Scroll wrap profile of liquid-injected scroll compressor

A scroll compressor and scroll tooth technology, applied in the field of compressors, can solve the problems of liquid shock, affecting the safe and reliable operation of liquid injection scroll compressors, and sudden pressure increases, so as to increase the amount of liquid injection and save compression work Consumption, the effect of increasing the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

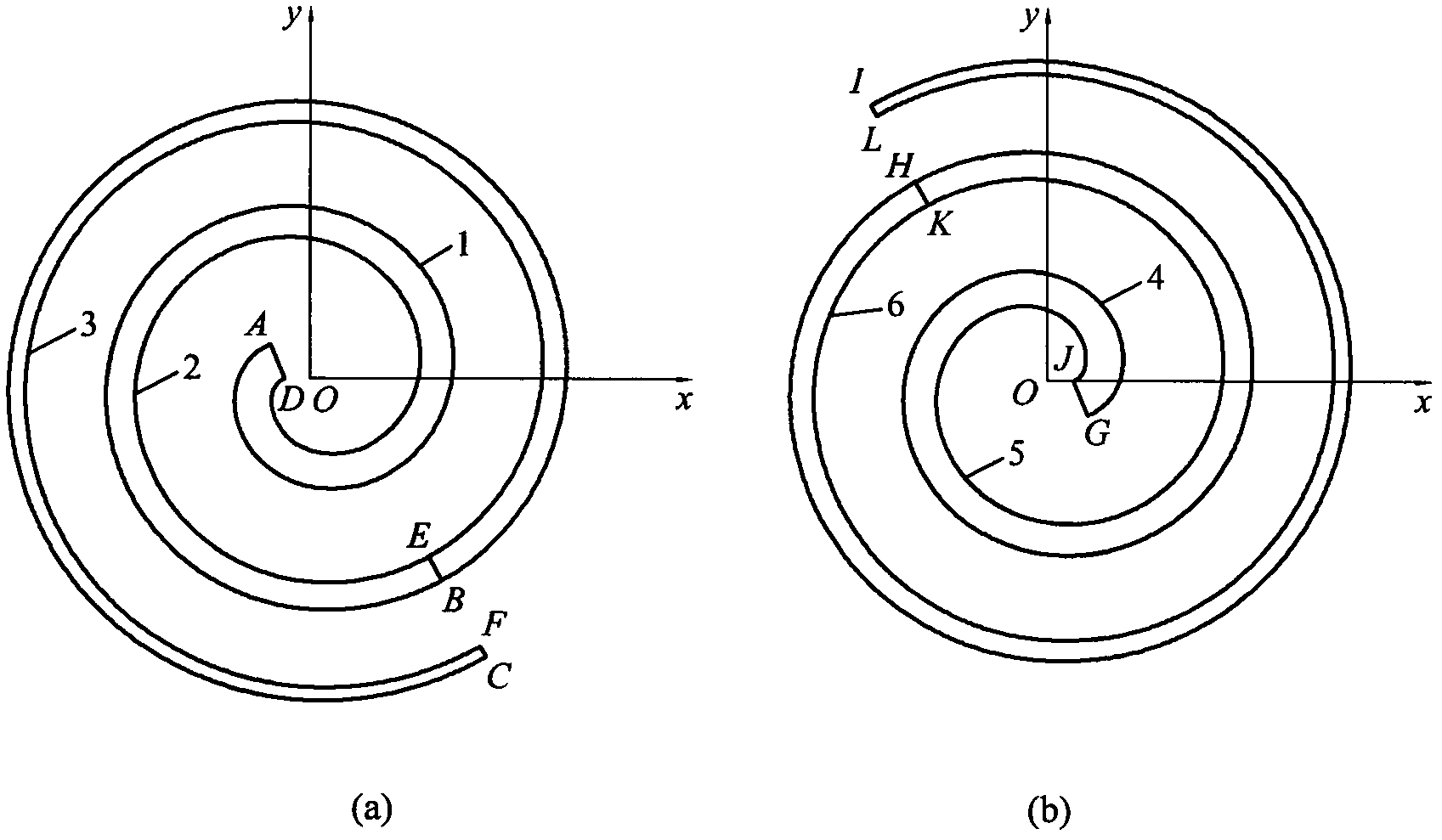

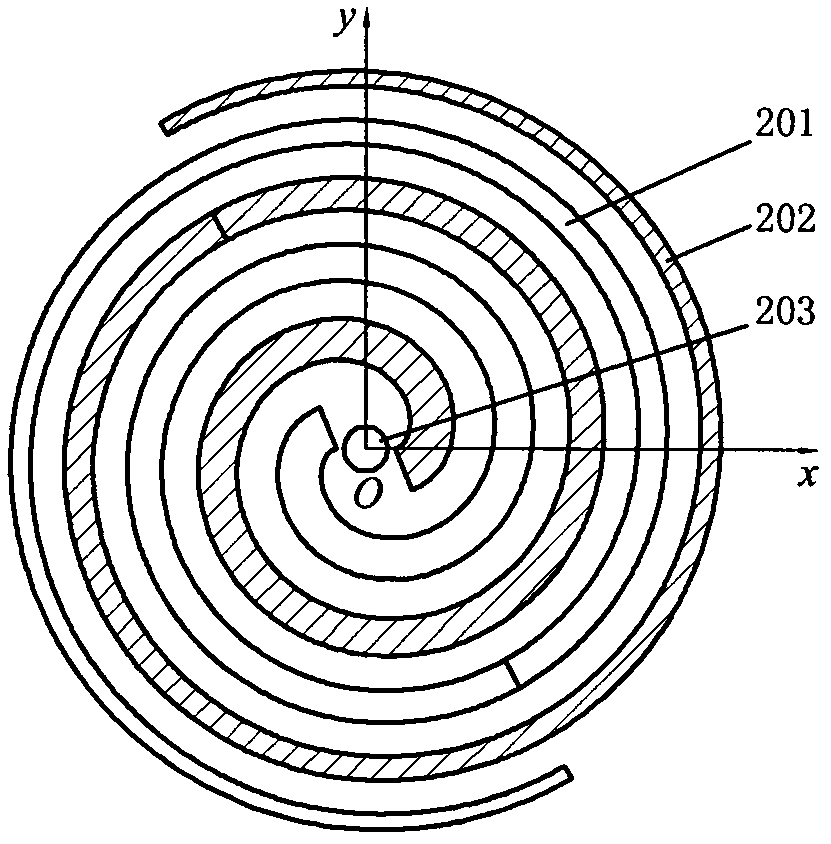

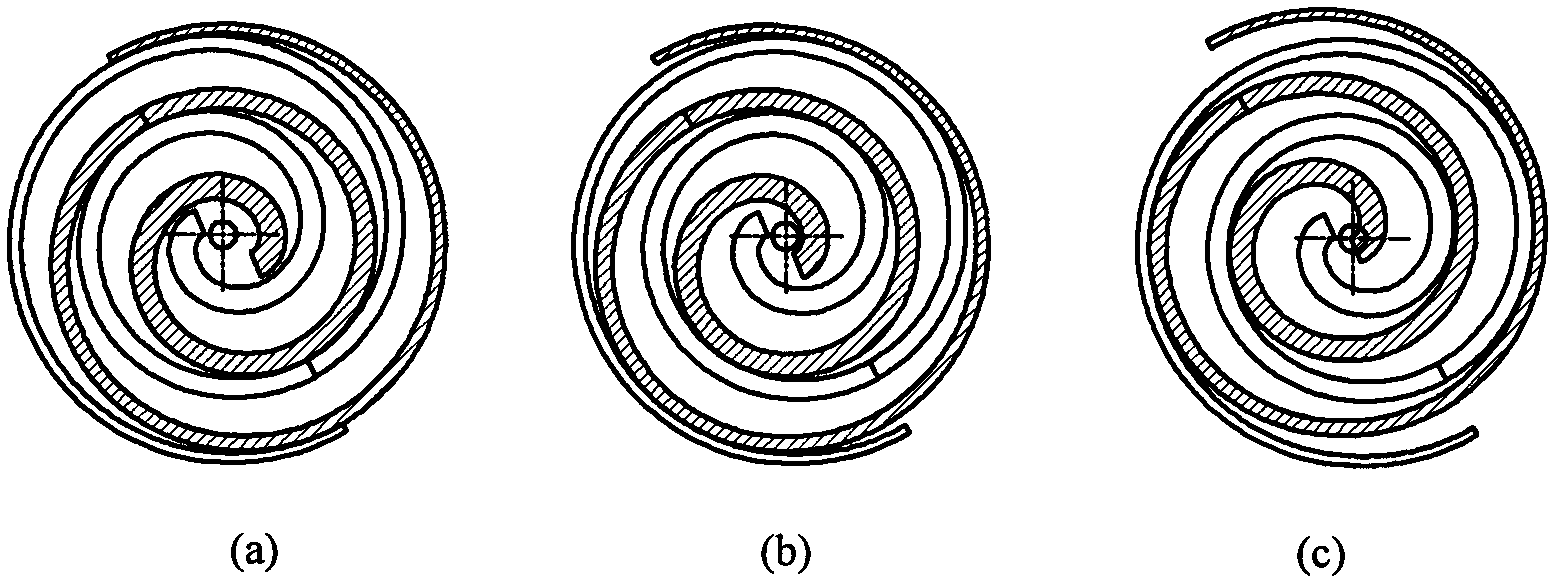

[0016] Such as figure 1 As shown, it is the proposed spiral tooth profile with variable meshing clearance and gradual wall thickness, (a) is the fixed scroll, (b) is the moving scroll, the fixed scroll and the moving scroll The profile lines are exactly the same, staggered by 180°. The outer profiles of the fixed scroll and the orbiting scroll are both composed of a variable-diameter base circle involute, and the inner profiles are composed of two smoothly connected curves. To the outer circle are respectively: the involute of the base circle of variable diameter and the normal equidistant curve of the involute of the base circle of variable diameter. The equation of each curve is as follows:

[0017] Curve 1, the equation of the involute line ABC of the variable diameter base circle outside the static vortex is

[0018] x 1 ( t ) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com