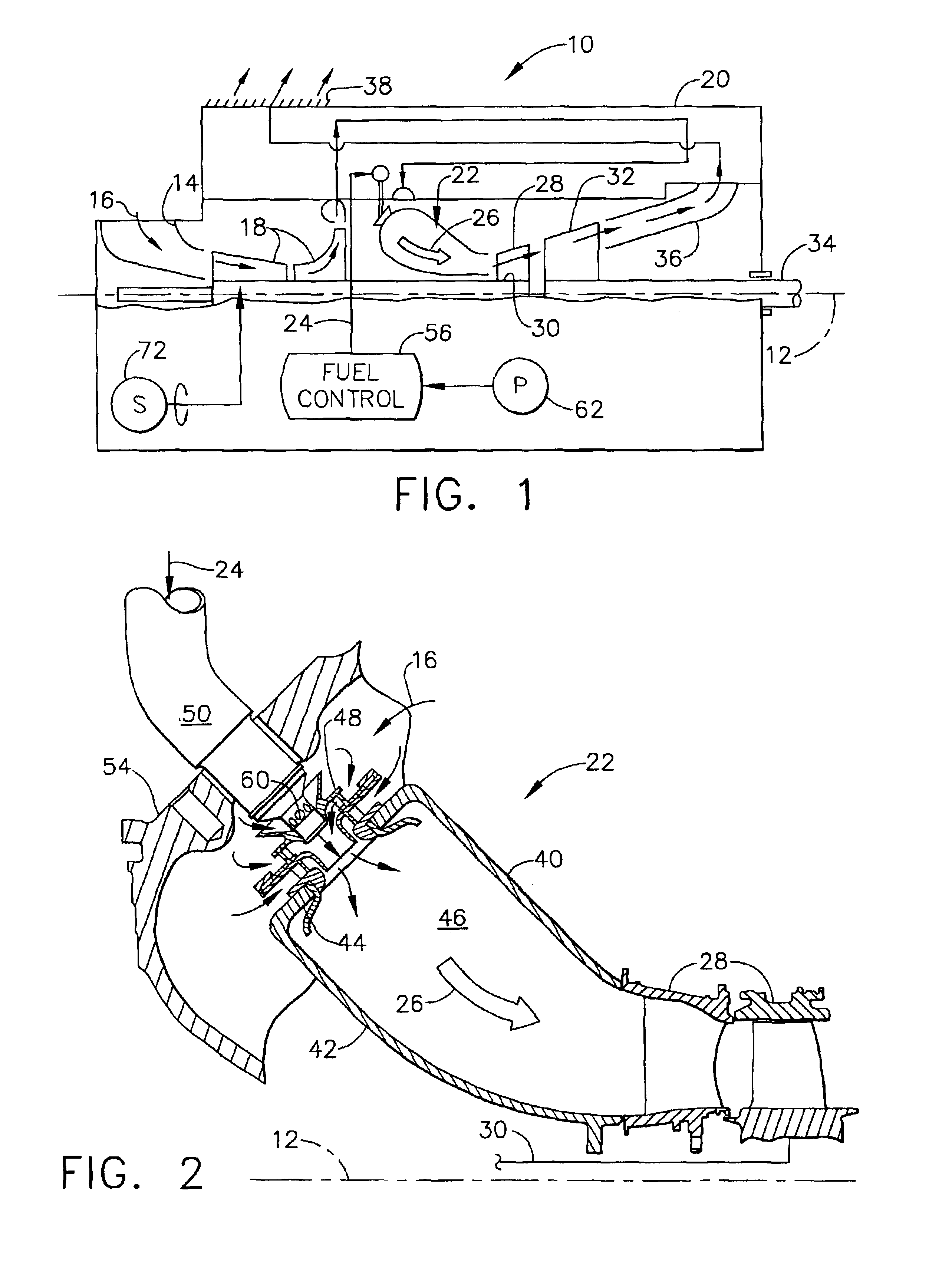

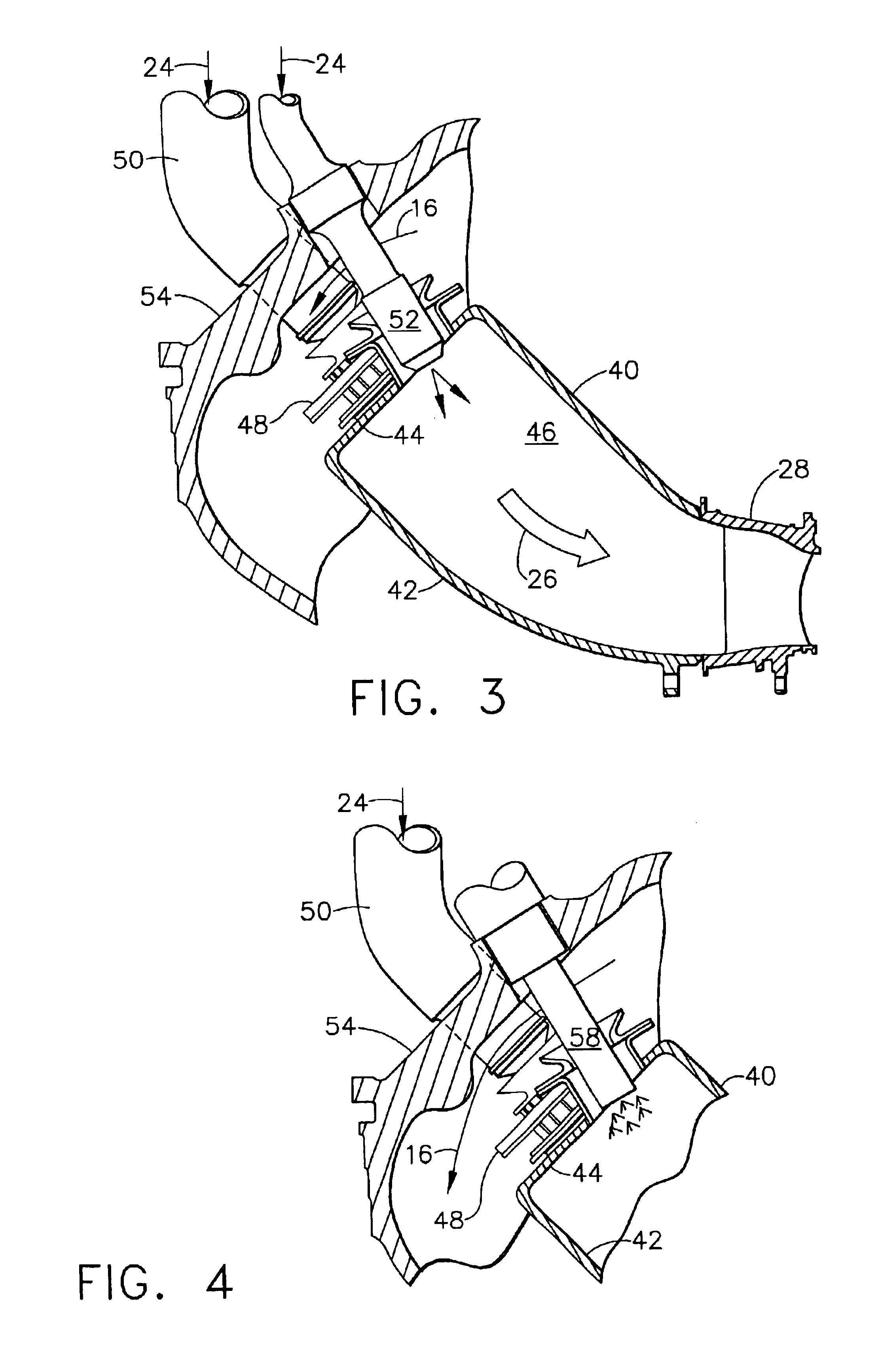

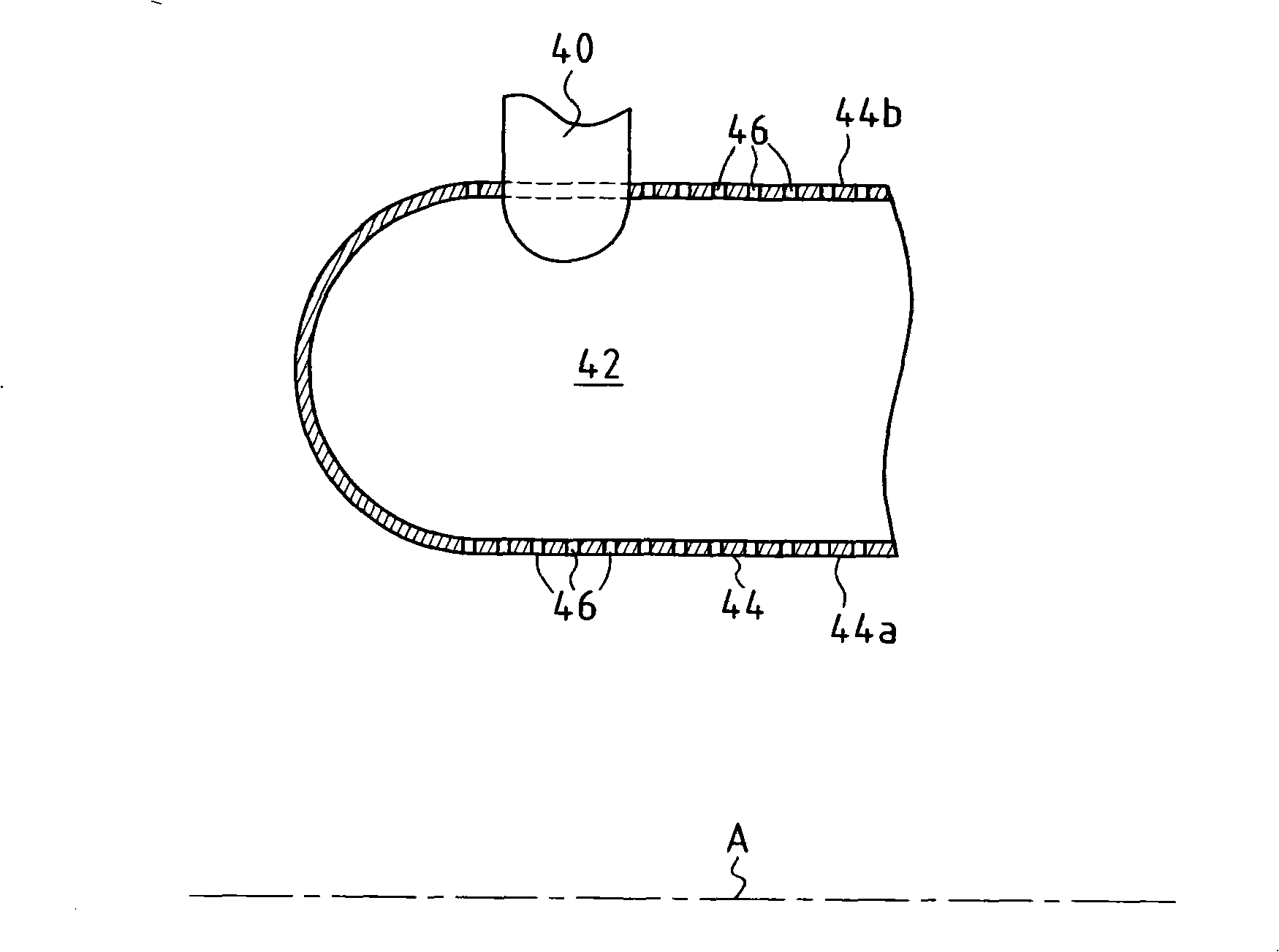

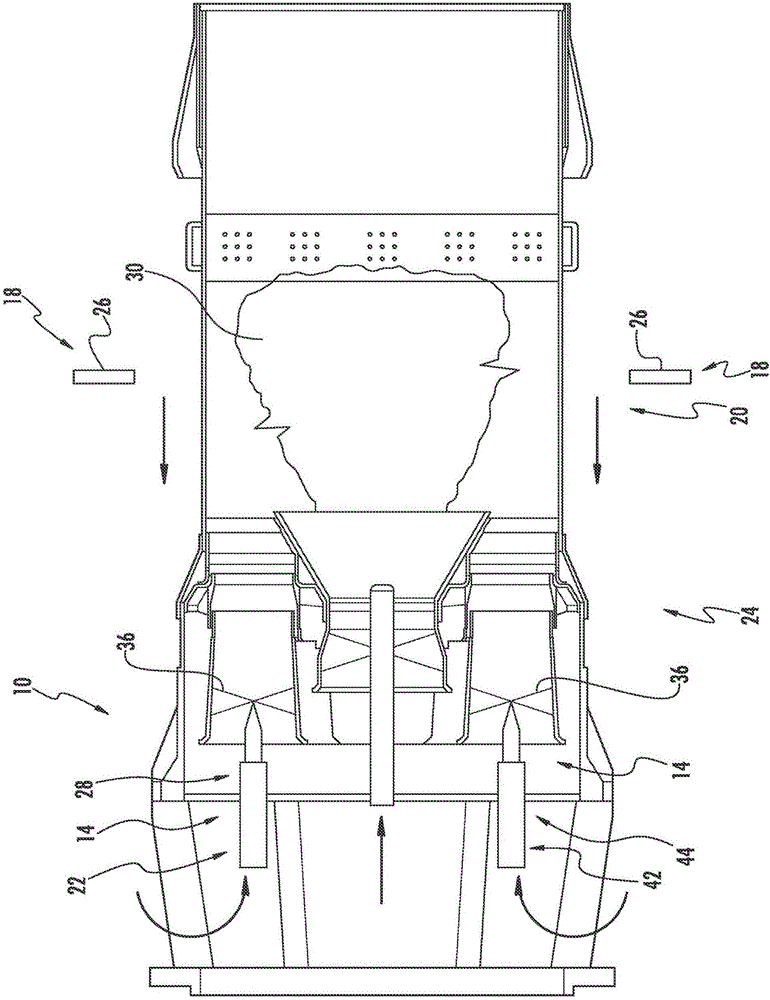

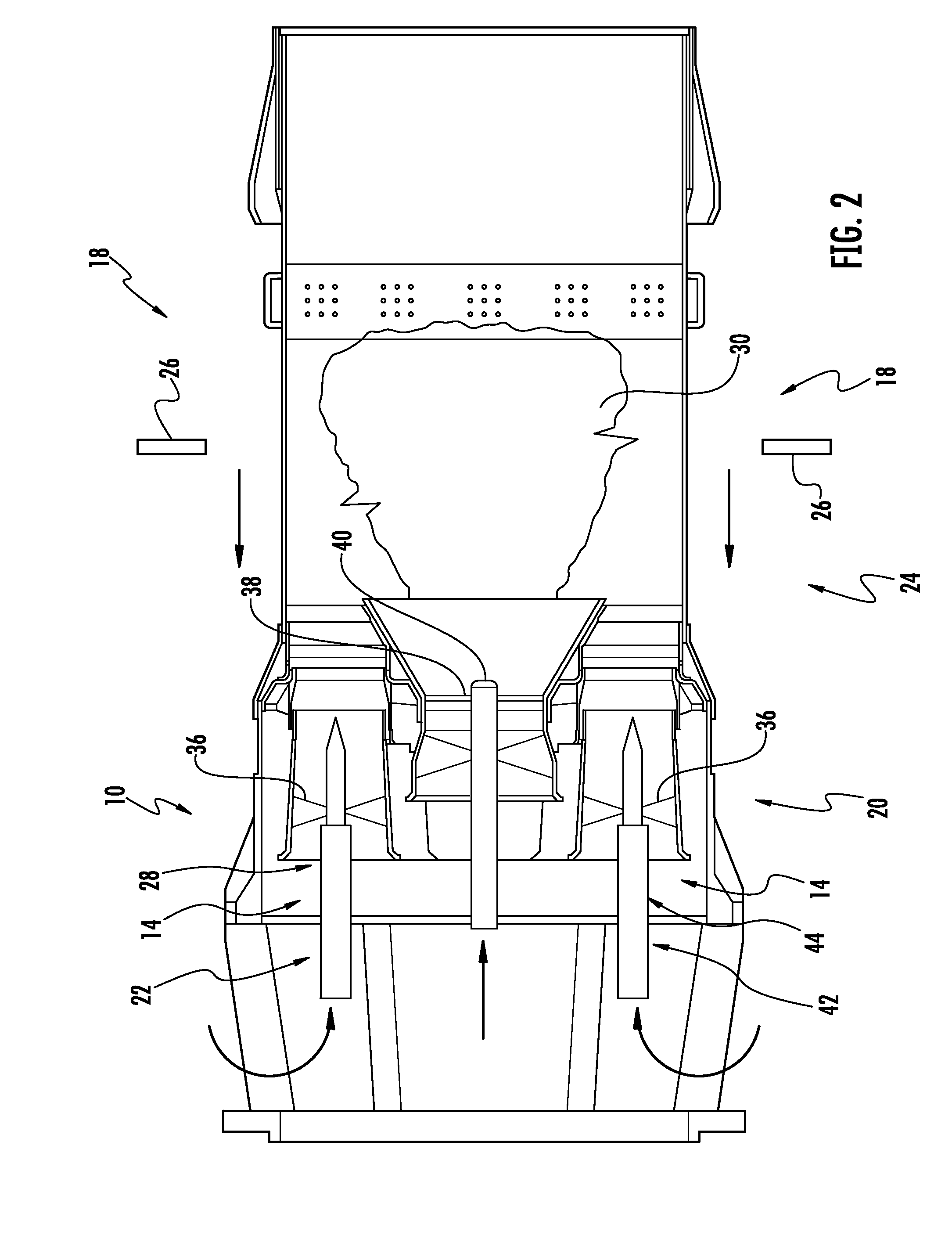

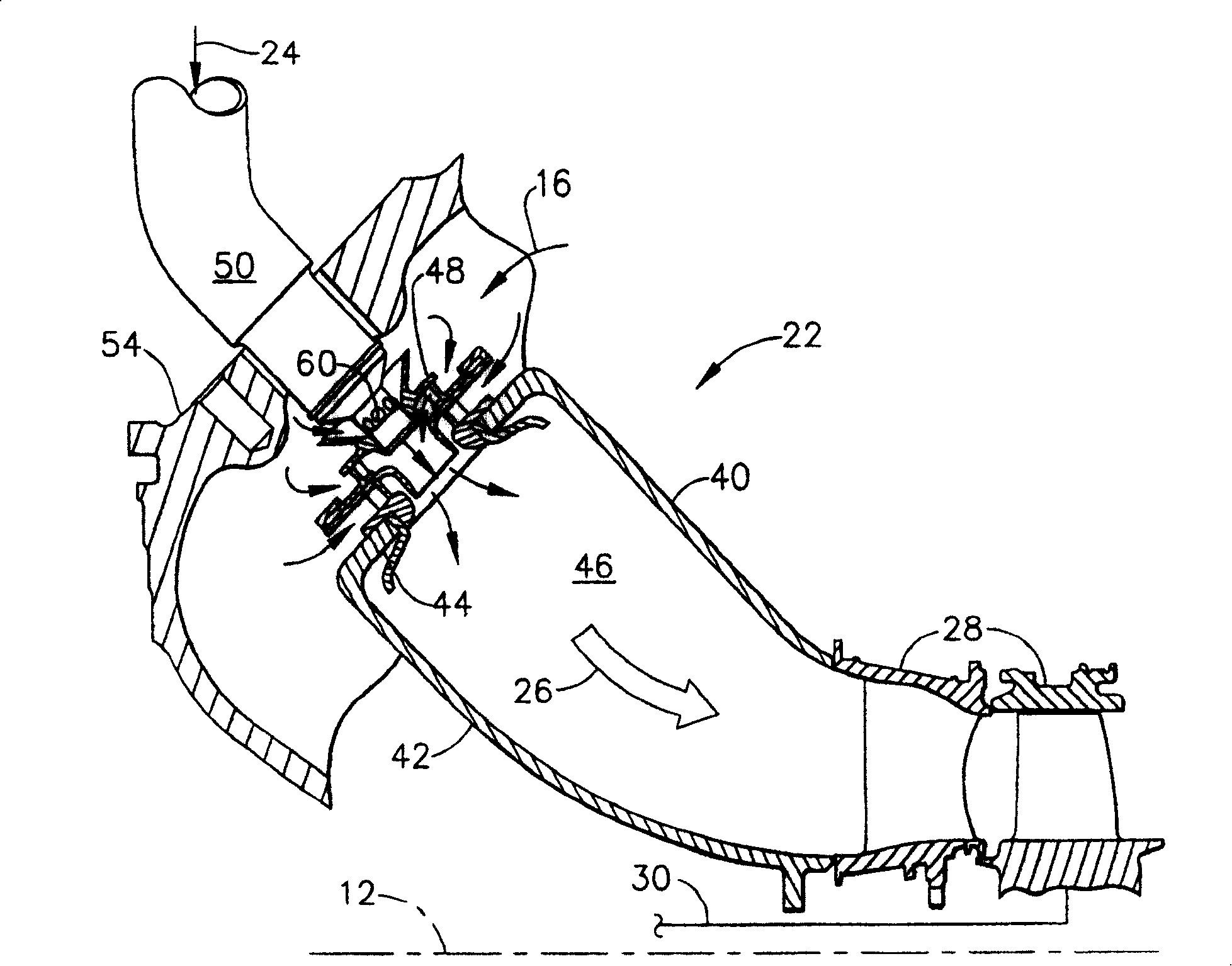

Sector staging combustor

InactiveUS6968699B2Improve combustion efficiencyLower ratioBurnersContinuous combustion chamberCombustorCombustion chamber

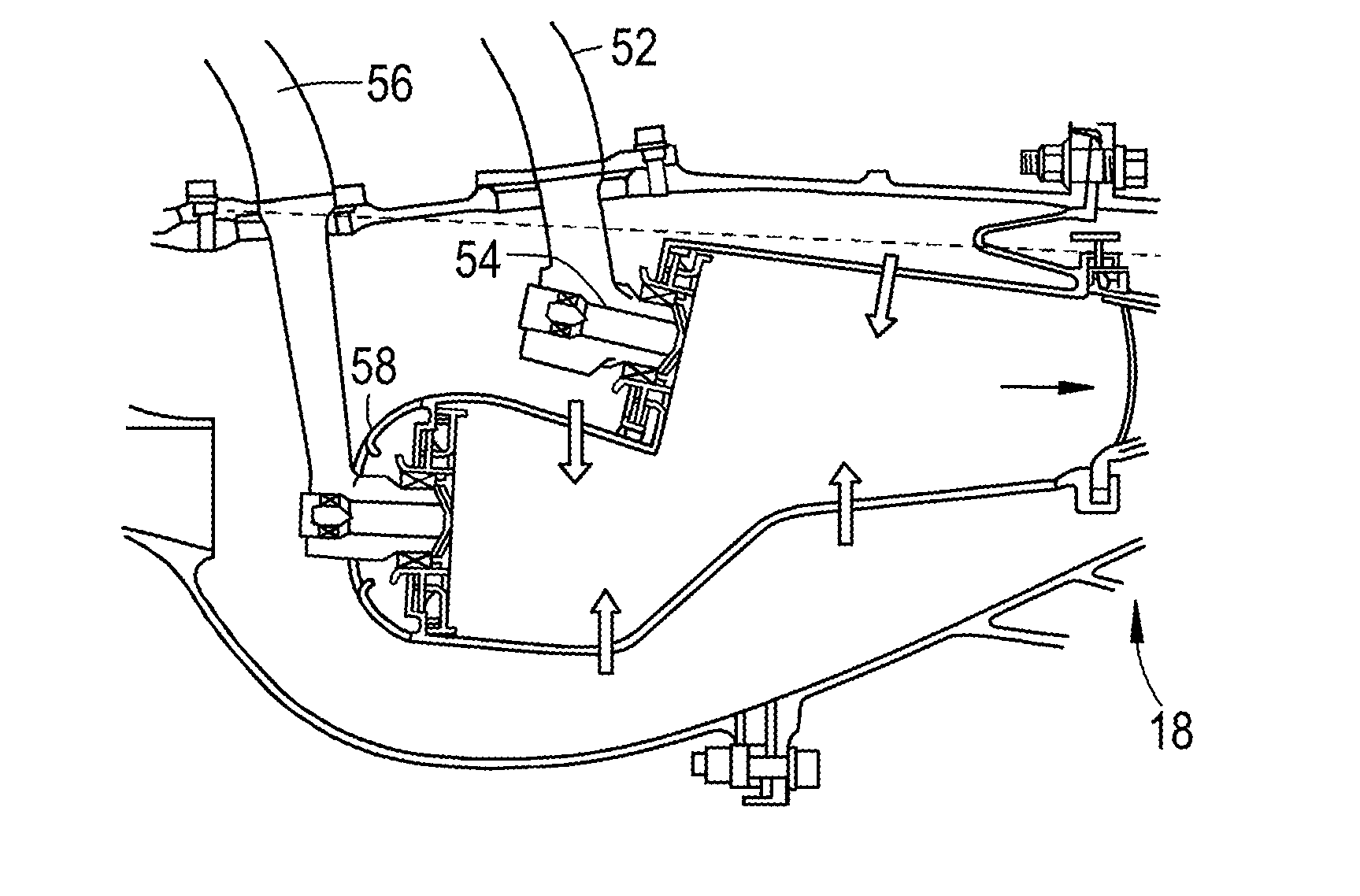

A combustor includes outer and inner liners joined together by a dome to define a combustion chamber. A row of air swirlers is mounted in the dome and includes corresponding main fuel injectors for producing corresponding fuel and air mixtures. Pilot fuel injectors fewer in number than the main injectors are mounted in the dome between corresponding ones of the swirlers. Staged fuel injection from the pilot and main injectors is used for starting the combustor during operation.

