Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

41 results about "Minimum ignition energy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

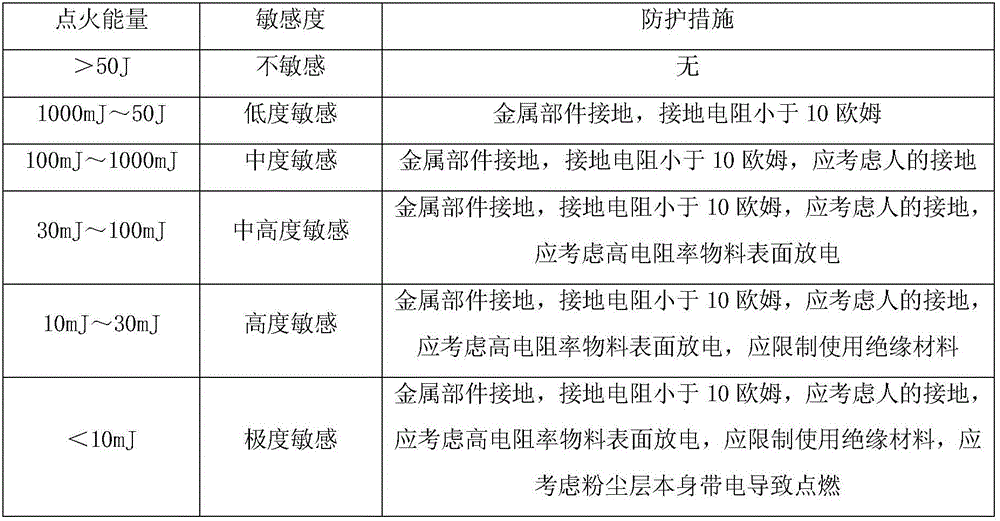

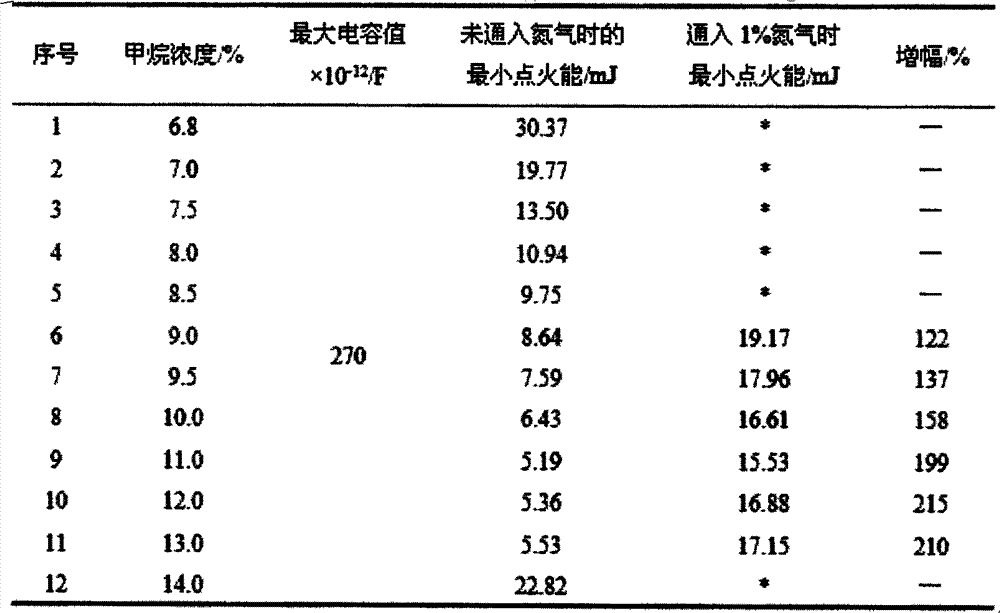

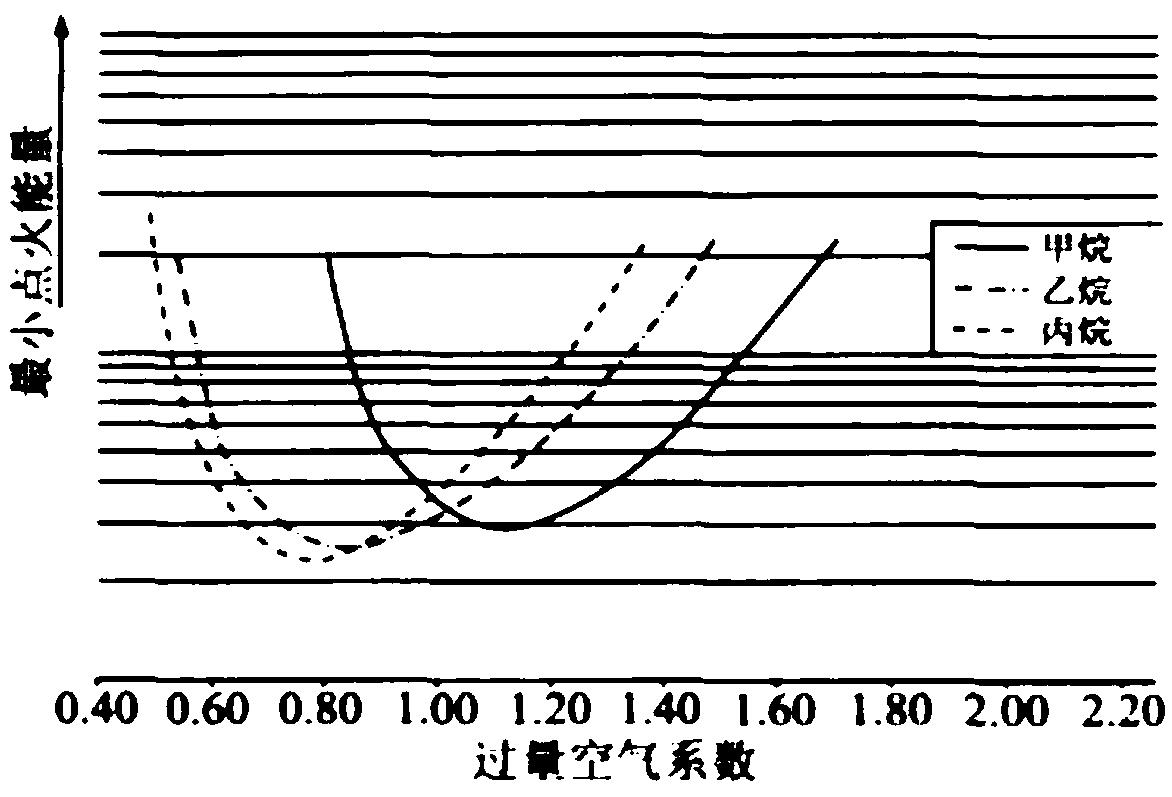

Minimum ignition energy is the minimum amount of energy required to ignite a combustible vapor, gas or dust cloud, for example by means of an electrostatic discharge. Ignition of a fuel/air mixture is possible only when the rate of liberation of heat near the ignition zone is greater than the heat loss by conduction. Heat loss due to radiation is not considered, as it is assumed to be negligible, and the ignition process is assumed to be steady and one-dimensional. MIE is measured in joules. Explosives, hydrogen, unsaturated hydrocarbons and alkanes in oxygen have the lowest MIE: in the range of 1 to 100 μJ. Alkanes in air, distillate fuels, hybrid mixtures and extremely sensitive dusts have a MIE range of 0.1 to 10 mJ. Combustible dusts have a MIE range of 0.01 to 10 J. The lowest ignition energy value occurs at the stoichiometric combustion concentration. For most materials this can be calculated from the carbon and hydrogen content and is typically about twice the lower flammable limit.

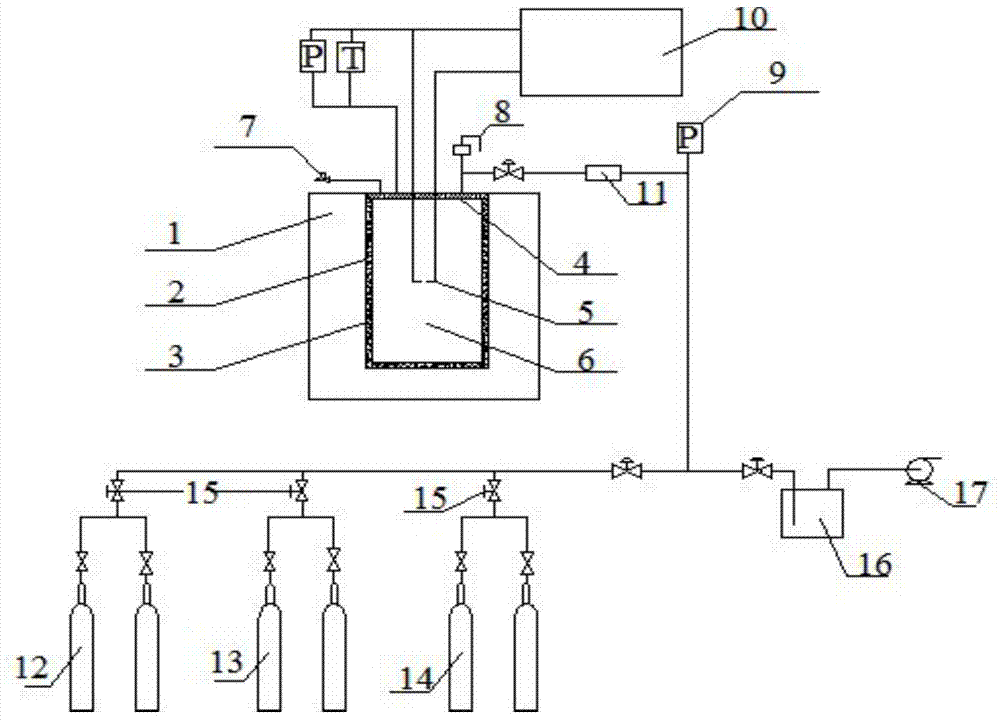

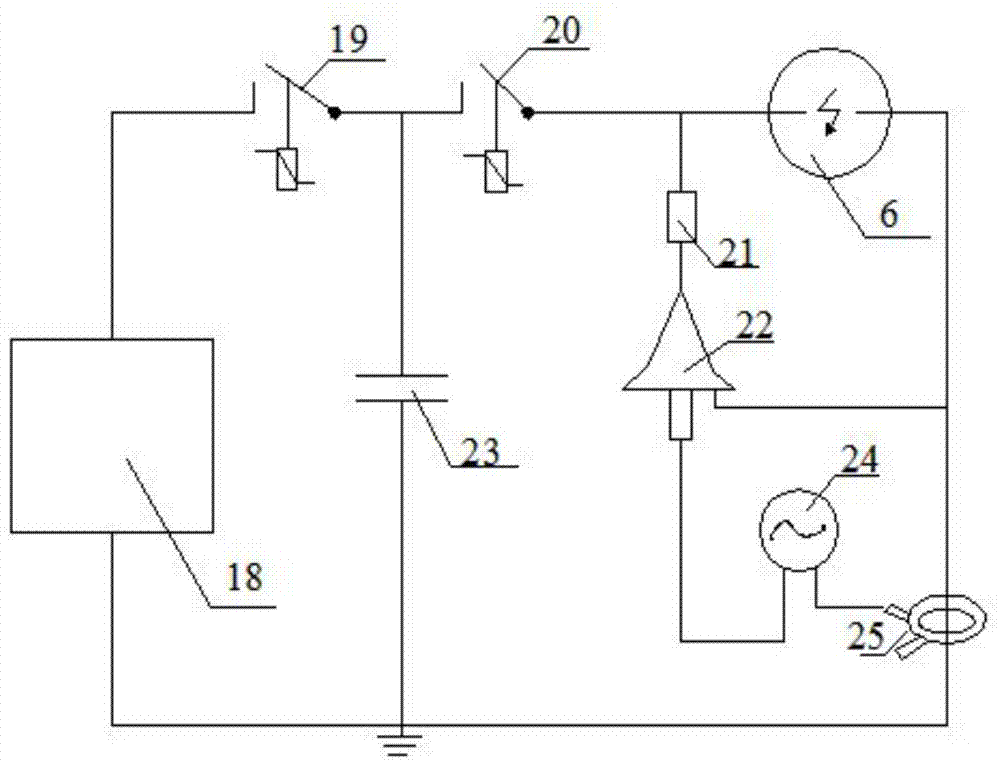

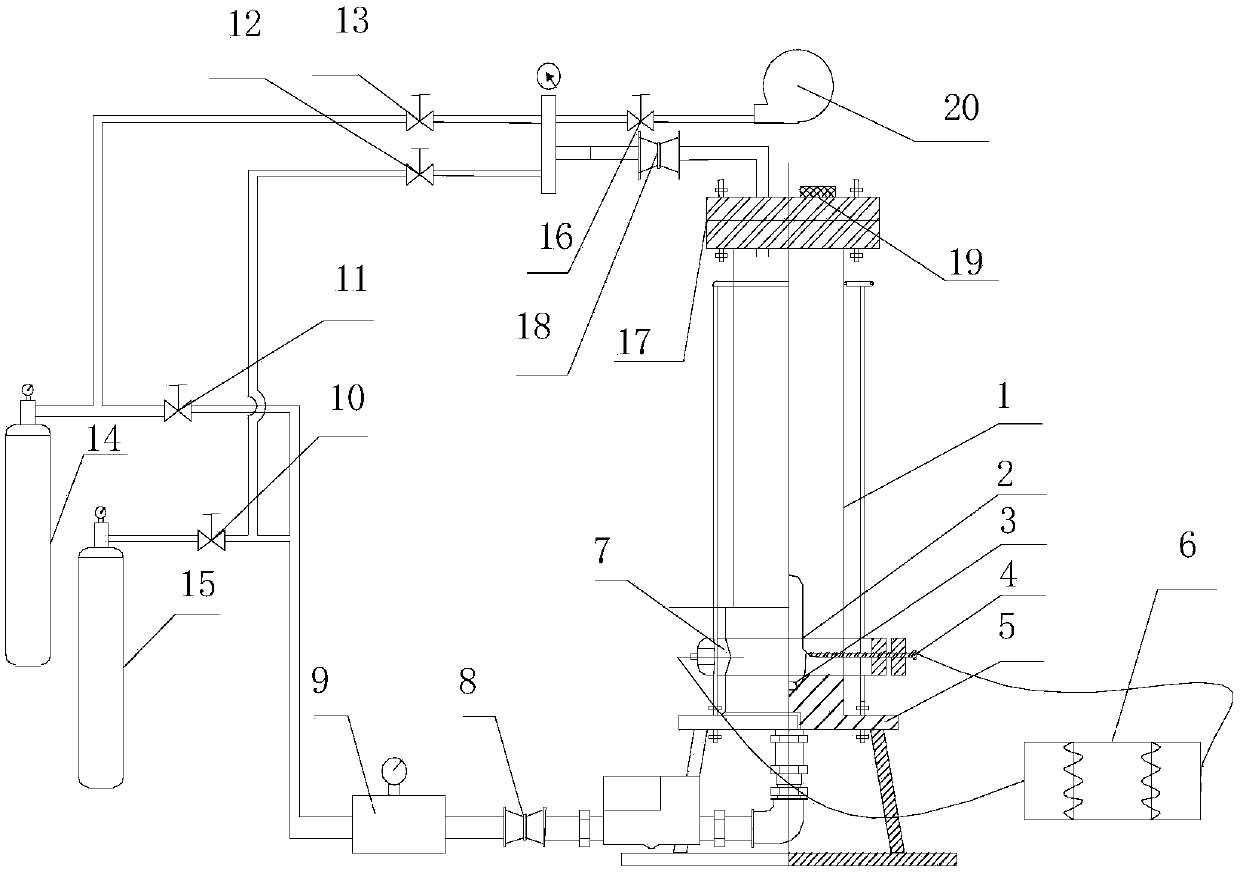

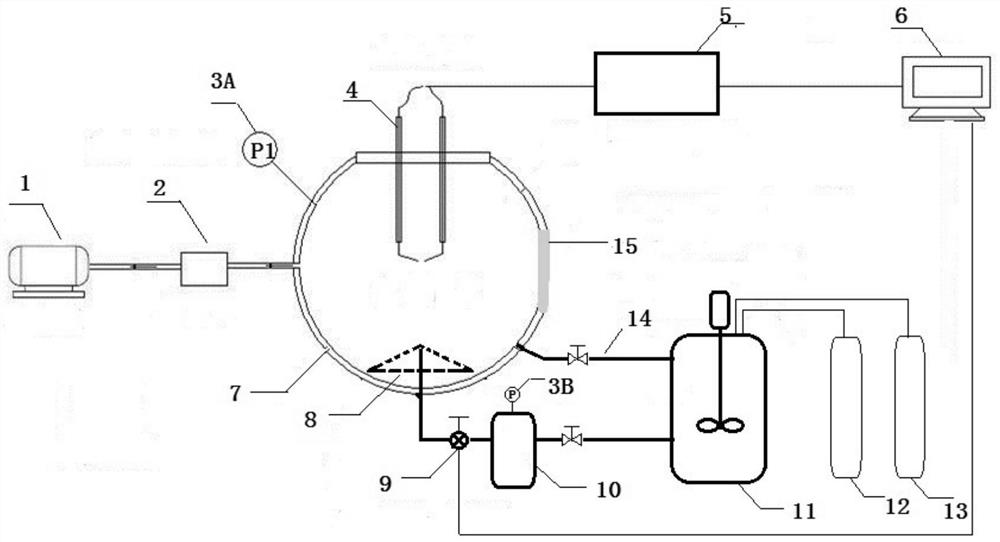

Ultralow temperature combustible gas explosion minimum ignition energy testing system and method

