Method for enabling laser to induce metal target plasma to achieve ignition of flammable gas and device for achieving same

A plasma and laser-induced technology, which is applied in the fields of combustion ignition, combustion method, lighting and heating equipment, etc., can solve the problems of low ignition success rate, high minimum ignition energy, and high laser output energy requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

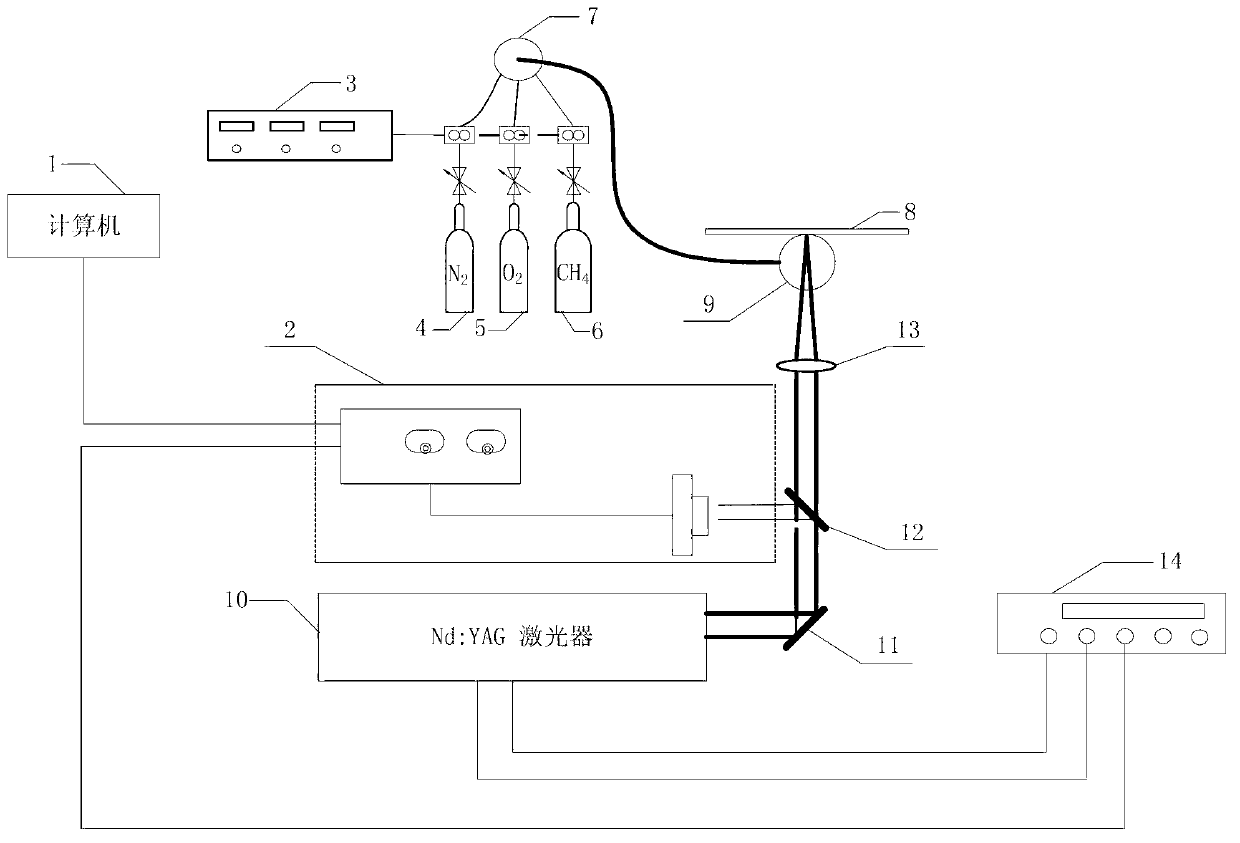

[0020] Specific implementation mode 1. Combination figure 1 Describe this specific embodiment, a kind of method that laser induces metal target plasma to realize combustible gas ignition, it is realized by the following steps:

[0021] Step 1. Pass the premixed combustible gas in the premixed tank into the quartz tube;

[0022] Step 2. Place a metal target on the side above the nozzle of the quartz tube; use a Nd:YAG laser to emit a laser beam, and use a focusing device to focus the laser beam on the surface of the metal target, induce the metal target to generate plasma, and place the quartz tube nozzle on the surface of the metal target. The premixed combustible gas at the place ignites.

[0023] In the above process, an energy meter is also used to measure the reflected energy of the laser beam passing through the beam splitter, so as to obtain the minimum ignition energy.

[0024] The gas in step 1 can also be a mixed gas of methane and air, or N 2 , O 2 and CH 4 of m...

specific Embodiment approach 2

[0026] Specific Embodiment 2. A device for realizing the ignition of combustible gas by laser-induced metal target plasma described in Specific Embodiment 1, which includes N 2 Cylinder 4, O 2 Cylinder 5, CH 4 Gas bottle 6, premix tank 7, metal target 8, quartz tube 9, Nd:YAG laser 10, reflector 11, beam splitter 12 and lens 13;

[0027] The N 2 The gas outlet of gas cylinder 4 and the N of premix tank 7 2 The air inlet is connected; the O 2 The gas outlet of cylinder 4 and the O of premix tank 7 2 Inlet communication; the CH 4 The gas outlet of gas cylinder 4 and the CH of premix tank 7 4 The air inlet is communicated; the air outlet of the premix tank 7 is communicated with the end of the quartz tube 9; the metal target 8 is arranged on the side above the mouth of the quartz tube 9;

[0028] The laser light that Nd:YAG laser device 10 produces is reflected to spectroscope 12 by reflector 11, is divided into reflected light and transmitted light through spectroscope 12...

specific Embodiment approach 3

[0029] Embodiment 3. The difference between this embodiment and the device for igniting combustible gas by laser-induced metal target plasma described in Embodiment 2 is that it also includes a dual-channel energy meter 2, and the No. 1 reflected light is incident on the Probe for dual channel energy meter 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com