Owner:GENERAL ELECTRIC CO

Fuel injector

ActiveUS20120304649A1Increased complexityContinuous combustion chamberTurbine/propulsion fuel supply systemsCombustion chamberMain injector

A fuel injector includes: a pilot injector configured to spray fuel so as to form a first combustion region in a combustion chamber; and a main injector provided coaxially with the pilot injector so as to surround the pilot injector and configured to supply a fuel-air mixture that is a mixture of the fuel and air to form a second combustion region in the combustion chamber, wherein the main injector includes: a first inflow channel through which the air having a major flow component in an axial direction is taken; a second inflow channel through which the air having a major flow component in a radial direction is taken and which causes the air therein to meet the air from the first inflow channel; and a main fuel injecting portion configured to inject the fuel only to the second inflow channel.

Owner:KAWASAKI HEAVY IND LTD +1

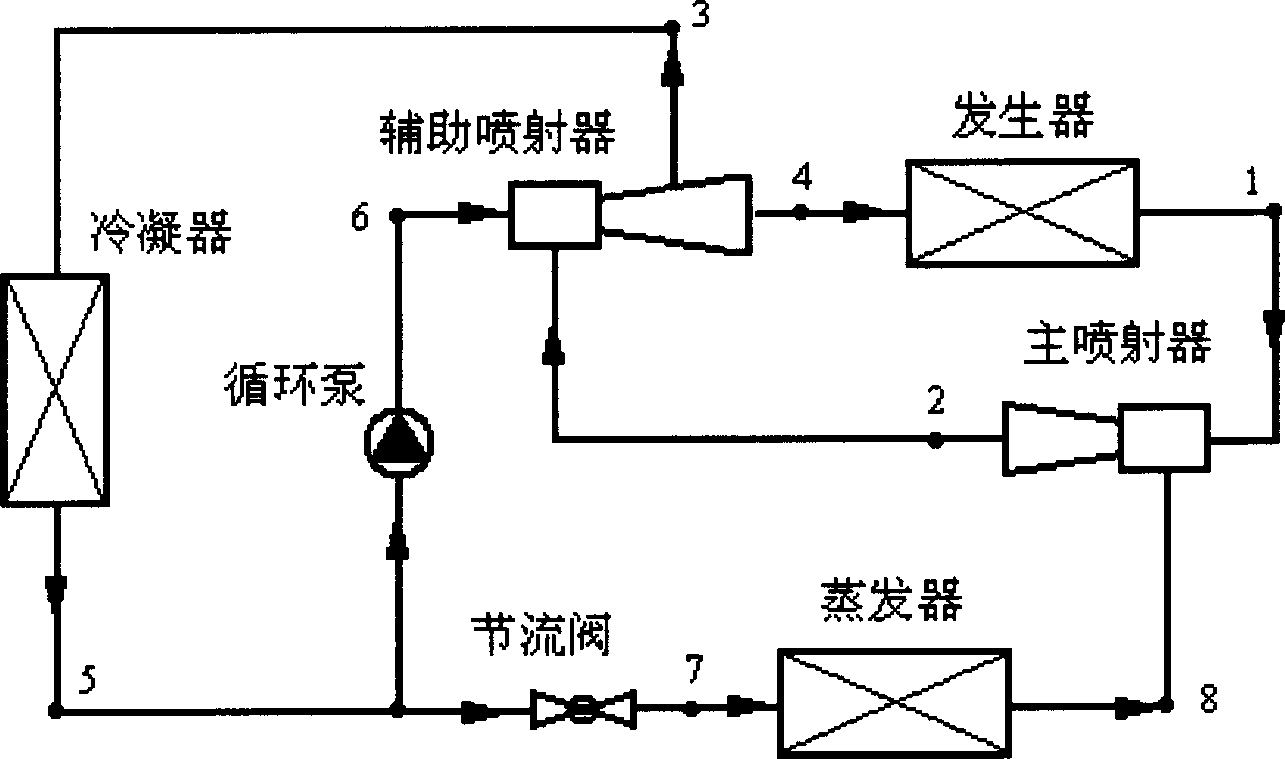

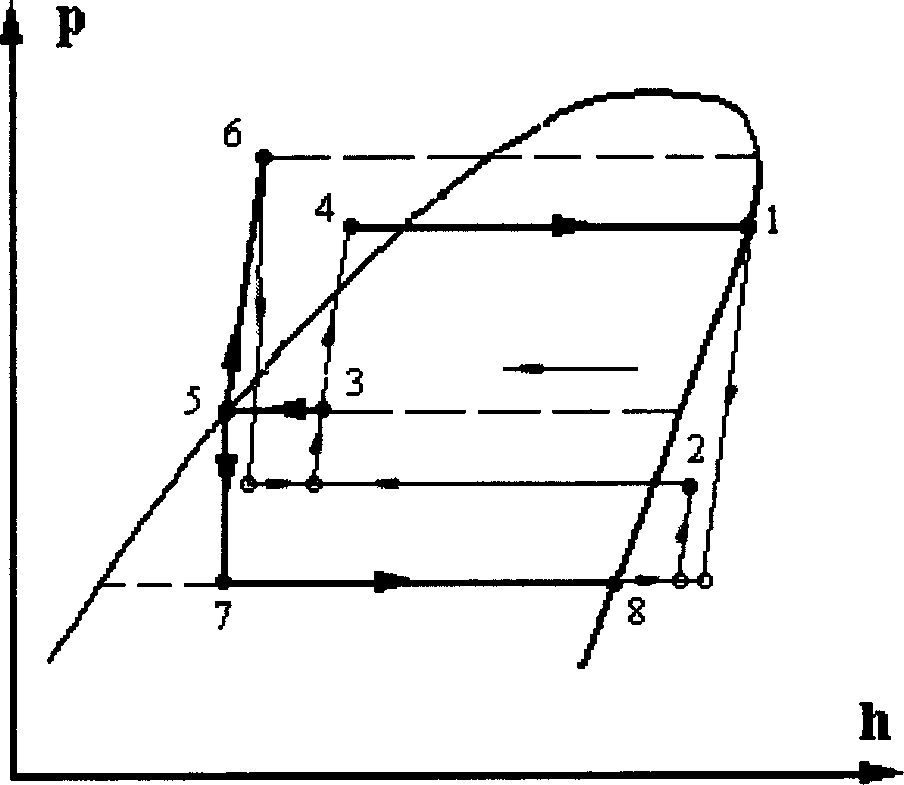

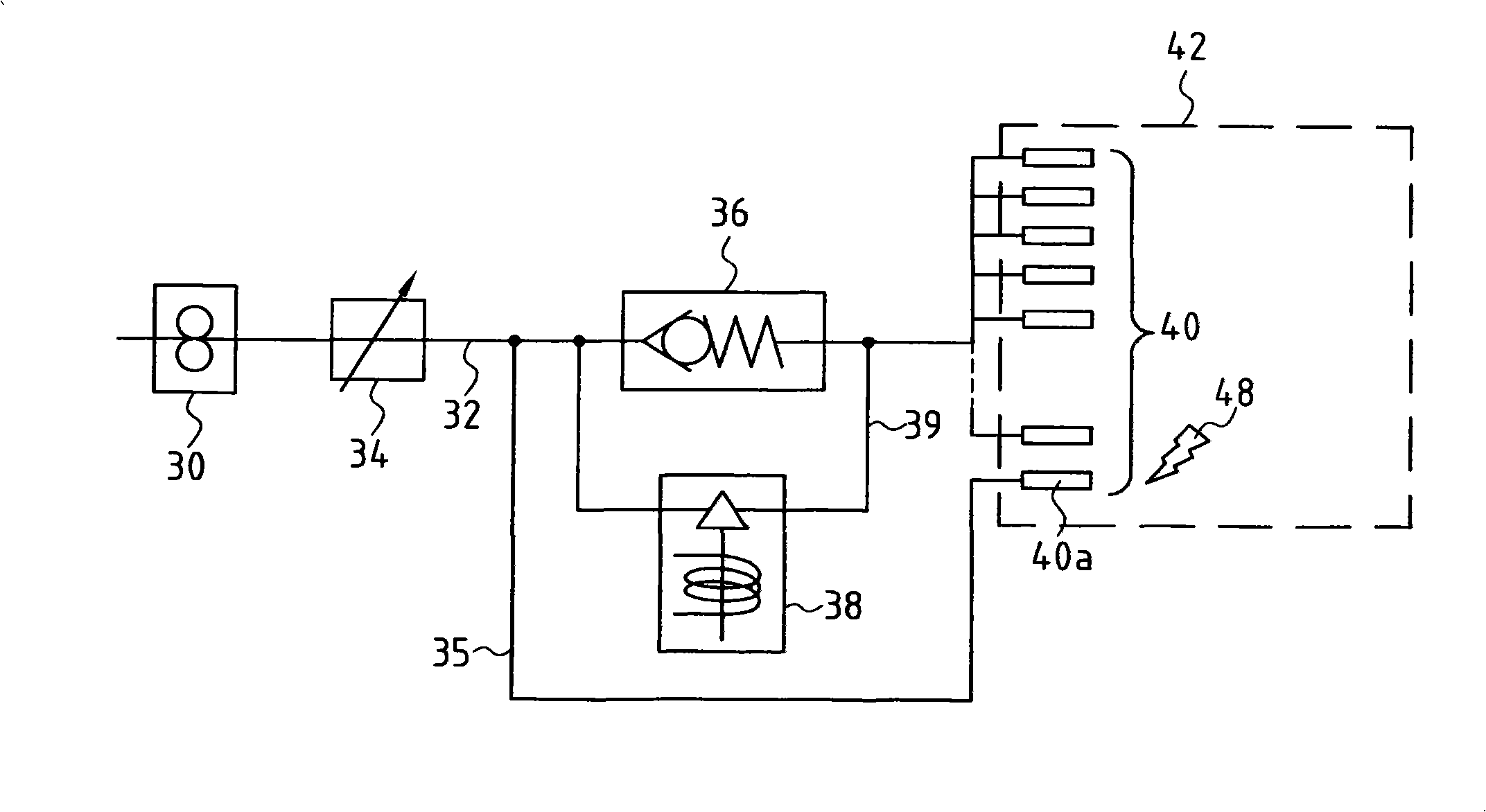

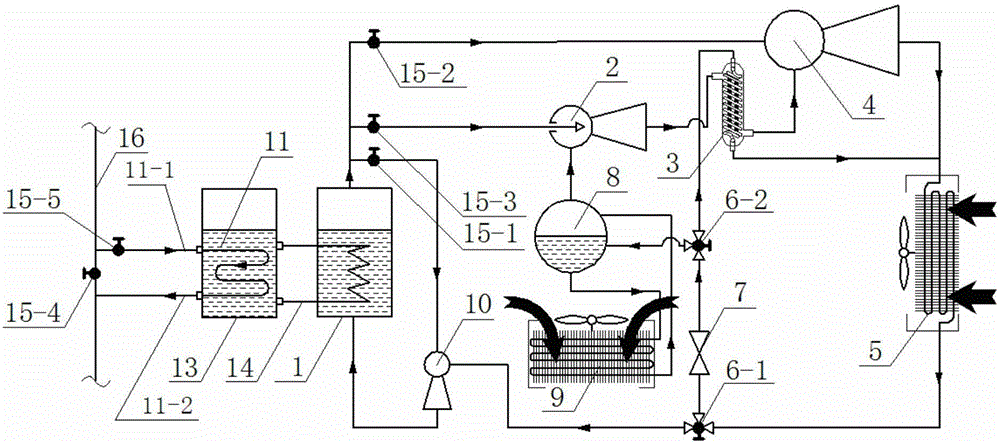

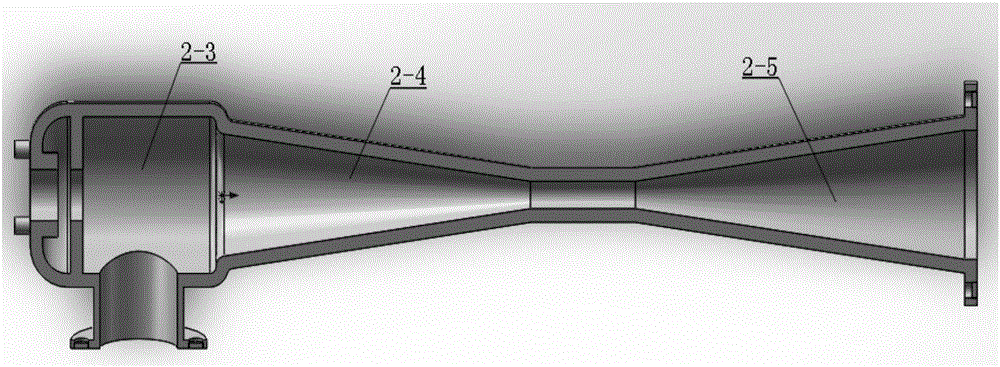

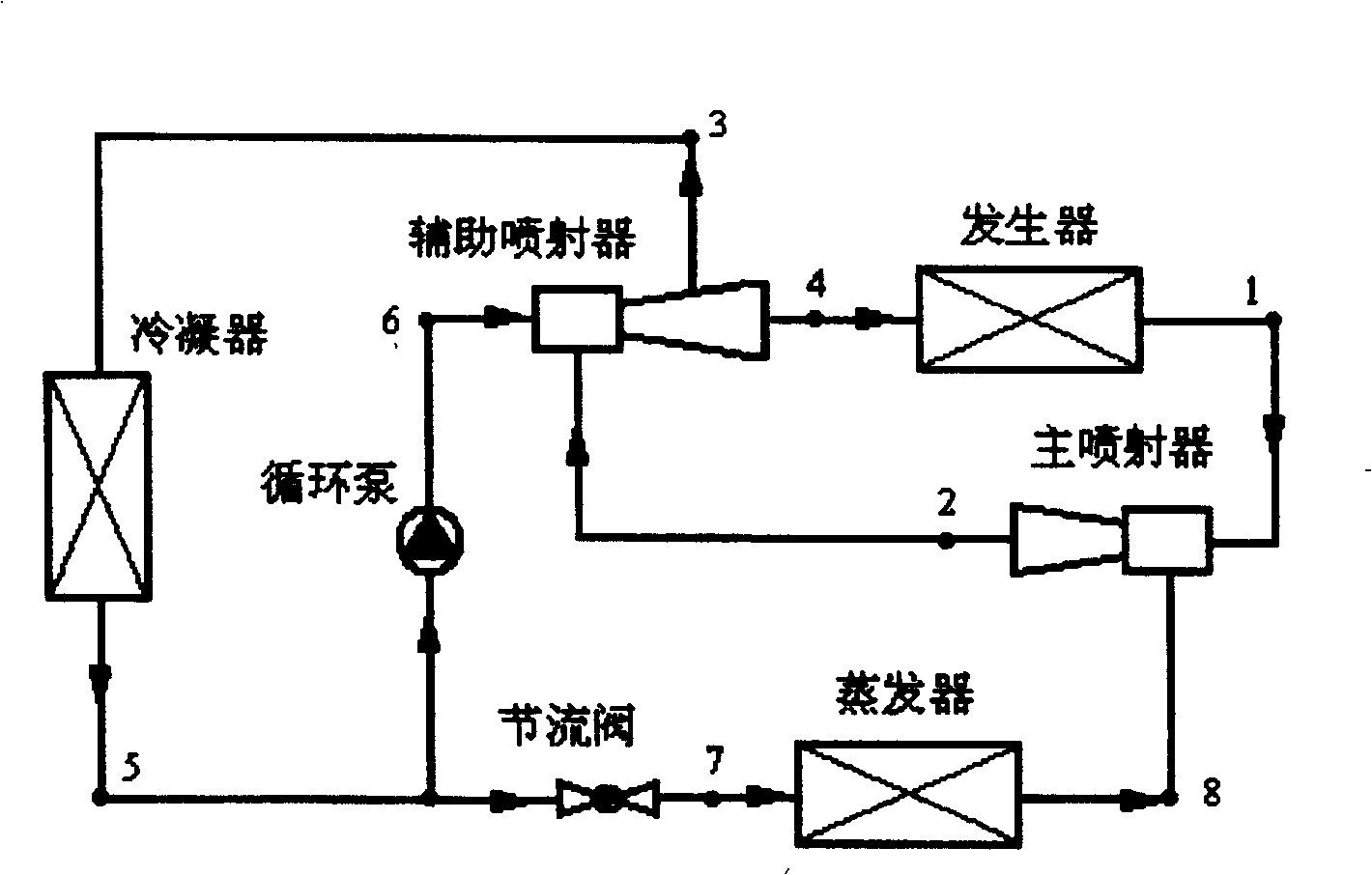

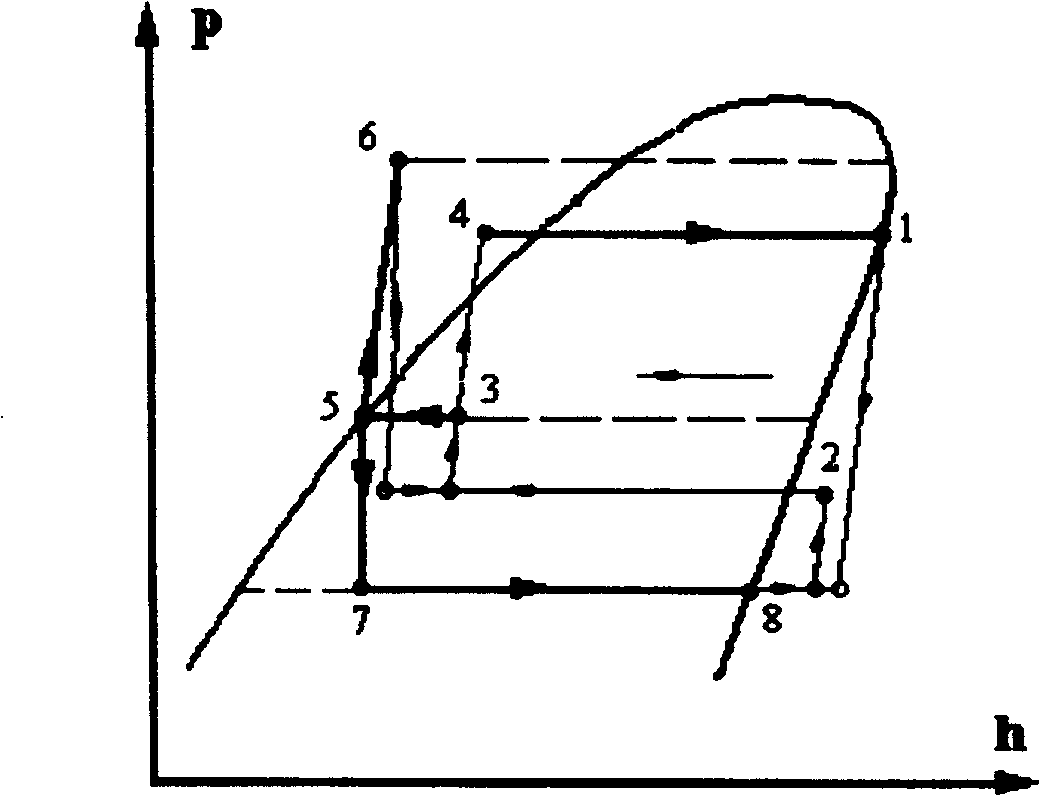

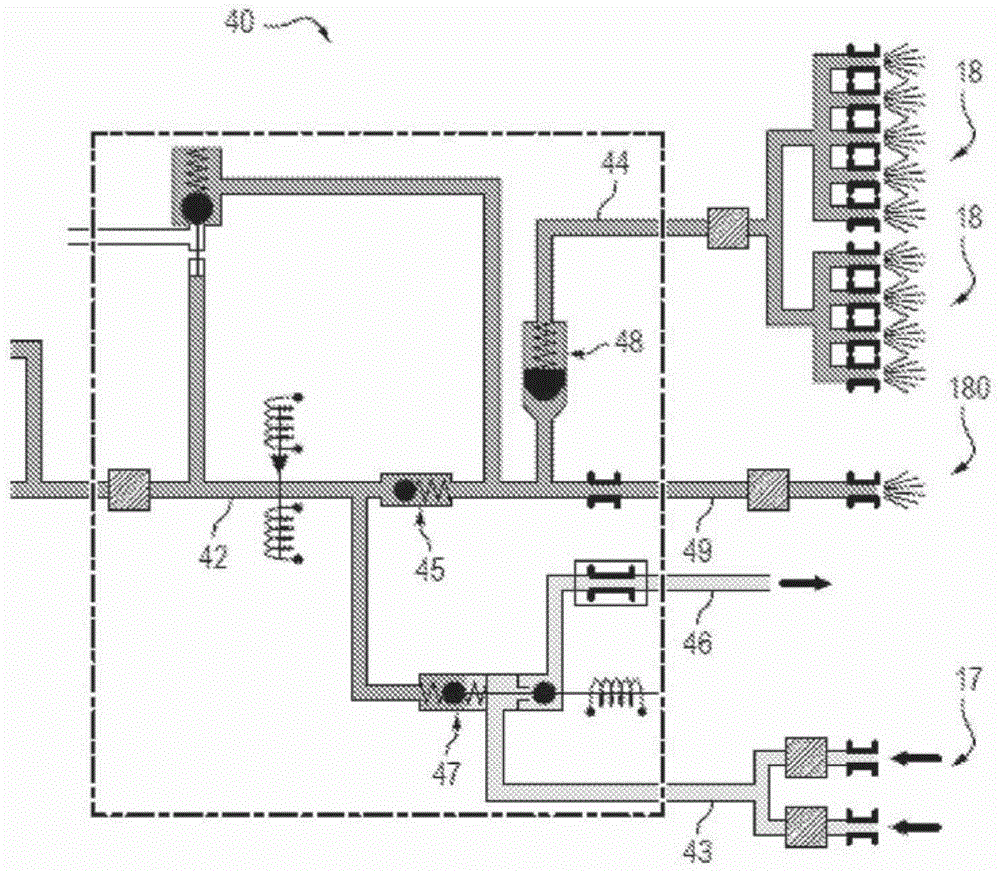

Steam jetting refrigerating circulation system

A steam jet refrigeration cycle system comprises a producer, an evaporator, a condenser, a circulation pump, a throttle valve and main and secondary injectors. The producer is used for producing the high-pressure refrigerant working steam. The main injector is used for jetting the low-pressure refrigerant steam coming from the evaporator and the secondary injector is used for jetting the low-pressure refrigerant steam coming from the main injector. The circulating pump outputs the high-pressure refrigerant liquid. The refrigerant liquid coming from one outlet of a diffuser returns to the producer and the refrigerant gas-liquid mixture coming from the other outlet enters to the condenser to condense. The produced refrigerant liquid is divided into two ways, one way is sent to the secondary injector by the circulating pump and the other enters to the evaporator through the throttle valve. The refrigeration is realized by evaporative heat-absorbing of the refrigerant in the evaporator.