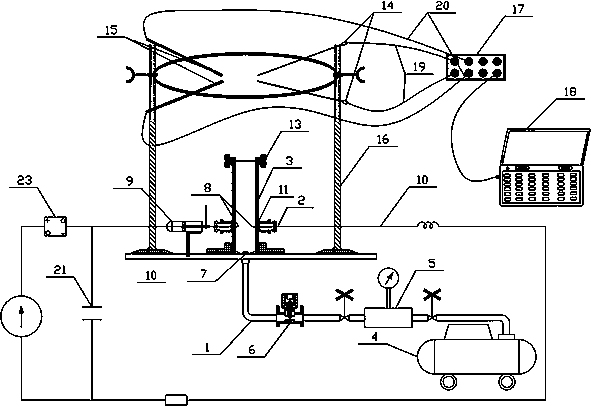

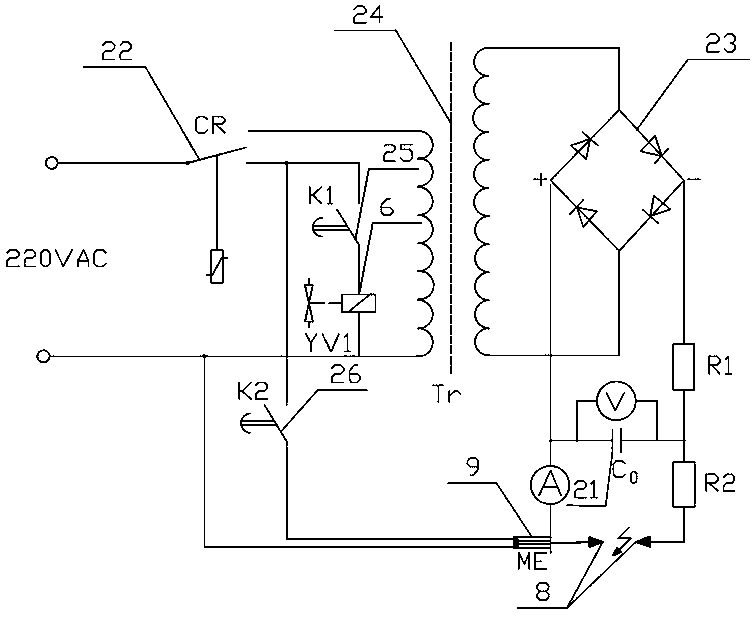

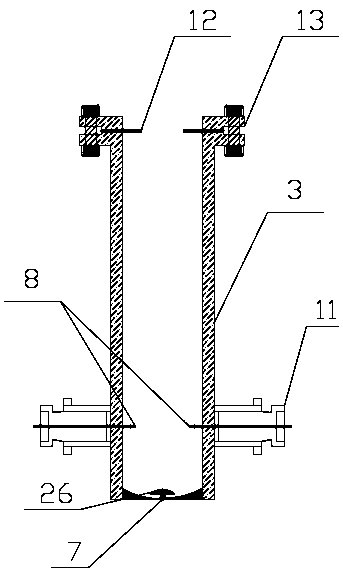

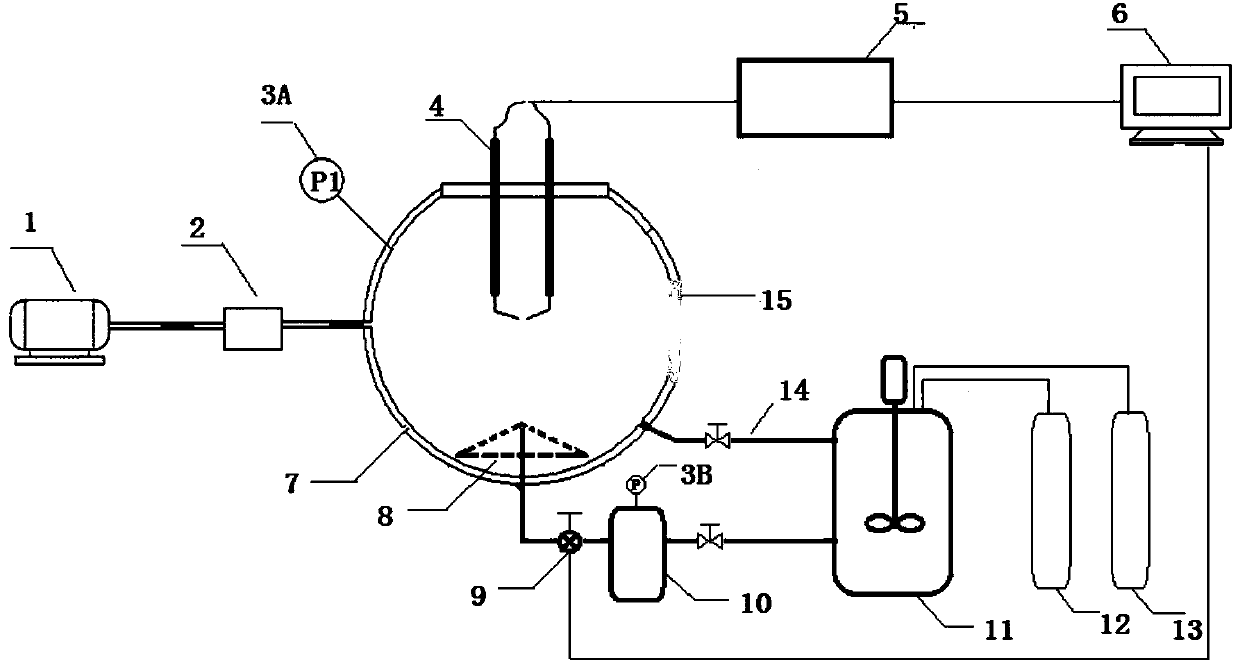

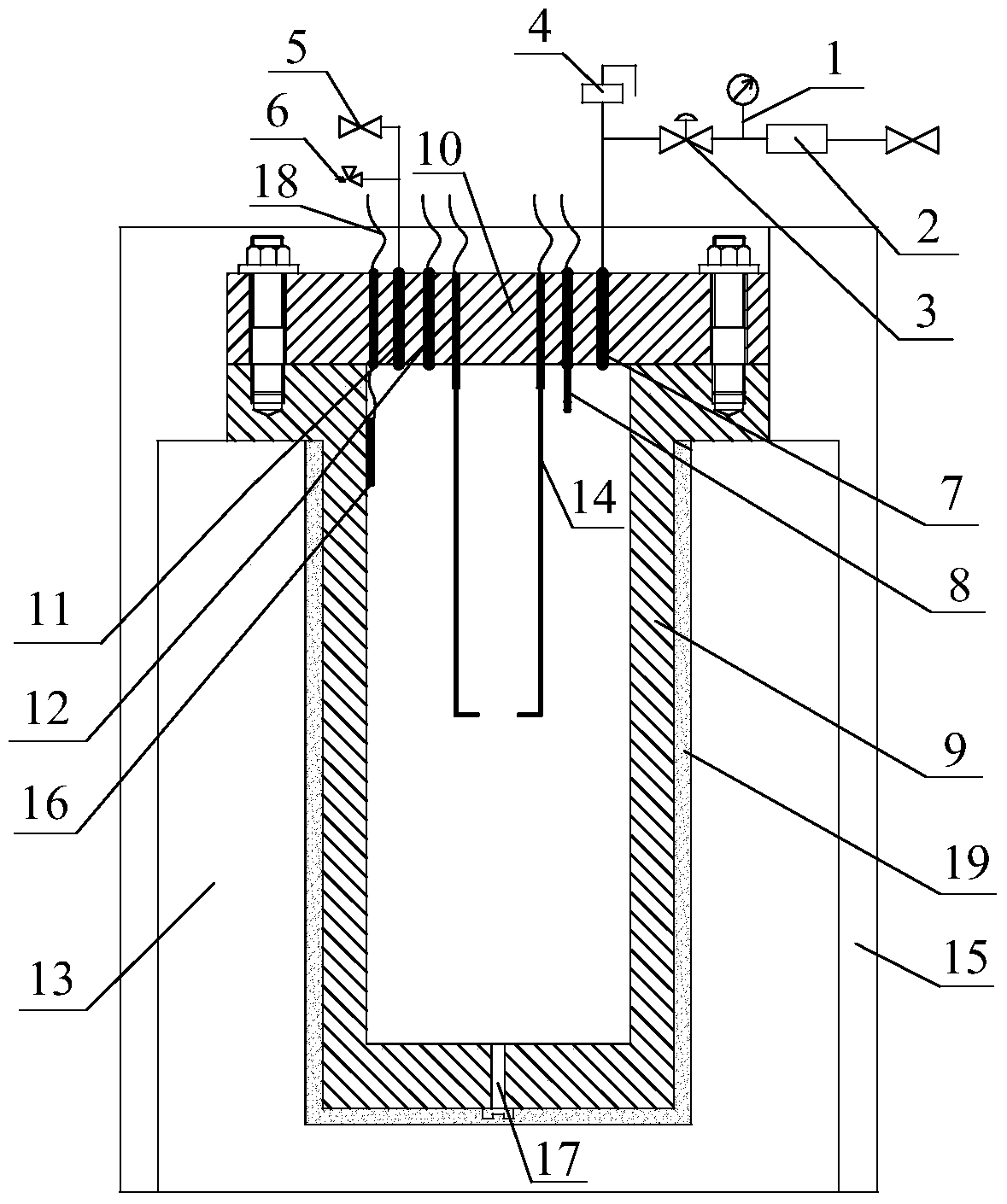

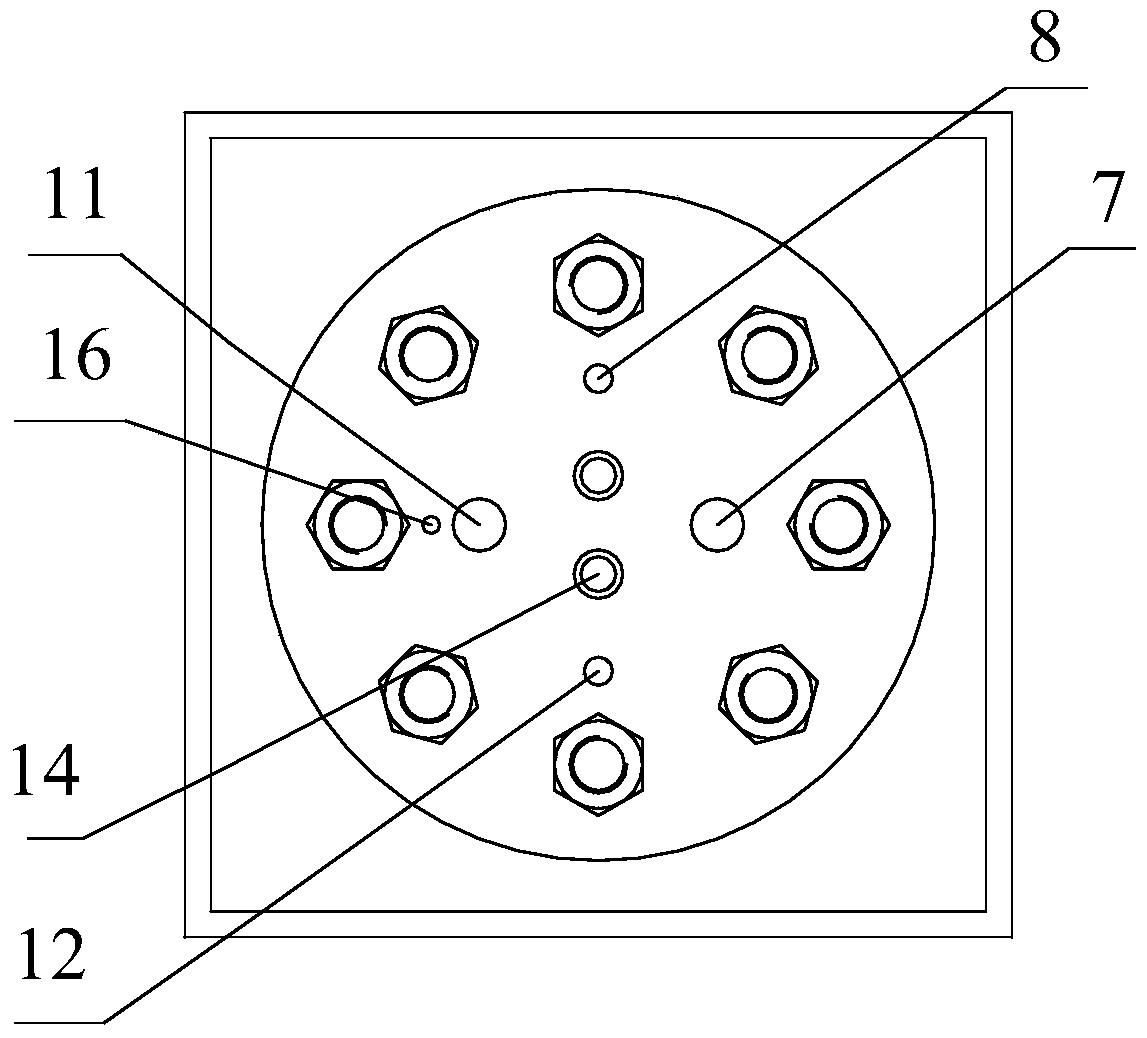

The invention relates to an ultralow temperature combustible gas explosion minimum ignition energy testing system and method. The testing system comprises a vacuumizing system, a gas distribution system, a refrigerating system, an integral circuit ignition system and a data acquiring system; an explosion container is installed in the refrigerating system, the vacuumizing system is connected with the explosion container through a connection pipeline of the gas distribution system, the gas distribution system is communicated with the inside of the explosion container through the connection pipeline thereof; the integral circuit ignition system comprises an ignition energy test table, an ignition electrode in the explosion container, a high pressure probe and a current transformer; the ignition energy test table is connected with the ignition electrode, the high pressure probe and the current transformer are respectively connected with the ignition energy test table and the ignition electrode; and the data acquiring system comprises a data acquirer, a pressure sensor and a temperature sensor which are respectively connected with the data acquirer and installed in the explosion container. The testing system disclosed by the invention is high in safety performance, precise in testing performance, and capable of precisely testing the minimum ignition energy of the combustible gas explosion under ultralow temperature and high pressure, the tested data have important significance for guiding the safety production of the oxygen-containing coal bed gas liquefication process.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Minimum ignition energy testing device

InactiveCN103954737AControl and Prevention of DetonationAvoid impenetrableFuel testingProcess engineeringEngineering

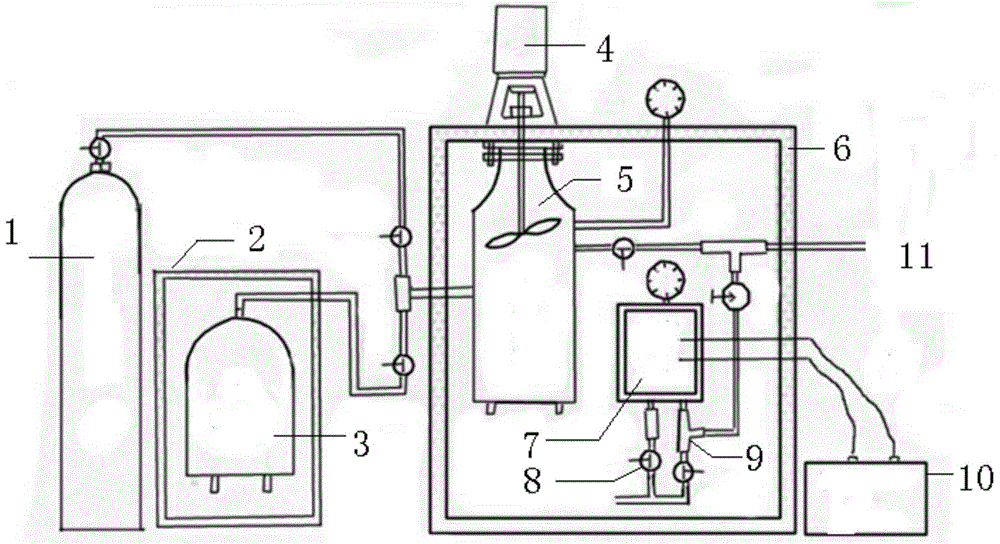

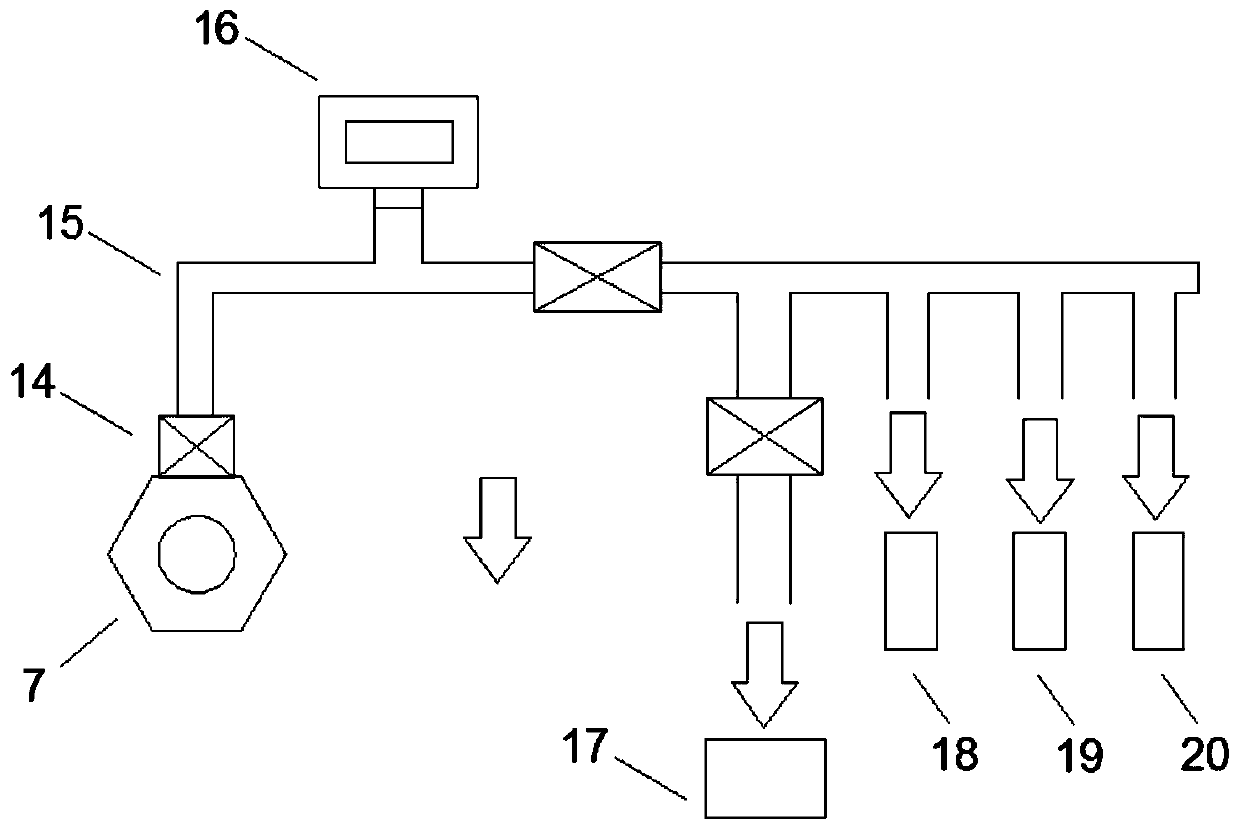

The invention relates to a minimum ignition energy testing device mainly used for solving problems of existing technology that testing temperature range is relatively narrow, and testing accuracy is relatively low. According to the minimum ignition energy testing device, the main body of a mixer (5) is provided with an air inlet pipeline, a steam inlet pipeline, and a mixed gas outlet pipeline; a stirrer (4) is arranged in the mixer (5); a reactor (7) is provided with an gas inlet (9); the two sides of the reactor (7) are provided with electrode regulators; one end of an ignition electrode is connected with the electrode regulators via threaded connection, and the other end is connected with a precise sparker (10); the mixed gas outlet pipeline of the mixer (5) is connected with the gas inlet (9) of the reactor (7); a connection pipeline between a mixed gas outlet of the mixer (5) and the gas inlet (9) of the reactor is connected with a vacuum pump. The minimum ignition energy testing device is capable of solving the above problems, and can be used for minimum ignition energy testing.

Owner:CHINA PETROLEUM & CHEM CORP +1

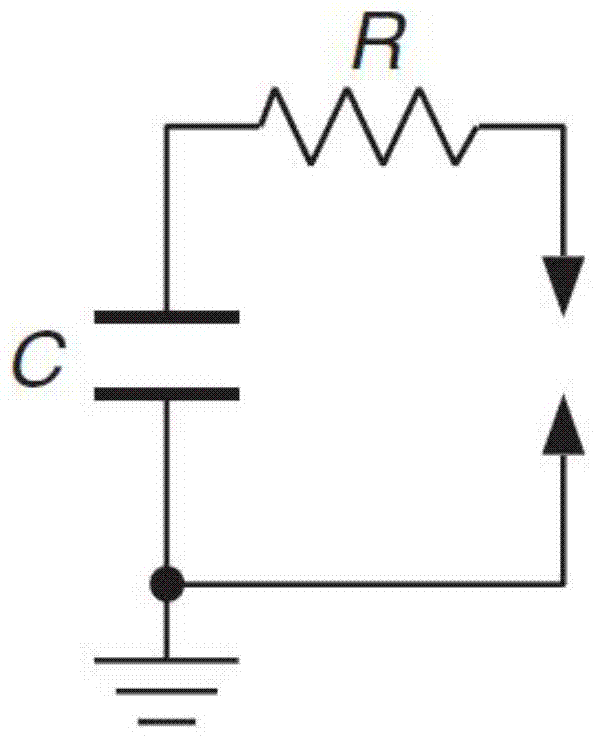

Method for determining charging capacitance of capacitor

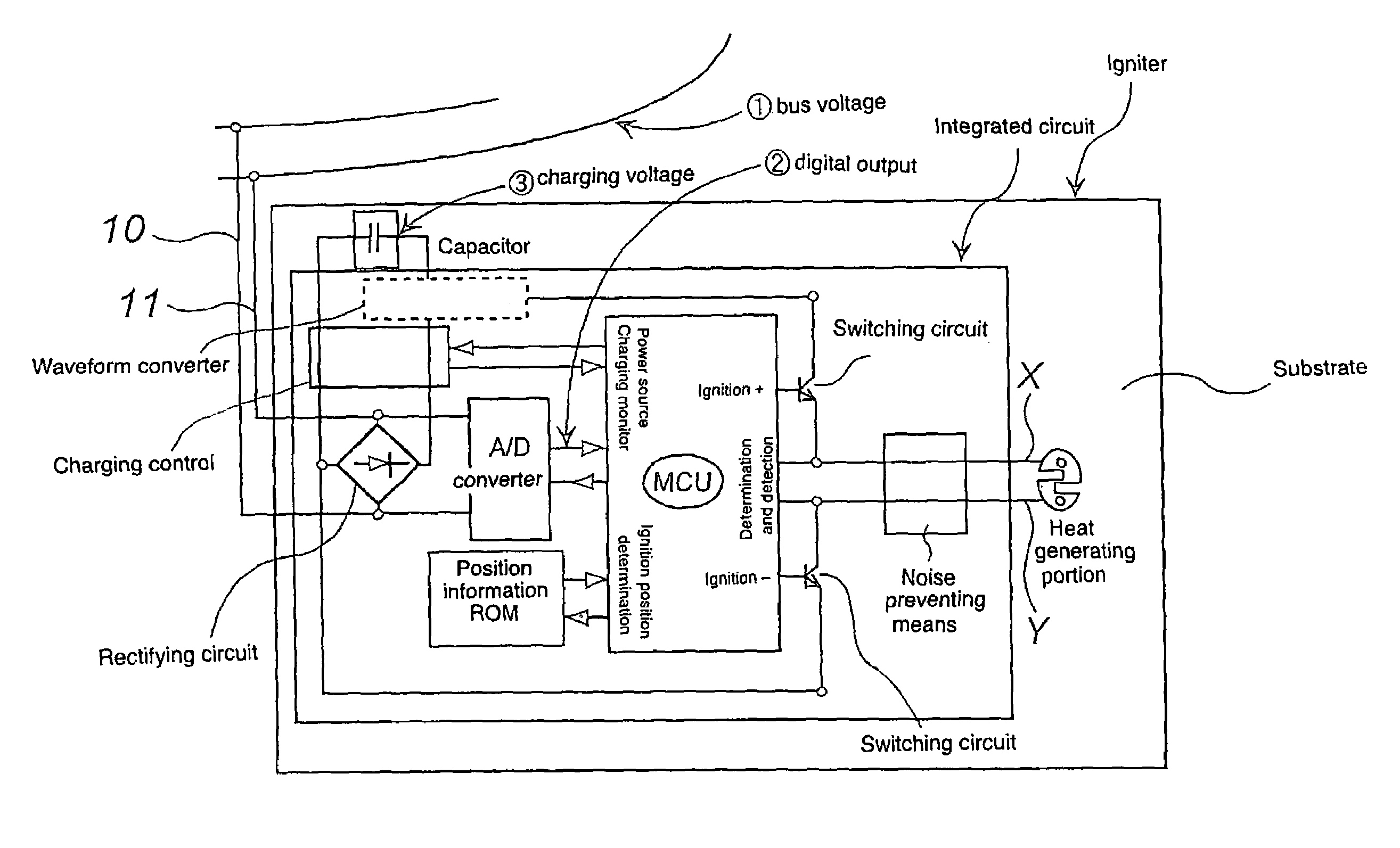

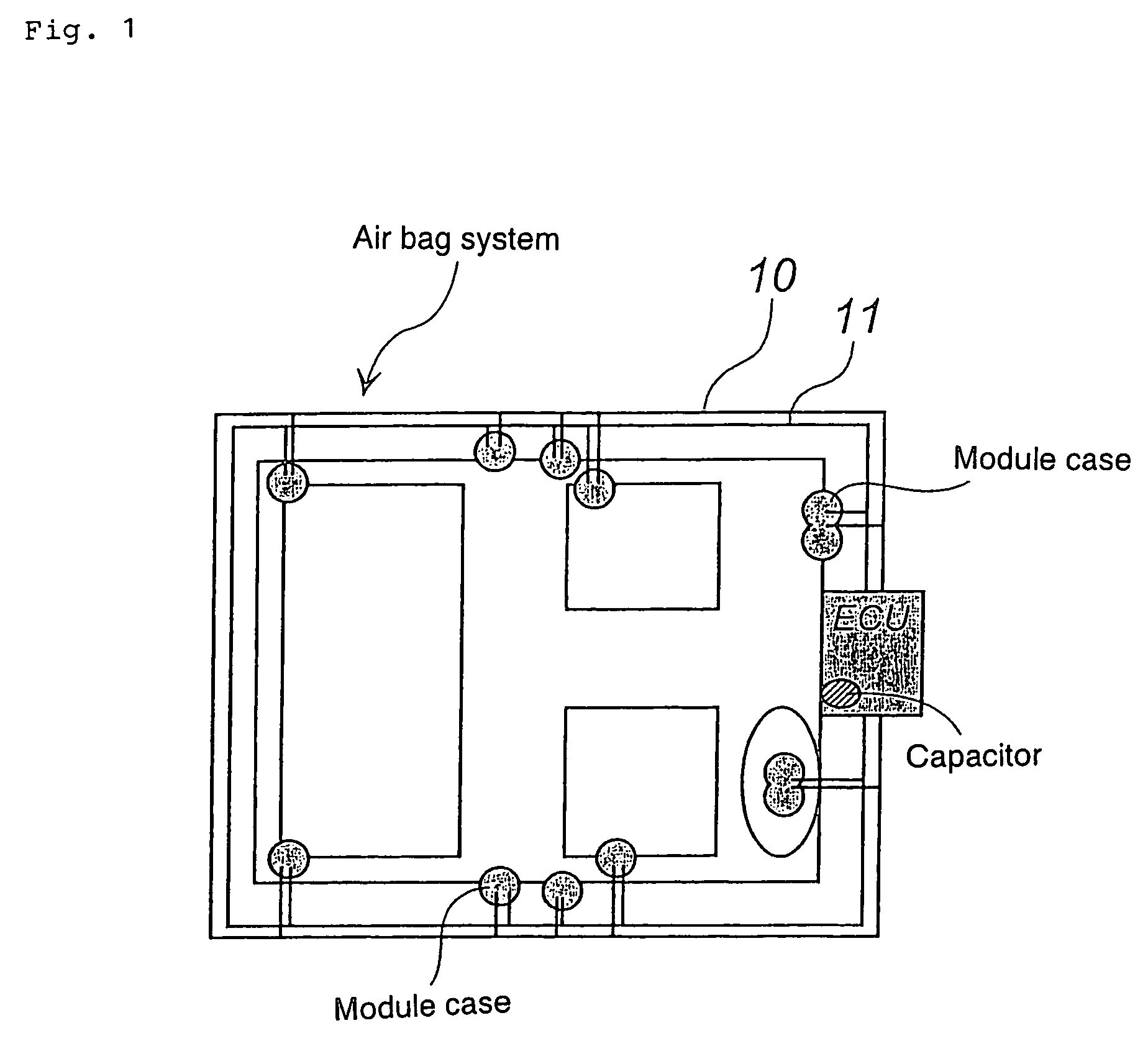

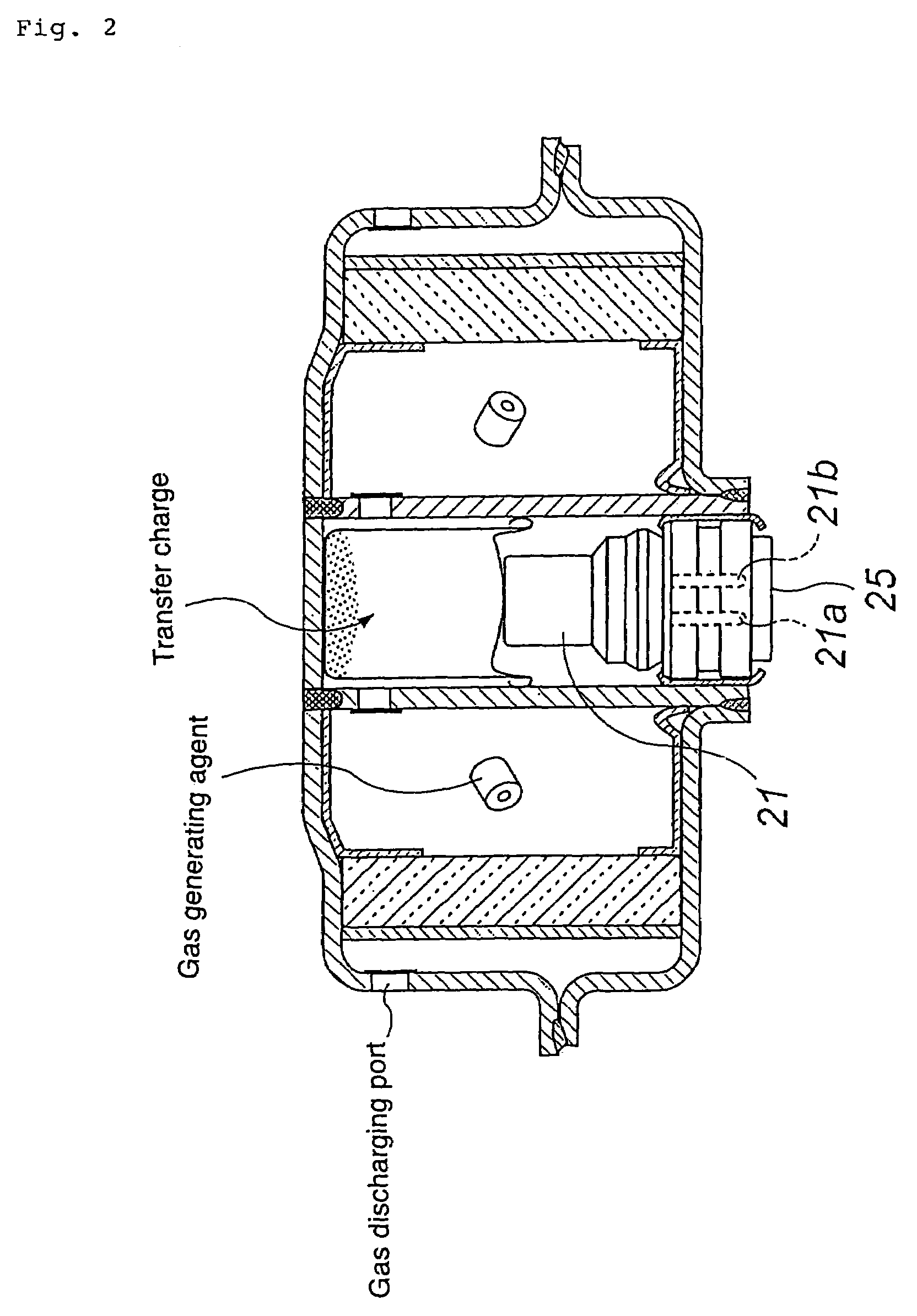

ActiveUS7155353B2Good adhesionReduce weightIncandescent ignitionResistance/reactance/impedenceCapacitanceMicrocomputer

