Tail gas waste heat driving injection refrigeration system for vehicle air conditioner

A technology of refrigeration system and automobile air conditioner, applied in the field of refrigeration and energy saving of auto parts, can solve the problems of many moving parts of refrigeration system, decrease of engine power performance, increase of energy consumption, etc., to achieve simple system, reduce exhaust temperature, and improve activity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0038] Unless expressly stated otherwise, throughout the claims and specification, the term "comprises" or variations thereof such as "comprises" or "includes" etc. will be understood to include the stated elements or constituents and not exclude other elements or other components.

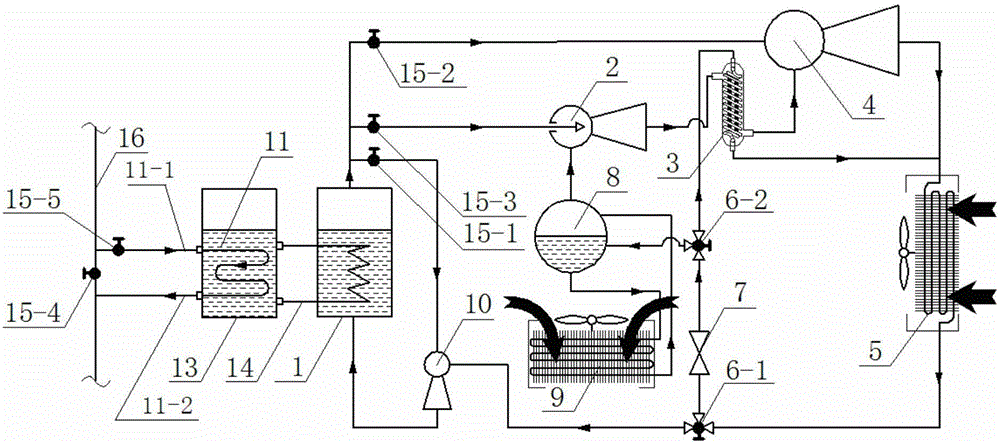

[0039] The structure of an exhaust waste heat-driven jet refrigeration system for automobile air conditioners is as follows: figure 1 as shown,

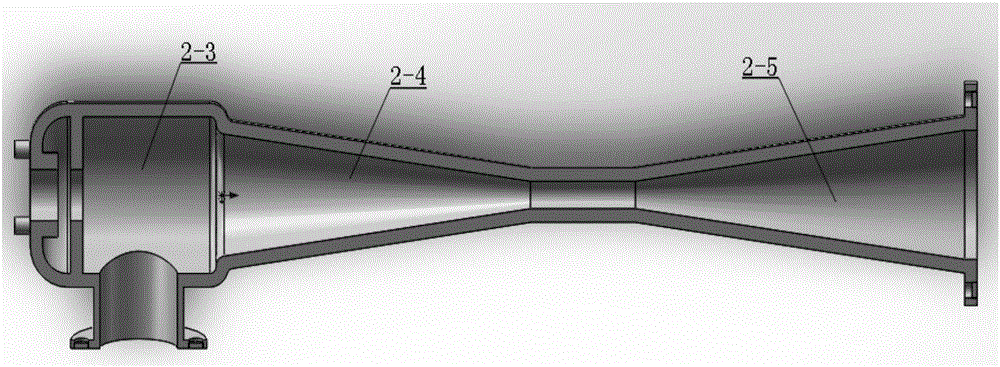

[0040] An exhaust waste heat-driven injection refrigeration system for automobile air conditioners consists of an exhaust heat exchanger 13, a heat exchange copper tube 14, a generator 1, a main injector 2, an intermediate heat exchanger 3, a first auxiliary injector 4, and a co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com