Owner:XI AN JIAOTONG UNIV

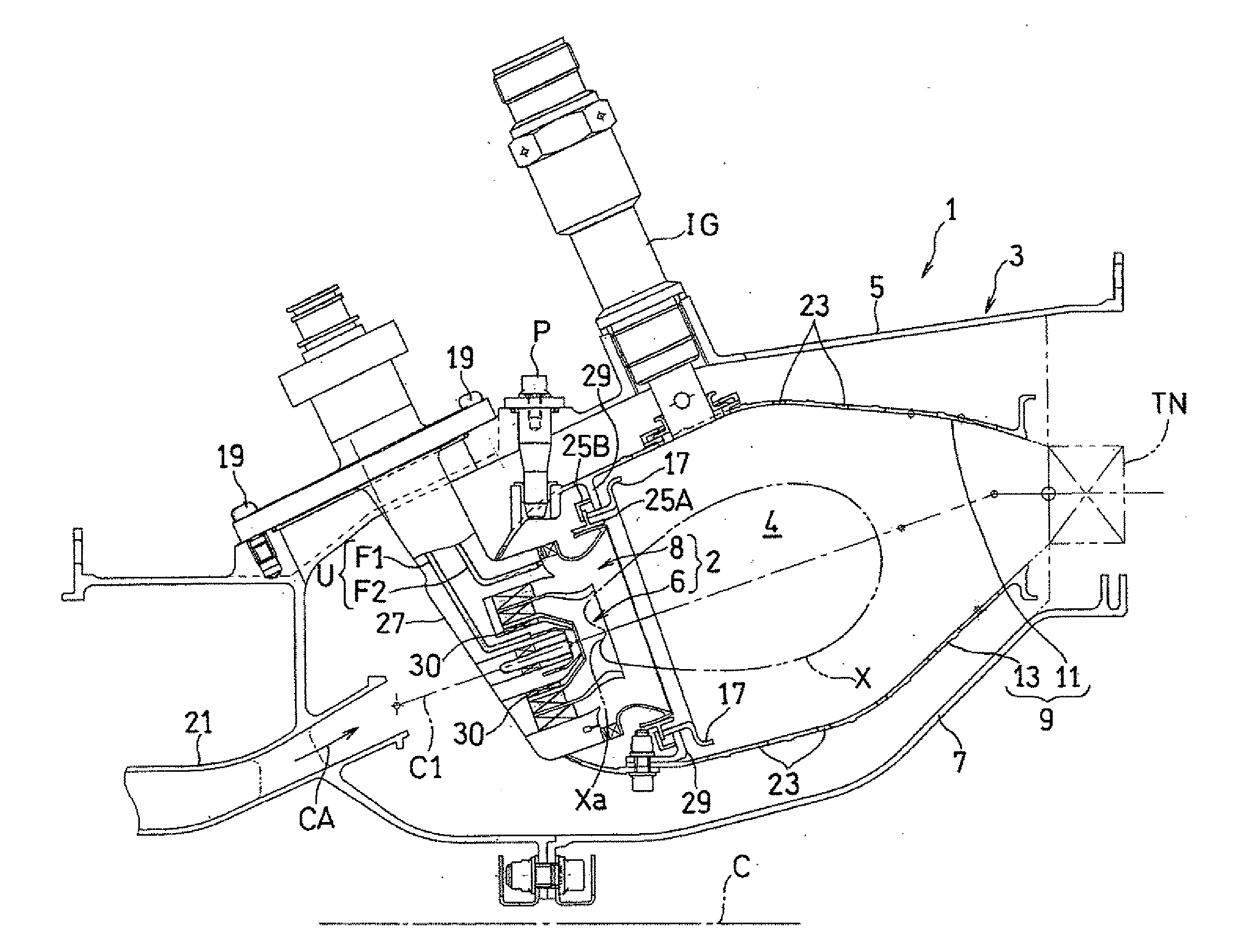

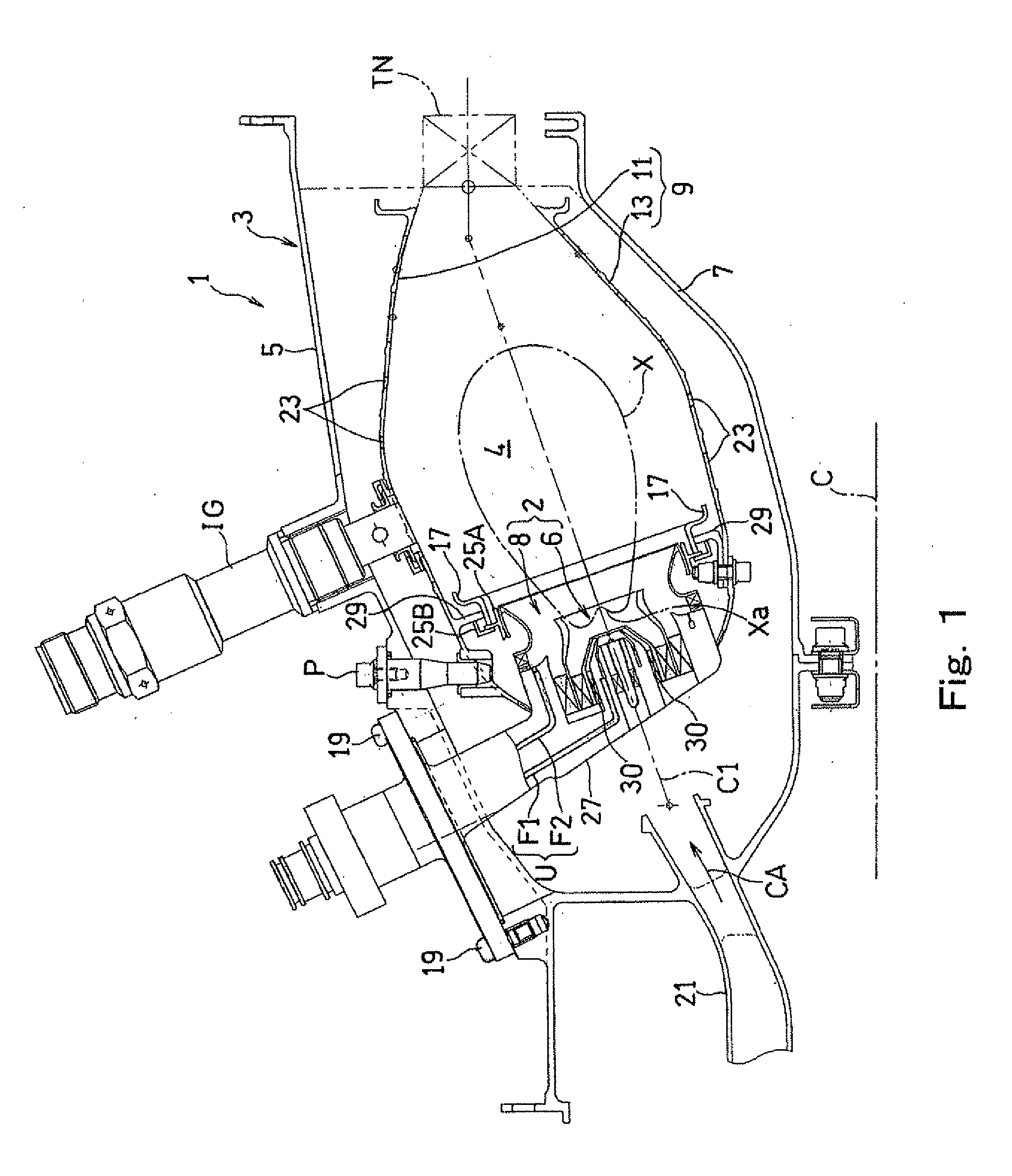

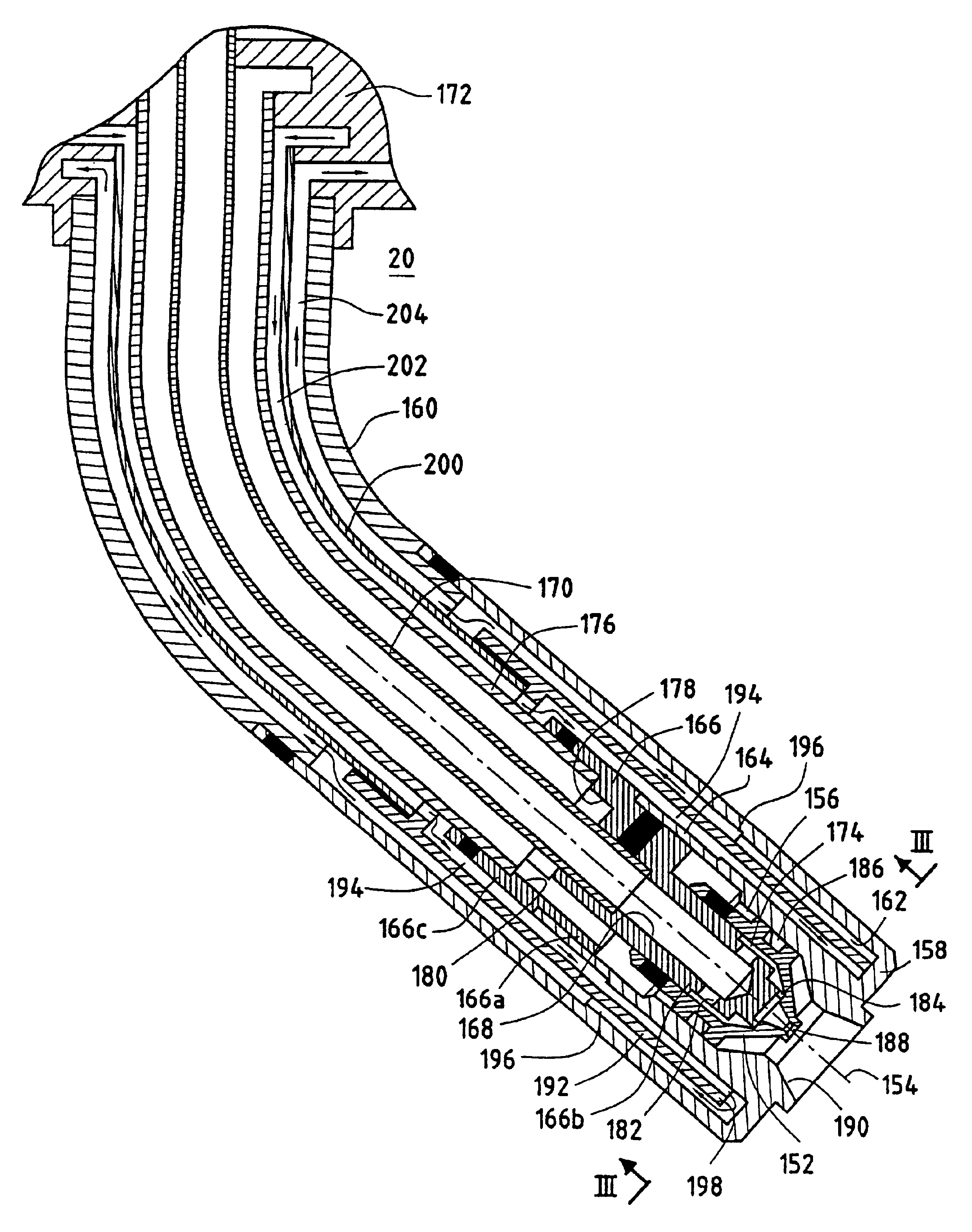

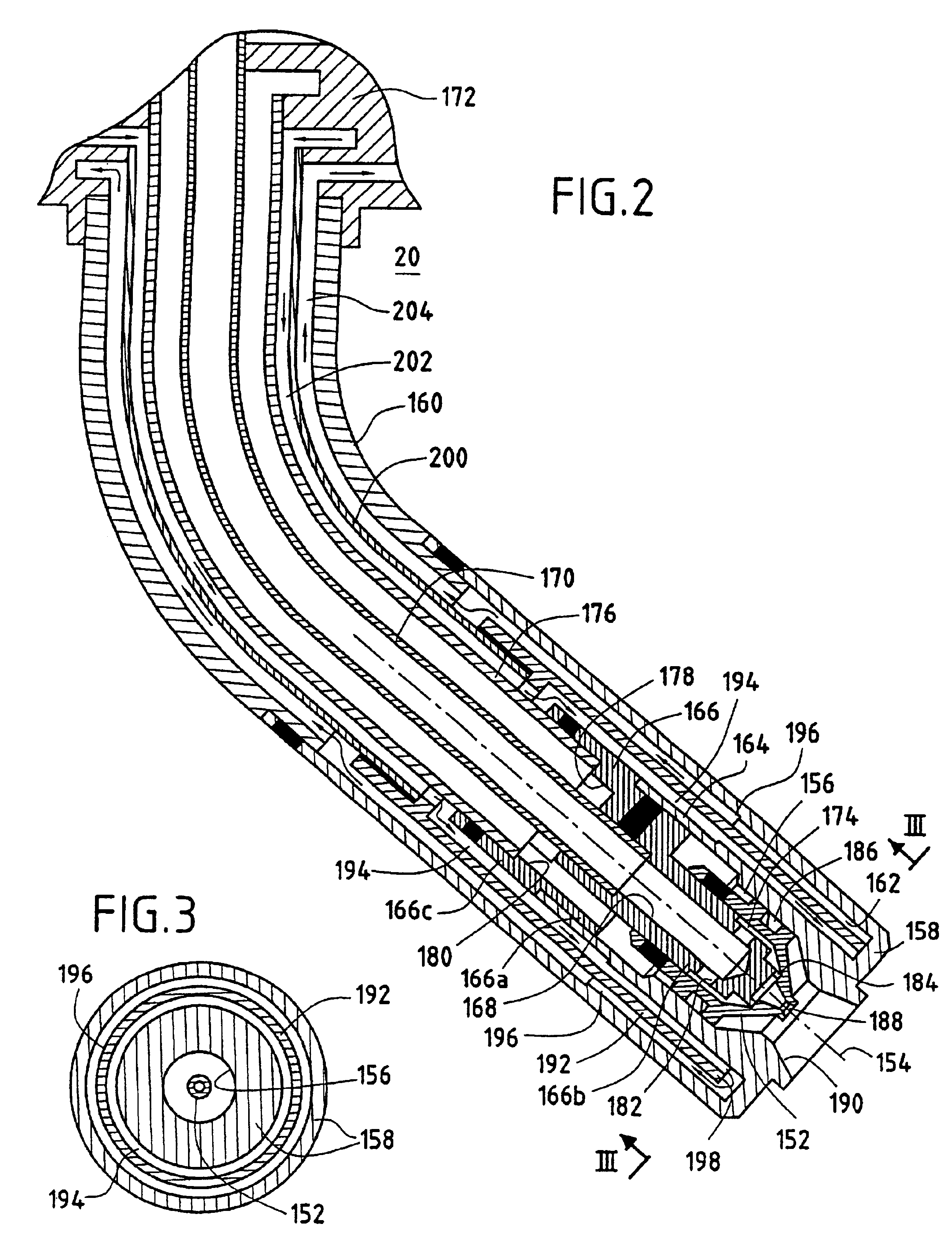

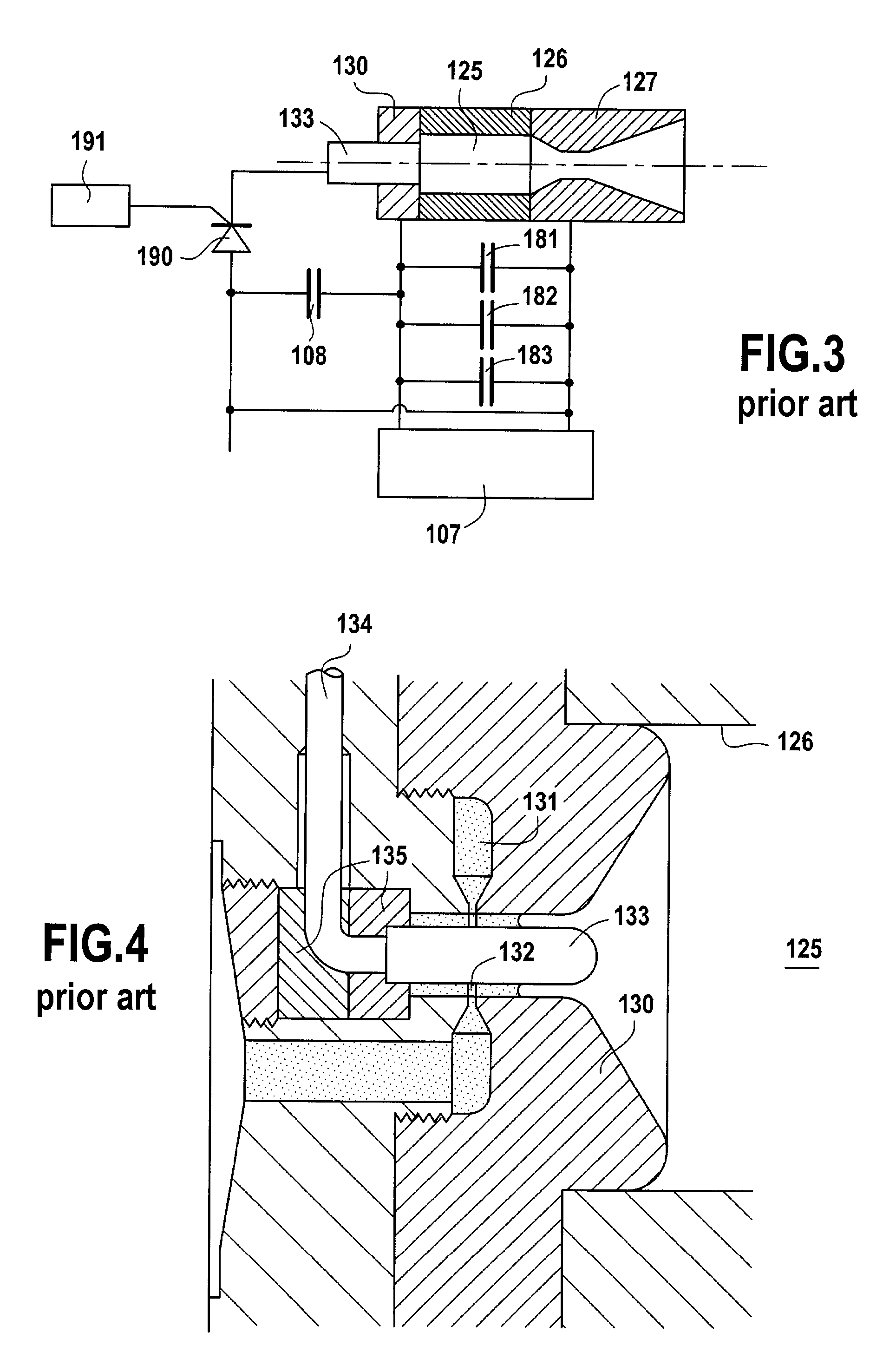

Full cooling of main injectors in a two-headed combustion chamber

InactiveUS6775984B2Without significantly altering the size of the injectorsPrevents maximum effectivenessBurnersContinuous combustion chamberCombustion chamberEngineering

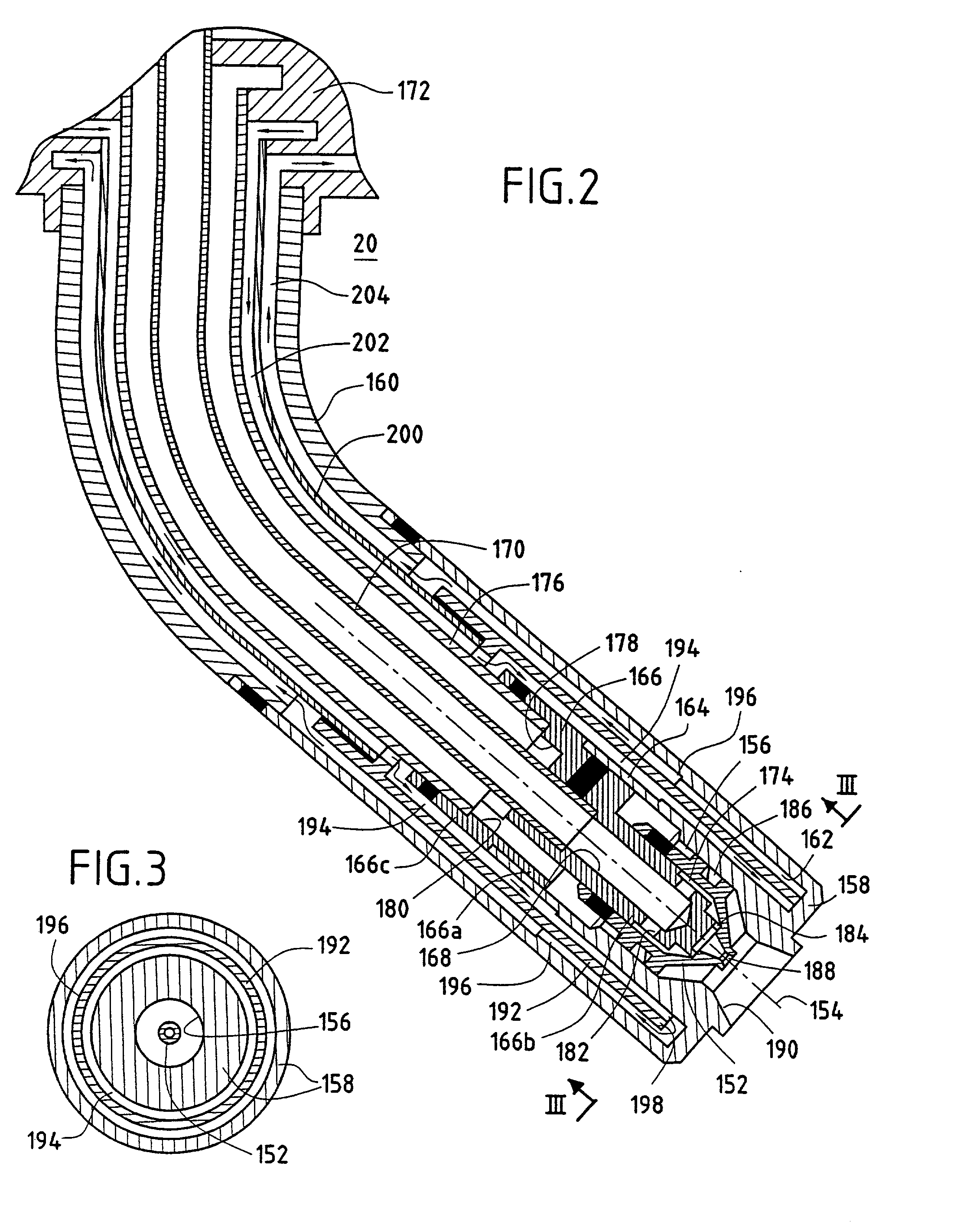

An injector of a two-headed combustion chamber of a turbomachine has a first feed tube which is connected to an annular injection piece for discharging primary fuel into the combustion chamber. It also has a second feed tube surrounding the first feed tube and connected to a cylindrical endpiece for discharging secondary fuel into said combustion chamber. This endpiece has an annular channel of diameter that is greater than the diameter of the second feed tube and that extends over its entire length. A third tube is provided that surrounds the second tube and that is connected to a tubular separation element which is inserted in the annular channel of the cylindrical endpiece so as to form two annular spaces in which a cooling fluid can flow over 360° all the way to the end of the injector.

