Sector staging combustor

A staged combustion and segmental technology, applied in the direction of burners, combustion chambers, combustion equipment, etc., can solve complex problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

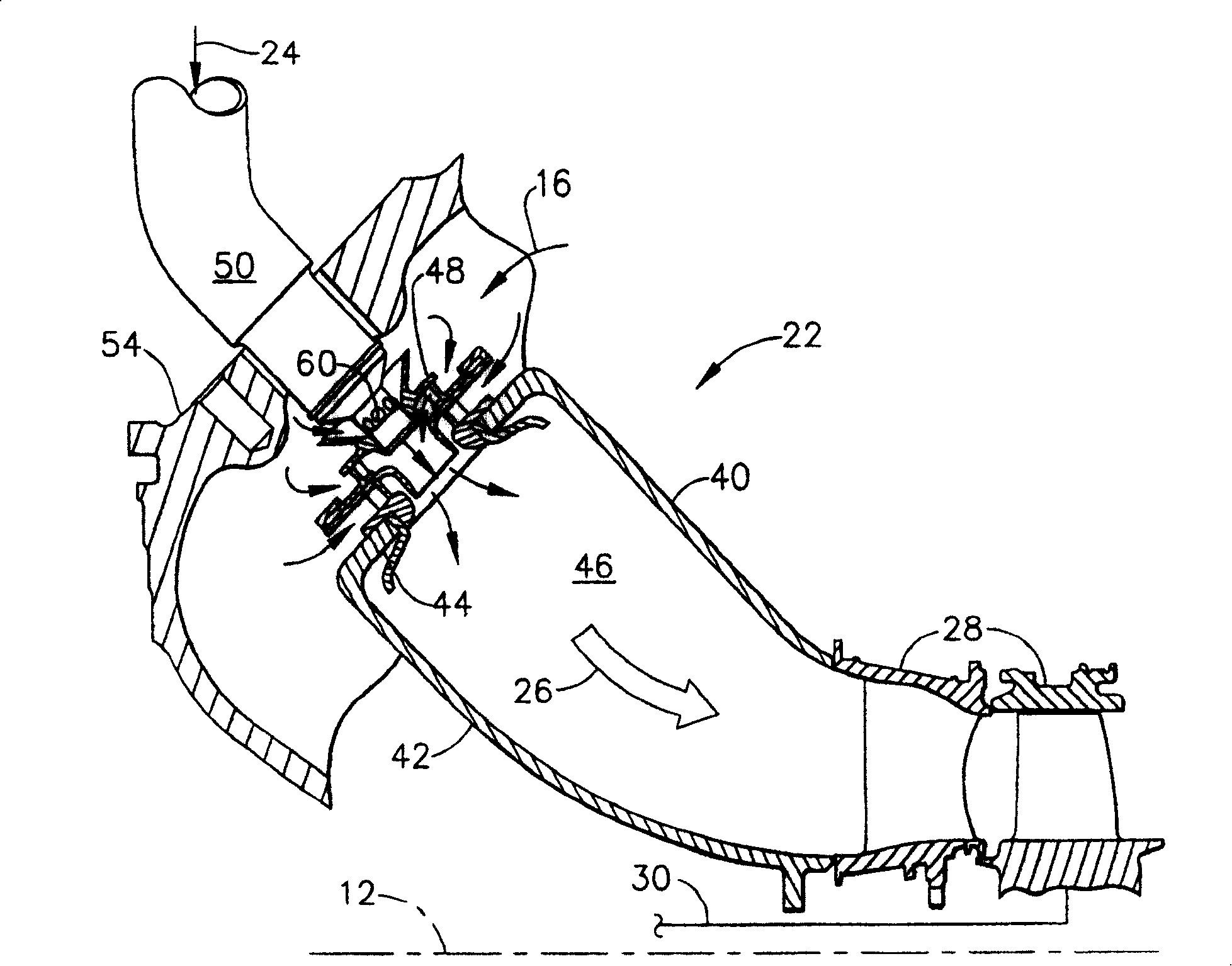

[0022] exist figure 1 Schematically shown in is a gas turbine engine 10 specifically configured for use in a land vehicle (not shown) to provide propulsion power therefor. The engine is axisymmetric about a longitudinal or axial centerline axis 12 and includes an inlet 14 at an upstream end to receive ambient air 16 .

[0023] Next to the inlet is a multi-stage axial centrifugal compressor 18 which pressurizes the air 16 , from which the air 16 is then discharged to a surrounding recuperator or heat exchanger 20 . The compressor discharge air is heated in a recuperator, as further described below, and returned to the upstream end of the annular combustor 22 as appropriate.

[0024] Fuel 24 is mixed with pressurized air 16 and ignited in a combustor to generate therein hot combustion gases 26 which are discharged from a downstream outlet port to a single stage high pressure turbine (HPT) 28 . The rotor disk of the HPT 28 is suitably connected to a first rotor or shaft 30 whic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com