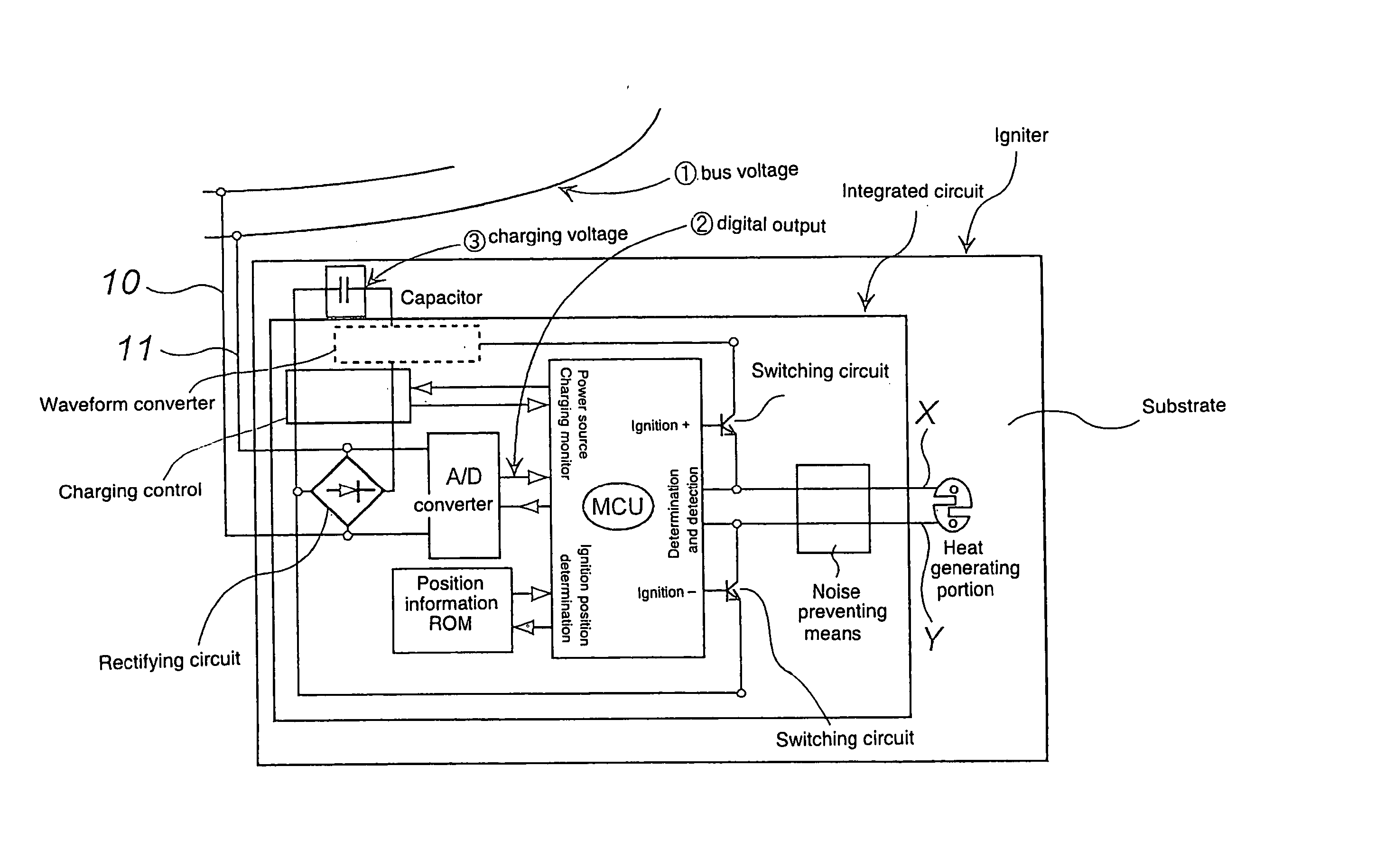

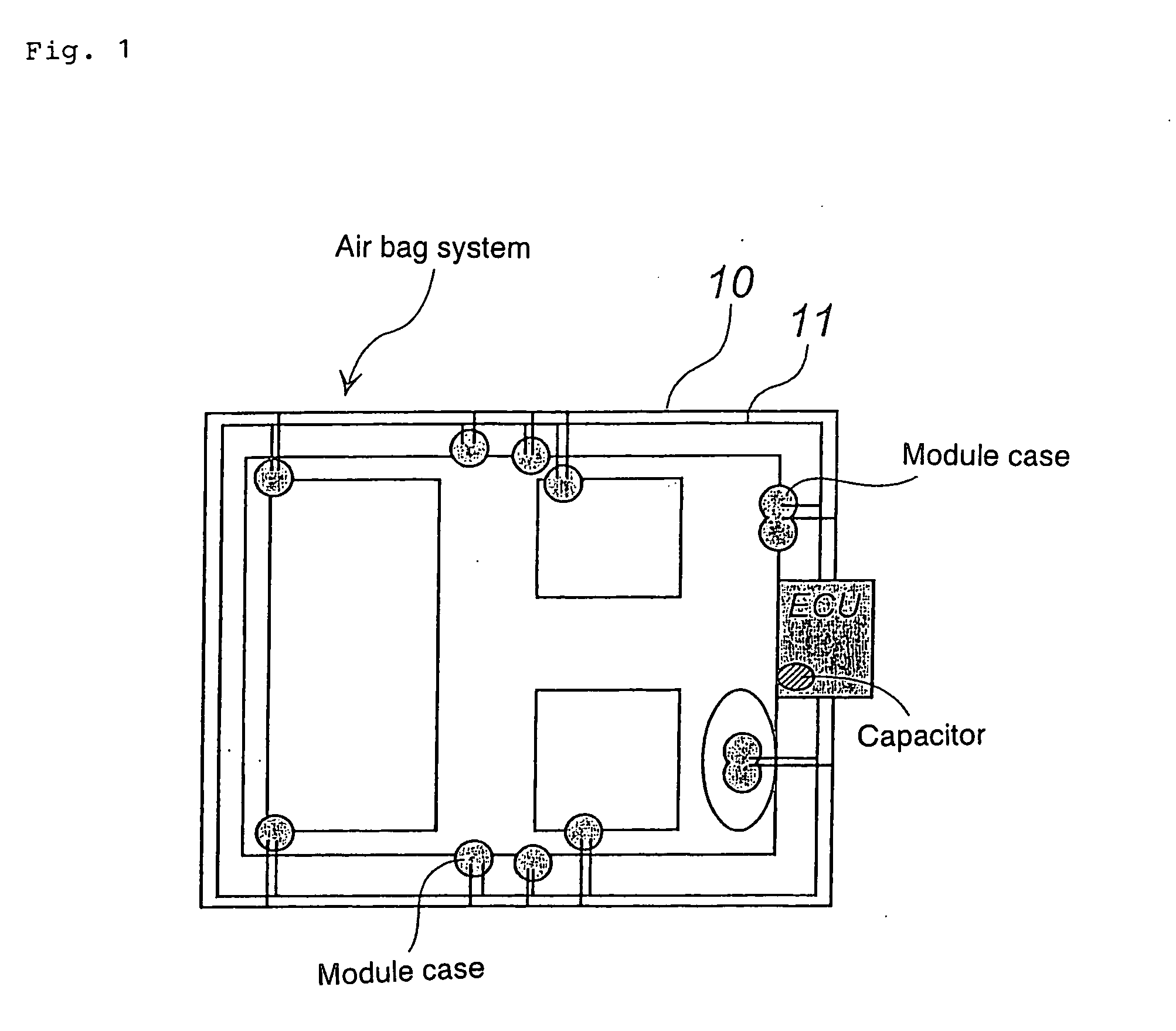

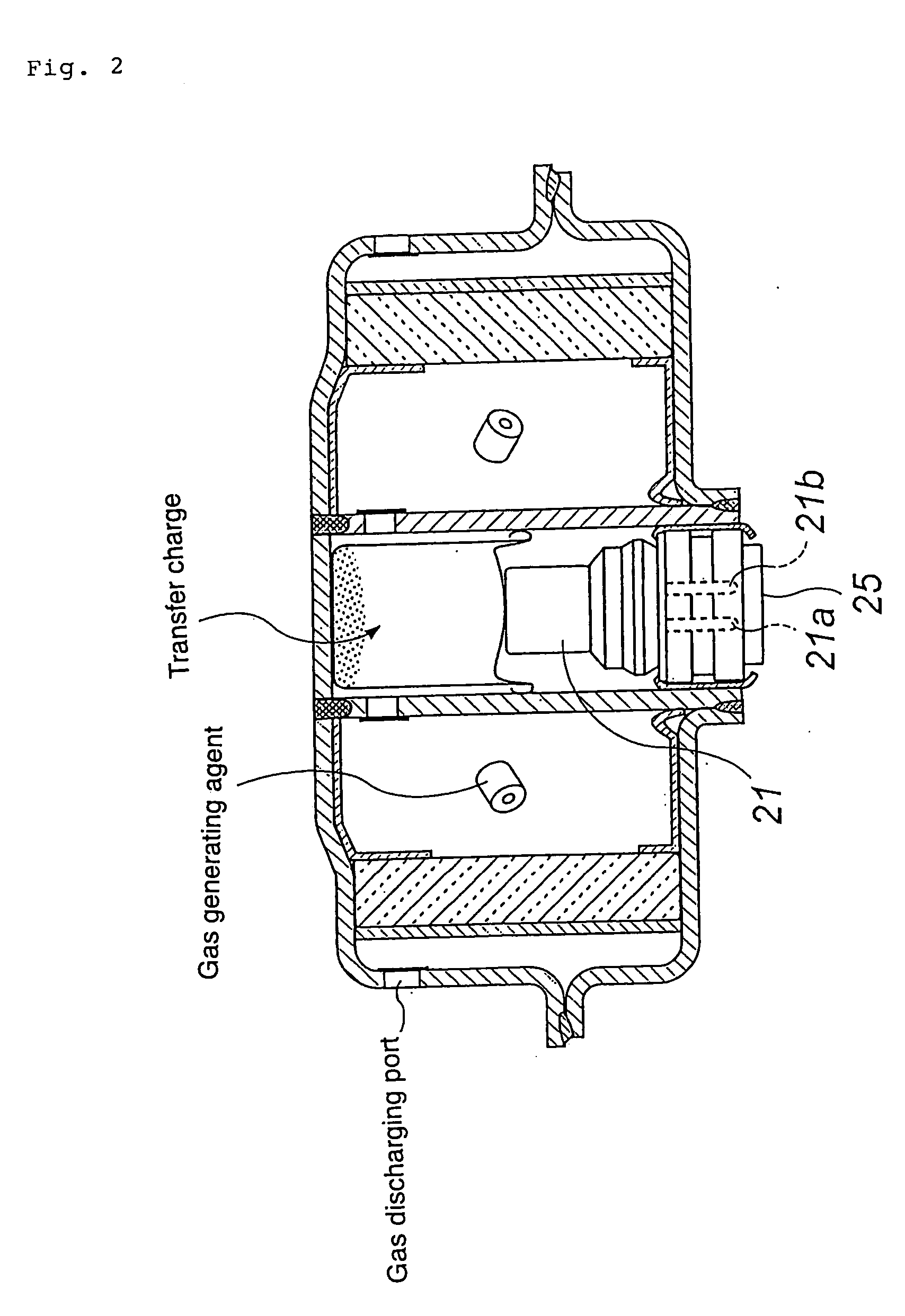

A method of determining a charging capacitance of a capacitor in an air bag system having an electronic control unit for controlling a gas generator, a bus line having a loop wire extending from the electronic control unit, gas generators connected to the loop wire, each gas generator having an igniter connected to the loop wire via a connector, one of the igniter and the connector being provided with an integrated circuit having the capacitor for providing power to a heat generating portion, a switching circuit for turning ON / OFF a supplying of current to the heat generating portion, and a microcomputer unit for controlling the switching circuit, the method including, determining a minimum charging capacitance of the capacitor necessary to operate the igniter based on a charging voltage and a minimum ignition energy required for making the heat generating portion of the igniter generate heat to ignite the priming.

Owner:DAICEL CHEM IND LTD

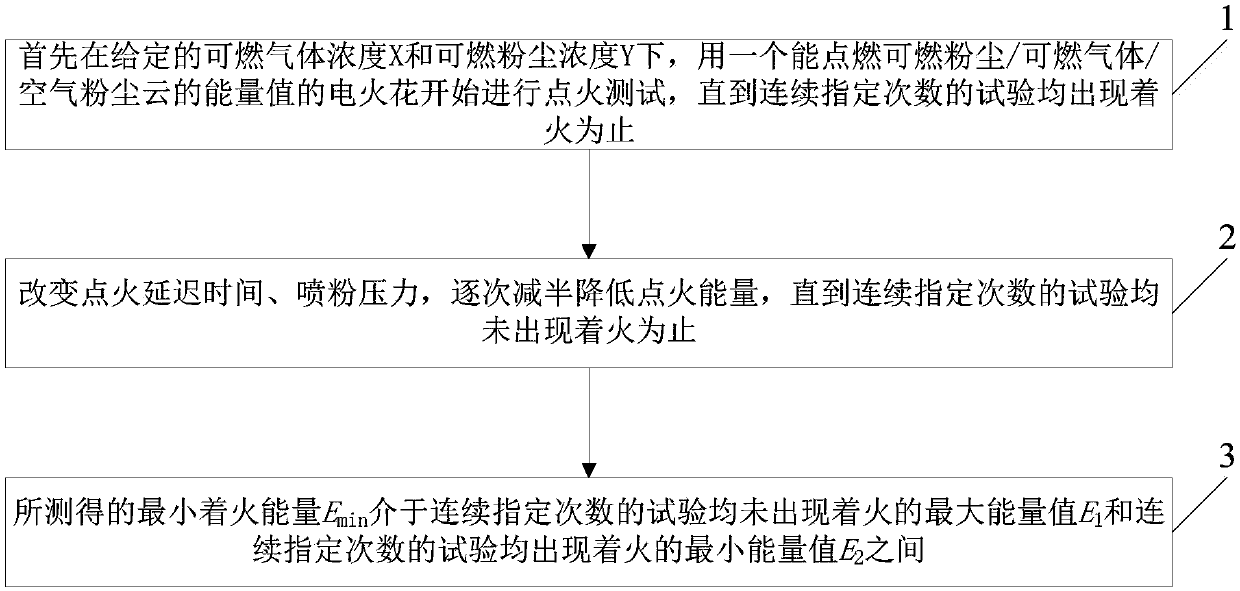

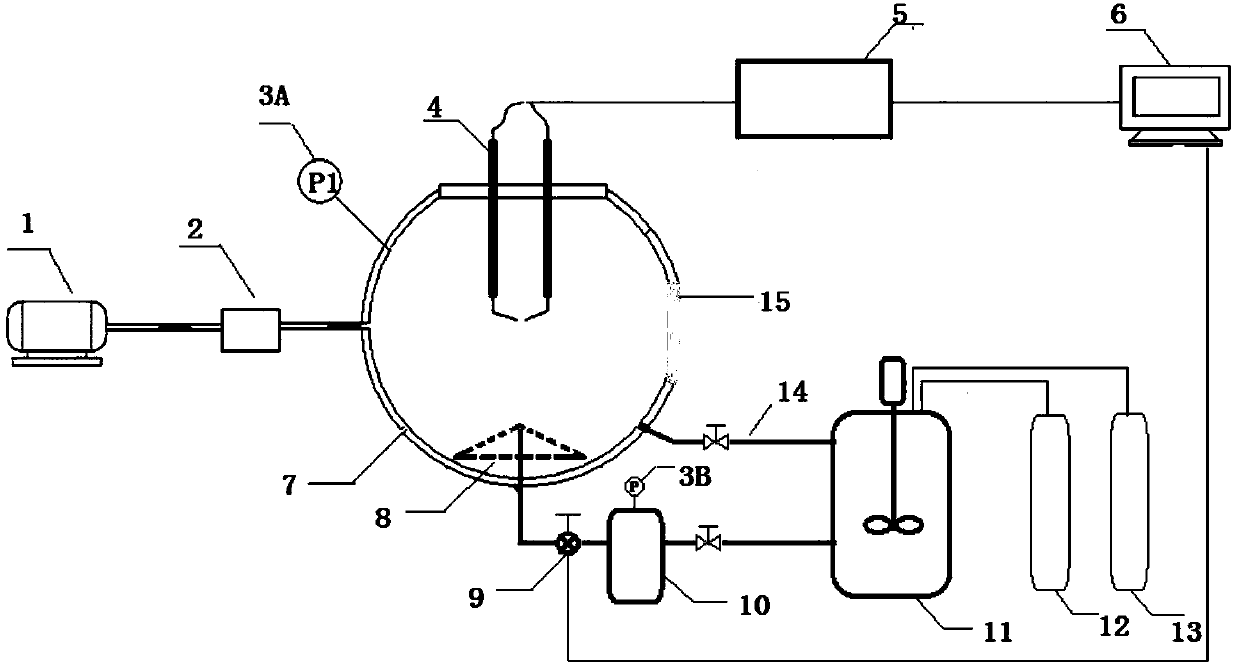

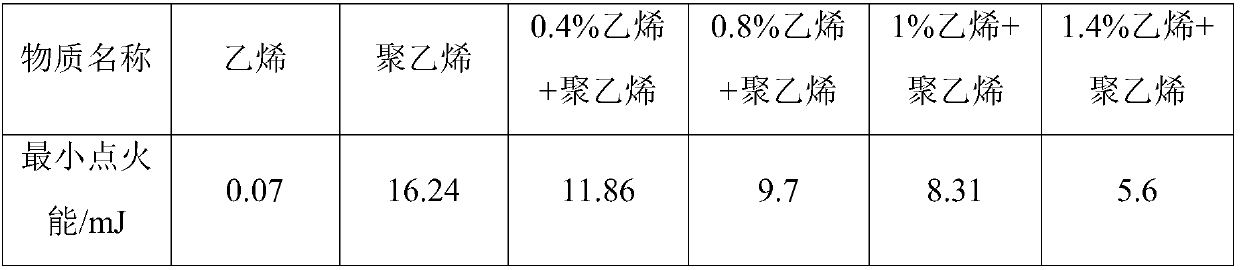

Method and device for testing minimum ignition energy of combustible dust/combustible gas mixture

PendingCN107782480AEvenly distributedAccurately measure the minimum ignition energyMeasurement of explosion forceInlet valveEngineering

The invention discloses a method and device for testing the minimum ignition energy of a combustible dust / combustible gas mixture. The device comprises a quartz glass tube, an ignition electrode, a diffuser, a copper sleeve, a base, a high-voltage discharging device, an ignition electrode joint seat, a gas storage tank, a first air inlet valve, a second air inlet valve, a third air inlet valve, afourth air inlet valve, a first compressed gas bottle, a second compressed combustible gas bottle, a control valve, a blind flange, an explosion venting valve and a vacuum pump, wherein the quartz glass tube is vertically fixed at the base through bottom threads; the ignition electrode is fixed at the lower part of the quartz glass tube through the ignition electrode joint seat and the copper sleeve; and the diffuser is used for raising dust covering the surface of the diffuser up through airflow so as to form dust cloud. By improving a gas distribution technique and a powder spraying technique, the uniform distribution of the combustible dust / combustible gas mixture in air is realized in the ignition moment, so that the minimum ignition energy of the combustible dust / combustible gas mixture can be accurately detected.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

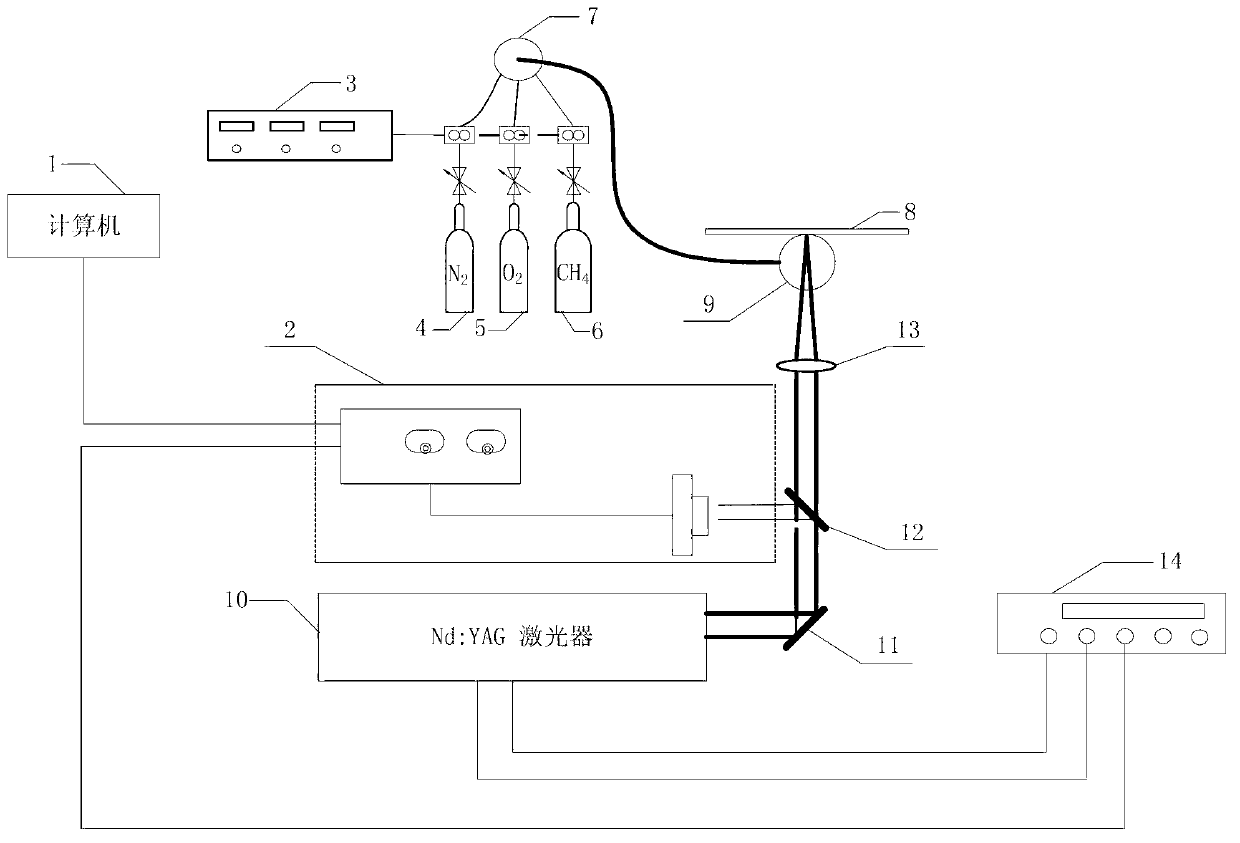

Method for enabling laser to induce metal target plasma to achieve ignition of flammable gas and device for achieving same

InactiveCN103343982AMiniaturizationPromote engineering applicationCombustion ignitionLight beamCombustible gas

The invention provides a method for enabling laser to induce metal target plasma to achieve ignition of flammable gas and a device for achieving the method, and relates to the method for achieving ignition of the flammable gas and the device for achieving the method. The method and the device for achieving the method solve the problem that an existing method for enabling laser to directly breakdown the gas to induce the plasma to conduct ignition is high in minimum ignition energy, low in ignition success rate and high in requirement for laser output energy. The method includes the steps of enabling premixed gas to enter a quartz tube, emitting a laser bundle through a Nd:YAG laser, focusing the bundle on the surface of a metal target, inducing the metal target to produce the plasma and igniting the premixed gas in the quartz tube. According to the device, the gas outlet of a premixing tank is communicated with the tail end of the quartz tube, the metal target is arranged on the side face, above the tube opening of the quartz tube, of the quartz tube, laser produced by the Nd:YAG laser is reflected to a spectroscope through a mirror and divided into reflected light and transmission light through the spectroscope, the first reflected light is emitted outward, and the transmission light penetrates through a lens and is focused on the metal target through the lens. The method and the device are suitable for situations where flammable gas ignition is needed.