Owner:HISPANO SUIZA SA

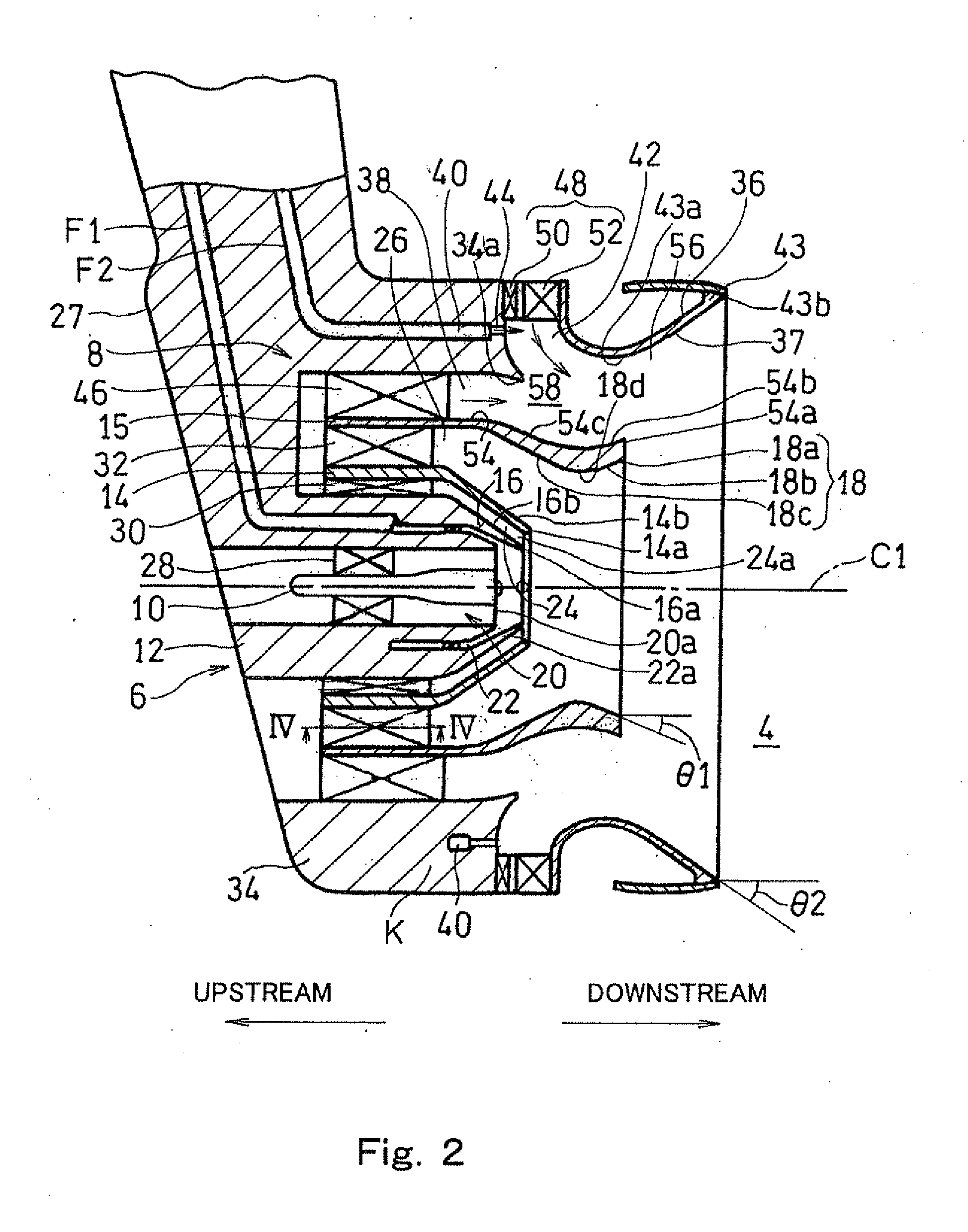

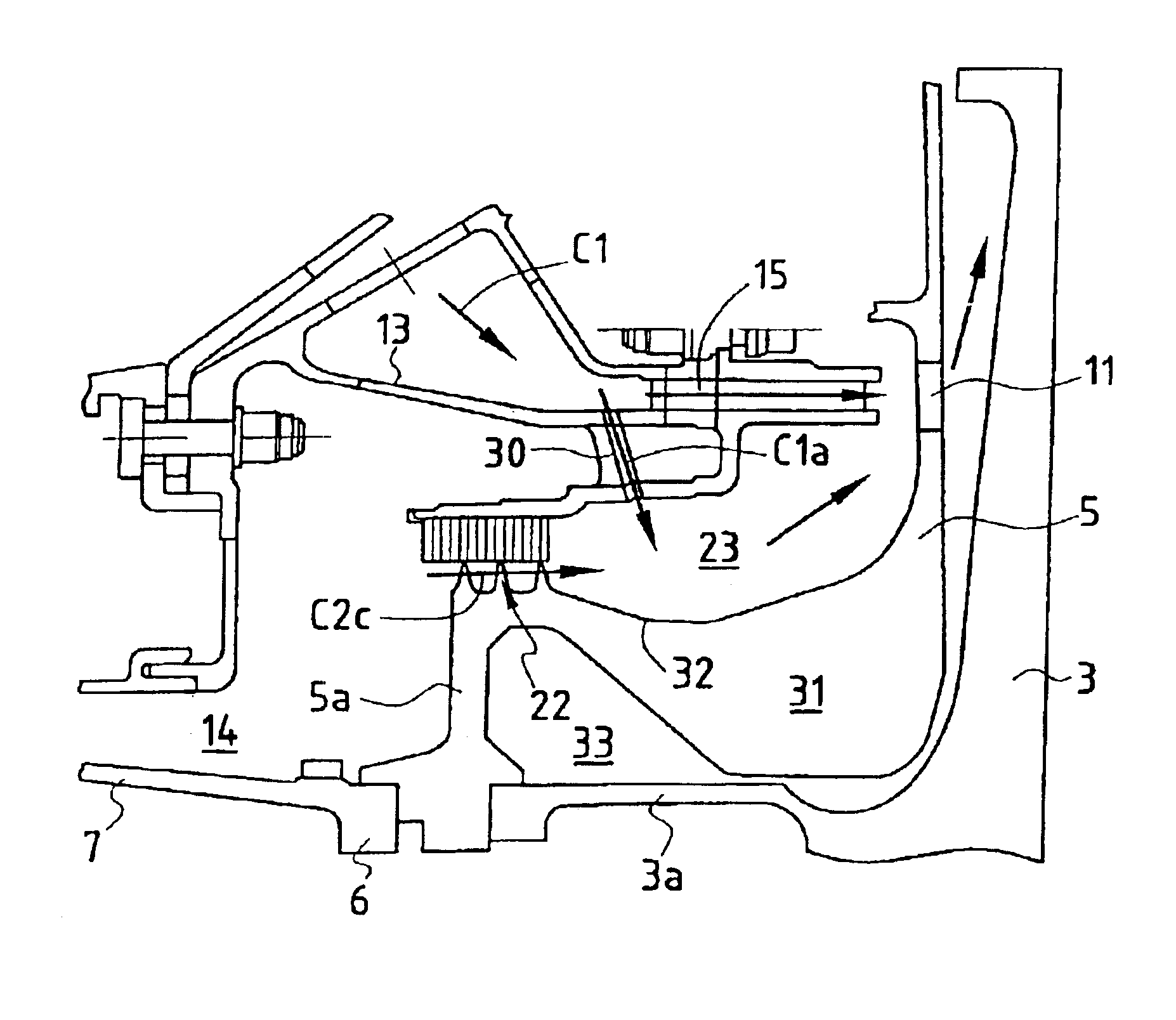

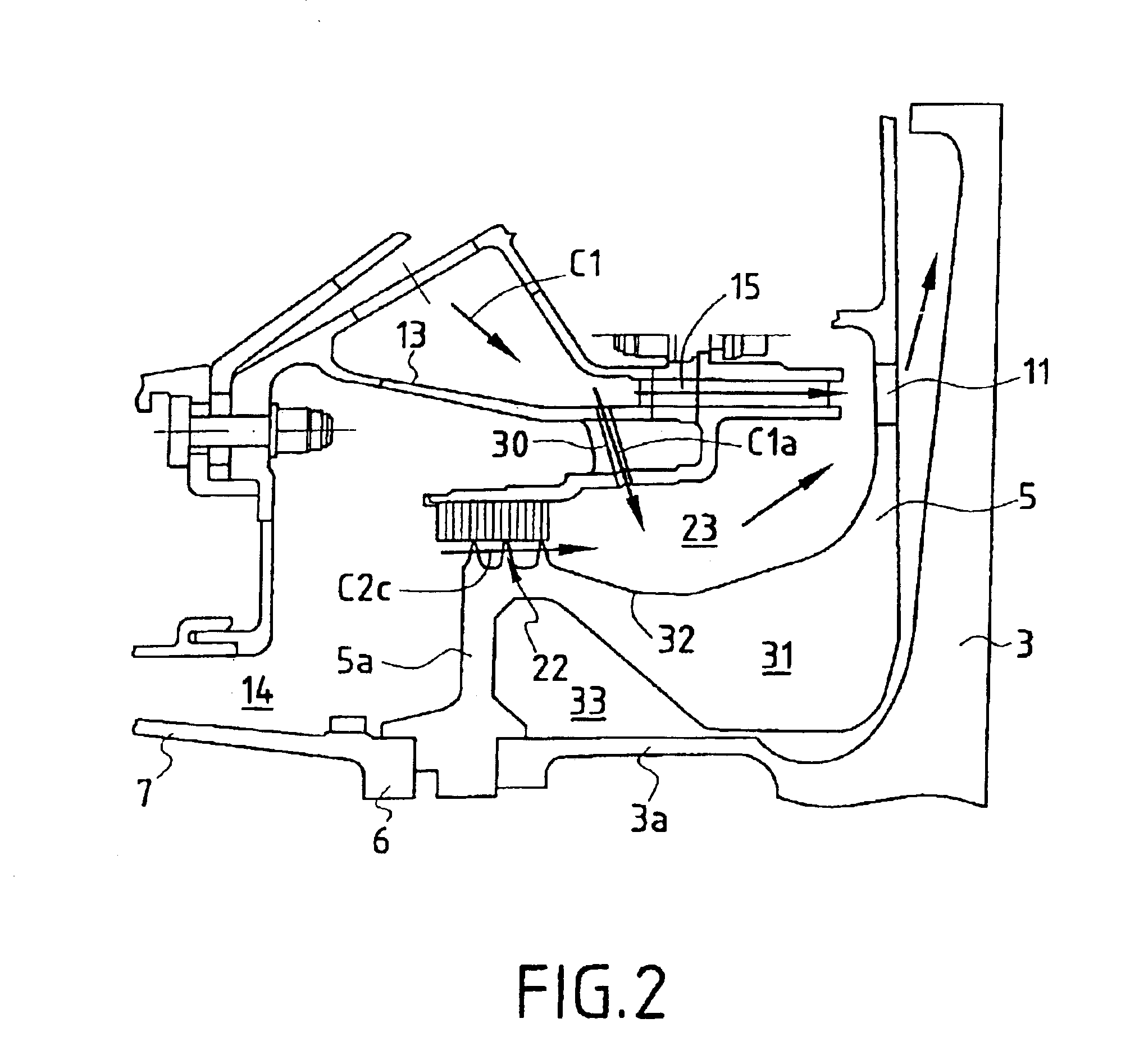

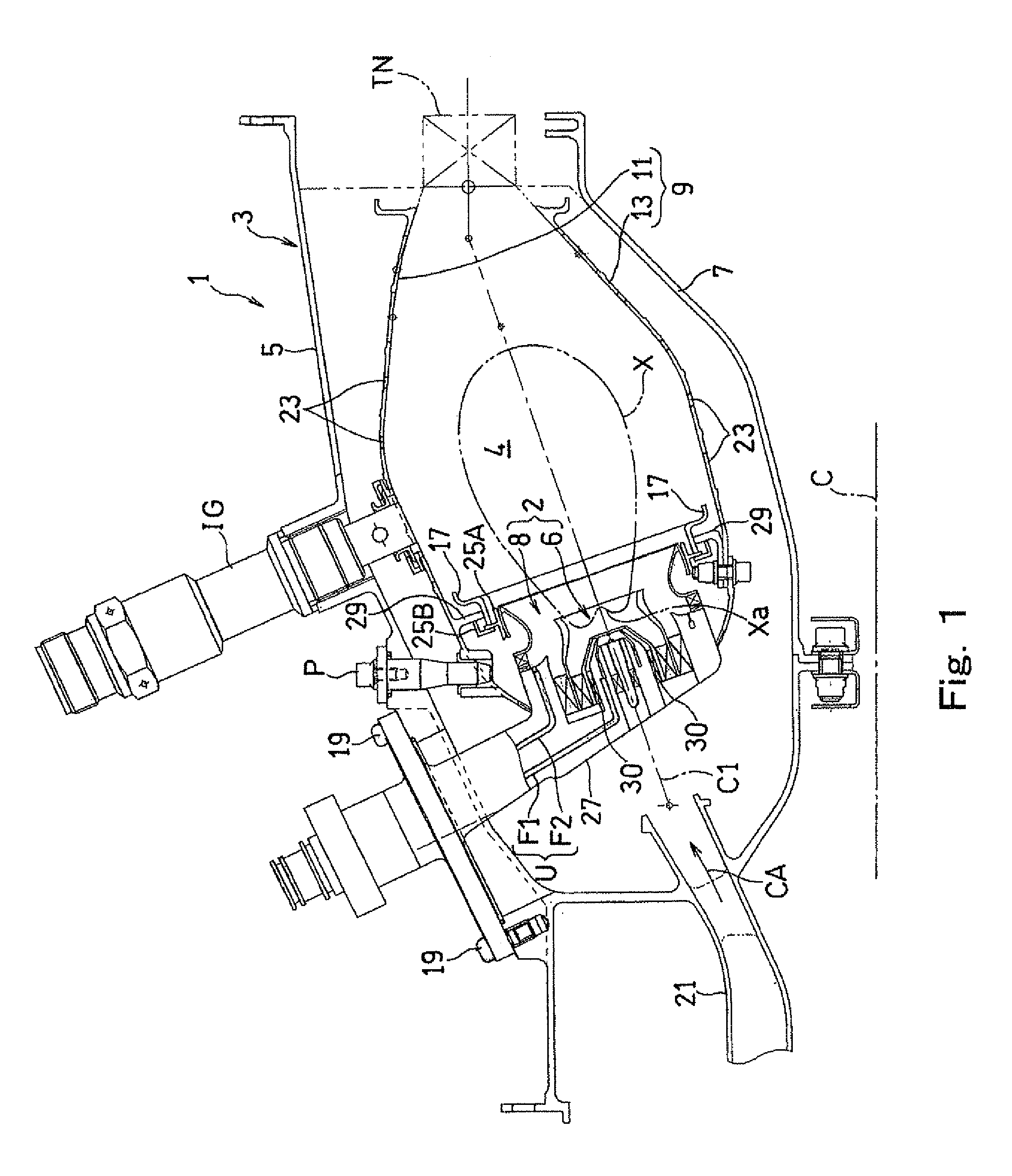

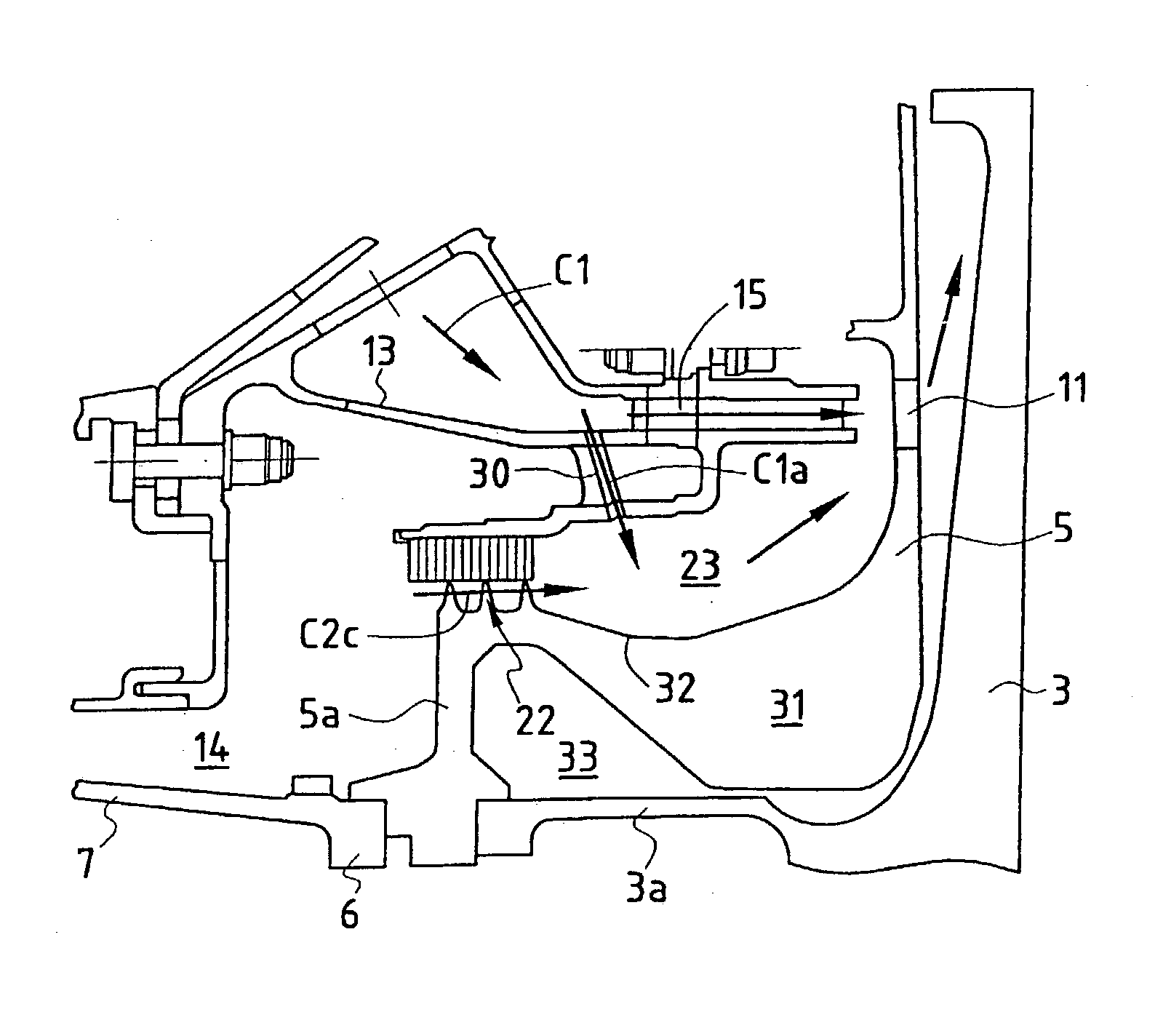

Cooling the upstream end plate of a high pressure turbine by means of a system of dual injectors at the end of the combustion chamber

InactiveUS6787947B2Small sizeExtended service lifePropellersPump componentsCombustion chamberEngineering

The invention relates to a device for ventilating a high pressure turbine rotor which comprises a turbine disk and an upstream end plate. A first circuit for cooling blades delivers a first air flow via main injectors and holes formed in the end plate. A second cooling circuit delivers a second air flow through a discharge baffle situated downstream from the compressor, a fraction of this second flow serving to cool the upstream top face of the end plate through a second baffle situated beneath the main injectors. A branch connection is provided between the first circuit and the enclosure situated downstream from the second baffle and it delivers a third flow which is set into pre-rotation by additional injector means formed in the form of inclined bores.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

