Turbo machine combustion assembly comprising an improved fuel supply circuit

A fuel supply and supply circuit technology, applied in the fuel control of turbine/propulsion device, gas turbine device, turbine/propulsion fuel delivery system, etc., can solve the problem of high production cost and achieve the effect of maintenance life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

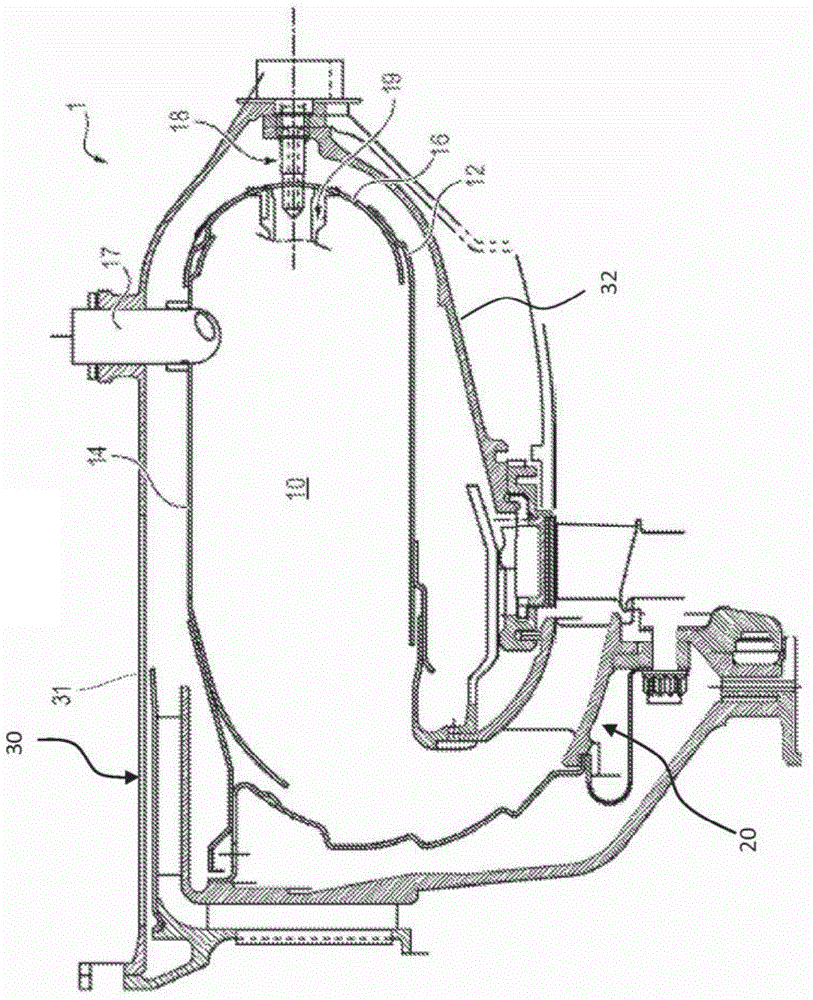

[0058] Reference Figure 3a with Figure 3b , Represents the turbine combustion assembly 1, which includes a combustion chamber 10 and a casing 30 (in Figure 3b Indicated in), the combustion chamber 10 is defined by two axisymmetric outer walls 14 and an inner wall 12, and the outer wall 14 and the inner wall 12 extend nestingly with each other and are connected by an annular combustion chamber end wall 16.

[0059] The housing also includes an outer wall 31 (in Figure 3b Middle) and inner wall (not in Figure 3b Indicated in), the inner wall 12 and the outer wall 14 of the combustion chamber are fastened to the outer wall 31 and the inner wall respectively.

[0060] The turbine 1 also includes a plurality of fuel injectors, including at least one starter injector 17 (preferably, at least two starter injectors 17), and a plurality of main injectors 18 (preferably, at least three main injectors 18), For example, eight main injectors.

[0061] The ignition system includes at least on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com