Owner:HARBIN INST OF TECH

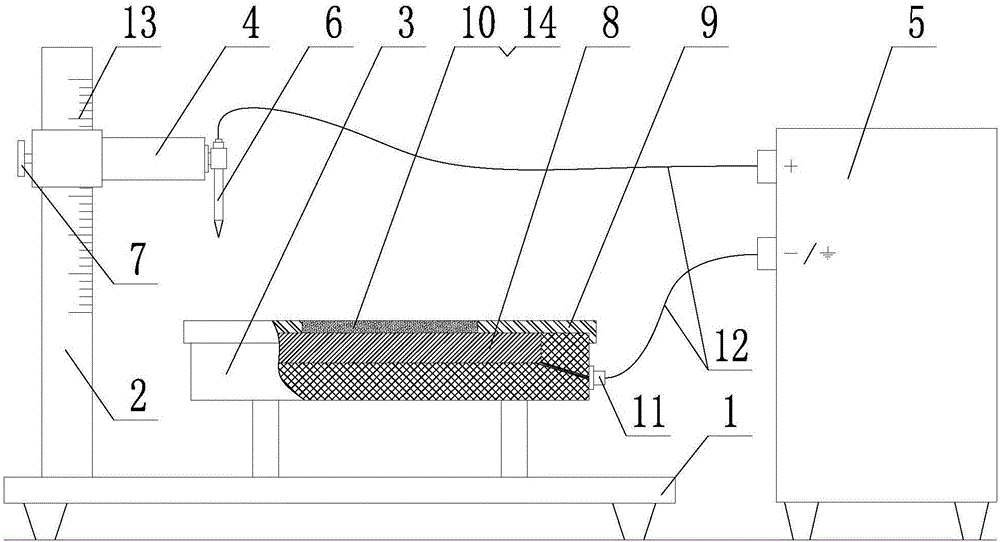

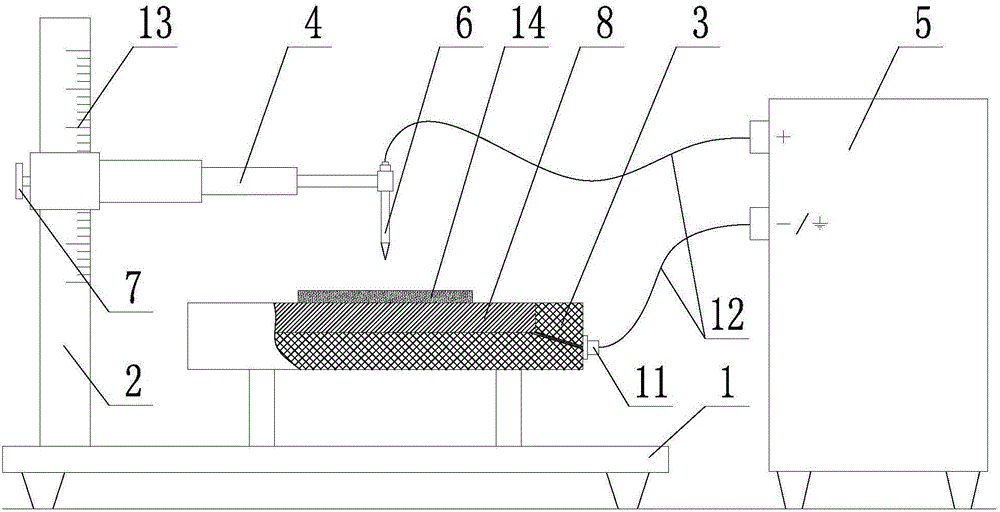

Dust-layer ignition sensitivity testing device and method under action of electric sparks

ActiveCN105891254AMeets fire susceptibility testsImprove the fire sensitivity evaluation index systemMaterial exposibilityInvestigating phase/state changeHigh energyMinimum ignition energy

The invention provides a dust-layer ignition sensitivity testing device and method under the action of electric sparks. The device comprises a base, a stand column, a dust carrying platform, a retractable cantilever beam and an electric spark generator, wherein a needle tip electrode is fixedly arranged at one end of the retractable cantilever beam, and the other end of the retractable cantilever beam sleeves the stand column; the dust carrying platform is provided with a dust drawing disc and a dust-layer preparation cover; an anode of the electric spark generator is connected with the needle tip electrode, and a cathode of the electric spark generator is conducted to the dust drawing disc. The method comprises the following steps: horizontally arranging the testing device and finishing wiring; controlling the retractable cantilever beam to be retracted back and preparing a dust layer according to a set thickness; controlling the retractable cantilever beam to be stretched so that the tip of the needle tip electrode is located just above the dust layer, and adjusting the distance between the needle tip electrode and the dust layer; starting the electric spark generator and outputting highest energy; identifying whether dust to be detected has ignition sensitivity or not; if so, preparing the dust layer again and carrying out a sensitivity test of the ignition sensitivity; measuring smallest ignition energy of the dust layer under different thicknesses through adjusting output energy of the electric spark generator and the thickness of the dust layer.

Owner:NORTHEASTERN UNIV

Method for determining charging capacitance of capacitor

ActiveUS20040095024A1Incandescent ignitionResistance/reactance/impedenceCapacitanceElectrical resistance and conductance

The present invention provides a method of determining a charging capacitance of a capacitor in an air bag system using a bus system. The method is a method of determining a charging capacitance of a capacitor in which a charging capacitance of a capacitor required for activating an air bag system normally is obtained from the following formula (I). C=l 2E / V<2> (I) (In the formula, C represents a capacitor charging capacitance, V represents a charging voltage, and E represents the minimum ignition energy required for making the heat generating portion of the igniter generate heat to ignite a priming, which is obtained by the following formula (II): E=Imin<2>x(Rmax+r1+r2)xT+wxl 10 (II) Imin: the minimum ignition current value (A) Rmax the maximum resistance value of the heat generating portion (Omega) r1: an ON resistance value of the switching circuit (the maximum ON resistance value at 150° C.) (Omega) r2: a resistance value of the other elements (Omega) T: a time period in which a current flows in the heat generating portion (sec) w: a power consumed by the whole integrated circuit when the switching circuit is OFF)

Owner:DAICEL CHEM IND LTD

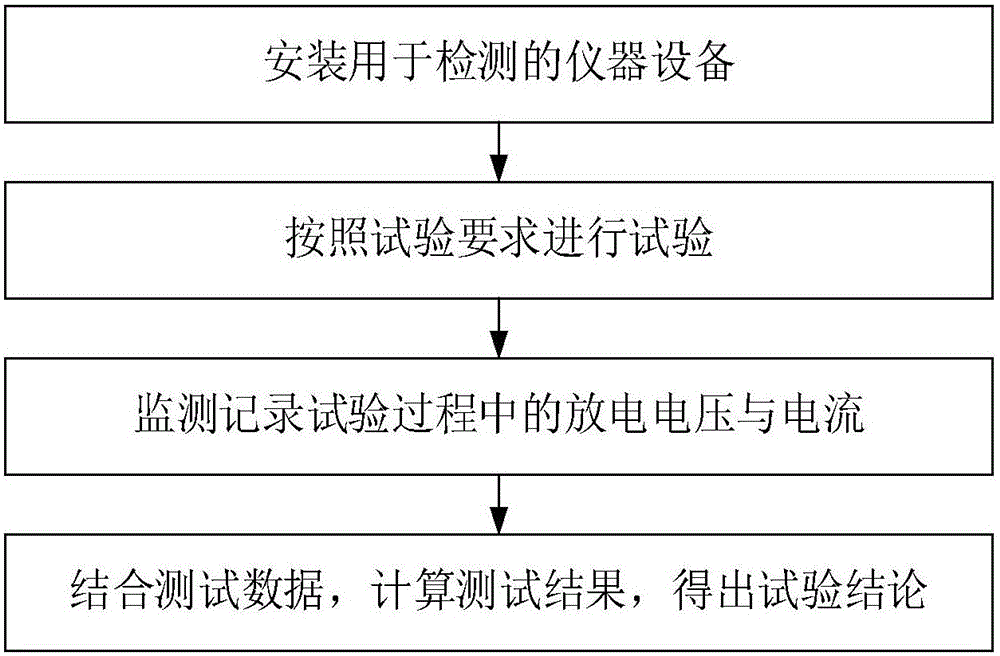

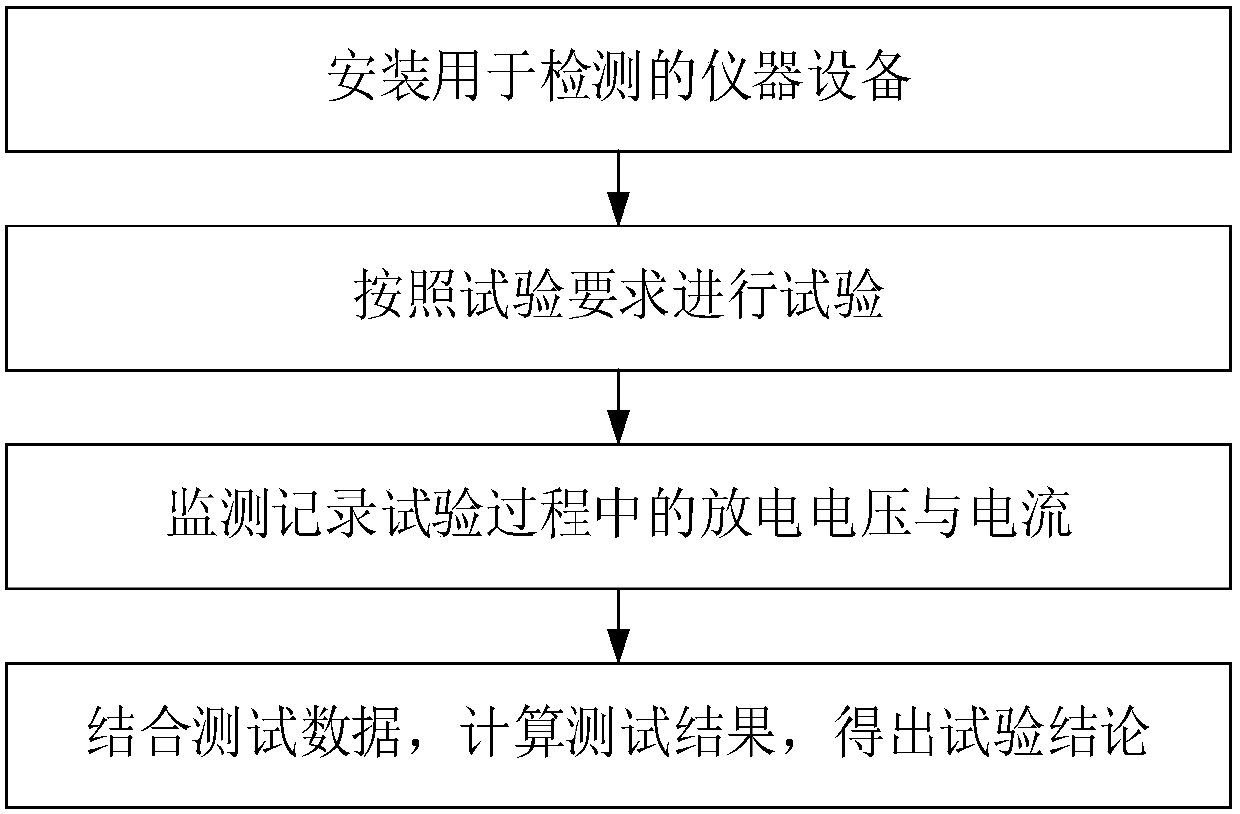

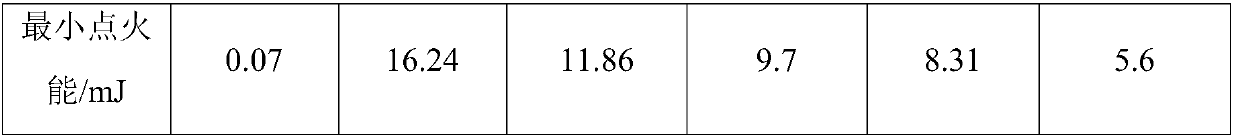

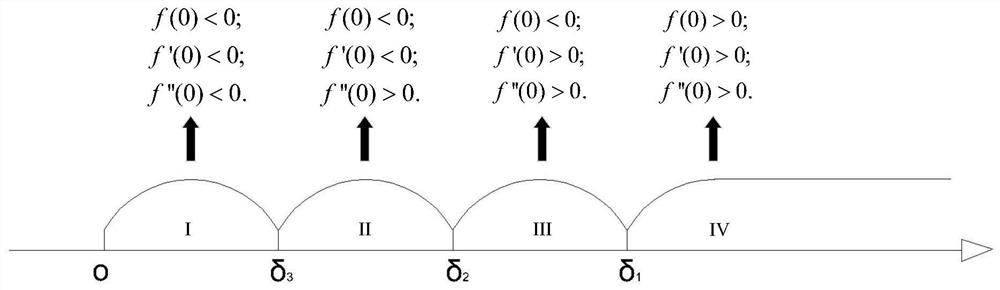

Method for determining minimum ignition energy of combustible gas in semi-open space

The invention discloses a method for determining minimum ignition energy of combustible gas in a semi-open space. The determination method disclosed by the invention is an up-and-down method. A comprehensive test device for the blasting characteristics of the combustible gas is mainly composed of a gas delivery and preparation system, a gas pre-mixing system, an explosion chamber, an ignition system and a data acquisition system. Main test items comprise a gas layered test, a gas concentration test, an explosion upper-limit and lower-limit test, an explosion pressure and temperature test, a minimum ignition energy test, an explosion process research, a combustible gas cloud formation and diffusion research, and an explosion suppression effect search. According to the method disclosed by the invention, the mixing of the combustible gas and air is relatively uniform; and the improved 20L gas explosion test device has the advantages of being practical, convenient, cheap and the like, and can be used as a standard test device and a demonstration device for scientific research and teaching in the safety engineering major and the fire and explosion protection major.

Owner:CHANGZHOU UNIV

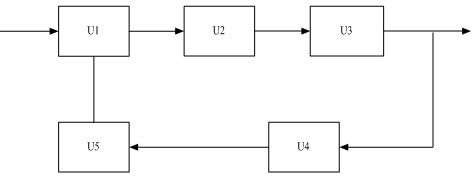

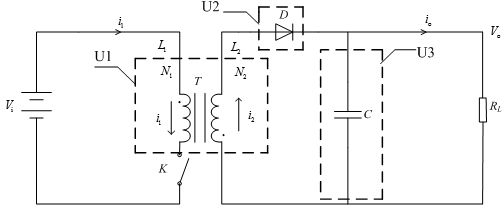

Intrinsic safety LED (Light Emitting Diode) driving power source with high power for mines

InactiveCN102595700ASimple structureExtended service lifeElectric light circuit arrangementEnergy saving control techniquesEngineeringPetrochemical

The invention relates to an intrinsic safety LED (Light Emitting Diode) driving power source with high power for mines and belongs to a driving power source for LED lamps. The intrinsic safety LED driving power source with high power comprises a high frequency flyback converter, a rectifying circuit, an output filtering circuit, a feedback circuit and a PWM (Pulse Width Modulation) controller, wherein an output end of the high frequency flyback converter is connected with the rectifying circuit; the output end of the rectifying circuit is connected with the output filtering circuit; the output end of the output filtering circuit is a circuit output end and simultaneously is connected with an input end of the feedback circuit; and the feedback circuit is connected with the high frequency flyback converter through the PWM controller. Compared with the prior art, the intrinsic safety LED driving power source has the advantages that the power source is always kept constant under the condition of changing a load or input voltage and output current, and when the short-circuiting happens in the output, the released energy is below the minimum ignition energy value of a gas, thereby the explosion is avoided; and the intrinsic safety LED driving power source has simple structure and long service life, is energy-saving and environment-friendly, is convenient to carry and is suitable for hazardous areas such as coal mines, petrochemical industries and the like.

Owner:CHINA UNIV OF MINING & TECH

Experimental device and method for measuring combustion and explosion characteristics of dust cloud

PendingCN109827994ADetermination of minimum ignition energyMeasuring pressureChemical analysis using combustionMaterial heat developmentData acquisitionInjection air

Owner:NINGBO UNIVERSITY OF TECHNOLOGY

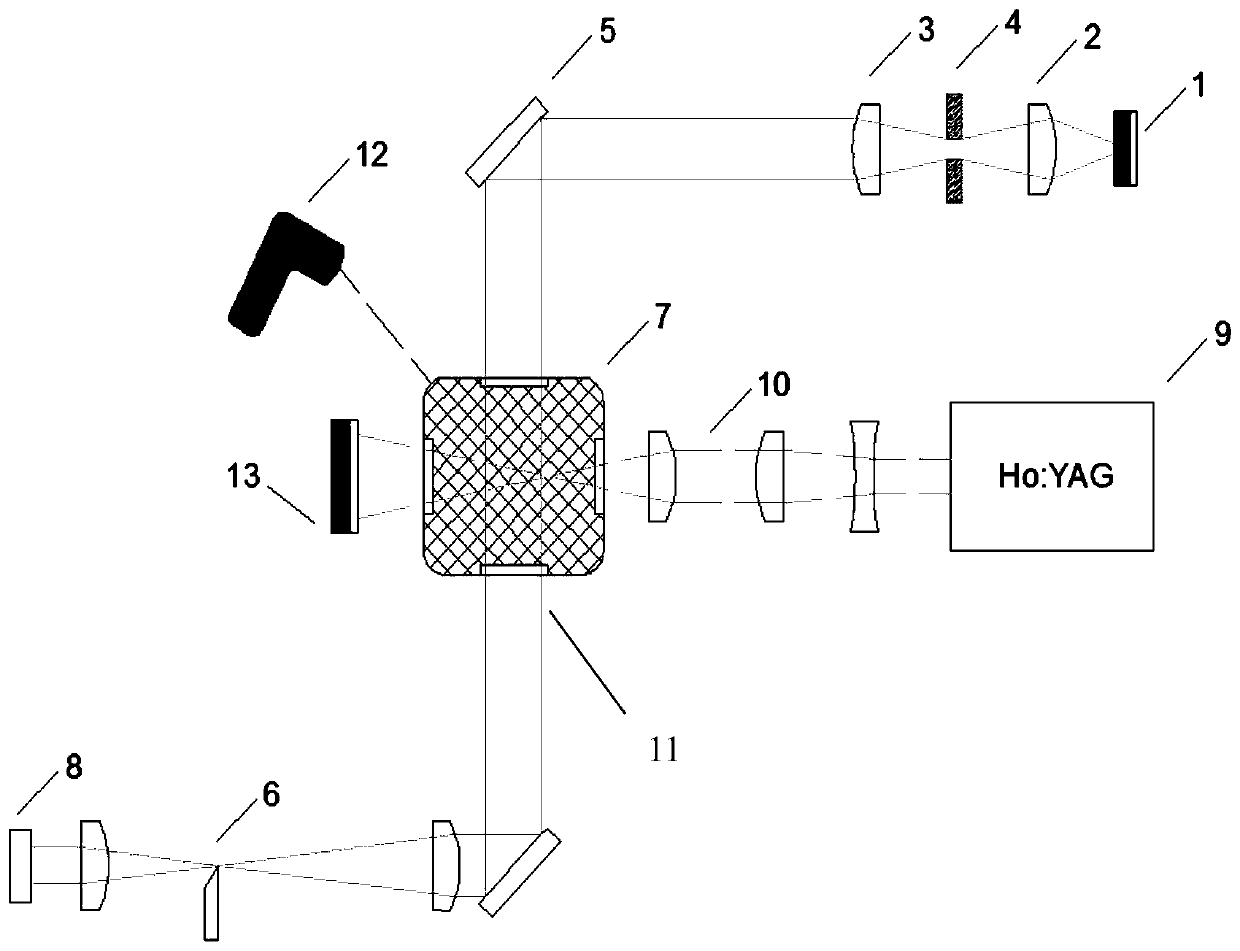

2 micrometer-waveband laser ignition device and method

ActiveCN109736993ASolve the problem of laser ignition failureImprove ignition success rateNon-fuel substance addition to fuelEngine ignitionHigh energyPlane mirror

The invention discloses a 2 micrometer-waveband laser ignition device and method, and belongs to the technical field of laser. The ignition method comprises two stages, and at the first stage, a Ho:YAG laser of the waveband through self help, and fuel is preheated; at the second stage, a stable and high-energy 1064 nm laser is adopted for ignition. A preheating device comprises a heating part anda detecting part. According to the detecting part, a high-brightness LED lamp, a convex lens, a concave lens, a diaphragm and a plane mirror are used for setting up an imaging system, by means of an experimental combustion sealed chamber and a high-speed CMOS, the heat distribution condition of vapor at the preheating stage is recorded through a schlieren method, and the temperature of fuel is monitored through an infrared thermometer. According to the heating part, the Ho:YAG laser is firstly used for focusing two laser beams at the output end through the concave lens and the convex lens, fuel is preheated on the waist thinning portion, and after the monitoring temperature is reached, ignition is carried out through the high-power Nd:YAG of 1064 nm. The success rate of ignition is greatlyincreased, meanwhile, the minimum ignition energy is reduced, and engine ignition at a lean-burn state is achieved.