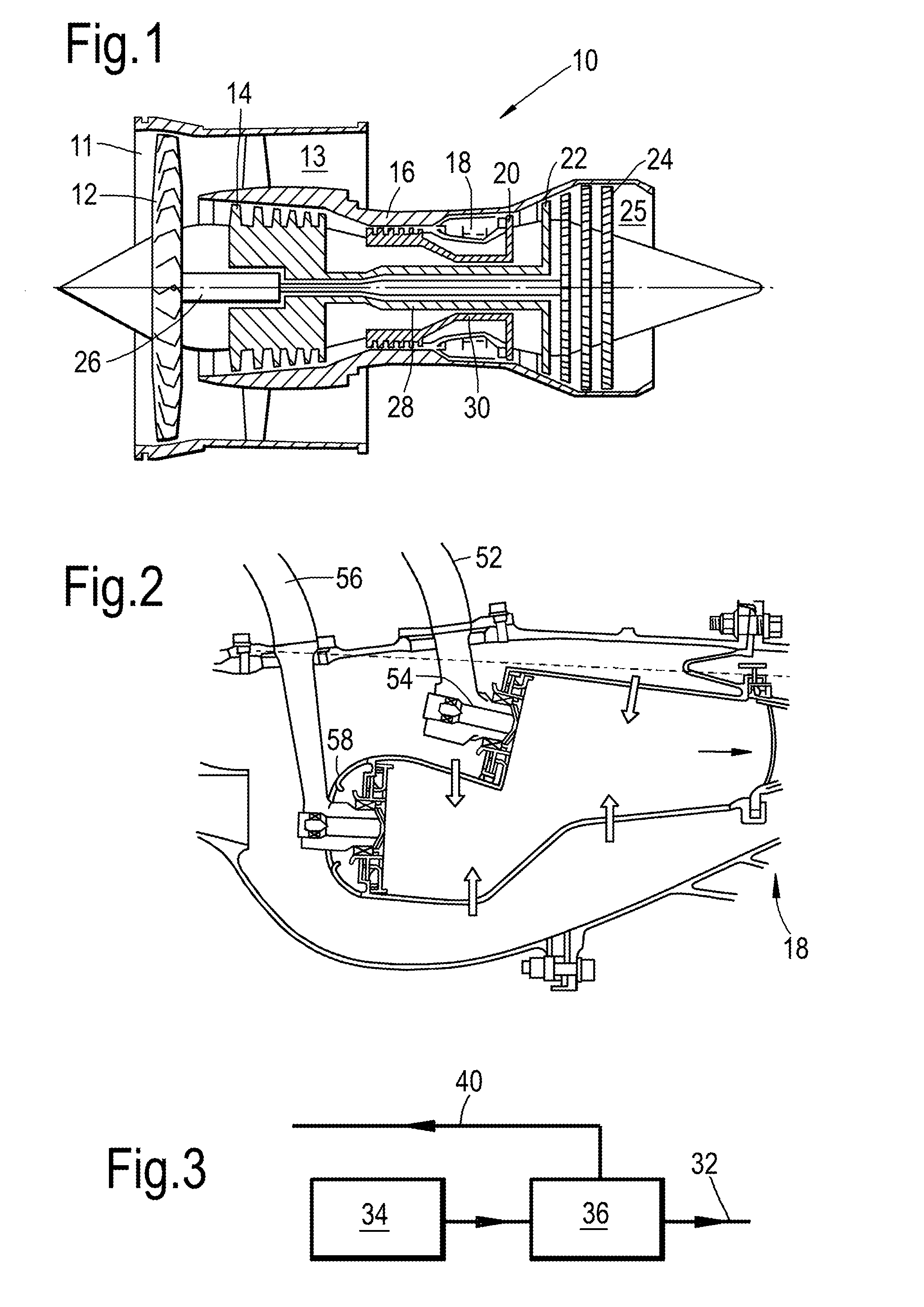

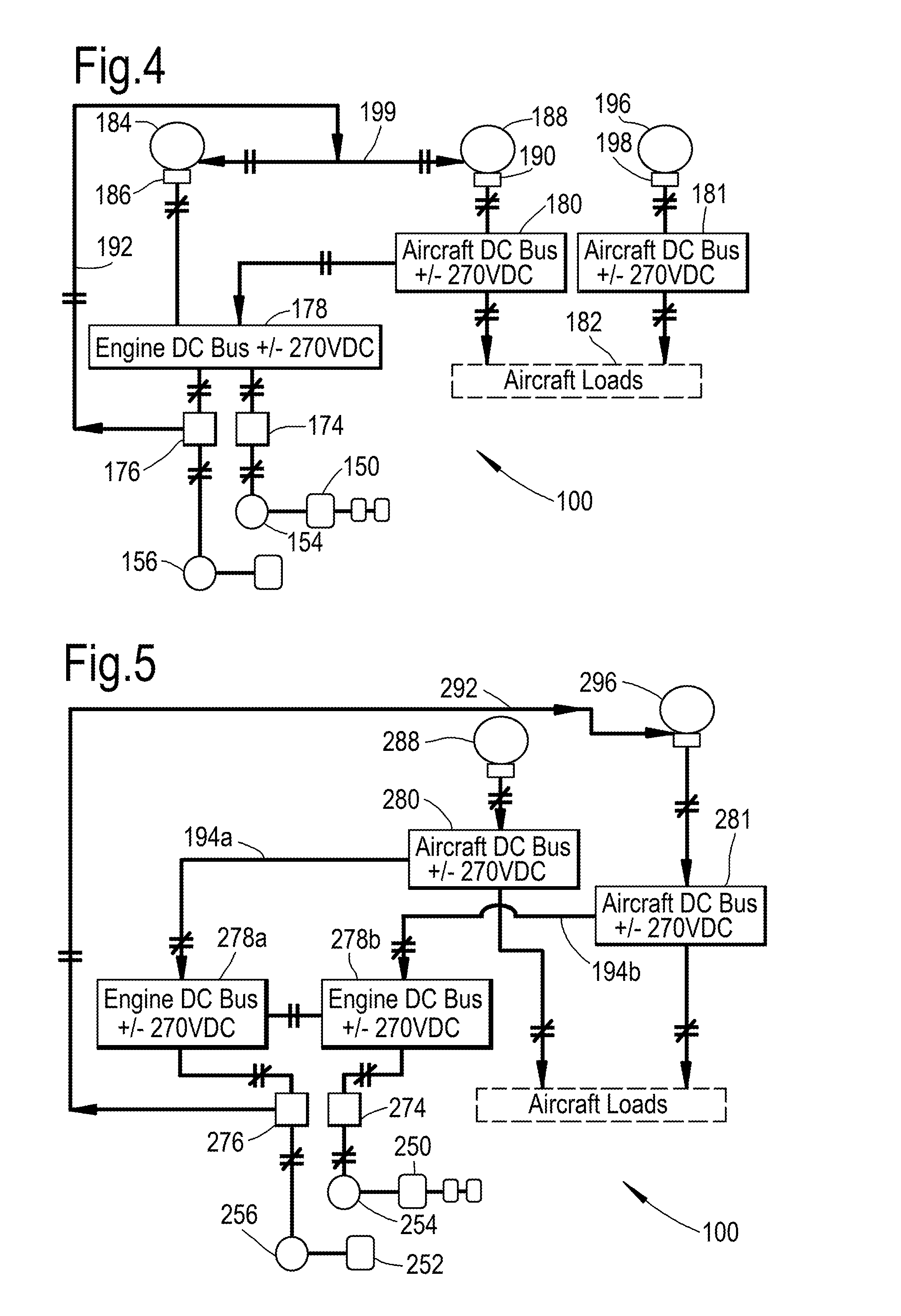

Gas turbine engine fuel system

InactiveUS20160109133A1Reduce wasteInherent redundancyContinuous combustion chamberTurbine/propulsion engine ignitionCombustorGas turbines

A fuel system for a gas turbine engine, the gas turbine engine including a combustor having a pilot fuel injector and a main fuel injector, the fuel system including first and second variable flow fuel pumps configured to provide metered fuel flow to the pilot injector, and the main injector respectively; first and second variable speed electric motors configured to drive respective first and second fuel pumps; wherein each of the electric motors includes a polyphase motor including a stator having concentrated windings.

Owner:ROLLS ROYCE PLC

Full cooling of main injectors in a two-headed combustion chamber

InactiveUS20020073707A1Prevents maximum effectivenessInhibition formationBurnersContinuous combustion chamberCombustion chamberCooling fluid

An injector of a two-headed combustion chamber of a turbomachine has a first feed tube which is connected to an annular injection piece for discharging primary fuel into the combustion chamber. It also has a second feed tube surrounding the first feed tube and connected to a cylindrical endpiece for discharging secondary fuel into said combustion chamber. This endpiece has an annular channel of diameter that is greater than the diameter of the second feed tube and that extends over its entire length. A third tube is provided that surrounds the second tube and that is connected to a tubular separation element which is inserted in the annular channel of the cylindrical endpiece so as to form two annular spaces in which a cooling fluid can flow over 360° all the way to the end of the injector.

Owner:HISPANO SUIZA SA

Method of starting a gas turbine helicopter engine, a fuel feed circuit for such an engine, and an engine having such a circuit

InactiveCN101255821AGood fuel injectionIncrease pressureContinuous combustion chamberTurbine/propulsion fuel supply systemsEngineeringTurbine

The present invention provides a method of starting a gas turbine helicopter engine. At least one of the main injectors of the engine, forming a starter main injector, is fed directly by the pressurized feed pipe, while a head loss is imposed between the pressurized feed pipe and the other main injectors. Ignition is caused to take place at the starter main injector, and after ignition, said head loss imposed between the feed pipe and the other main injectors is eliminated so that all of the main injectors are fed with fuel at substantially the same pressure, without any imposed head loss. The present invention also provides a fuel supply circuit for such an engine, and engine having such a circuit.

Owner:TURBOMECA SA

Fuel injector with radial and axial air inflow

ActiveUS9429324B2Increased complexityContinuous combustion chamberEfficient propulsion technologiesCombustion chamberMain injector

A fuel injector includes: a pilot injector configured to spray fuel so as to form a first combustion region in a combustion chamber; and a main injector provided coaxially with the pilot injector so as to surround the pilot injector and configured to supply a fuel-air mixture that is a mixture of the fuel and air to form a second combustion region in the combustion chamber, wherein the main injector includes: a first inflow channel through which the air having a major flow component in an axial direction is taken; a second inflow channel through which the air having a major flow component in a radial direction is taken and which causes the air therein to meet the air from the first inflow channel; and a main fuel injecting portion configured to inject the fuel only to the second inflow channel.

Owner:KAWASAKI HEAVY IND LTD +1

Cooling the upstream end plate of a high pressure turbine by means of a system of dual injectors at the end of the combustion chamber

InactiveUS20030223893A1Small sizeExtended service lifePropellersPump componentsCombustion chamberHigh pressure

The invention relates to a device for ventilating a high pressure turbine rotor which comprises a turbine disk and an upstream end plate. A first circuit for cooling blades delivers a first air flow via main injectors and holes formed in the end plate. A second cooling circuit delivers a second air flow through a discharge baffle situated downstream from the compressor, a fraction of this second flow serving to cool the upstream top face of the end plate through a second baffle situated beneath the main injectors. A branch connection is provided between the first circuit and the enclosure situated downstream from the second baffle and it delivers a third flow which is set into pre-rotation by additional injector means formed in the form of inclined bores.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

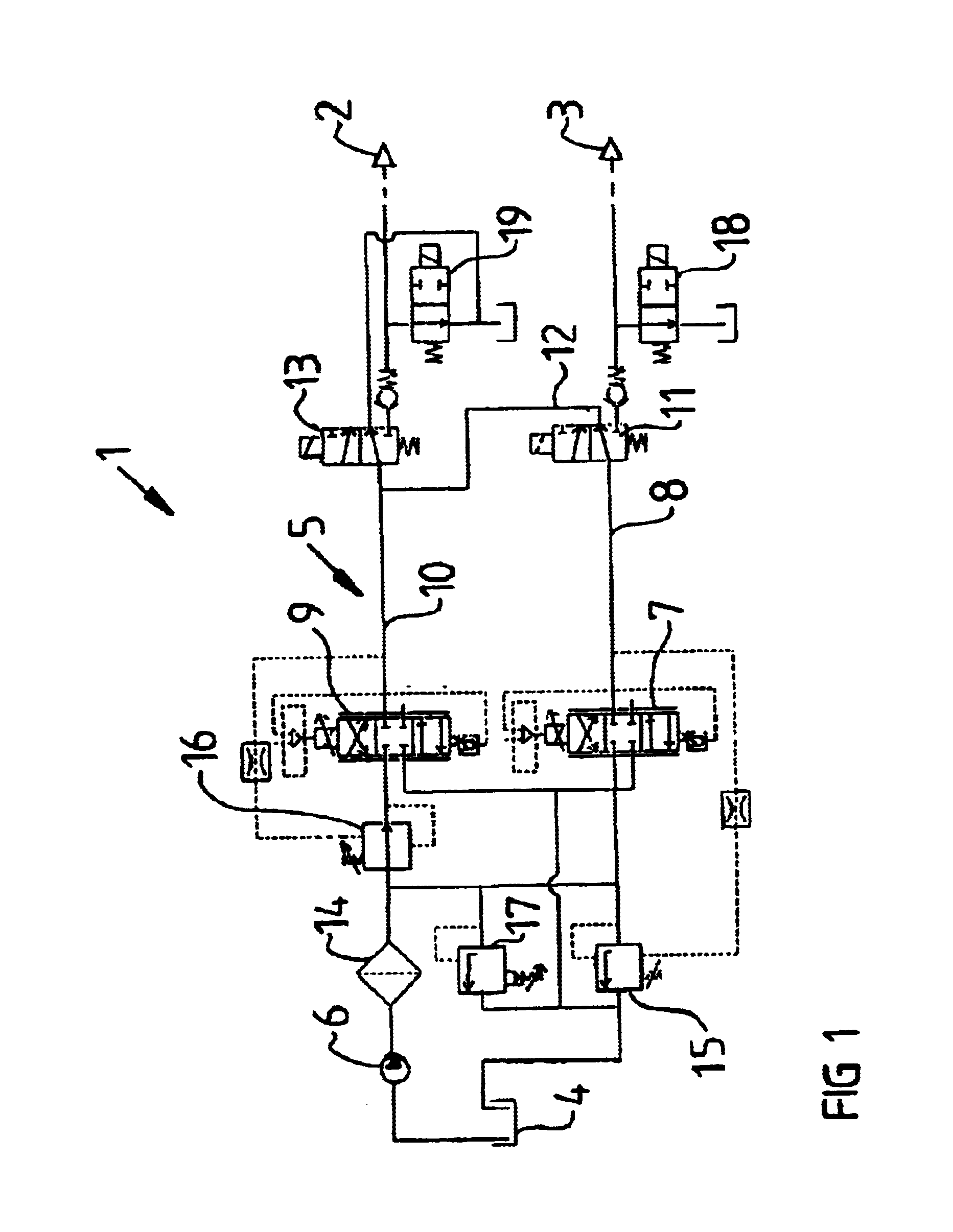

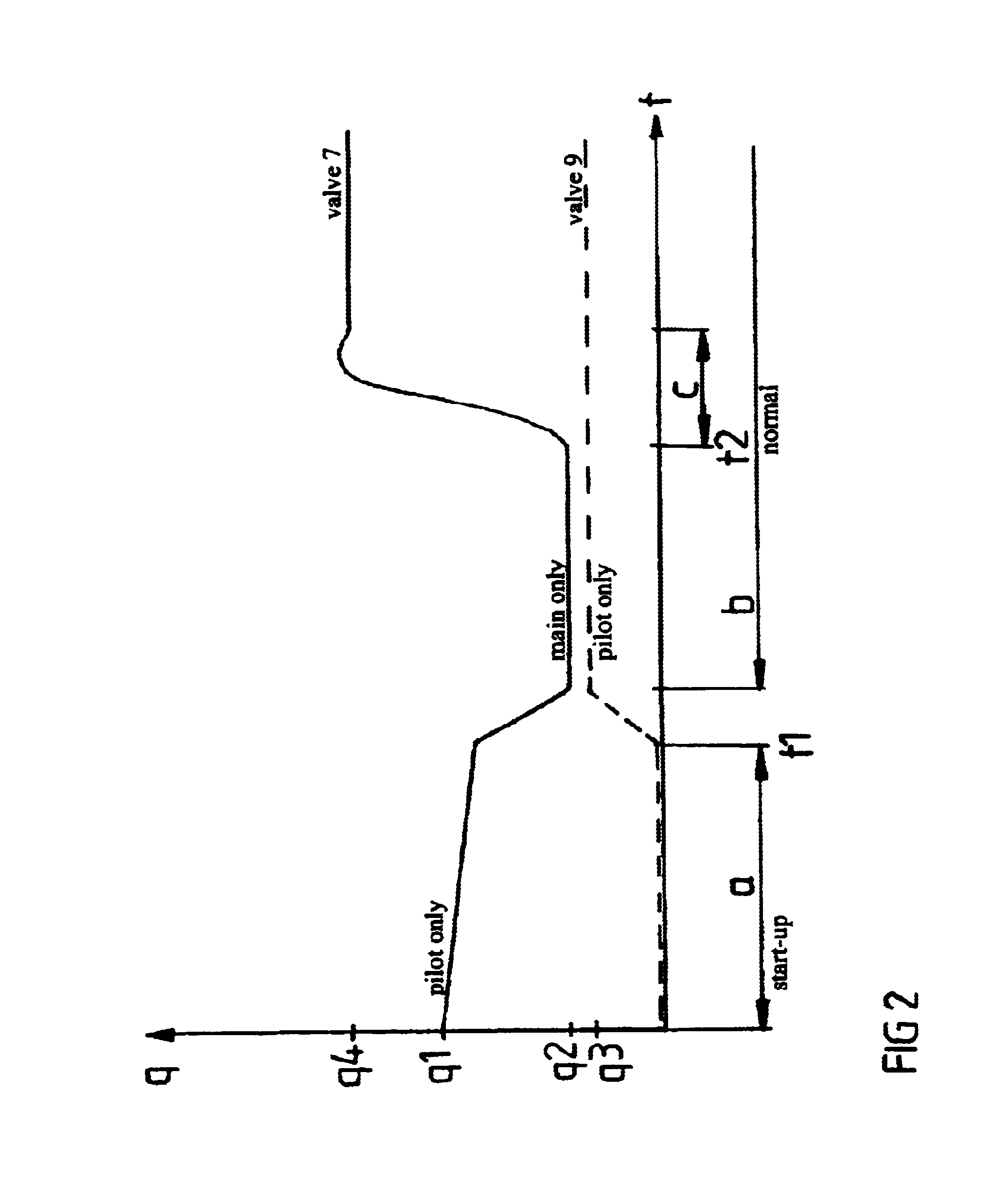

Method and a device for supplying fuel to a combustion chamber

InactiveUS6915640B2Emission reductionImprove securityBurnersFuel supply regulationCombustion chamberFuel tank

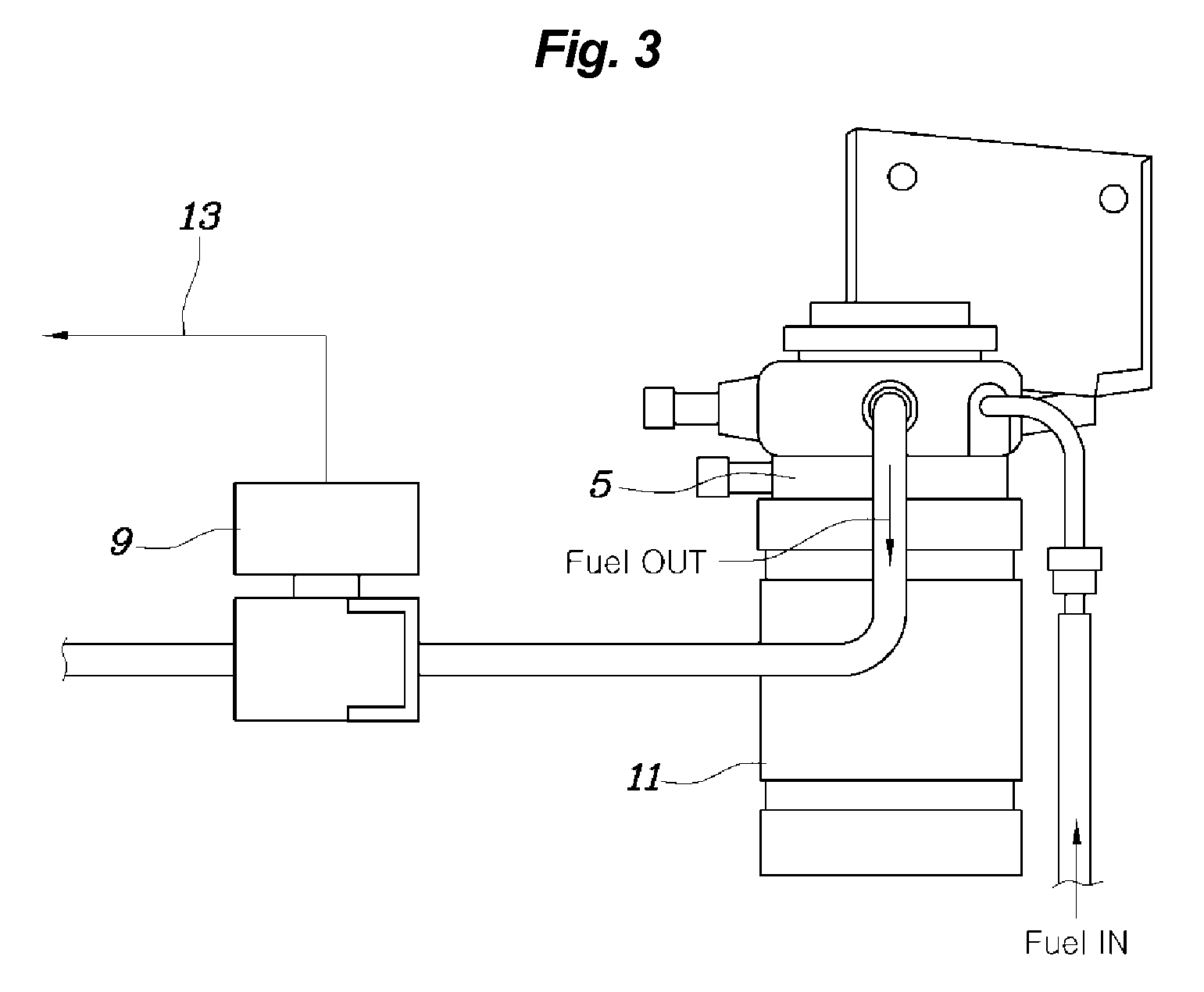

Method and device (1) for supplying fuel to a combustion chamber that includes at least one main injector (3) and at least one pilot injector (2). The device includes a fuel tank (4), a line system (5) coupled from the fuel tank to the injectors (2, 3), a pump (6) for pumping fuel from the tank to the injectors, and a first regulator valve (7) for regulating the flow of fuel in a first line (8) in the system which is connected to the pilot injector (2). The device further includes a second regulator valve (9) for regulating the flow of fuel through a second line (10) in the system, which is connected to the pilot injector (2). The second regulator valve (9) is designed to regulate a substantially smaller flow than the first regulator valve (7).

Owner:VOLVO AERO CORP

Tail gas waste heat driving injection refrigeration system for vehicle air conditioner

ActiveCN106196717AReduce exhaust temperatureHigh activityMechanical apparatusBoilers/analysersEngineeringVapor-compression refrigeration

The invention discloses a tail gas waste heat driving injection refrigeration system for a vehicle air conditioner for replacing a traditional steam compression refrigeration system for the vehicle air conditioner. The system consists of a tail gas heat exchanger, a generator, a main injector, an auxiliary injector, an evaporator, a condenser, a flash tank, an expansion valve, an electric three-way adjusting valve and an electromagnetic valve. The system has the following advantages: (1) the traditional steam compression refrigeration system for the vehicle air conditioner is replaced; and the performance reduction and the energy consumption rise of an engine caused by driving of a compressor are prevented; (2) the vehicle tail gas waste heat is reasonably used, and the exhaust temperature of tail gas is reduced, so that the activity of a catalyst in a catalytic converter is improved, and the environmental heat pollution and the harmful gas emission are reduced; (3) the system has no moving parts, needs no lubricating oil, is simple, and is reliable in work; and (4) the system uses water as a refrigerant, and totally has no harm to human bodies and environments.

Owner:GUANGXI UNIV

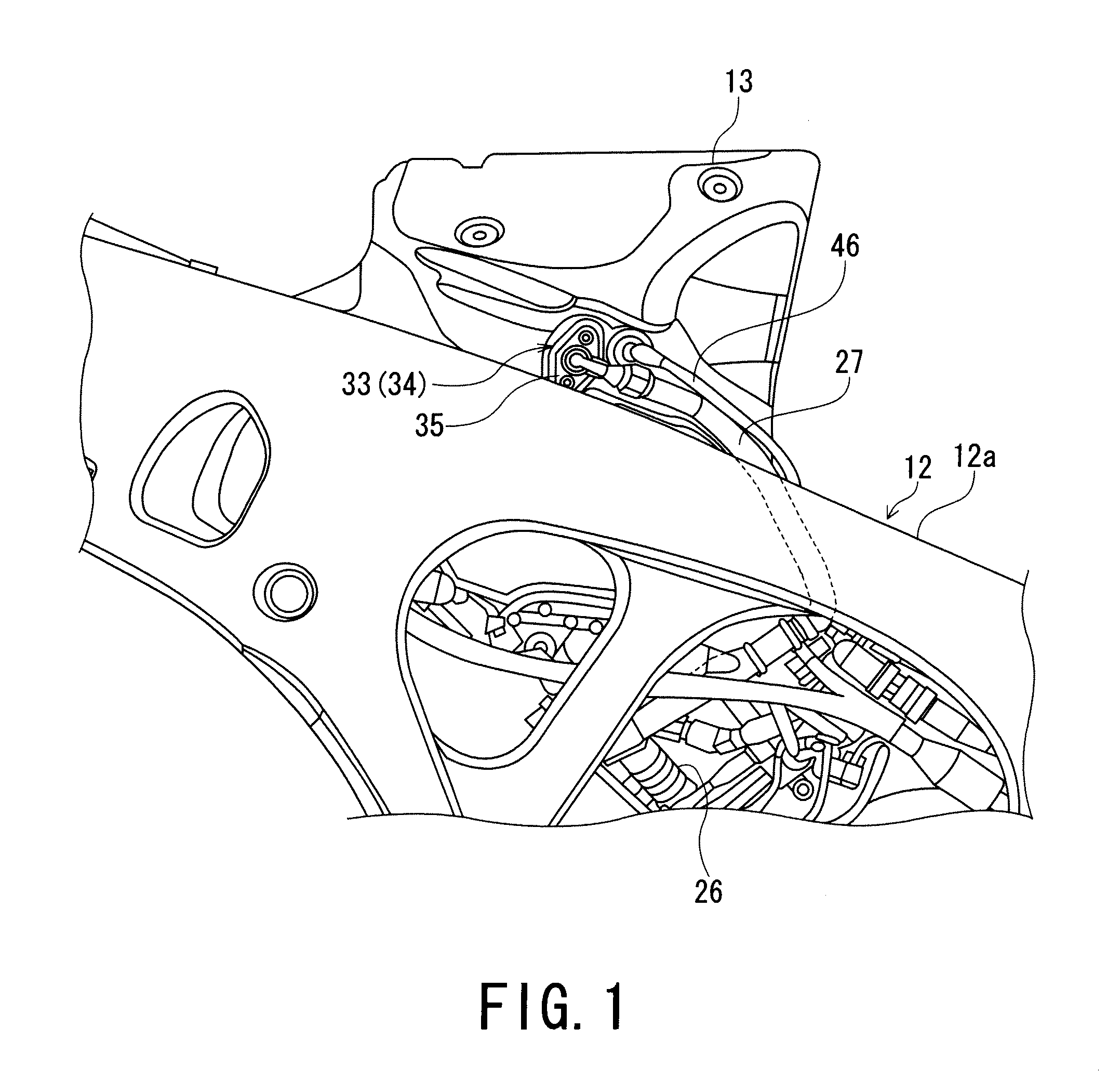

Fuel supply device for internal combustion engine

ActiveUS20130186370A1Simple structureImprove engine performanceLow pressure fuel injectionMachines/enginesExternal combustion engineEngineering

A fuel supply device for an internal combustion engine including a throttle valve and an airbox is provided with a main injector disposed at a downstream side of the throttle valve, an auxiliary injector disposed at an upstream side of the throttle valve and in the airbox, and a delivery pipe disposed inside the airbox and adopted to supply and distribute a fuel to the auxiliary injector. The delivery pipe has both ends which are supported on two side walls of the airbox.

Owner:SUZUKI MOTOR CORP

Pilot fuel injector with swirler

ActiveUS9366442B2Improve efficiencyImprove ignitabilityContinuous combustion chamberMachines/enginesCombustion chamberMain injector

A fuel injector includes: a pilot injector configured to spray fuel so as to form a first combustion region in a combustion chamber; and a main injector provided coaxially with the pilot injector so as to surround the pilot injector and configured to supply a fuel-air mixture that is a mixture of the fuel and air to form a second combustion region in the combustion chamber, wherein the pilot injector includes: a center nozzle configured to eject air jet flowing straight in an axial direction on a central axis of the pilot injector; an inside swirler provided on a radially outer side of the center nozzle and configured to cause inflow air to swirl around the central axis; and a pilot fuel injecting portion configured to inject the fuel from between the center nozzle and the inside swirler to air flow in the center nozzle.

Owner:KAWASAKI HEAVY IND LTD +1

Steam jetting refrigerating circulation system

InactiveCN100434834CSimple structureImprove the coefficient of performanceCompression machinesEngineeringHigh pressure

A steam jet refrigeration cycle system comprises a producer, an evaporator, a condenser, a circulation pump, a throttle valve and main and secondary injectors. The producer is used for producing the high-pressure refrigerant working steam. The main injector is used for jetting the low-pressure refrigerant steam coming from the evaporator and the secondary injector is used for jetting the low-pressure refrigerant steam coming from the main injector. The circulating pump outputs the high-pressure refrigerant liquid. The refrigerant liquid coming from one outlet of a diffuser returns to the producer and the refrigerant gas-liquid mixture coming from the other outlet enters to the condenser to condense. The produced refrigerant liquid is divided into two ways, one way is sent to the secondary injector by the circulating pump and the other enters to the evaporator through the throttle valve. The refrigeration is realized by evaporative heat-absorbing of the refrigerant in the evaporator.

Owner:XI AN JIAOTONG UNIV

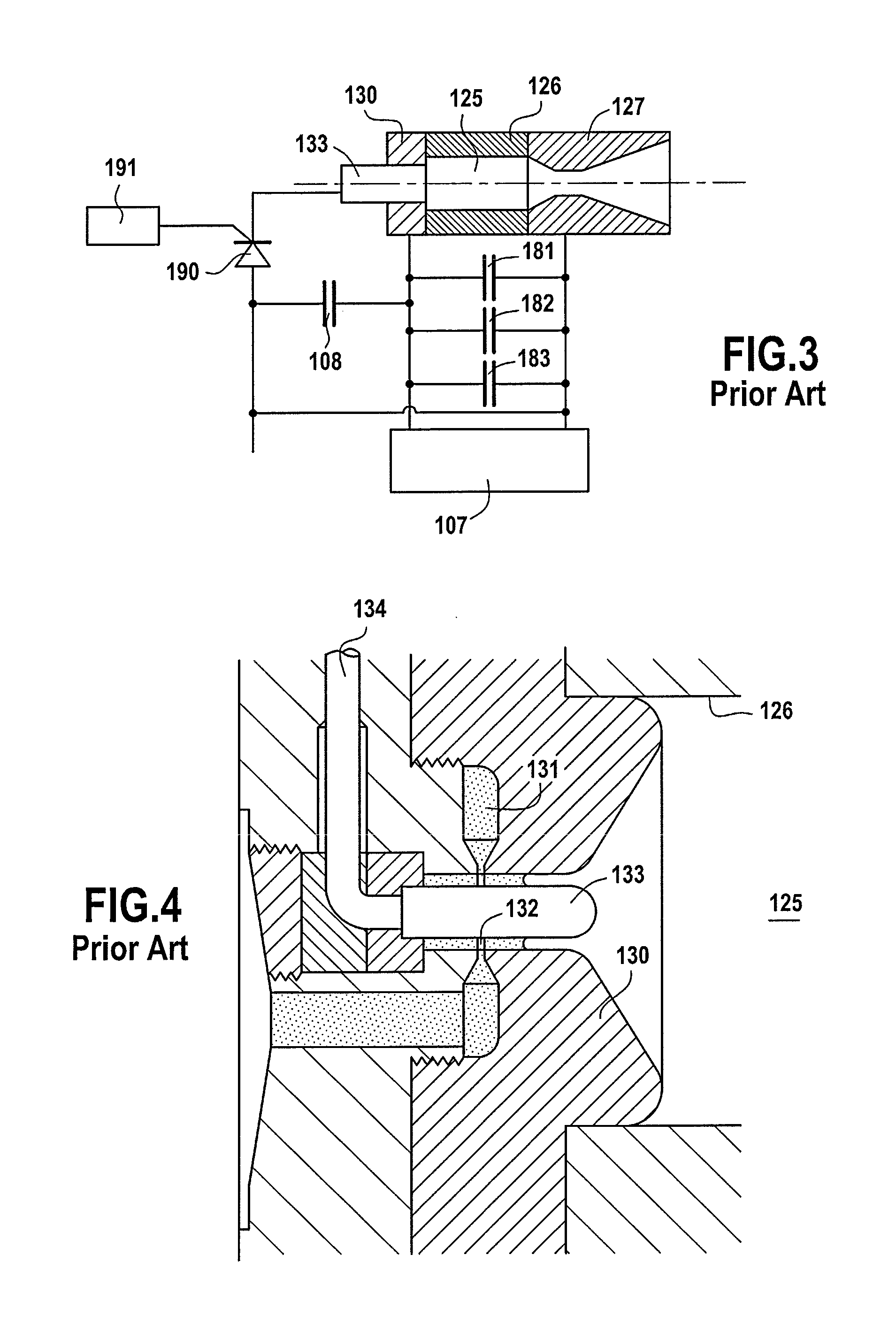

Electrolytic igniter for rocket engines using liquid propellants

InactiveUS8375697B2Increase flexibilityShorten the timeGas turbine plantsRocket engine plantsElectricityCombustion chamber

The electrolytic ignitor comprises an injector constituting a first electrode and including a fuel injector device, an oxidizer injector device, and an electrolyte injector device. A second electrode electrically insulated from the injector extends downstream beyond the injector. An electrolyte distribution channel for delivering electrolyte in the form of free jets through the electrolyte injector device comprises at least one injection hole in the vicinity of the fuel injector device and the oxidizer injector device. An electrical power supply circuit is adapted to raise the second electrode to a potential in the range 50 V to 1000 V relative to the potential of the first electrode. The electrolyte injected through the injection hole is capable of causing ignition of a gaseous mixture in a combustion chamber of an ignitor torch suitable for incorporating in a main injector of a rocket engine.

Owner:ARIANEGRP SAS

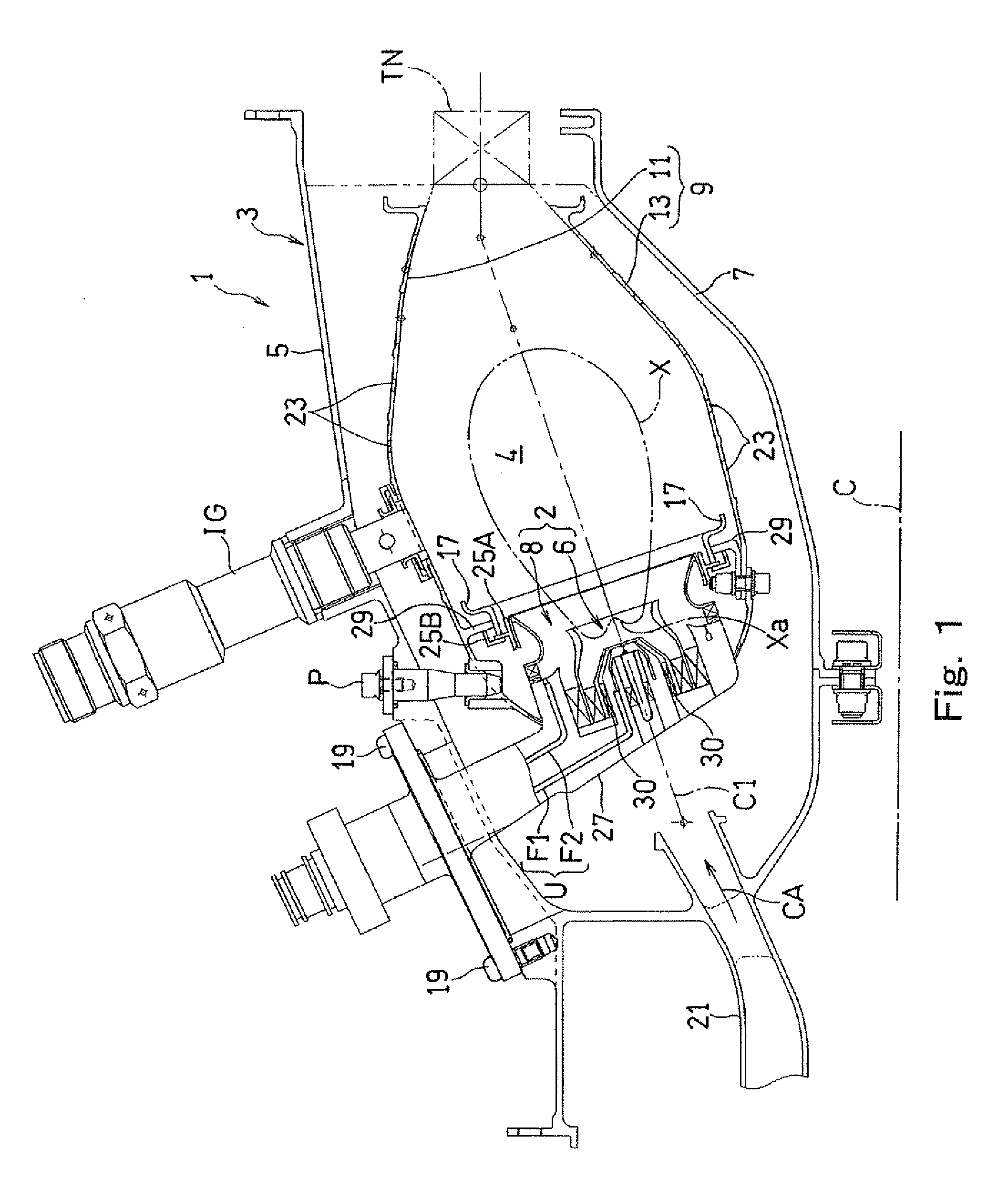

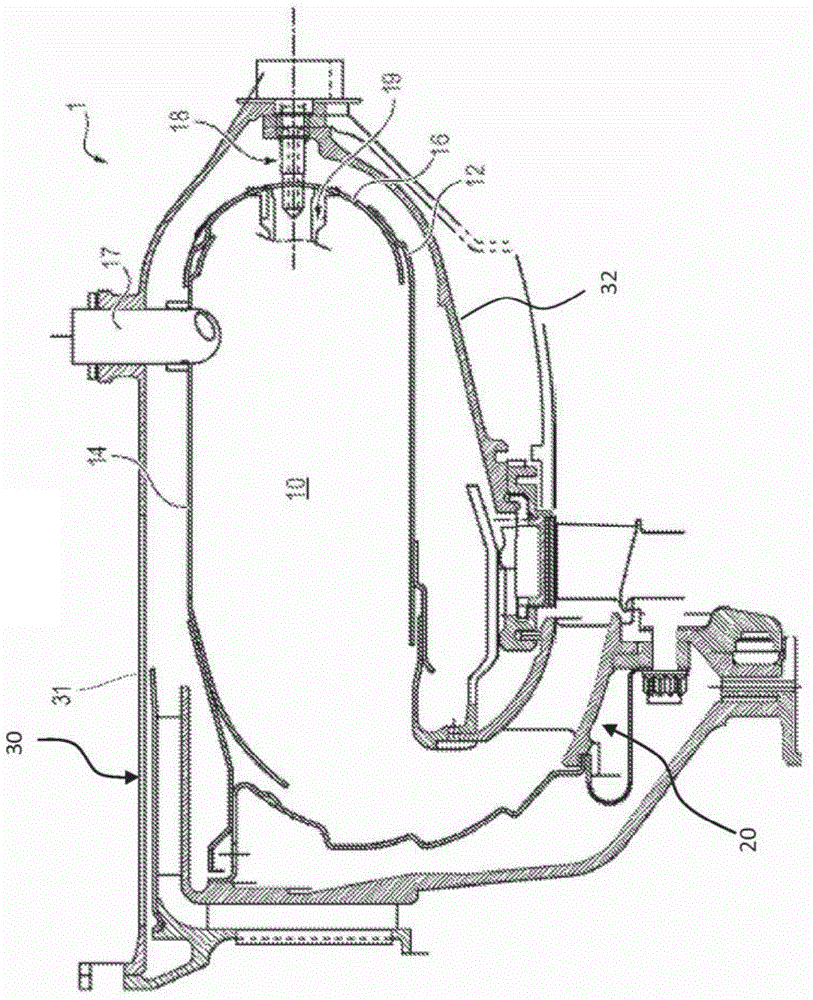

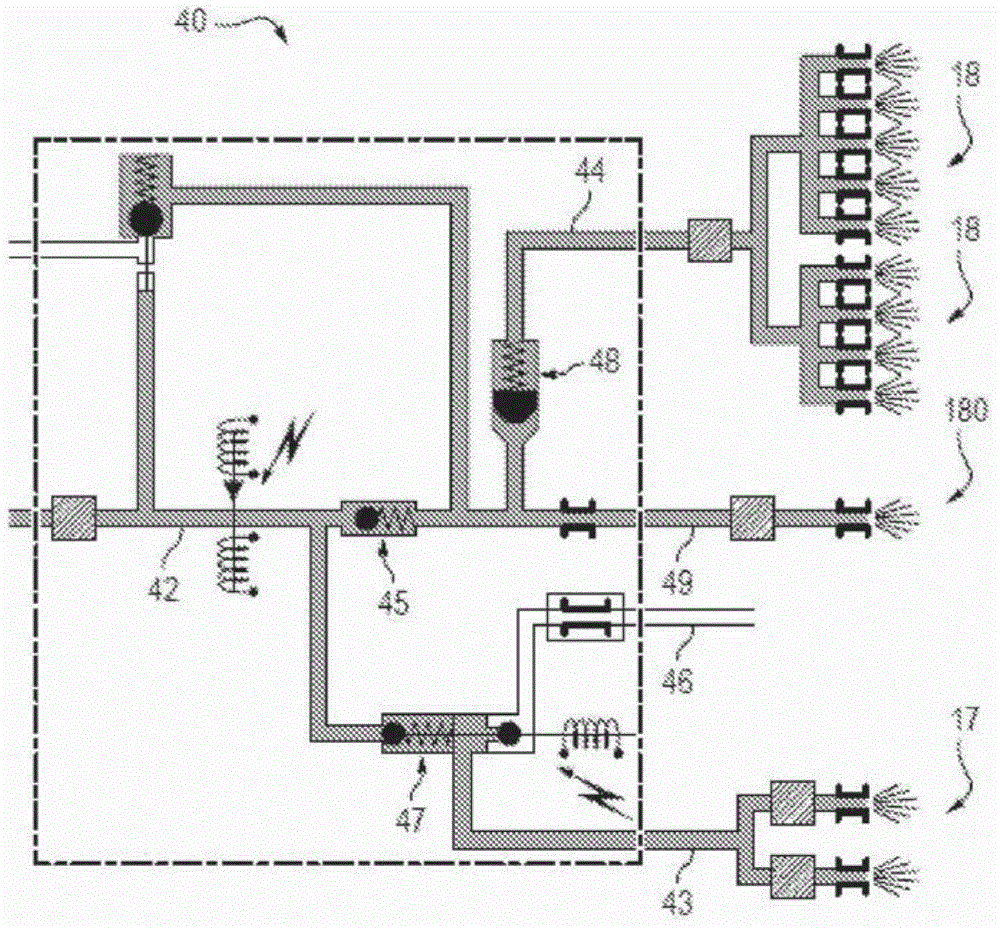

Turbo machine combustion assembly comprising an improved fuel supply circuit

ActiveCN105102789AGuaranteed uniformityLife maintenanceContinuous combustion chamberGas turbine plantsCombustion chamberEngineering

Turbo machine combustion assembly (1) comprising a combustion chamber (10), at least one starting injector (17), a plurality of main injectors (18) distributed at constant angular intervals around the circumference of the combustion chamber, each starting injector being positioned between two consecutive main injectors, equal distances therefrom, and a fuel supply circuit (40) supplying fuel to the injectors, in which assembly the combustion chamber is delimited by two axisymmetric walls - an external wall (14) and an internal wall (12) - which are connected by an annular chamber end wall (16), the fuel supply circuit being designed to supply at least one starting injector continuously, each continuously-supplied starting injector being oriented toward the chamber end wall and dimensioned to spread a spray (F) of fuel between 120° and 180° wide, and the flow rate of fuel injected by the main injectors (18') between which the starting injectors are positioned being reduced by comparison with the flow rate injected by the other main injectors (18).