Owner:HARBIN ENG UNIV

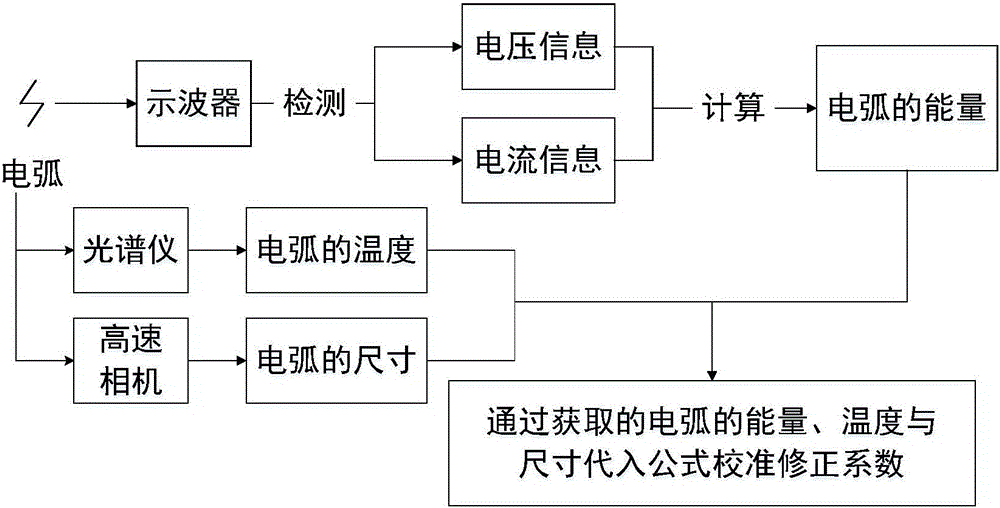

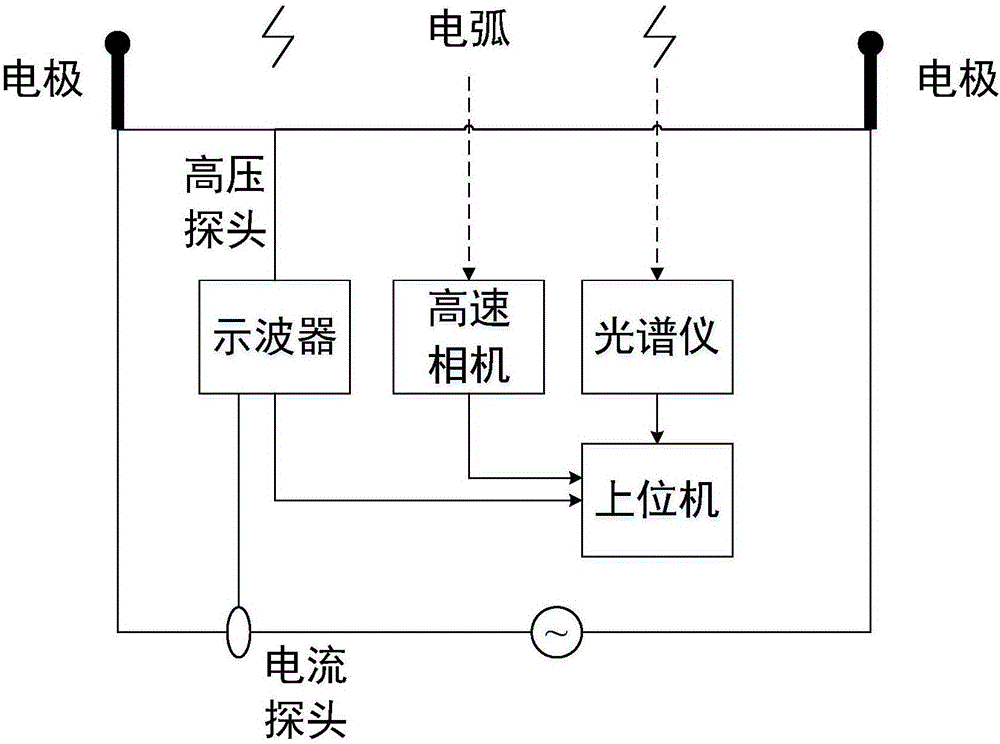

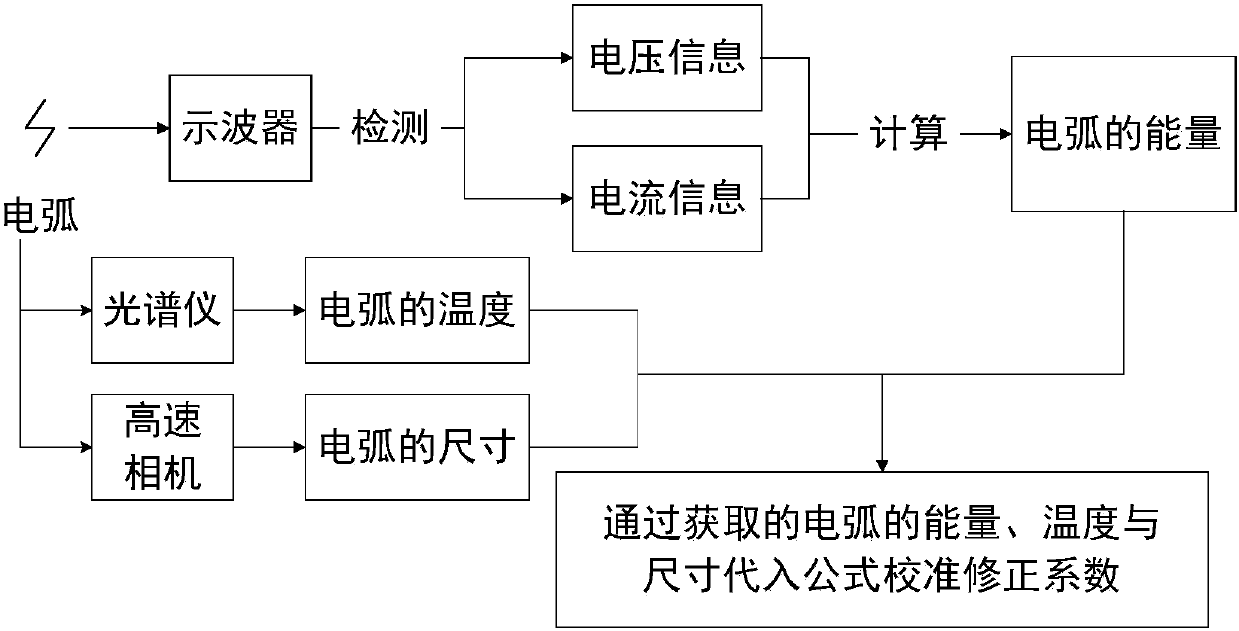

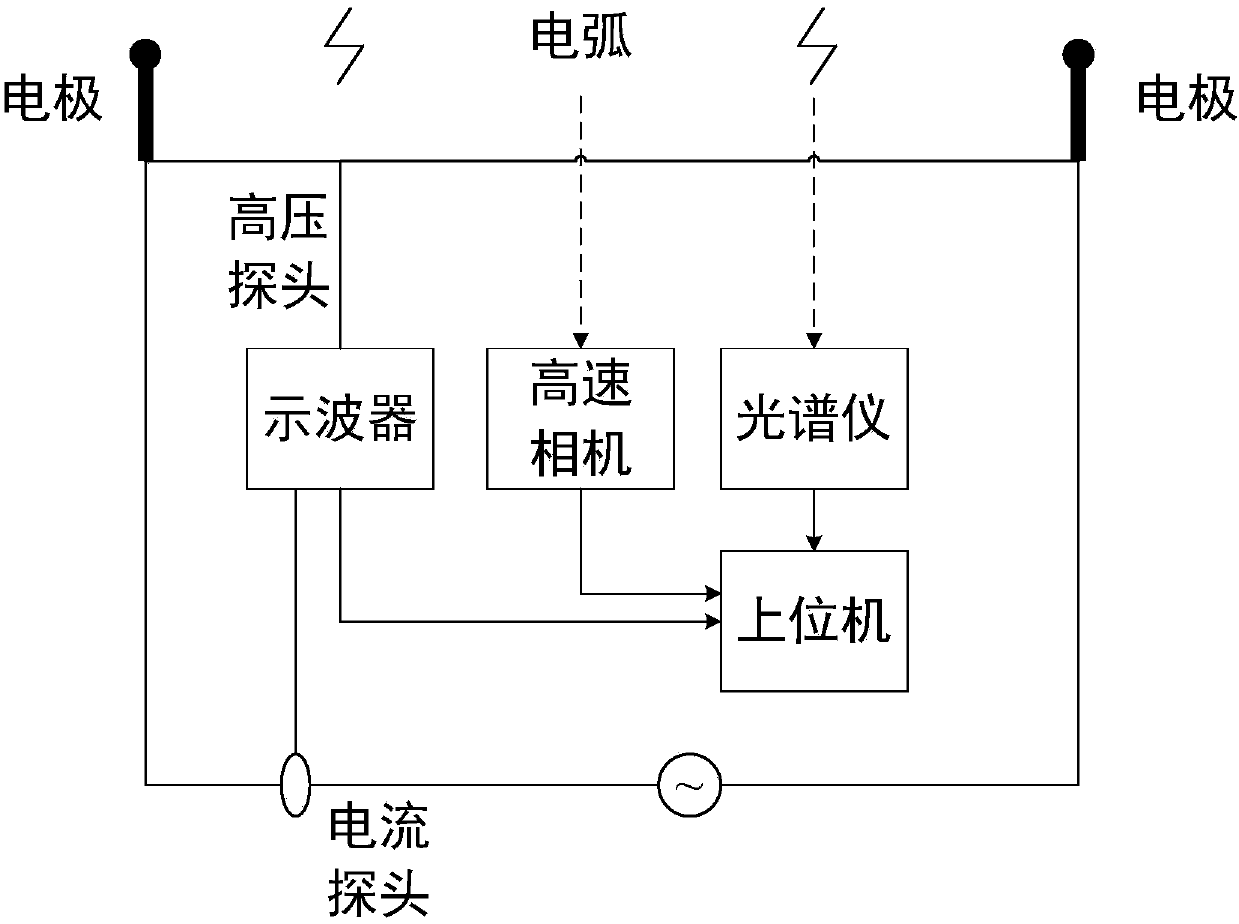

Method and device for calibrating eclectic arc discharge energy correction factor

ActiveCN105891769AEasy to use and set upImprove accuracyElectrical measurementsEmpirical formulaMinimum ignition energy

The invention relates to a method and a device for calibrating an eclectic arc discharge energy correction factor. A formula of eclectic arc discharge energy is given according to a semi-empirical formula of minimum ignition energy; energy generated in the electric arc discharge process is calculated according to a relation that the voltage and the current of a gas discharge electric arc change along with time, and finally, in combination with the temperate of the eclectic arc obtained by measurement, the arc length and the radius, the value of the correction factor in the formula is calibrated. The method comprises the following steps: (1) measuring the voltage and current information of the gas discharge electric arc; (2) obtaining the energy generated in the discharge process through an integral of a product of the voltage and the current on a time axis by adopting a mathematical method; (3) measuring the spectral information of the electric arc to obtain the temperature of the electric arc; (4) measuring the size information of the electric arc, wherein the size information comprises length and radius; (5) substituting into the calibration formula of the discharge energy E of the electric arc according to the energy obtained in the step (2), the temperature obtained in the step (3) and the size information obtained in the step (4) to obtain the value of the correction factor K1. The method provided by the invention is convenient to configure and flexible to operate and can quantifiably measure and calibrate the correction factor in the electric arc discharge energy formula.

Owner:BEIHANG UNIV

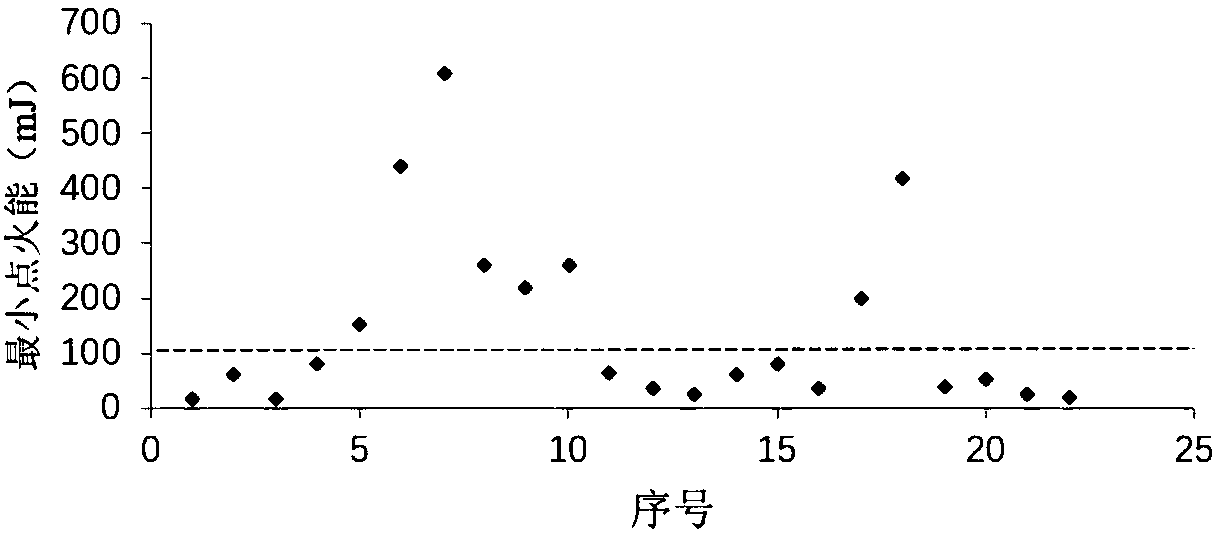

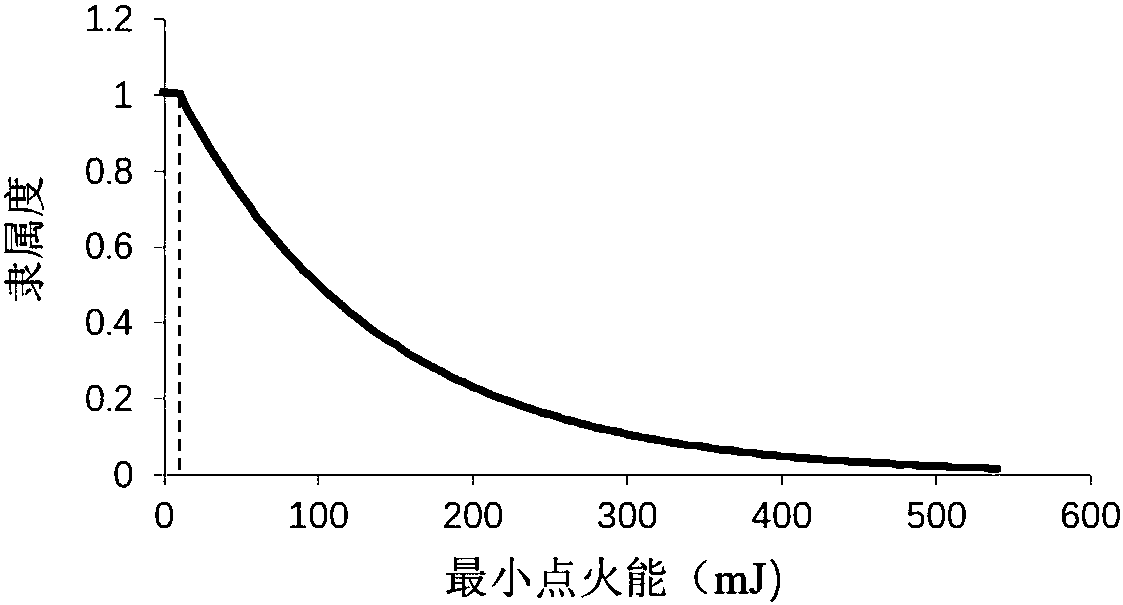

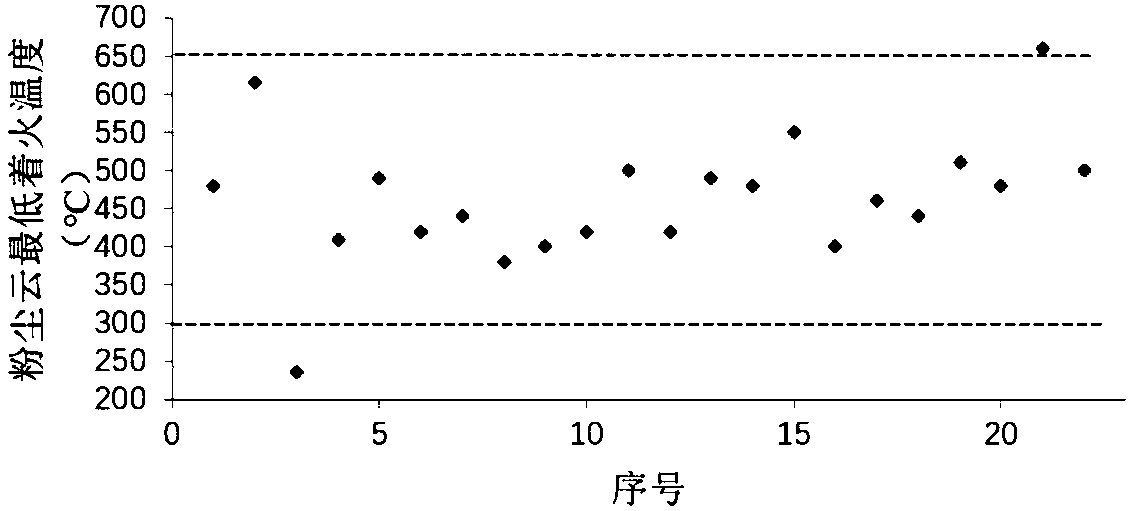

Method for comprehensively evaluating the combustible dust explosion hazard level by utilizing multi-element dust explosion parameters

InactiveCN109389256ARapid identification of explosion hazardsThe evaluation method is simpleResourcesLower limitPressure rise

The invention discloses a method for comprehensively evaluating the combustible dust explosion hazard level by utilizing multi-element dust explosion parameters. The method adopts fuzzy mathematics theory and analytic hierarchy process (AHP) in the system evaluation method, Using representative conventional explosives, According to the minimum ignition energy of dust cloud, the minimum ignition temperature of dust cloud, the minimum ignition temperature of dust layer, the lower limit of explosion, the maximum explosion pressure, the maximum explosion pressure rise rate and the characteristic parameters of explosion index, the membership function is established, and the evaluation model is established to evaluate the explosion hazard of different dust. The comprehensive evaluation method ofthe combustible dust explosion hazard grade established by the invention is simple, Easy to popularize, avoid tedious calculation and test, combine the existing data to obtain the corresponding comprehensive index value, easy to form a common evaluation standard, the result is intuitive, rapid identification of combustible dust dust explosion hazards, can provide guidance for the enterprise design safety production process.

Owner:NANJING UNIV OF SCI & TECH

Calibration method and calibration device for arc discharge energy correction coefficient

ActiveCN105891769BEasy to use and set upImprove accuracyElectrical measurementsMinimum ignition energyEmpirical formula

The invention relates to a method and a device for calibrating an eclectic arc discharge energy correction factor. A formula of eclectic arc discharge energy is given according to a semi-empirical formula of minimum ignition energy; energy generated in the electric arc discharge process is calculated according to a relation that the voltage and the current of a gas discharge electric arc change along with time, and finally, in combination with the temperate of the eclectic arc obtained by measurement, the arc length and the radius, the value of the correction factor in the formula is calibrated. The method comprises the following steps: (1) measuring the voltage and current information of the gas discharge electric arc; (2) obtaining the energy generated in the discharge process through an integral of a product of the voltage and the current on a time axis by adopting a mathematical method; (3) measuring the spectral information of the electric arc to obtain the temperature of the electric arc; (4) measuring the size information of the electric arc, wherein the size information comprises length and radius; (5) substituting into the calibration formula of the discharge energy E of the electric arc according to the energy obtained in the step (2), the temperature obtained in the step (3) and the size information obtained in the step (4) to obtain the value of the correction factor K1. The method provided by the invention is convenient to configure and flexible to operate and can quantifiably measure and calibrate the correction factor in the electric arc discharge energy formula.

Owner:BEIHANG UNIV

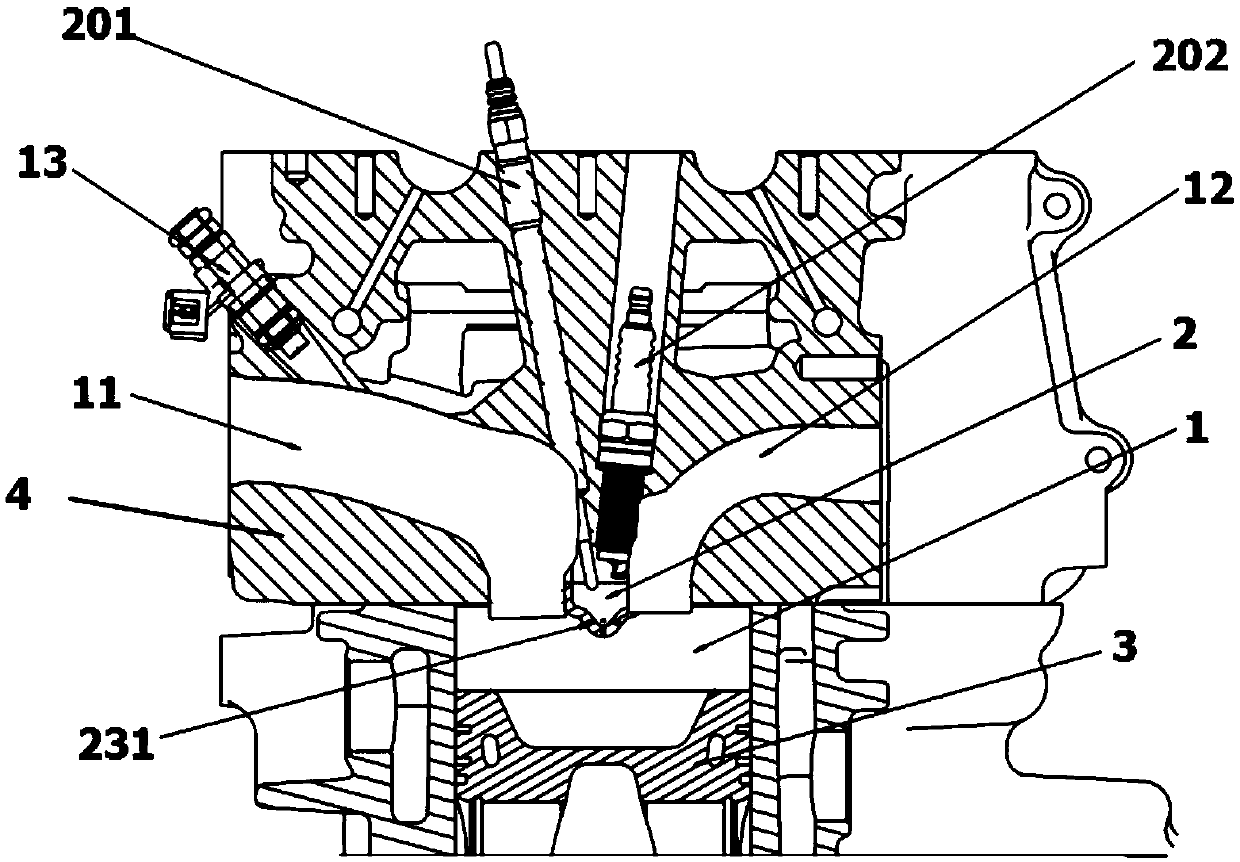

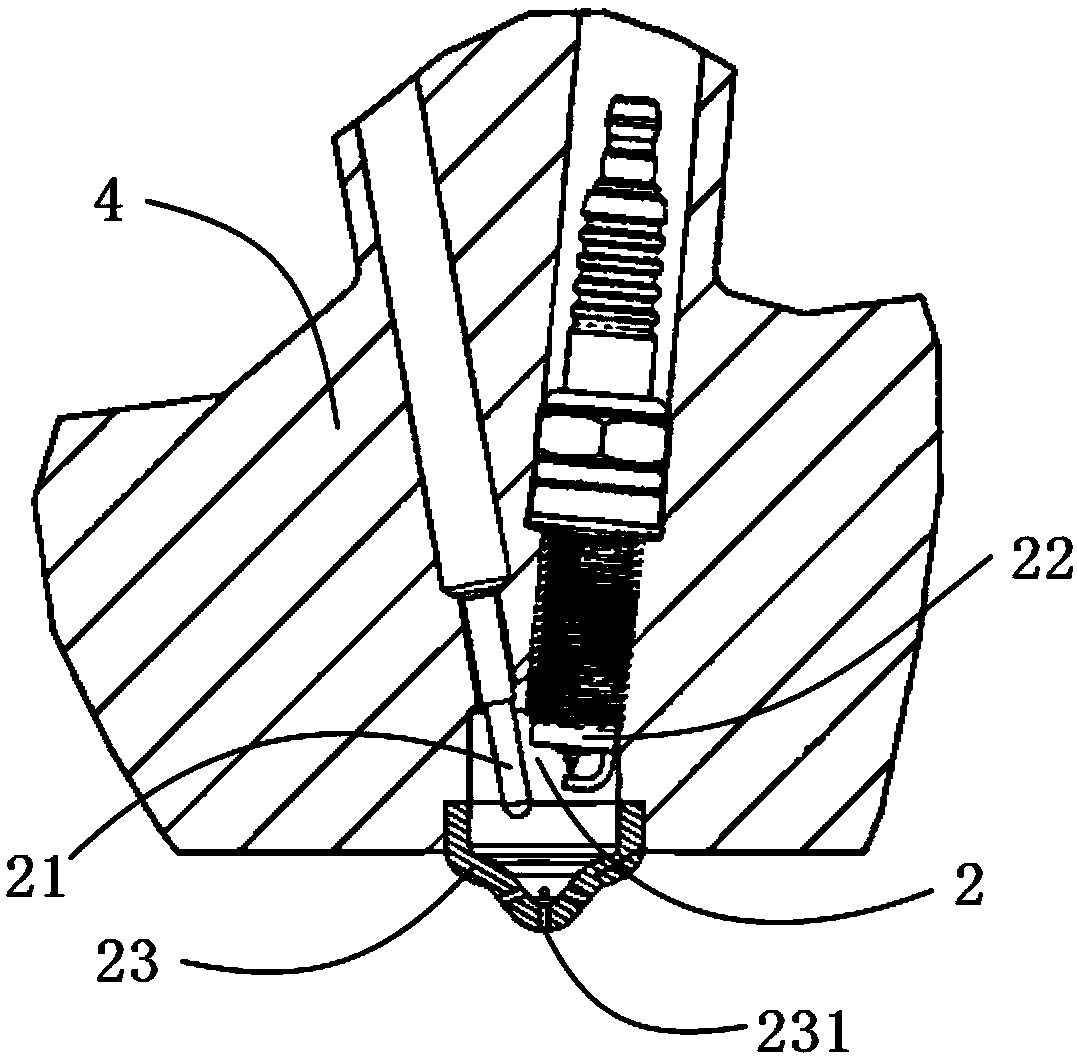

Ignition system and vehicle for methanol engine

InactiveCN109630336AReduce heat loadHigh thermal efficiencyFuel injection apparatusMachines/enginesHigh concentrationCombustion chamber

The invention provides an ignition system and a vehicle for a methanol engine and relates to the field of methanol engines. The ignition system includes a main combustion chamber and a pre-combustionchamber, wherein an intake valve is arranged in the main combustion chamber, and the intake valve communicates with a main injector for injecting a lean mixture having a first predetermined concentration into the main combustion chamber; the pre-combustion chamber communicates with the main combustion chamber through a pre-combustion chamber nozzle, and a spark plug electrode and a pre-injection nozzle are arranged in the pre-combustion chamber; and the spark plug is arranged in a methanol pre-combustion chamber. Due to the high concentration of the rich mixture gas, the requirement for minimum ignition energy of the spark plug is reduced. By igniting the concentrated methanol mixture gas in the pre-combustion chamber, the concentrated mixed methanol flame is injected into the main combustion chamber, the lean mixture gas of methanol in the main combustion chamber is combusted, and the ignition energy is greatly increased. By using of the system, the combustion temperatures and enginethermal loads are reduced while engine NOX emission is reduced and engine thermal efficiency is improved.