Owner:TURBOMECA SA

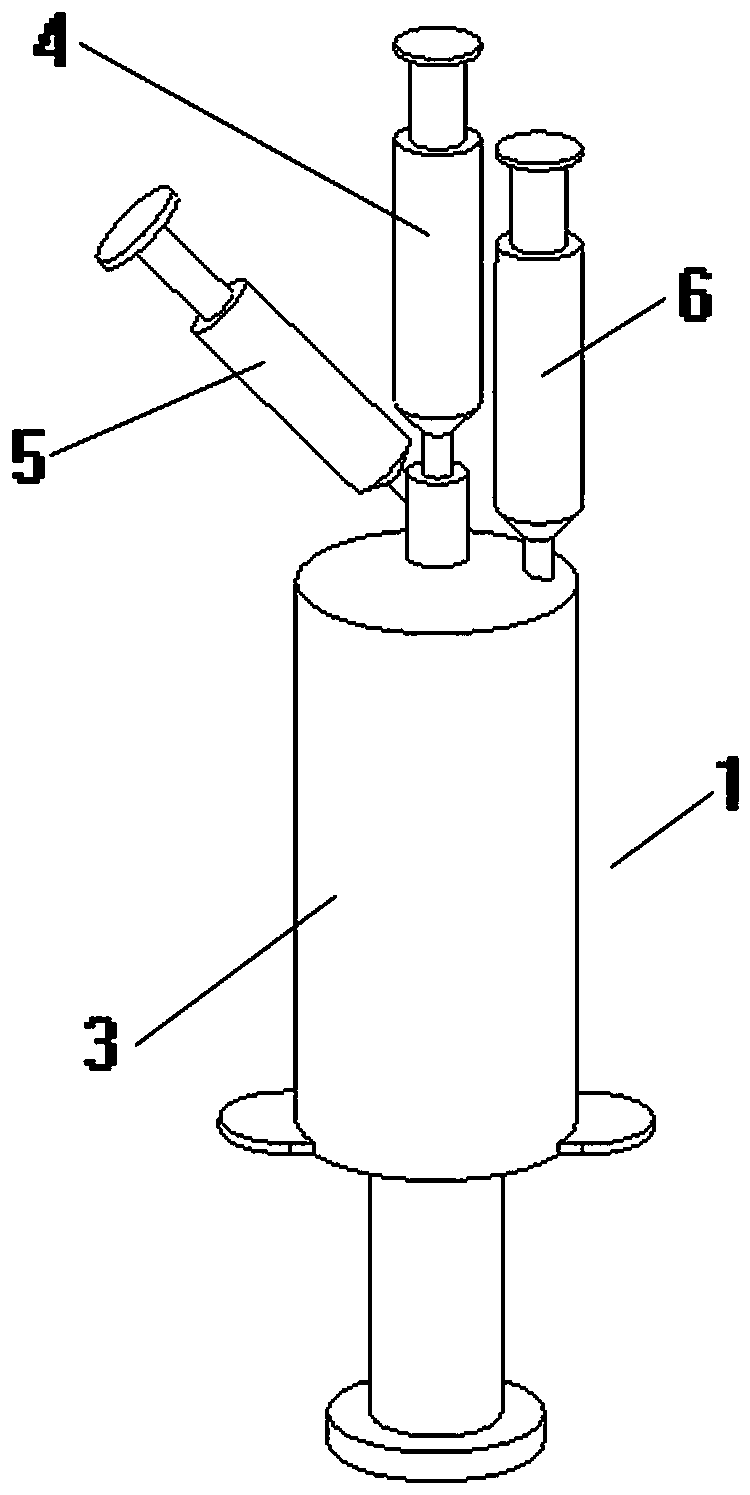

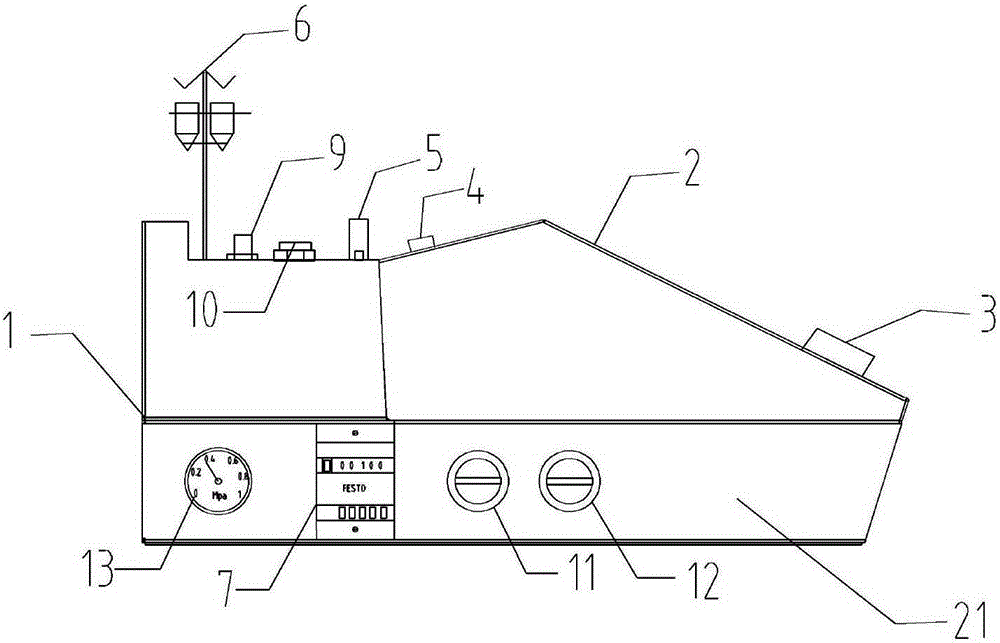

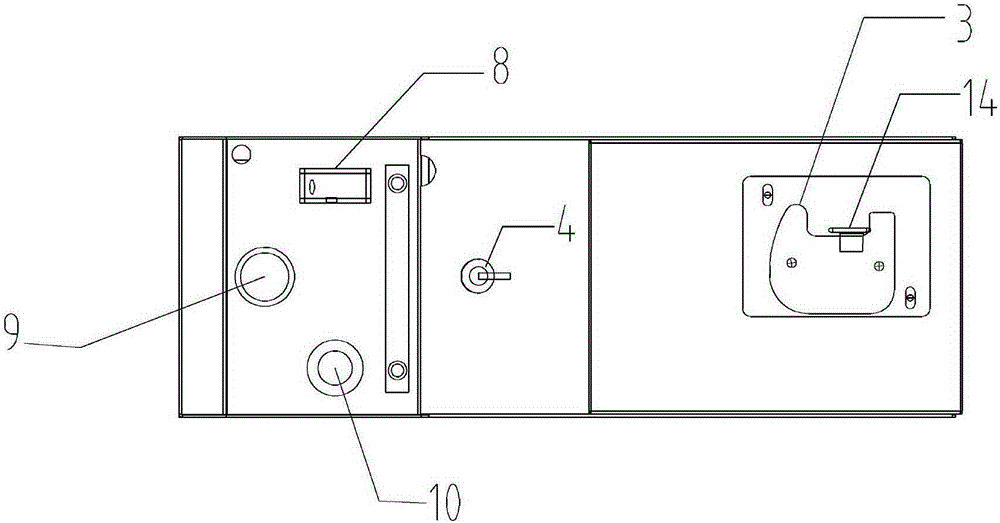

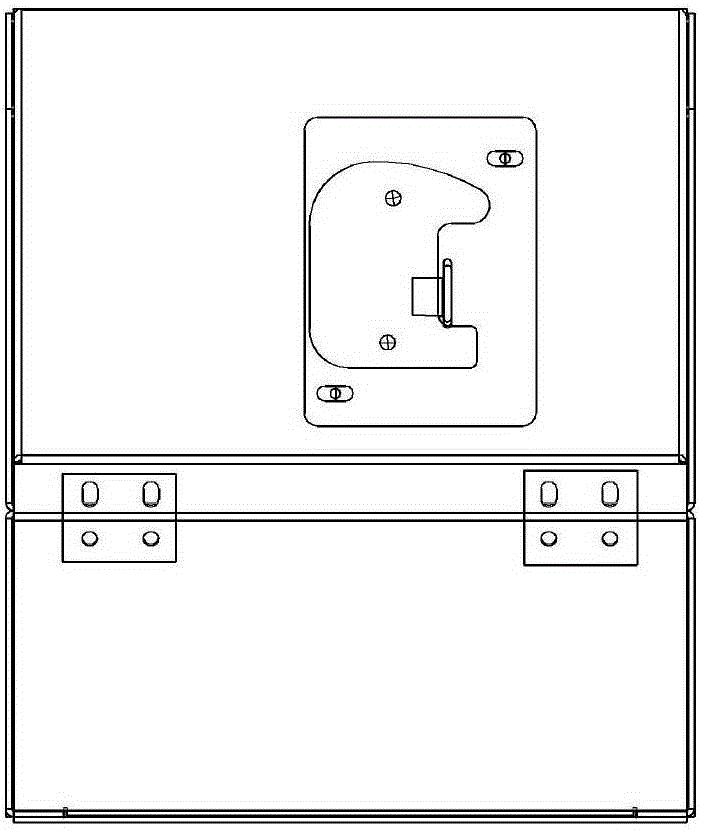

Automatic nucleic acid extracting device applicable to space

The invention discloses an automatic nucleic acid extracting device applicable to space. The device comprises a translation table, a stepping motor, a limiting switch, an injector set, a silicon rubber tube, a pressing pipe valve, electromagnets and a control circuit. The injector set is formed by fixedly connecting five 1 ml injectors for storing reagents needed by nucleic acid extraction; the injectors are fixed to the translation table, the translation table is driven by the stepping motor and can push and pull pistons of the injectors; the limiting switch is located at the end of the stroke of the pistons of the injectors and used for feeding back the position of the motor; the injectors are connected together through the silicon rubber tube, and the pressing pipe valve is used for controlling on-off of the silicon rubber tube; the two electromagnets are located at the two sides of the main injector for generating an oscillation magnetic field. The full-automatic extracting processfrom samples to purified nucleic acid inside a liquid closed system is achieved, no risk of aerosol contaminations is caused, the device can be used for automatically extracting nucleic acid of biological samples under the micro-gravity environment, and integration with a follow-up nucleic acid processing module is facilitated.

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

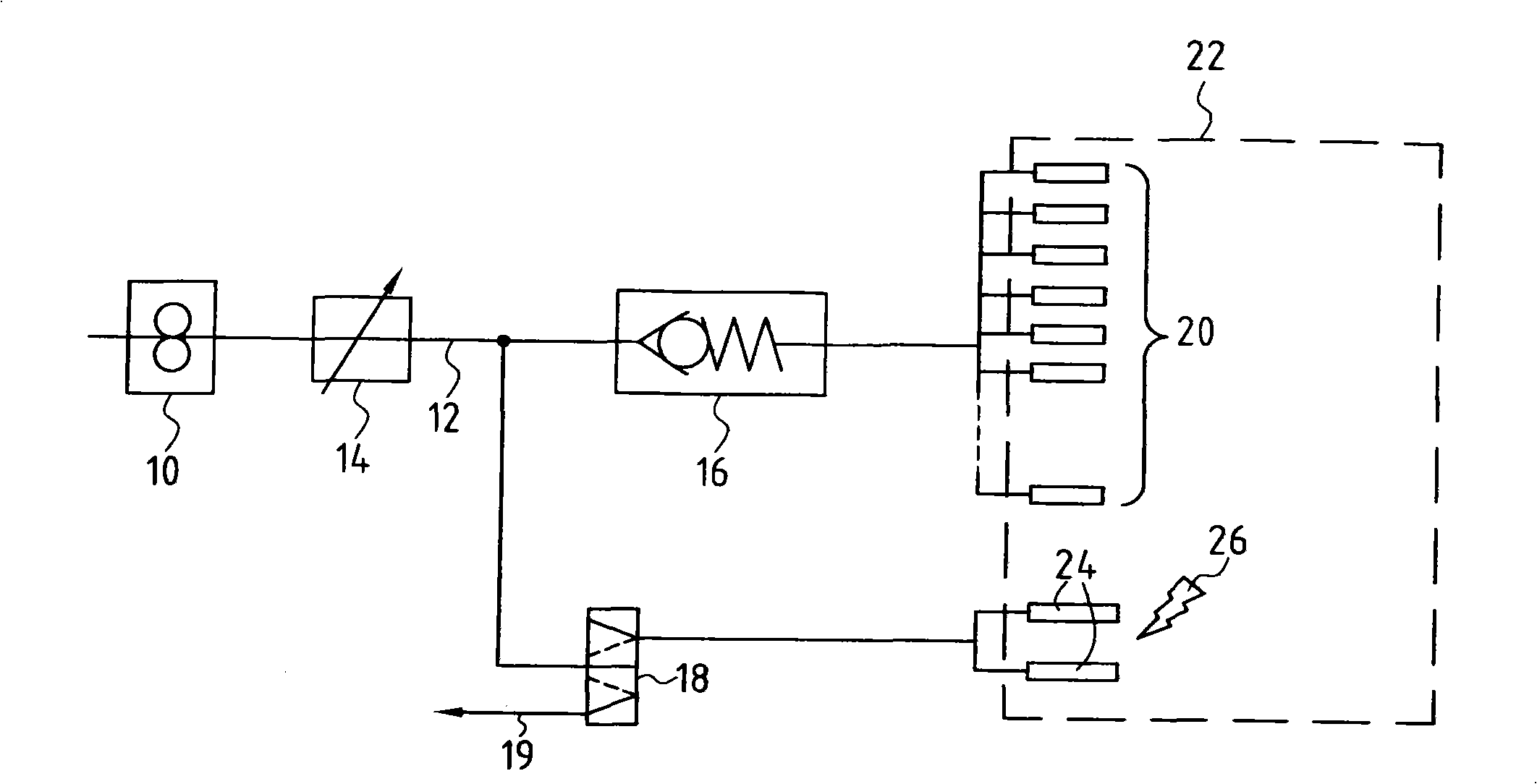

Fuel injection system for a turbine engine

A fuel system (10) for a turbine engine (12) for improving efficiency in a fuel system (10) where a major stage (14) and secondary stage (16) can be combined and held to a relatively constant fuel ratio while maintaining acceptable engine dynamics and NOx emissions is disclosed. The fuel system (10) may be formed from a first premix injector assembly stage (18) positioned upstream from a combustor basket (20), whereby the first premix injector assembly stage (18) is a secondary injector system. The fuel system (10) may be formed from a first primary injector assembly stage (22), which is a main injector system, positioned downstream from the first premix injector assembly stage (18). The first premix injector assembly stage (18) and the first primary injector assembly stage (22) may be coupled together such that the fuel system (10) is capable of emitting fuel into a combustor (24) of the turbine engine (12) via the first premix injector assembly stage (18) and the first primary injector assembly stage (22) simultaneously.

Owner:SIEMENS AG

Method for the controlled purging of the fuel feeding system in the combustor of a gas turbine engine

InactiveCN101532433AReduce complexityLow running costBurnersBurner safety arrangementsDiffusion flameCombustion chamber

A method is described for the controlled purging of the fuel feeding system in the combustor of a gas turbine comprising at least one compressor (10), capable of compressing the air introduced into it through an inlet duct (12), at least one combustor (14), in which said compressed air is mixed and combusted with a gaseous fuel coming from a feeding duct (16), and at least one turbine (20), capable of transforming the energy of the combusted gas coming from said combustion chamber (14) into work energy which can be exploited for activating one or more operating machines (22). The combustor (14) is equipped with one or more burners (30), each equipped with at least one pilot injector (36) and one or more main injectors (38) for the adduction of the gaseous fuel inside the burner (30). The method comprises purging at least part of the main injectors (38) and relative manifolds (34) with a stream of gaseous fuel when the turbine is in diffusive flame functioning mode and purging the pilot injector (36) and relative manifold (32) with a stream of gaseous fuel when the turbine is in premixed flame functioning mode.

Owner:NUOVO PIGNONE SPA

Fuel injection system for a turbine engine

InactiveUS20150128600A1Improve efficiencyEmission of NOxContinuous combustion chamberGas turbine plantsCombustion chamberCombustor

A fuel system for a turbine engine for improving efficiency in a fuel system where a major stage and secondary stage can be combined and held to a relatively constant fuel ratio while maintaining acceptable engine dynamics and NOx emissions is disclosed. The fuel system may be formed from a first premix injector assembly stage positioned upstream from a combustor basket, whereby the first premix injector assembly stage is a secondary injector system. The fuel system may be formed from a first primary injector assembly stage, which is a main injector system, positioned downstream from the first premix injector assembly stage. The first premix injector assembly stage and the first primary injector assembly stage may be coupled together such that the fuel system is capable of emitting fuel into a combustor of the turbine engine via the first premix injector assembly stage and the first primary injector assembly stage simultaneously.

Owner:SIEMENS AG

Electrolytic igniter for rocket engines using monopropellants

InactiveUS8387359B2High levelEasy constructionGas turbine plantsRocket engine plantsElectricityDecomposition

The electrolytic ignitor comprises an injector constituting a first electrode, a second electrode that is electrically insulated from the injector and that extends downstream beyond the injector, and a distribution channel to deliver a first mono-propellant to a first mono-propellant injector device constituted by at least one injection hole opening out in the vicinity of the second electrode, and an electrical power supply circuit adapted to raise the second electrode to a potential lying in the range 50 V to 1000 V relative to the potential of the first electrode. The electrical power dissipated by ionic conduction in the free jet of the first mono-propellant is suitable for giving rise to spontaneous decomposition of the first mono-propellant and for producing combustion gas that ensures ignition of jets of a second mono-propellant coming from a main injector situated in the vicinity of the second electrode.

Owner:ARIANEGRP SAS

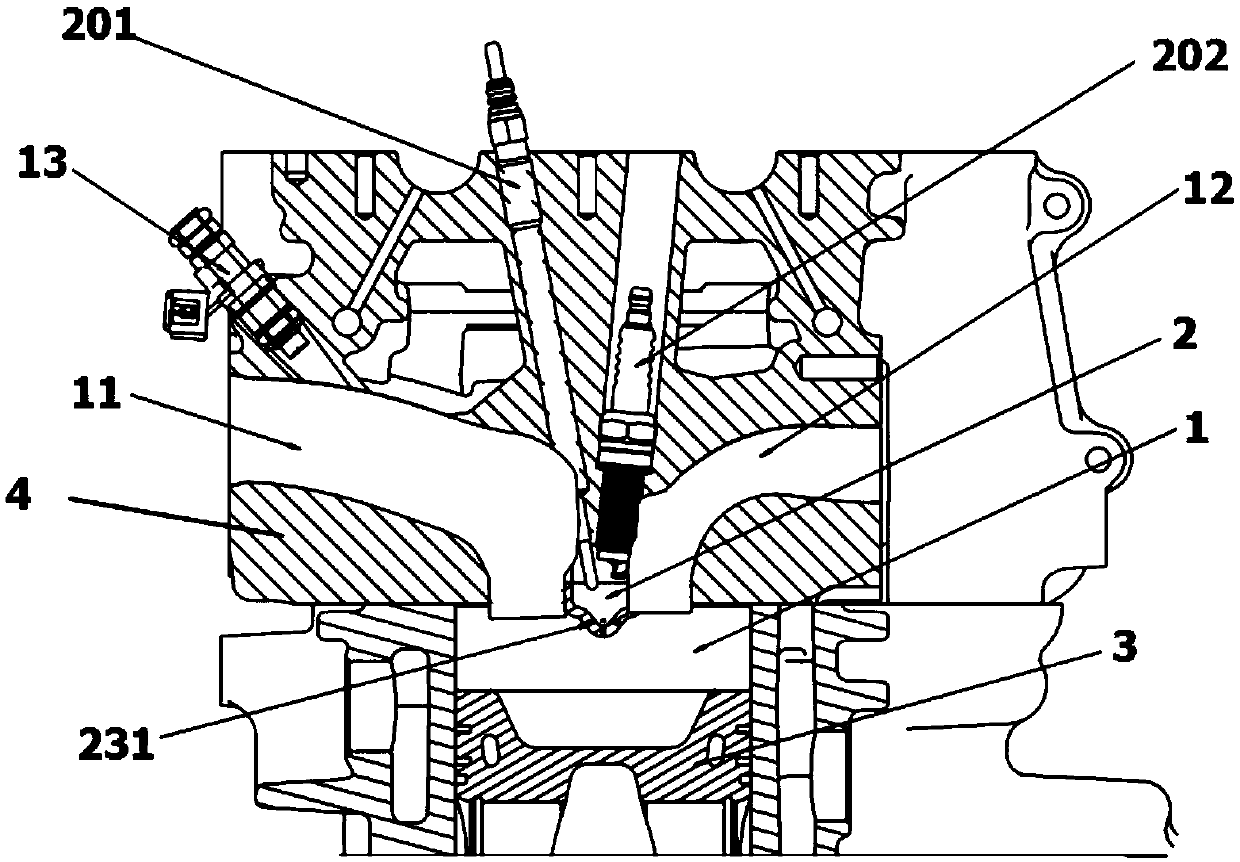

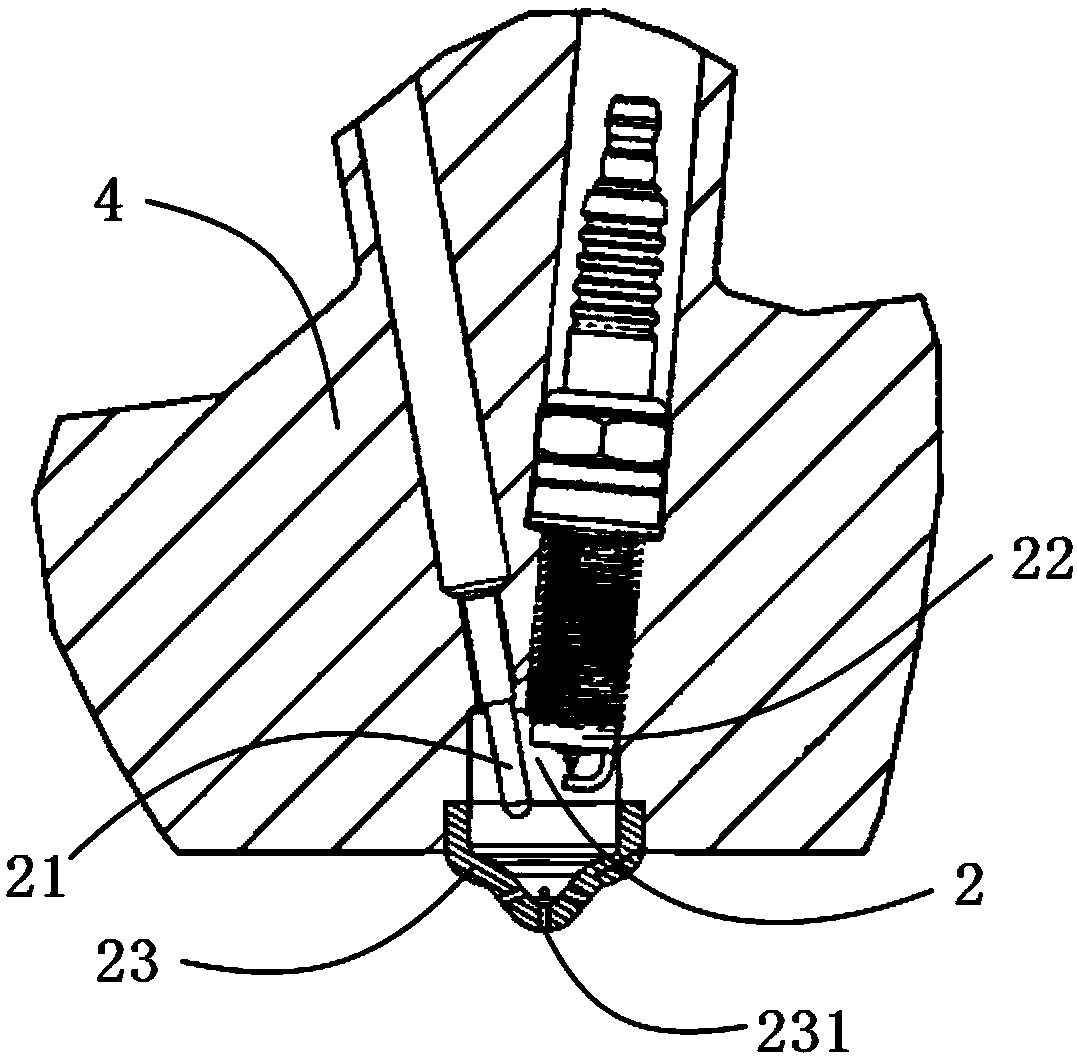

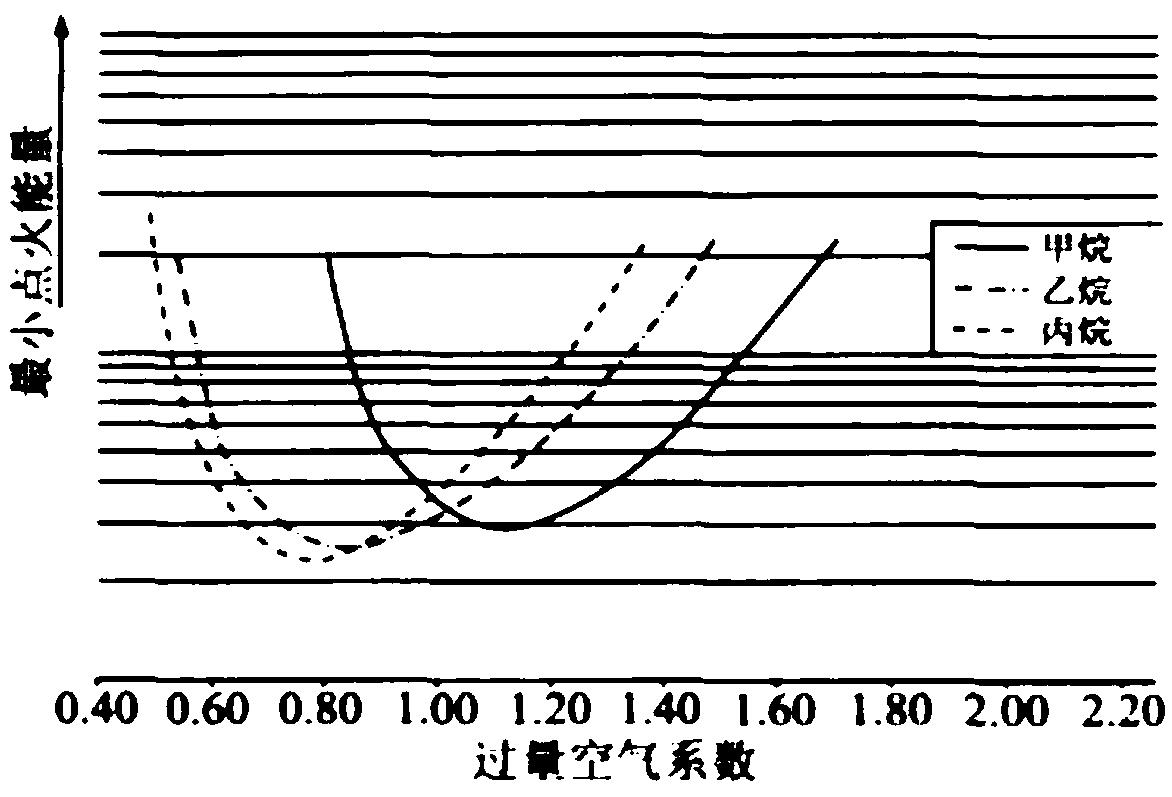

Ignition system and vehicle for methanol engine

InactiveCN109630336AReduce heat loadHigh thermal efficiencyFuel injection apparatusMachines/enginesHigh concentrationCombustion chamber

The invention provides an ignition system and a vehicle for a methanol engine and relates to the field of methanol engines. The ignition system includes a main combustion chamber and a pre-combustionchamber, wherein an intake valve is arranged in the main combustion chamber, and the intake valve communicates with a main injector for injecting a lean mixture having a first predetermined concentration into the main combustion chamber; the pre-combustion chamber communicates with the main combustion chamber through a pre-combustion chamber nozzle, and a spark plug electrode and a pre-injection nozzle are arranged in the pre-combustion chamber; and the spark plug is arranged in a methanol pre-combustion chamber. Due to the high concentration of the rich mixture gas, the requirement for minimum ignition energy of the spark plug is reduced. By igniting the concentrated methanol mixture gas in the pre-combustion chamber, the concentrated mixed methanol flame is injected into the main combustion chamber, the lean mixture gas of methanol in the main combustion chamber is combusted, and the ignition energy is greatly increased. By using of the system, the combustion temperatures and enginethermal loads are reduced while engine NOX emission is reduced and engine thermal efficiency is improved.