Owner:ZHEJIANG GEELY HLDG GRP CO LTD +2

Sparking plug aging degree detecting method and device, and vehicle

ActiveCN108869142AAccurate detection of aging degreeAccurate detectionElectric ignition installationMachines/enginesOnline testEngineering

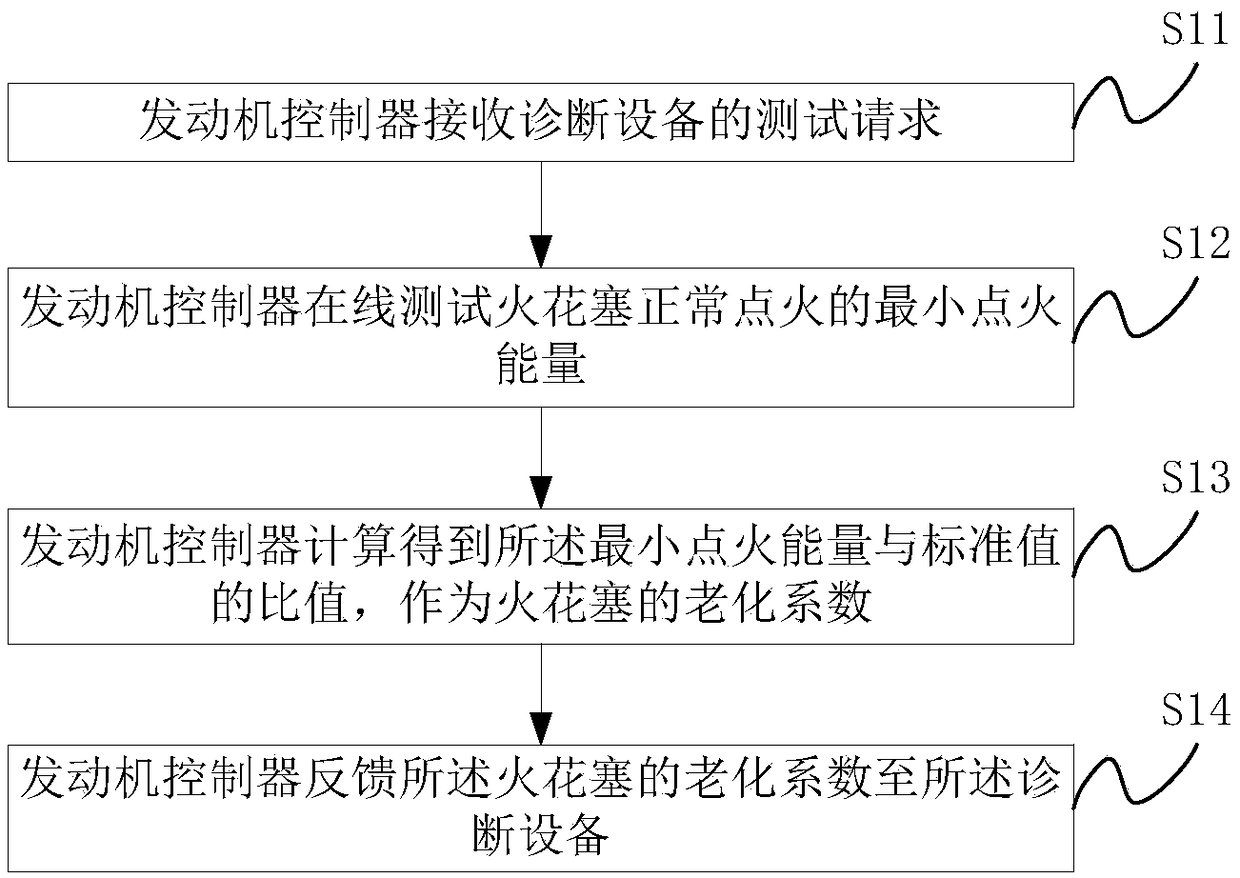

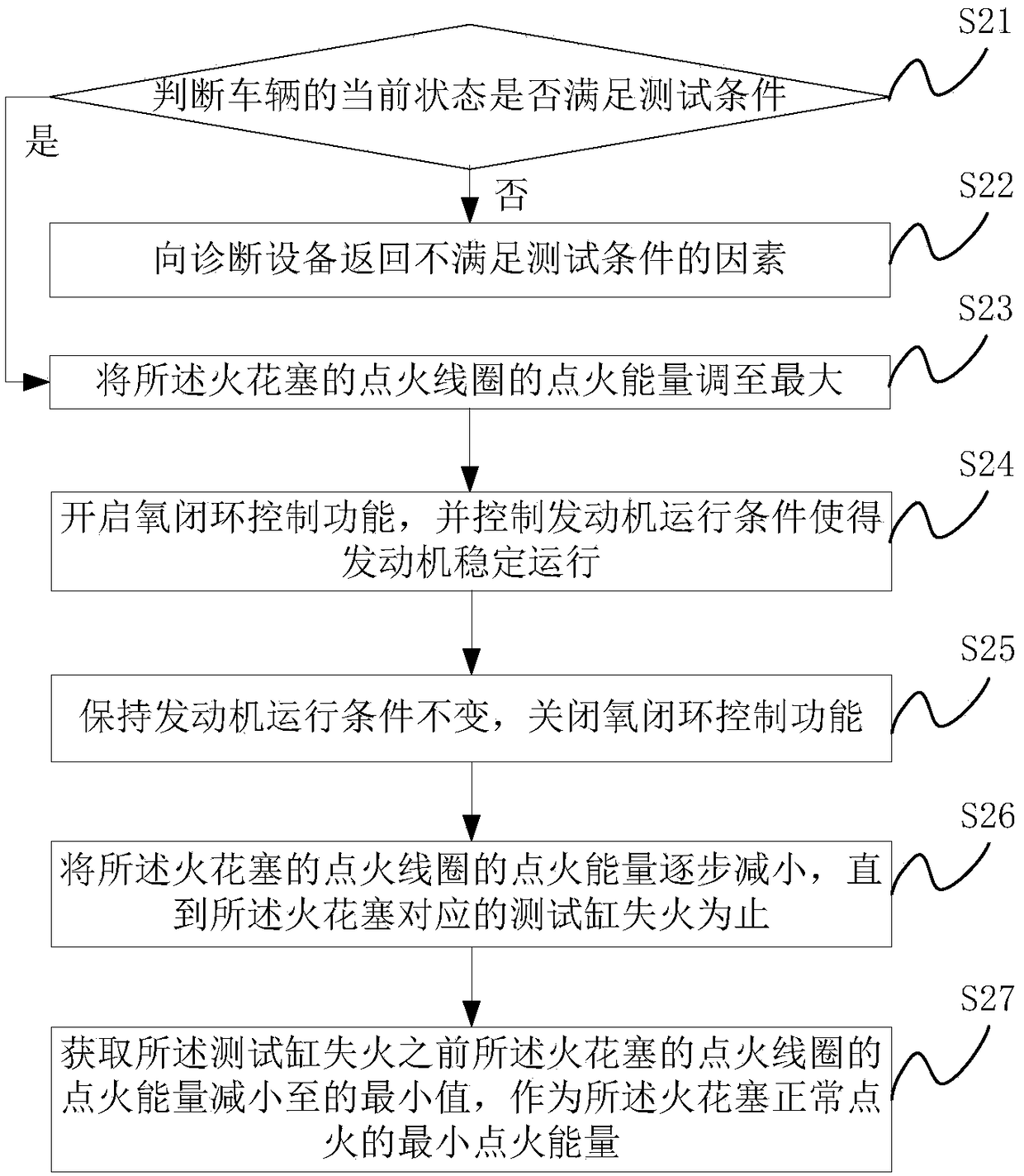

The invention discloses a sparking plug aging degree detecting method and device, and a vehicle. Through an online test of an engine, the ignition energy of a sparking plug is continuously adjusted, the minimum ignition energy of normal ignition of the sparking plug is determined, the minimum ignition energy is compared with a standard value, the aging coefficient of the sparking plug is determined, accurate detection of the aging degree of the sparking plug is achieved, and more accurate basis is provided for replacement and maintenance of the sparking plug.

Owner:WEICHAI POWER CO LTD

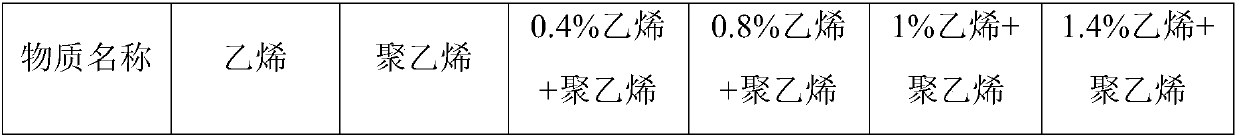

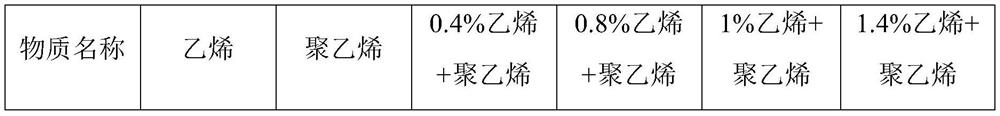

Testing method of minimum ignition energy of gas-solid two-phase combustible material

The invention relates to a testing method of the minimum ignition energy of a gas-solid two-phase combustible material. The testing method is mainly used for solving the problem that a minimum ignition energy testing method aiming at gas-solid two phases is not provided in the prior art. By adopting the testing method of the minimum ignition energy of the gas-solid two-phase combustible material,a minimum ignition energy testing device is adopted to conduct minimum ignition energy testing of the gas-solid two-phase combustible material, a spherical testing cavity serves as a device main body,a vacuum pump and a buffer tank are connected to a cavity body, an ignition electrode is mounted on a flange on the upper side of the cavity body, one end of a precise electric spark generator is connected with the ignition electrode, and the other end of the precise electric spark generator is connected with a computer. The problem is well solved through the technical scheme, and the testing method can be used for testing the minimum ignition energy of the gas-solid two-phase combustible material.

Owner:CHINA PETROLEUM & CHEM CORP +1

Minimum ignition energy test system and method for combustible gas explosion at ultra-low temperature

The present invention relates to a minimum ignition energy test system and method for combustible gas explosion at ultra-low temperature. The test system includes a vacuum pumping system, a gas distribution system, a refrigeration system, an integral circuit ignition system and a data acquisition system. An explosion container is installed in the refrigeration system , the vacuum system communicates with the explosion vessel through the connecting pipeline of the gas distribution system, and the gas distribution system communicates with the interior of the explosion vessel through the connecting pipeline; the integral ignition system includes an ignition energy test bench, an ignition electrode located in the explosion vessel, a The probe and current transformer, the ignition energy test bench are connected to the ignition electrode, the high-voltage probe and the current transformer are respectively connected to the ignition energy test bench and the ignition electrode; the data acquisition system includes a data collector and is connected to the data collector and installed on Pressure sensor and temperature sensor inside the explosion vessel. The test system of the present invention has high safety performance and accurate test performance, and can accurately test the minimum ignition energy of combustible gas explosion at ultra-low temperature and high pressure, and the measured data is of great significance for guiding the safe production of the oxygen-containing coalbed methane liquefaction process.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Device and method for testing the explosion characteristics of combustible gas at ultra-low temperature

ActiveCN104749218BEliminate the hassle of huge usageHigh riskMaterial exposibilityHeat conductingEnergy control

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

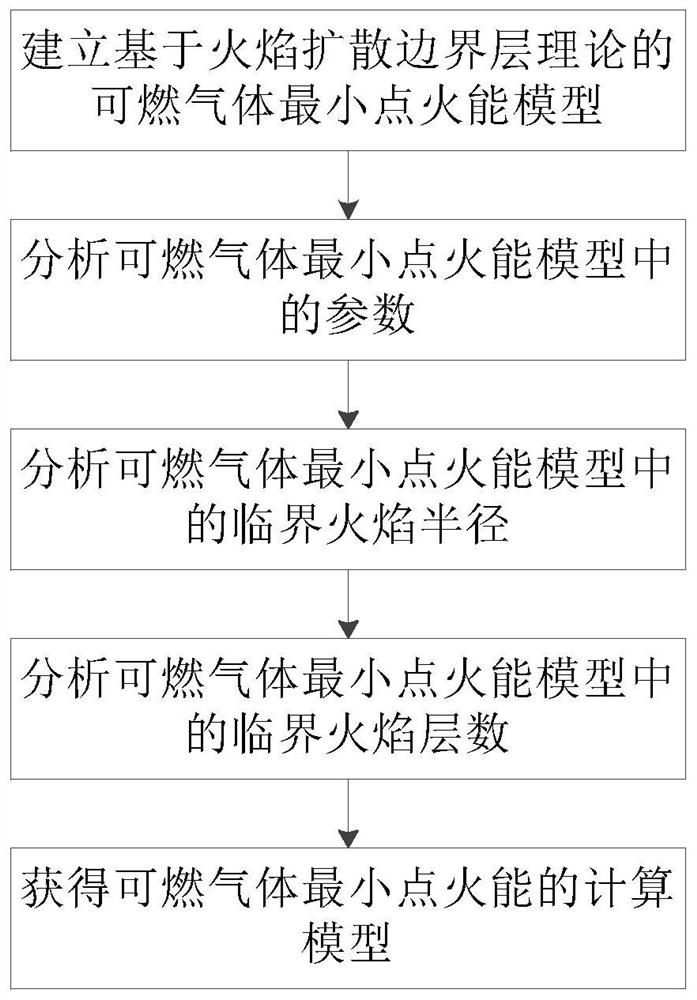

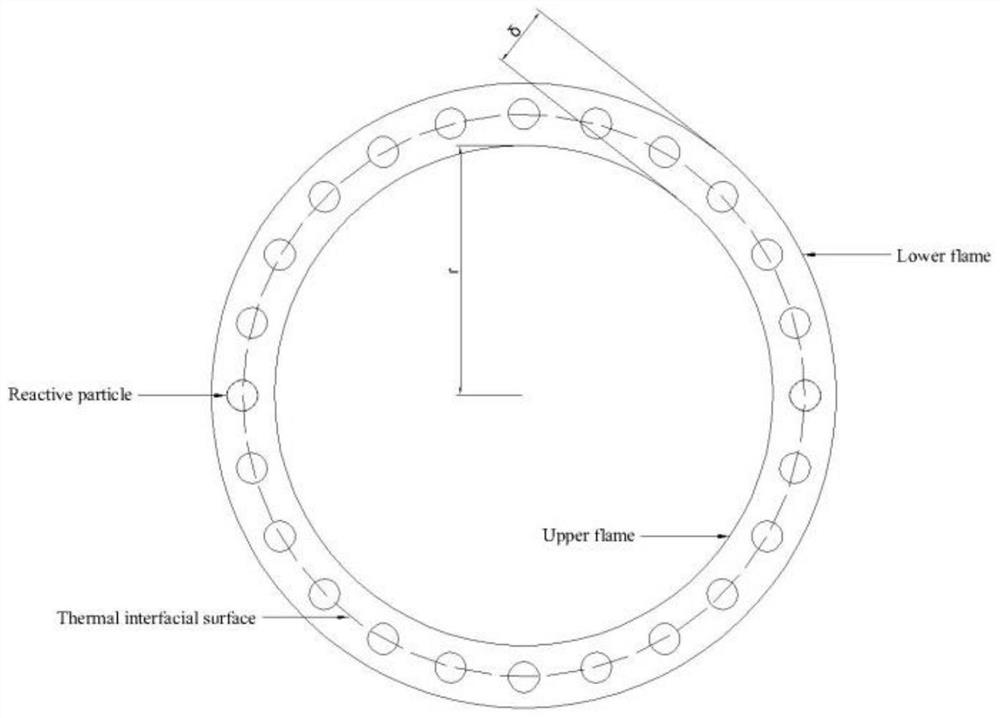

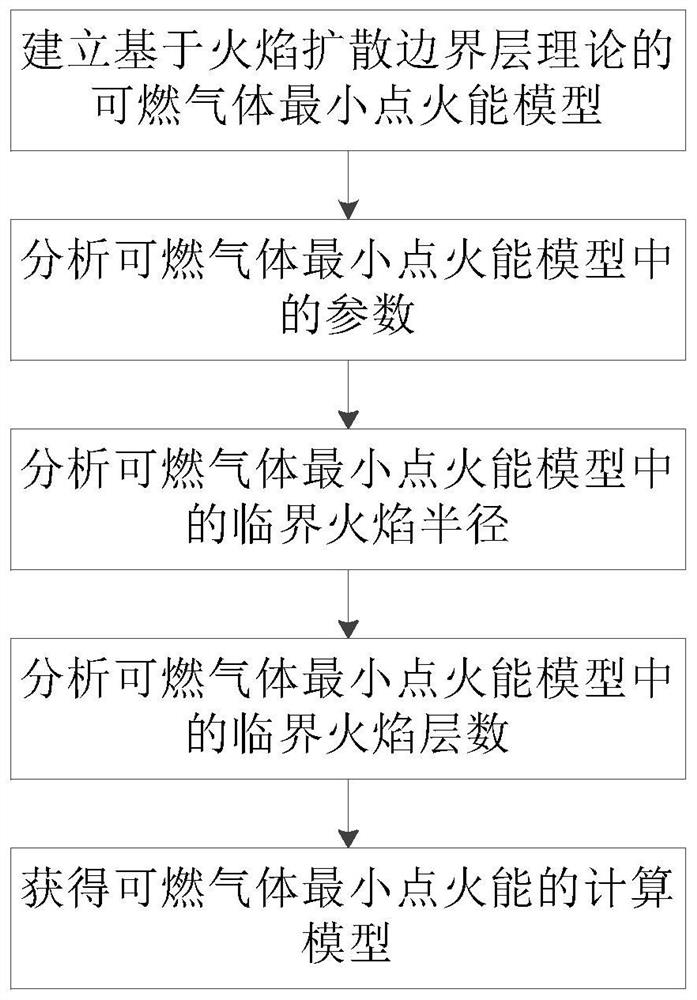

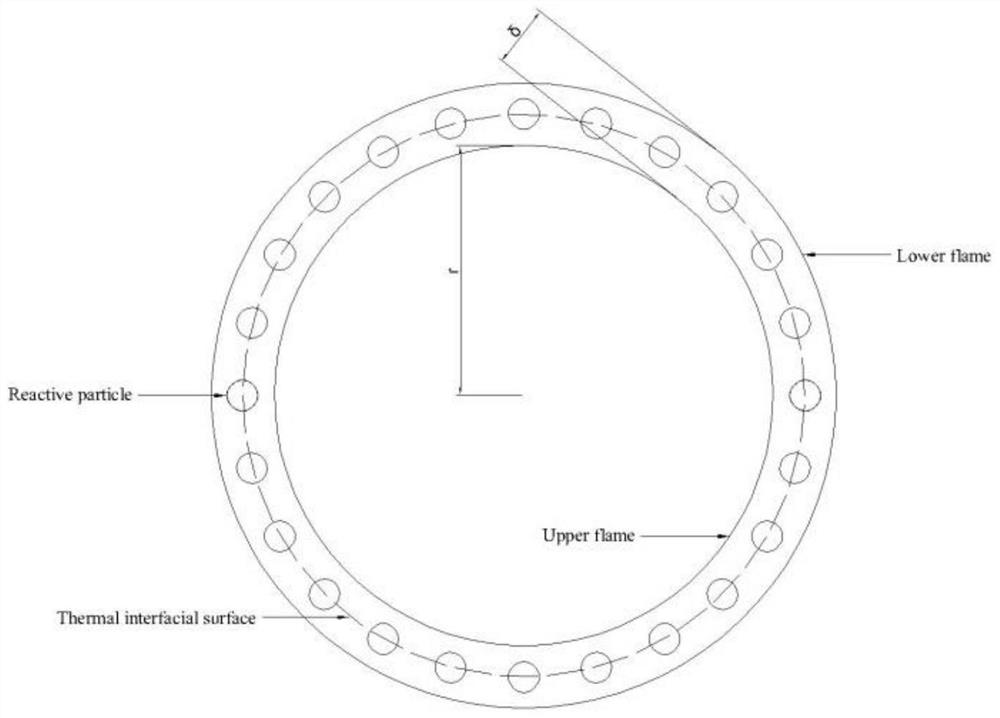

Combustible gas minimum ignition energy analysis method

ActiveCN112347690AEfficient analysisThe method steps are simpleFuel testingMaterial exposibilityThermodynamicsCombustible gas

The invention discloses a combustible gas minimum ignition energy analysis method. The method comprises the steps: 1, establishing a combustible gas minimum ignition energy model based on a flame diffusion boundary layer theory; 2, analyzing parameters in the combustible gas minimum ignition energy model; 3, analyzing the critical flame radius in the combustible gas minimum ignition energy model;4, analyzing the number of critical flame layers in the combustible gas minimum ignition energy model; 5, obtaining a calculation model of the minimum ignition energy of the combustible gas. The method is simple in step and reasonable in design, the calculation model of the minimum ignition energy is established on the basis of the flame diffusion boundary layer theory and the fuel property and incombination with the physicochemical basis, the minimum ignition energy of combustible gas can be effectively analyzed, the influence rule of model parameters on the minimum ignition energy of the combustible gas is analyzed, the analysis effect is remarkable, aa foundation is laid for detection of gas explosion performance, and popularization is facilitated.

Owner:XIAN UNIV OF SCI & TECH

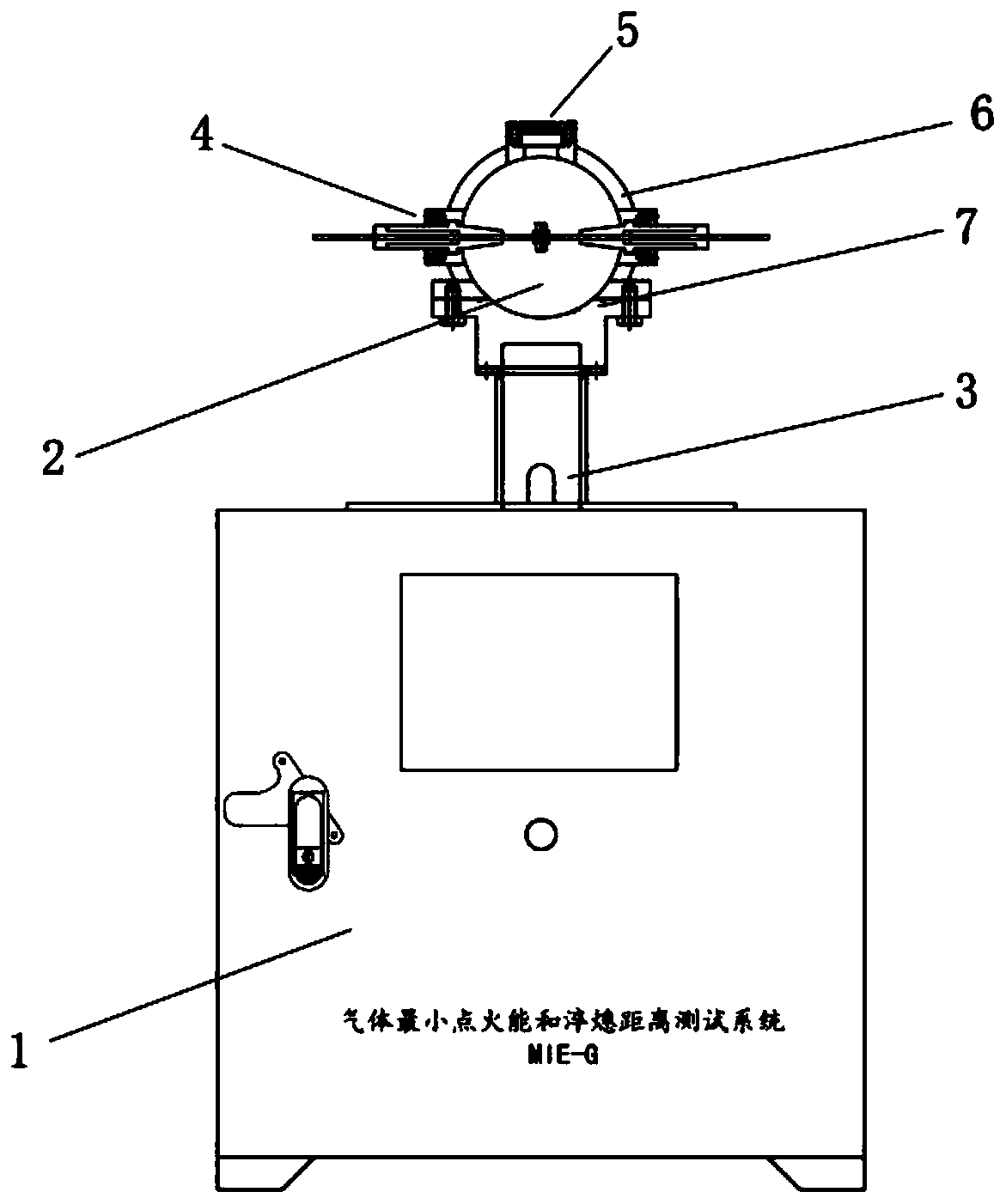

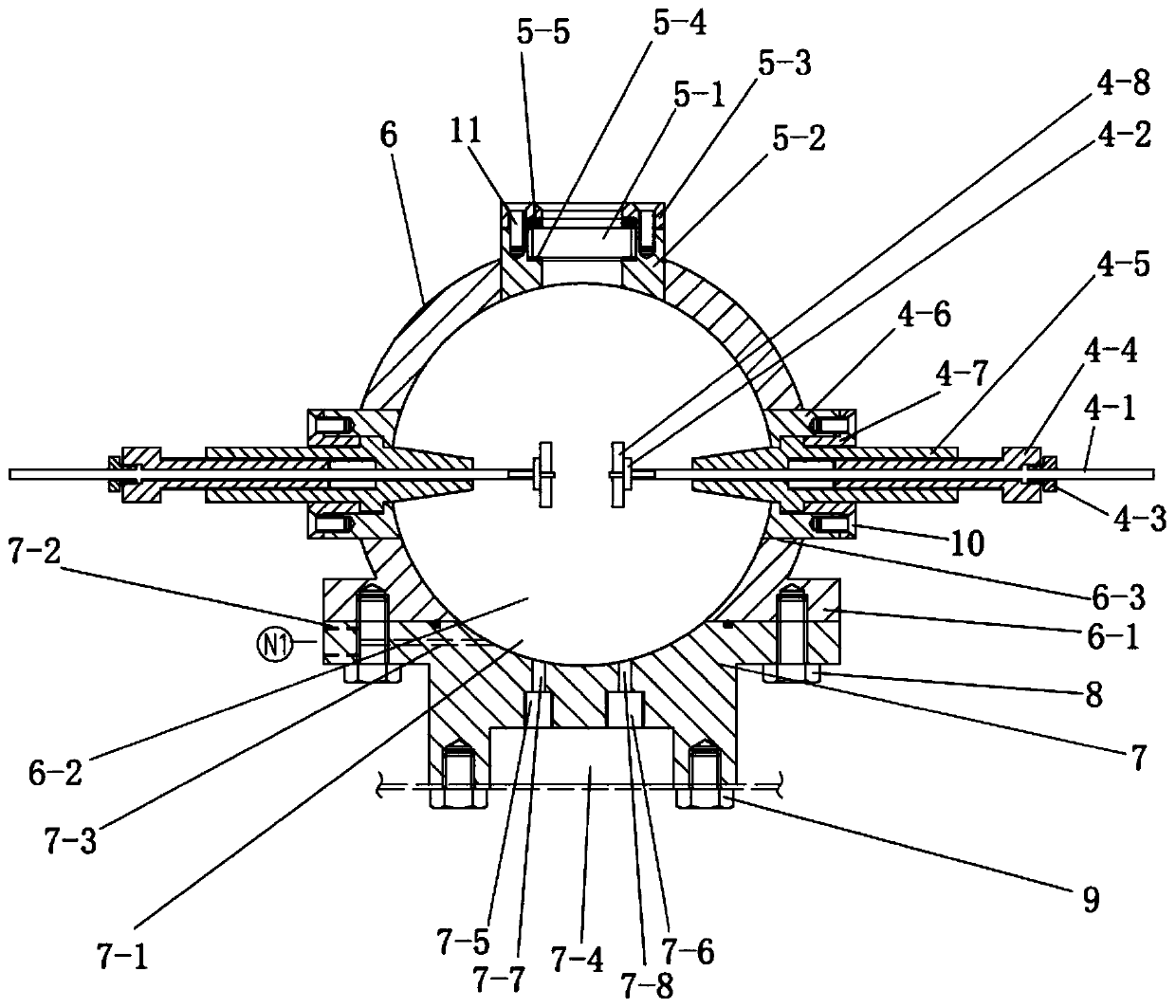

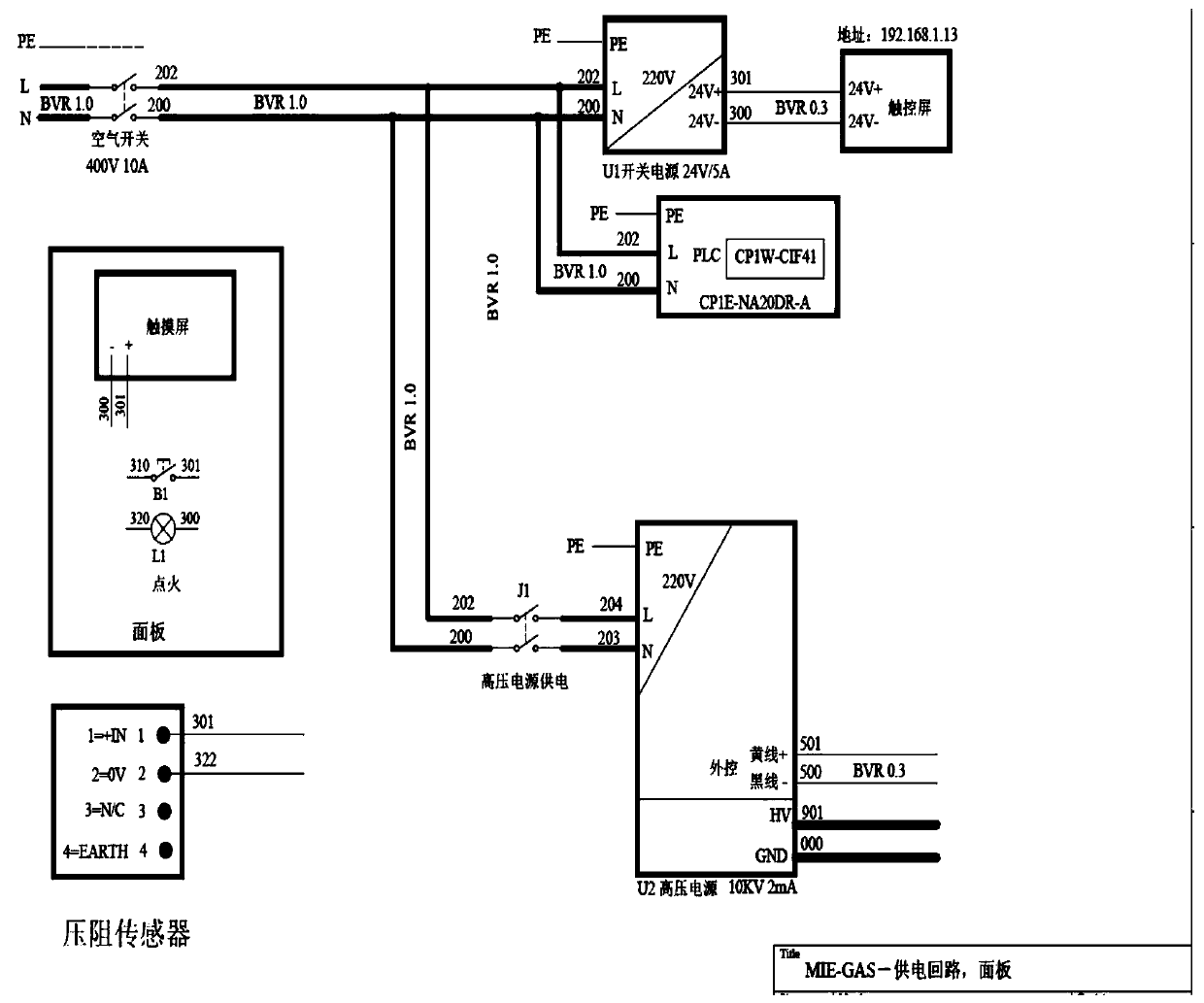

Test device for minimum ignition energy and quenching distance of gas mixture

The invention relates to the technical field of gas explosion performance test, and provides a test device for minimum ignition energy and quenching distance of a gas mixture. The test device comprises a control box, a spherical reaction container, a support, an electric spark generation system, and a gas distribution system, wherein the spherical reaction container comprises a spherical reactionpart and a base, the electric spark generation system comprises two groups of electric spark generation components symmetrically arranged at two sides of a vertical section passing a center of the sphere, the electric spark generation component comprises a metal electrode, a screw nut, an adjusting bolt, an insulating end, an electrode connector, an electrode sleeve, and an insulating flange, thegas distribution system comprises a vacuum pump, a pressure sensor, a temperature sensor, and a gas cut-off valve, the control box comprises a high voltage power supply, a relay, and a capacitor group, the high voltage power supply is electrically connected with the capacitor group through the relay, and a positive electrode and a negative electrode of the capacitor group are connected with two electrode rods respectively. The test device can test gas minimum ignition energy and quenching distance in one device, and improves test accuracy.

Owner:HUILE INSFORD ENVIRONMENTAL SAFETY RES INST (SUZHOU) CO LTD

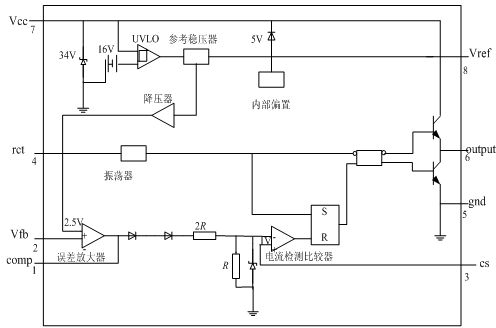

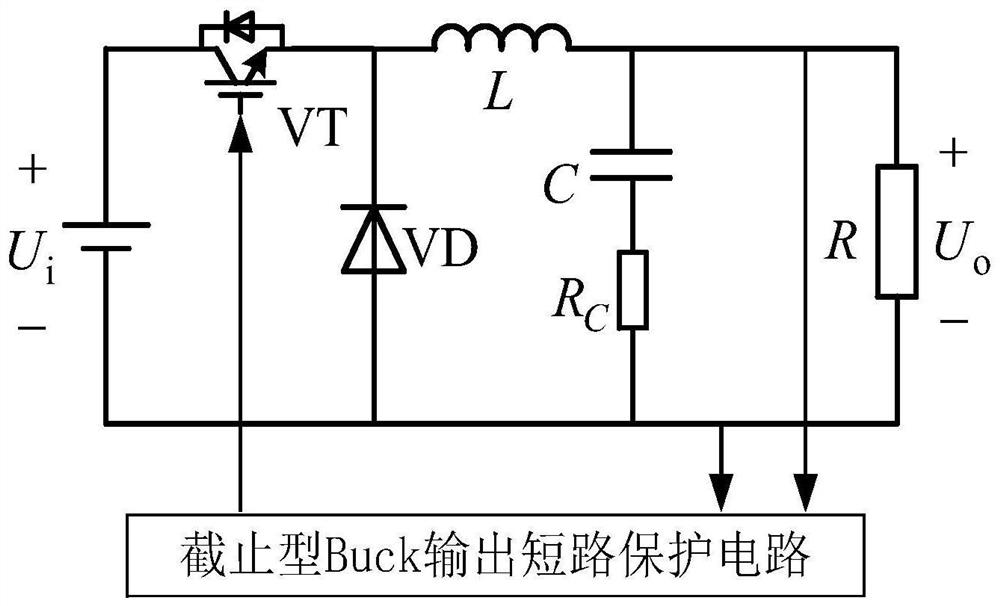

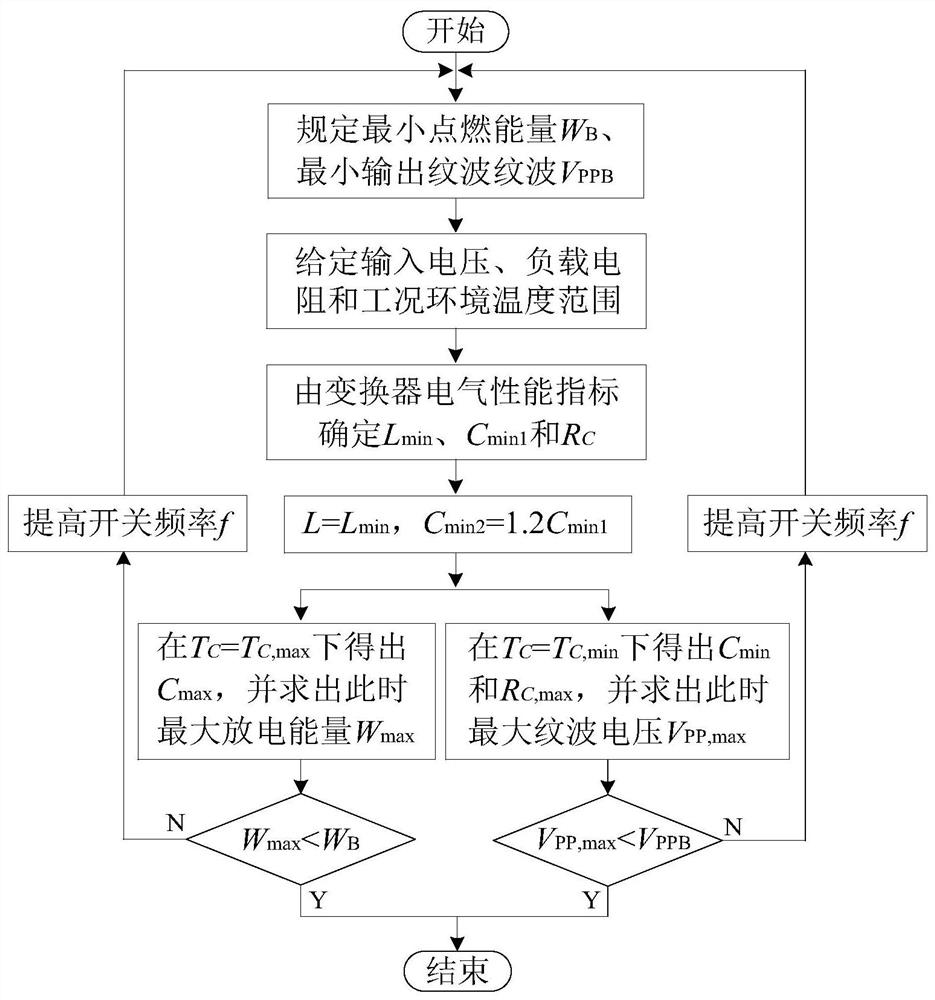

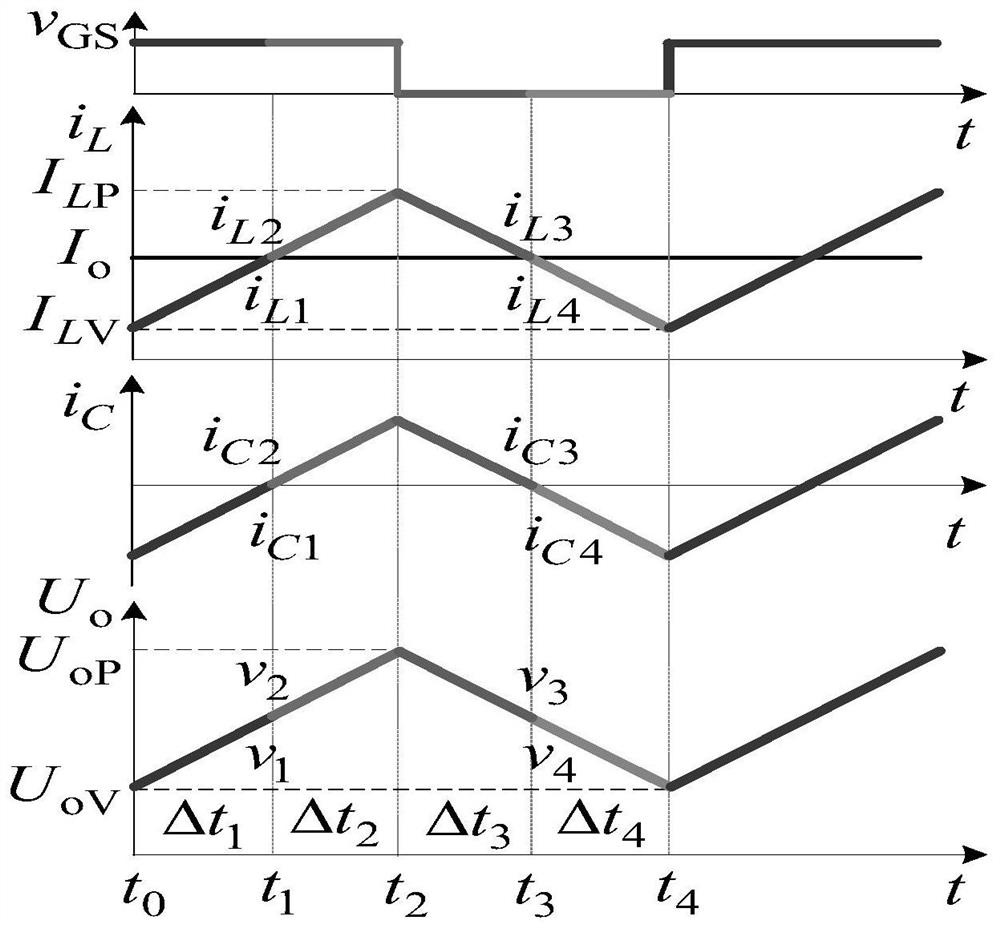

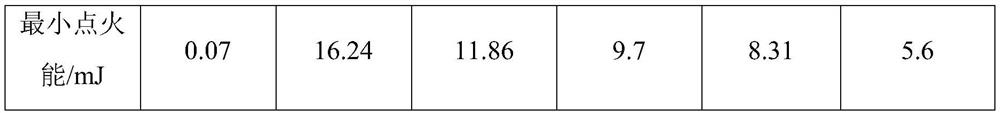

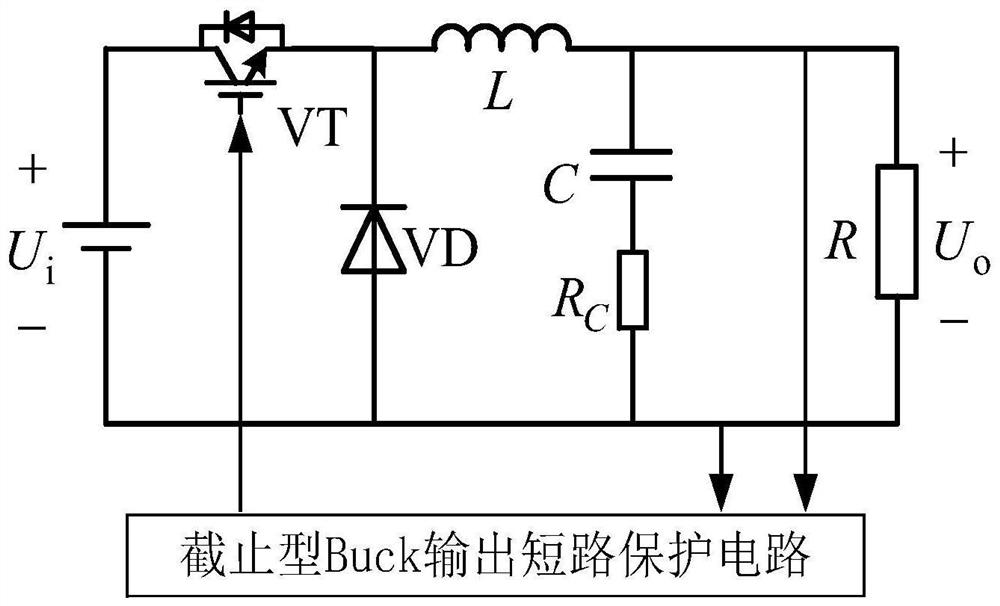

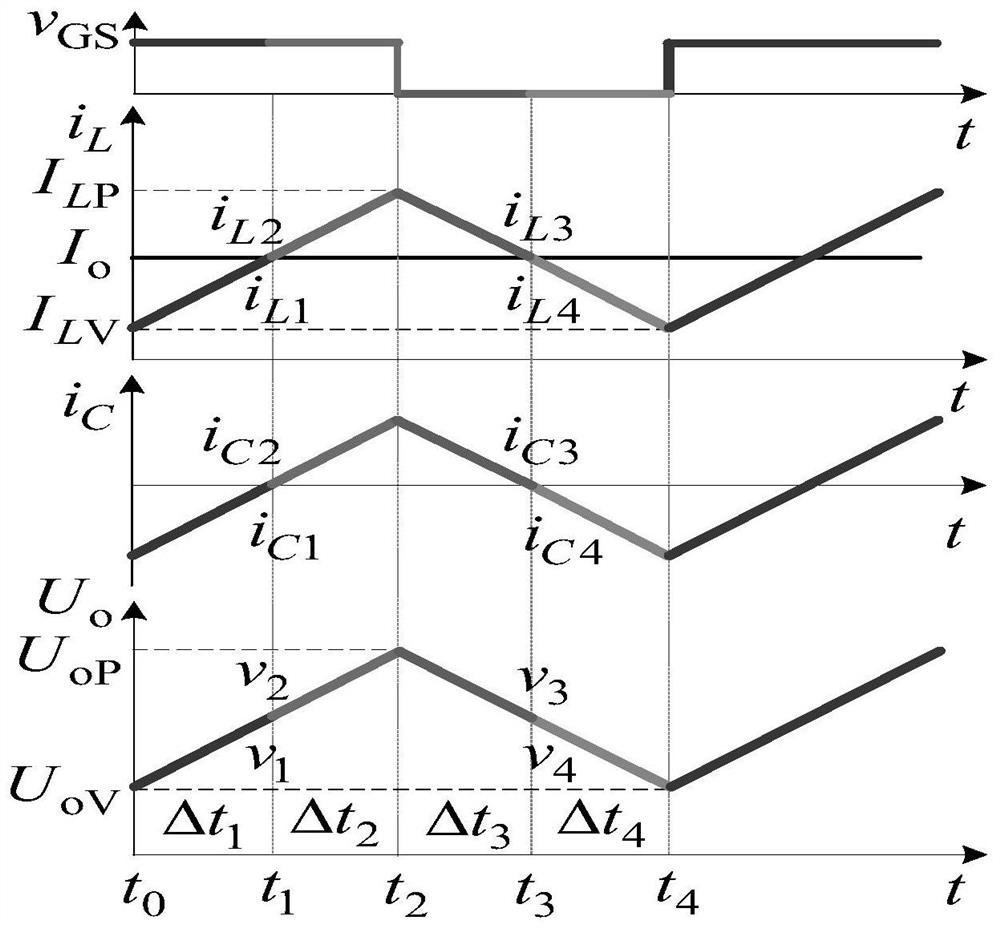

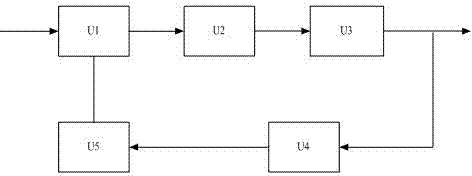

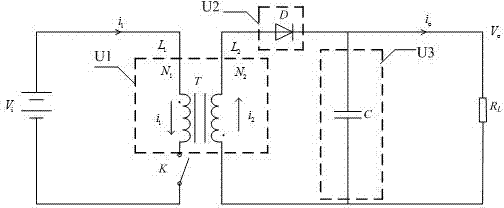

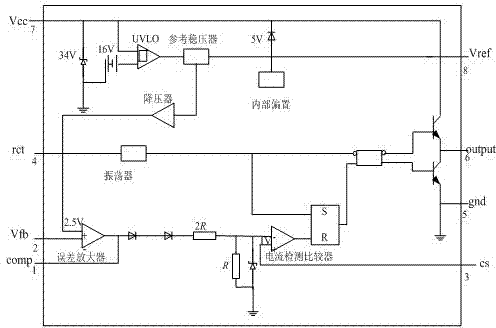

A Parameter Design Method of Intrinsically Safe Buck Converter Considering Temperature Effect

ActiveCN113437867BImprove output intrinsically safe performanceReduce marginDc-dc conversionElectric variable regulationCapacitanceConverters

The invention discloses an intrinsically safe Buck converter parameter design method considering the temperature effect, including: given the inductor current ripple, output ripple voltage and minimum ignition energy of the Buck converter; Input voltage range, load range, operating temperature range, output voltage, operating frequency and the resistance value R of the equivalent series resistance C ; Calculate the minimum inductance and input voltage and R of the intrinsically safe Buck converter C The minimum value of capacitance within the dynamic range; calculate the capacity range of Buck converter capacitor C and the resistance range of equivalent series resistance within the operating temperature range; calculate the maximum short-circuit discharge energy and maximum output ripple voltage according to the above design parameters, and judge whether they meet Output intrinsically safe requirements, if satisfied, the design is complete; if not satisfied, it is necessary to reduce R C Or increase the working frequency and repeat the above steps until the requirements are met. The invention effectively improves the output intrinsic safety performance of the converter.

Owner:秦智电子信息科技(深圳)有限公司

Test method for minimum ignition energy of gas-solid two-phase combustible materials

ActiveCN109668930BEasy to operateGood repeatabilityMaterial exposibilityThermodynamicsProcess engineering

Owner:CHINA PETROLEUM & CHEM CORP +1

Intrinsic safety Buck converter parameter design method considering temperature effect

ActiveCN113437867AImprove output intrinsically safe performanceReduce marginDc-dc conversionElectric variable regulationCapacitanceResistor

The invention discloses an intrinsic safety Buck converter parameter design method considering a temperature effect. The intrinsic safety Buck converter parameter design method comprises the steps that inductive current ripples, output ripple voltage and minimum ignition energy of a Buck converter are given; the input voltage range, the load range, the working temperature range, the output voltage and the working frequency of the Buck converter and the resistance value RC of an equivalent series resistor under the working condition are given; the minimum inductance and the input voltage of the intrinsic safety Buck converter and the minimum capacitance value in the RC dynamic range are calculated; the capacity range of the Buck converter capacitor C and the resistance value range of the equivalent series resistor in the working temperature range are calculated; according to the design parameters, the maximum short-circuit discharge energy and the maximum output ripple voltage are calculated, whether the output intrinsic safety requirement is met or not is judged, and if yes, design is completed; and if not, the RC needs to be reduced or the working frequency needs to be improved, and the steps are repeated until the requirements are met. The output intrinsic safety performance of the converter is effectively improved.