Owner:ZHEJIANG GEELY HLDG GRP CO LTD +2

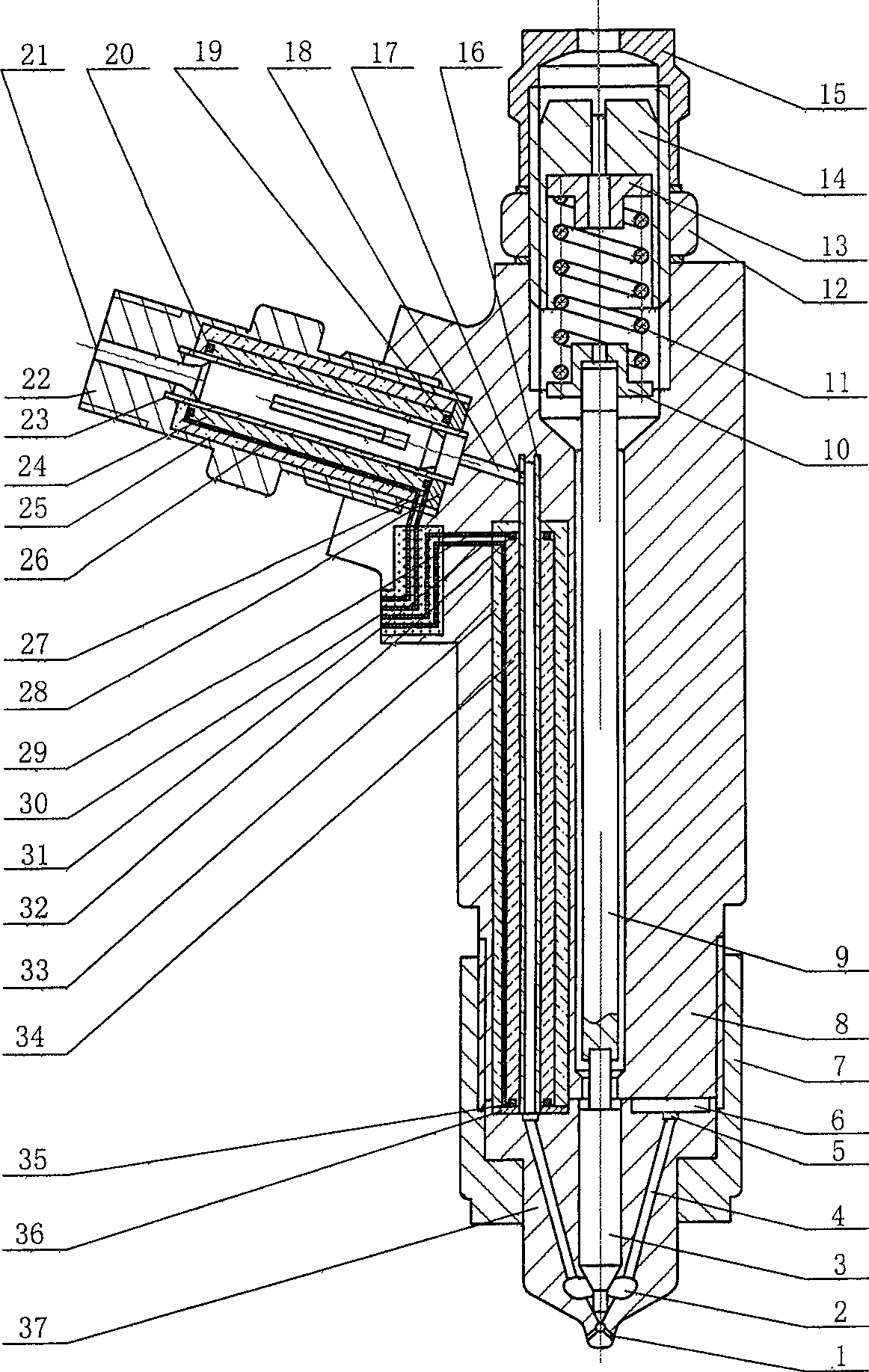

Fuel injector with built-in positive temperature coefficient ceramic heating material

InactiveCN100520049CReduce heatingEasy to sprayFuel injection apparatusMachines/enginesSelf limitingBoiling point

A fuel injector with a built-in positive temperature coefficient ceramic heating material mainly includes: a fuel injector needle valve, a fuel injector needle valve body, a fuel injector body, a fuel injector tappet, a fuel injector pressure regulating spring, a fuel injector Heat conduction round tube in the body, positive temperature coefficient heating ceramics in the fuel injector body, insulating sheath in the fuel injector body, heat conduction round tube in the oil inlet bolt, positive temperature coefficient heating ceramics in the oil inlet bolt, insulating sheath in the oil inlet bolt, etc. The positive temperature coefficient heating ceramics are placed in the oil inlet bolt and the fuel injector, and the self-limiting temperature of the diesel is heated through the heat conduction tube, and insulated through the insulating sheath. The invention provides a self-limiting temperature heating fuel injector for diesel oil in the process of cold start and warm-up, the heating temperature will not exceed the boiling point of diesel oil, the required heating amount is less, and the heating speed is faster, which can effectively Improve diesel engine emissions and improve its cold start performance.

Owner:CHINA JILIANG UNIV

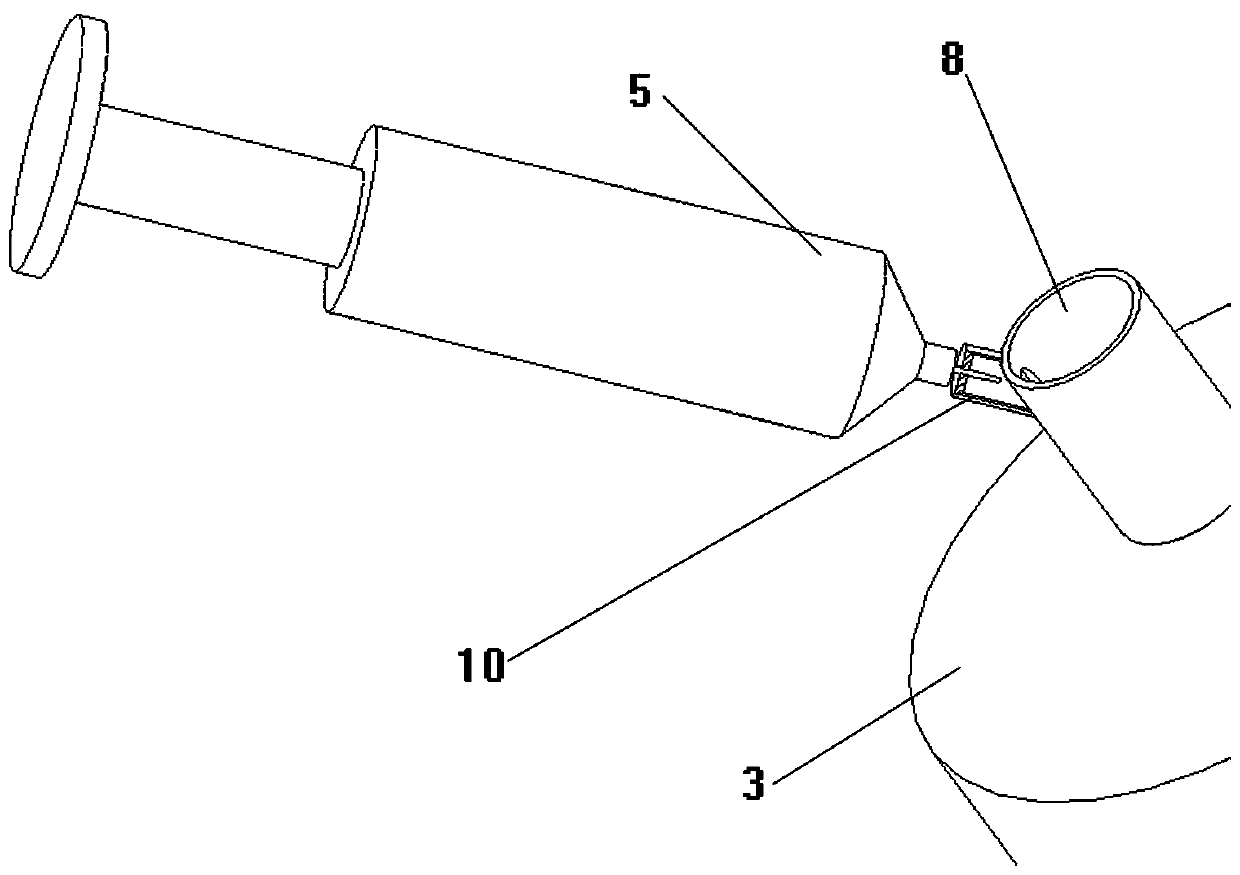

Liquid medicine mixing sprayer

The invention relates to a liquid medicine mixing sprayer which comprises injectors, a tee joint and a mixing spray head, wherein the front parts of the main injector and the auxiliary injector are connected with the mixing spray head through the tee joint, and the rear parts of core rods of the injectors are provided with a synchronizing pushing handle. A mixing cavity of the mixing sprayed head is internally provided with a spray core column, and the port of the spray core column is provided with an atomization sheet which is buckled on the spray core column. A growth factor product and coagulant are respectively stored in the main injector and the auxiliary injector, enter the mixing spray head according to the proportion, and are sprayed out by the atomization sheet. The invention is convenient for mixing the medicine, shortens the mixing time of the growth factor product and the coagulant, avoids the flocculation, and can make the liquid medicine be uniformly sprayed on wound in a vapourous state. The invention has simple structure, convenient operation and use, high working efficiency and good safety performance.

Owner:SHANDONG WEIGAO GROUP MEDICAL POLYMER

Reaction integrated device for experiment

PendingCN107862957AReduce concentrationSimplify the experimental stepsEducational modelsInfusion setEngineering

The invention belongs to the technical field of a chemical teaching tool, and particularly relates to a reaction integrated device for experiment. The reaction integrated device for experiment comprises a first injection device and a second injection device; the first injection device and the second injection device comprise main injectors, and first assistant injectors and second assistant injectors which are linked to the main injector; the first assistant injectors and second assistant injectors are connected through a U-shaped pipe. The experiment step is simplified and the preparation time before class is shortened; the injectors are used as generation and collection devices for preparing carbon dioxide, and the prepared carbon dioxide gas can be used immediately. The device can carryout the experiment of reaction between carbon dioxide and sodium hydroxide solution, and is composed of a part of components of 50 ml and 5 ml injectors and infusion apparatuses; the reaction integrated device is small and light, convenient to carry, simple in operation, strong in repeatability, and can be prepared to be a complete set device, and used for a long term.

Owner:魏凡博

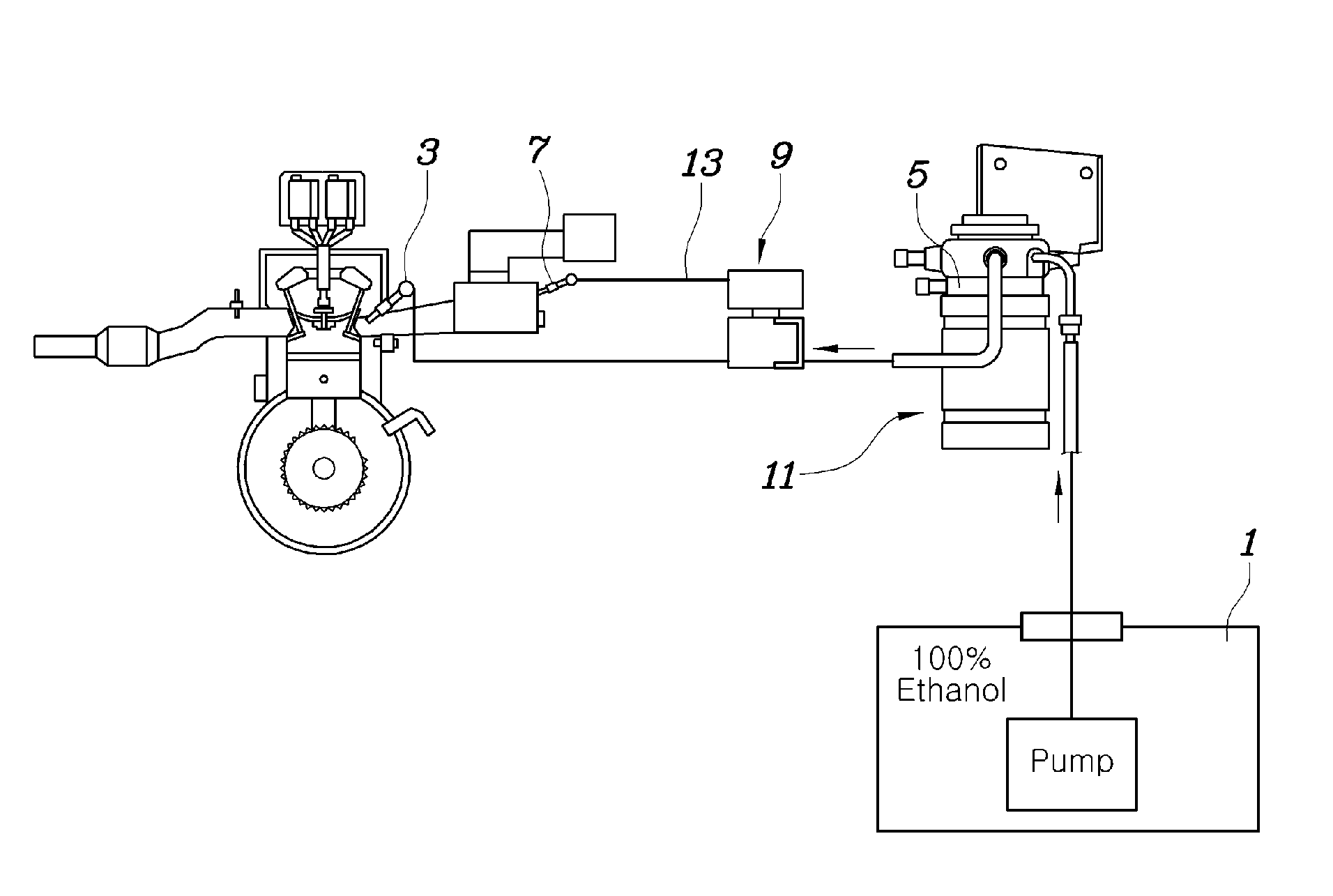

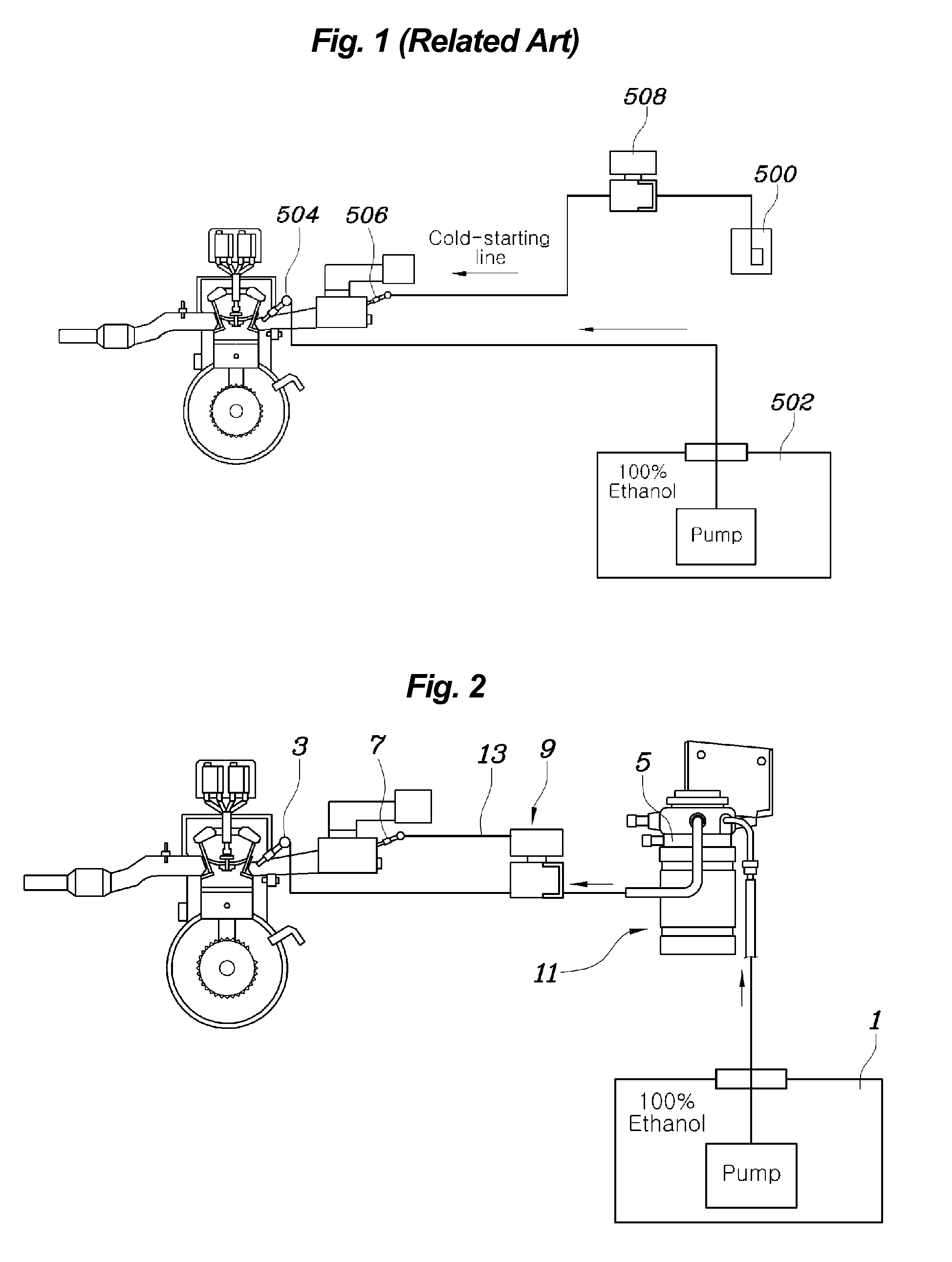

Fuel supply system of vehicle

ActiveUS8869778B2Reduce vehicle costReduce inconvenienceElectrical controlLow pressure fuel injectionFuel tankFuel supply

A fuel supply system of a vehicle, may include a fuel tank storing ethanol therein, a main injector installed at an engine to inject the ethanol from the fuel tank, a heater provided to heat the ethanol supplied from the fuel tank to the engine, a cold-starting injector installed at the engine to inject the ethanol heated by the heater, and a valve unit connected to the main injector and the cold-starting injector and performing a switching operation between a state of the ethanol being supplied from the fuel tank to the main injector and a state of the ethanol heated by the heater being supplied to the cold-starting injector.

Owner:KIA MOTORS CORP

Young bird automatic injection immunizing machine and young bird automatic injection immunizing method

InactiveCN106618786AAvoid risk of failureHigh efficiency of automatic injection of immunization vaccineVeterinary instrumentsEngineeringBottle

The invention discloses a young bird automatic injection immunizing machine, which comprises a machine body, a machine cover and a control cabinet, wherein vaccine bottles are arranged on a vaccine bottle bracket which is arranged at one side of the machine body; the vaccine bottles and injectors are connected by virtue of infusion tubes; the injectors are arranged at the other side of the machine body; the injectors include a main injector and a subordinate injector; and the subordinate injector is connected to the main injector by connecting a rapid connecting tube to a tee valve. The invention also discloses a young bird automatic injection immunizing method. The young bird automatic injection immunizing method is high in efficiency of automatically injecting immune vaccines, namely 4000-6000 birds / h or above, which is about 5 times as much as that of manual vaccine injection; the immunizing machine is precise in immunizing dosage control and capable of saving the usage amount of vaccines; and meanwhile, the immunizing machine is operated by a single person, so that labor cost is saved.

Owner:青岛凤鸣自动化设备有限公司

Sector staging combustor

InactiveCN100400967CIncrease main flameStable idle speedBurnersContinuous combustion chamberCombustorCombustion chamber

A combustor (22) includes outer and inner liners (40,42) joined together by a dome (44) to define a combustor chamber (46). A row of air swirlers (48) is mounted in the dome and includes corresponding main fuel injectors (50) for producing corresponding fuel and air mixtures. Pilot fuel injectors (52) fewer in number than the main injectors (50) are mounted in the dome between corresponding ones of the swirlers (48). Staged fuel injection from the pilot and main injectors is used for starting the combustor during operation.

Owner:GENERAL ELECTRIC CO

A jet air conditioner with thermal energy recycling

InactiveCN104633881BEnergy recovery in ventilation and heatingMechanical apparatusThermal energyLiquid state

Owner:山西方洁路路通净化技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com