Owner:SHAANXI SCI TECH UNIV

Intrinsic safety LED (Light Emitting Diode) driving power source with high power for mines

InactiveCN102595700BAvoid explosionSimple structureElectric light circuit arrangementEnergy saving control techniquesIntrinsic safetyFeedback circuits

The invention relates to an intrinsic safety LED (Light Emitting Diode) driving power source with high power for mines and belongs to a driving power source for LED lamps. The intrinsic safety LED driving power source with high power comprises a high frequency flyback converter, a rectifying circuit, an output filtering circuit, a feedback circuit and a PWM (Pulse Width Modulation) controller, wherein an output end of the high frequency flyback converter is connected with the rectifying circuit; the output end of the rectifying circuit is connected with the output filtering circuit; the output end of the output filtering circuit is a circuit output end and simultaneously is connected with an input end of the feedback circuit; and the feedback circuit is connected with the high frequency flyback converter through the PWM controller. Compared with the prior art, the intrinsic safety LED driving power source has the advantages that the power source is always kept constant under the condition of changing a load or input voltage and output current, and when the short-circuiting happens in the output, the released energy is below the minimum ignition energy value of a gas, thereby the explosion is avoided; and the intrinsic safety LED driving power source has simple structure and long service life, is energy-saving and environment-friendly, is convenient to carry and is suitable for hazardous areas such as coal mines, petrochemical industries and the like.

Owner:CHINA UNIV OF MINING & TECH

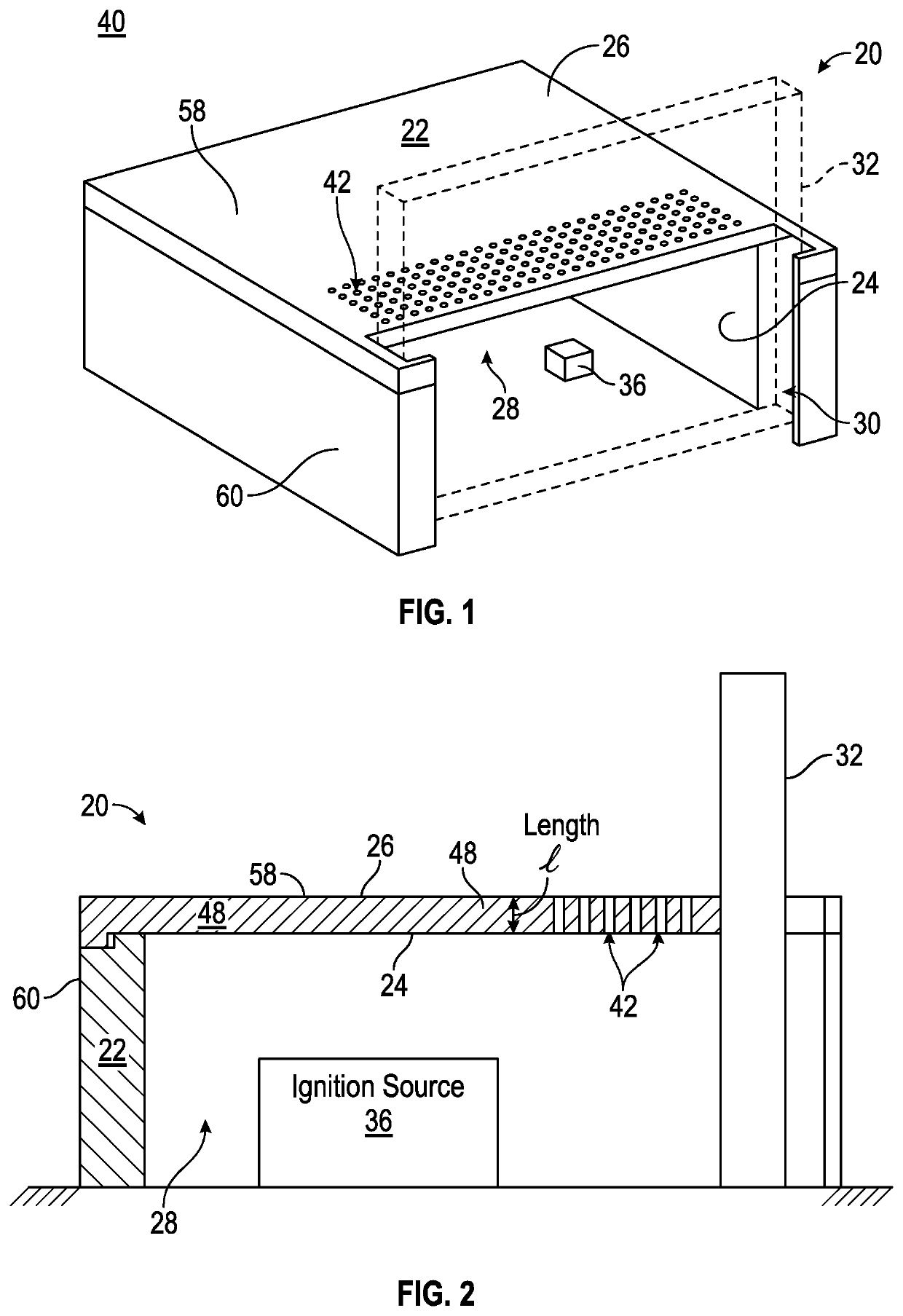

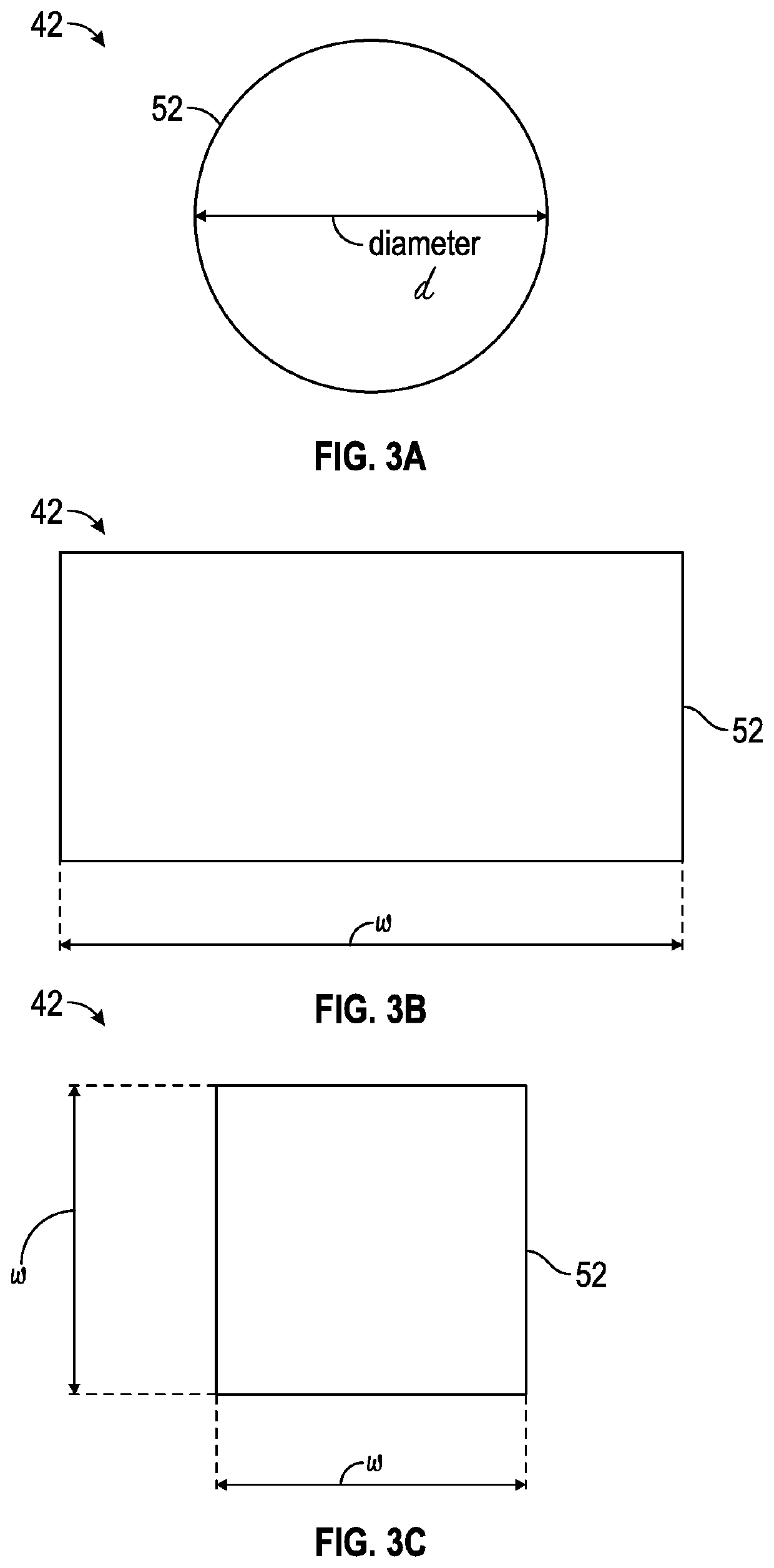

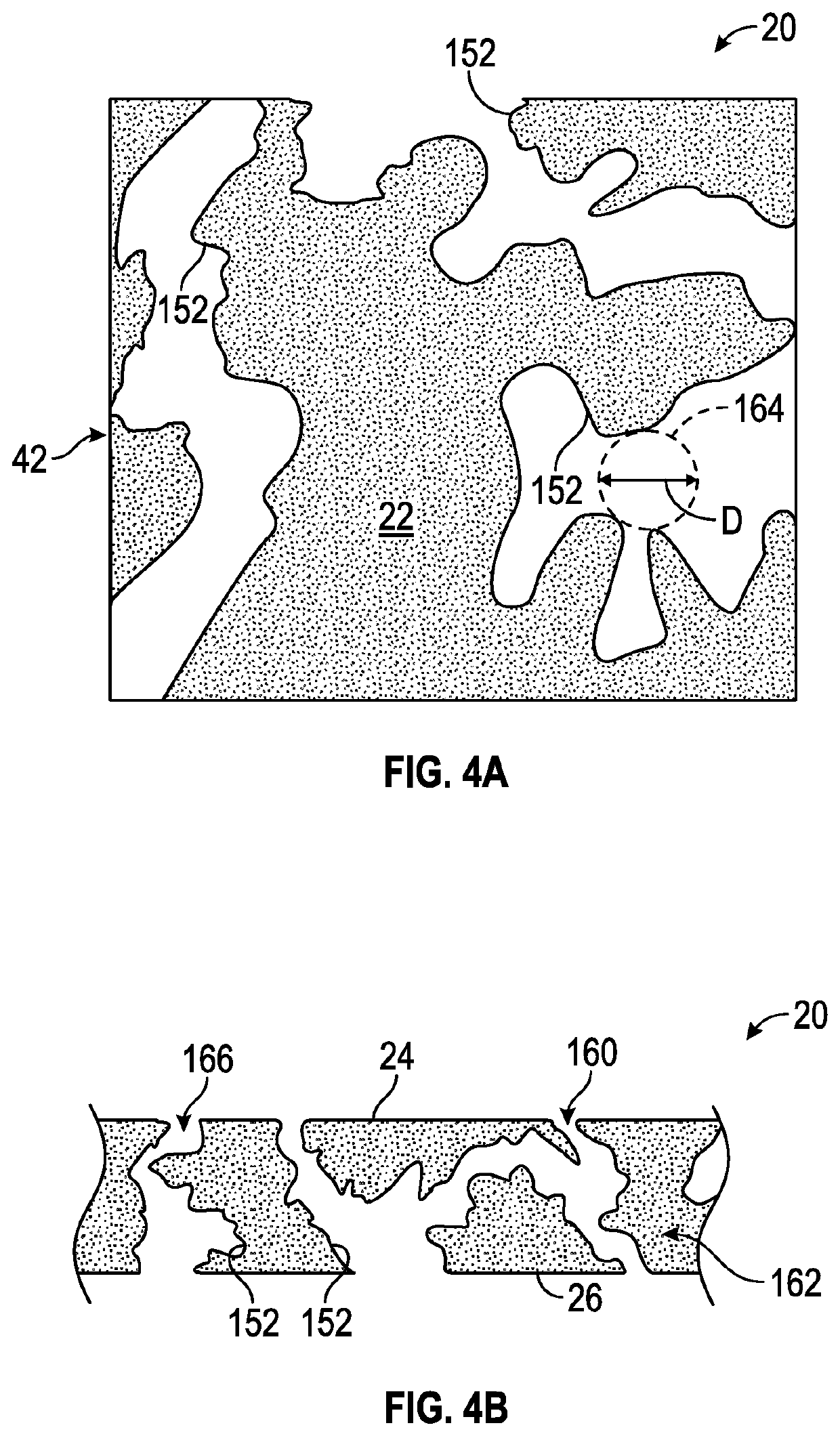

Ignition suppressing enclosure having vent paths for flame quenching

An ignition suppressing enclosure configured to contain an ignition source is disclosed and includes a body portion defining an inner surface, an outer surface, and an enclosed volume containing a flammable gaseous mixture. The enclosed volume is sized to contain the ignition source. The enclosed volume of the ignition suppressing enclosure is surrounded by an exterior combustible environment also containing the flammable gaseous mixture. The ignition suppressing enclosure includes one or more vent paths that extend between the inner surface and the outer surface of the body portion, where each individual vent path includes an effective diameter based on at least a minimum ignition energy of the flammable gaseous mixture. The effective diameter of the individual vent path is selected to quench a flame that occurs within the enclosed volume of the ignition suppressing enclosure.

Owner:THE BOEING CO

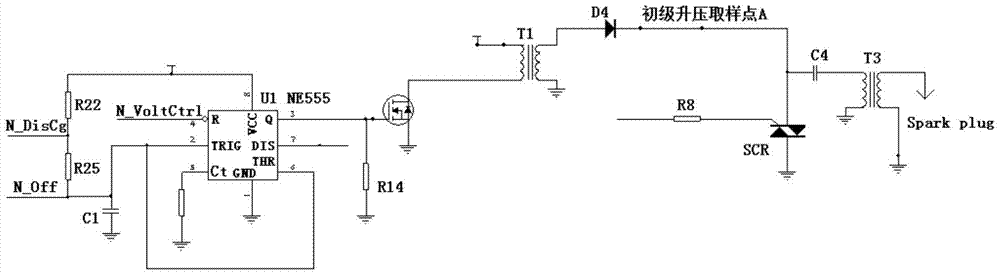

A closed-loop control method for a low-voltage direct current cdi igniter

ActiveCN105179135BImprove adaptabilityIncrease flexibilityMachines/enginesIgnition controlLoop controlThermodynamics

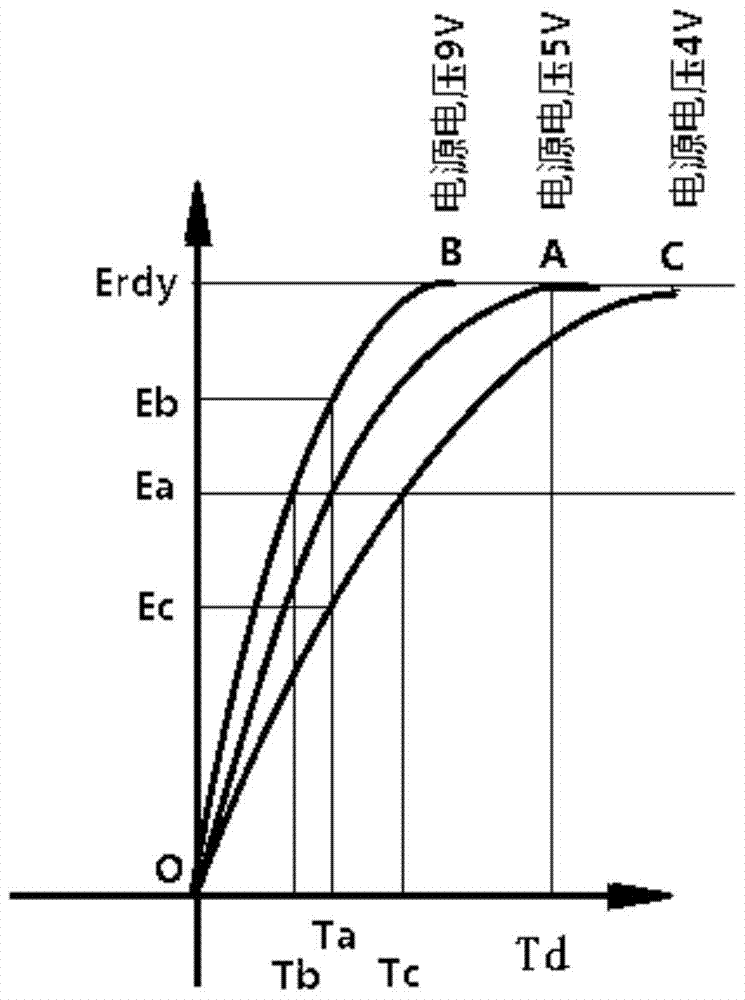

The invention relates to a closed-loop control method of a low-voltage DC CDI (Loop locked CDI, LLCDI) igniter, comprising steps: 1: setting a two-point or multi-point boost detection circuit, that is, the lowest ignition energy voltage point and the highest limited voltage point; 2: Measure the time Td for boosting the voltage to the highest limit point voltage when powering on, and load the appropriate duty cycle parameters accordingly; 3: Measure the time Ea for the boost charging voltage from zero (after the last ignition trigger) to the lowest ignition energy voltage point Point time Tp, 4: compare the measured Tp with the set standard Ts, and adjust the duty cycle of the boost signal by one (or more) duty cycle steps accordingly; 5: trigger discharge , the boost circuit starts working again; iteratively execute steps 3, 4, and 5 until the adjusted boost curve coincides with the predetermined boost curve at the highest degree, and the error between Tp and Ts is the smallest. The present invention improves the integration and efficacy of the DC CDI igniter through the series of closed-loop control methods.

Owner:欧阳小录

A Method for Analyzing the Minimum Ignition Energy of Combustible Gas

ActiveCN112347690BEfficient analysisThe method steps are simpleFuel testingMaterial exposibilityThermodynamicsDetonation

Owner:XIAN UNIV OF SCI & TECH

Testing device of minimum ignition energy of gas-solid two-phase combustible material

InactiveCN109668999AEasy to operateGood repeatabilityChemical analysis using combustionGas solidBuffer tank

The invention relates to a testing device of the minimum ignition energy of a gas-solid two-phase combustible material and application. The testing device is mainly used for solving the problem that aminimum ignition energy testing method aiming at gas-solid two phases is not provided in the prior art. The testing device of the minimum ignition energy of the gas-solid two-phase combustible material is adopted, a spherical testing cavity serves as a device main body, a vacuum pump and a buffer tank are connected to a cavity body, an ignition electrode is mounted on a flange on the upper side of the cavity body, one end of a precise electric spark generator is connected with the ignition electrode, and the other end of the precise electric spark generator is connected with a computer. The problem is well solved through the technical scheme, and the testing device can be used for testing the minimum ignition energy of the gas-solid two-phase combustible material.

Owner:CHINA PETROLEUM & CHEM CORP +1

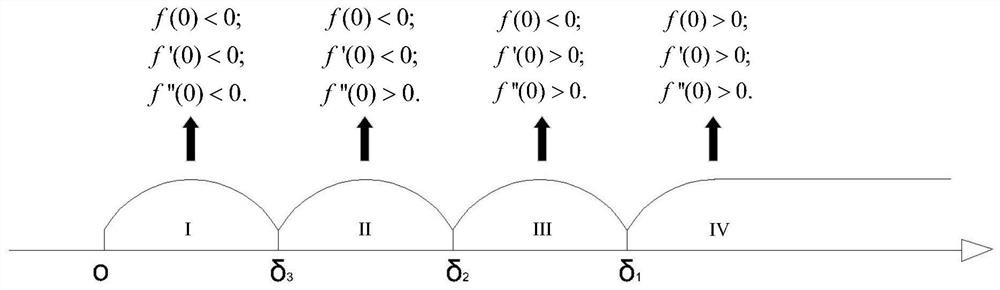

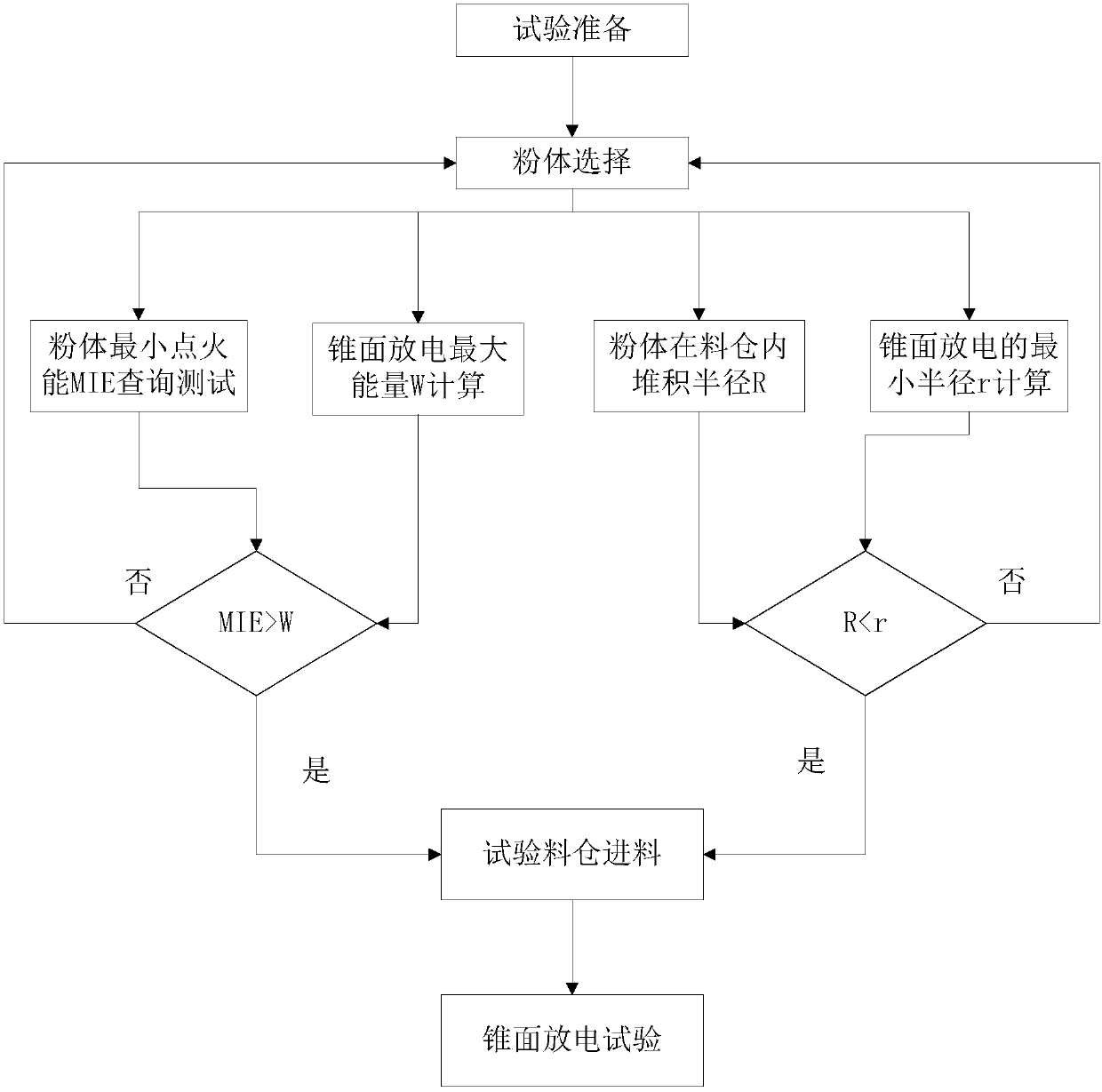

Conical surface discharge test method for powder bin

InactiveCN109683065AGuaranteed normal combustionGuaranteed explosionTesting dielectric strengthMeasuring interference from external sourcesMinimum ignition energyMaterials science

The invention relates to a conical surface discharge test method for a powder bin, which mainly solves the problems of easy explosion and poor safety caused by conical surface discharge in the prior art. The conical surface discharge test method for the powder bin comprises the following steps of: determining minimum ignition energy MIE of powder, calculating a maximum energy W of the conical surface discharge of the powder in a bin, calculating a minimum radius r of the conical surface discharge of the powder in the bin, and determining a relation among the MIE, the W and the r; wherein the minimum ignition energy MIE of the powder is obtained by an inquiry or a test; a calculation formula of the maximum energy W of the conical surface discharge of the powder in the bin is W=5.22D2.36d1.46, wherein D is a diameter of a grounding bin, m; and d is a median diameter of stacked powder, mm. According to the technical scheme, the minimum radius r of the conical surface discharge of the powder in the bin is calculated through a safety material level gauge, so that the problem is better solved, and the method can be used for the conical surface discharge test of the powder bin.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com