Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

224results about How to "Improve ignition success rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Thick oil reservoir fire flooding oil extraction combustion-supporting ignition method

InactiveCN102071918AConducive to production operationEasy to implementFluid removalCombustionEquivalent weight

The invention belongs to the technical field of fire flooding oil extraction and in particular relates to a thick oil reservoir fire flooding oil extraction combustion-supporting ignition method. The method is implemented by the following steps of: (1) building an injection well on the conventional well network and a plurality of production wells at the periphery of the conventional well network according to oil layer geological information to form an area well network or a row-line type well network, wherein in the row-line type well network, one well row is the injection well and the adjacent well rows are the production wells; (2) injecting high-temperature steam with equivalent weight of 250 to 300 cubic meters of water into the injection well in the step (1) and preheating a ground layer to 210 to 250 DEG C; and (3) at the later stage of injecting the steam, mixing a combustion improver and crude oil according to the weight ratio of the combustion improver to the crude oil of 8.5 to 11.6 percent, injecting the mixture into the ground layer together with the high-temperature steam, and then continuously injecting sufficient air. By the method, the threshold temperature of high-temperature oxidation of the crude oil is greatly reduced and oil is easy to ignite; ignition is easy to implement; the ignition time is shortened; the ignition success rate is high; and construction is performed conveniently.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Fire flooding oil extraction crude oil combustion-assistant ignition process

InactiveCN101122227AConducive to production operationEasy to implementFluid removalPlatinumCombustion

The invention relates to a crude oil assisted combustion and ignition technique for the fire flooding oil exploitation. With the techniques, high-temperature steam and a combustion additive mainly comprising platinum, palladium and other metal are injected into an oil layer through an injection well, so as to enter a normal ignition course more quickly. The ignition techniques can be implemented easily, the ignition period is short, and the ignition success rate is high. With the techniques, the ignition course can be completed smoothly within a shorter time, which is favorable for the production and operation of fire flooding oil exploitation.

Owner:LIAOHE GASOLINEEUM EXPLORATION BUREAU

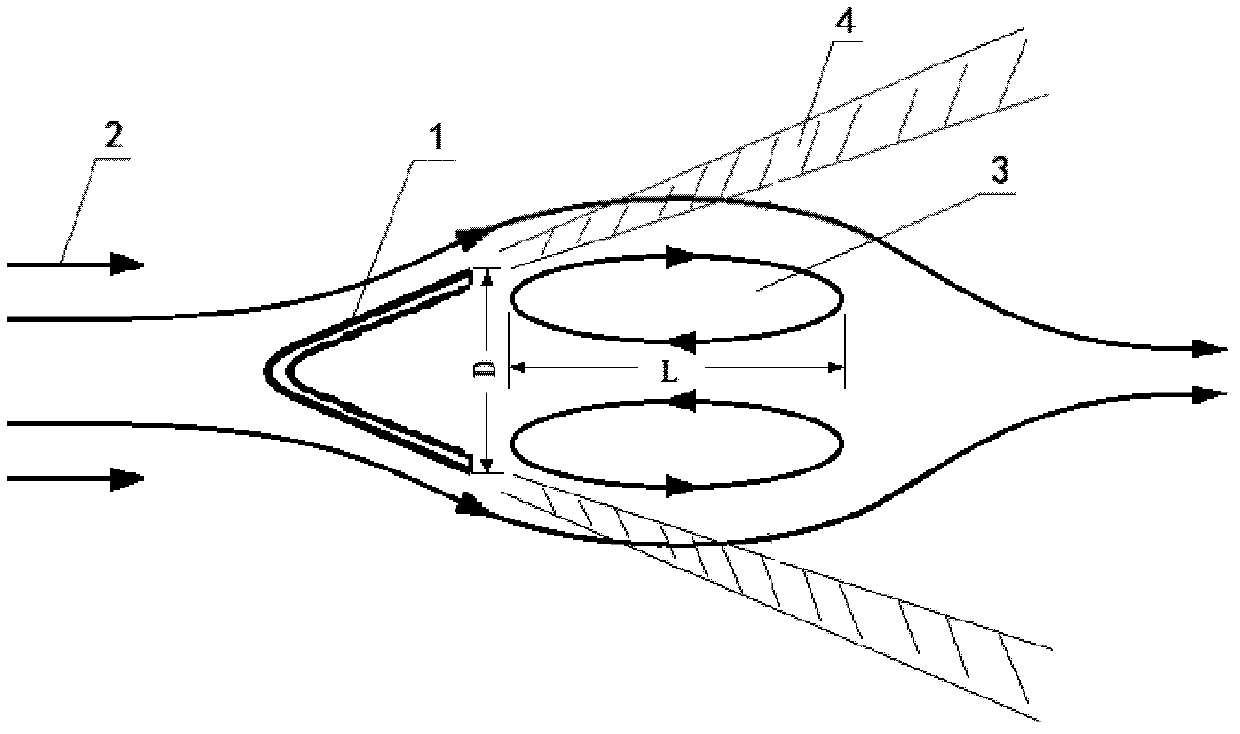

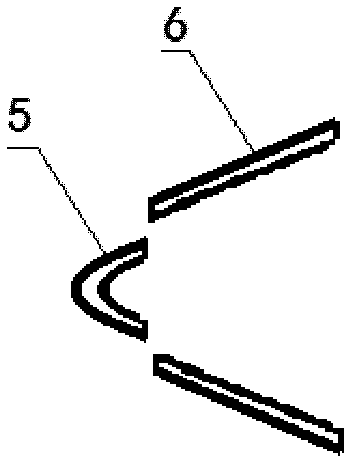

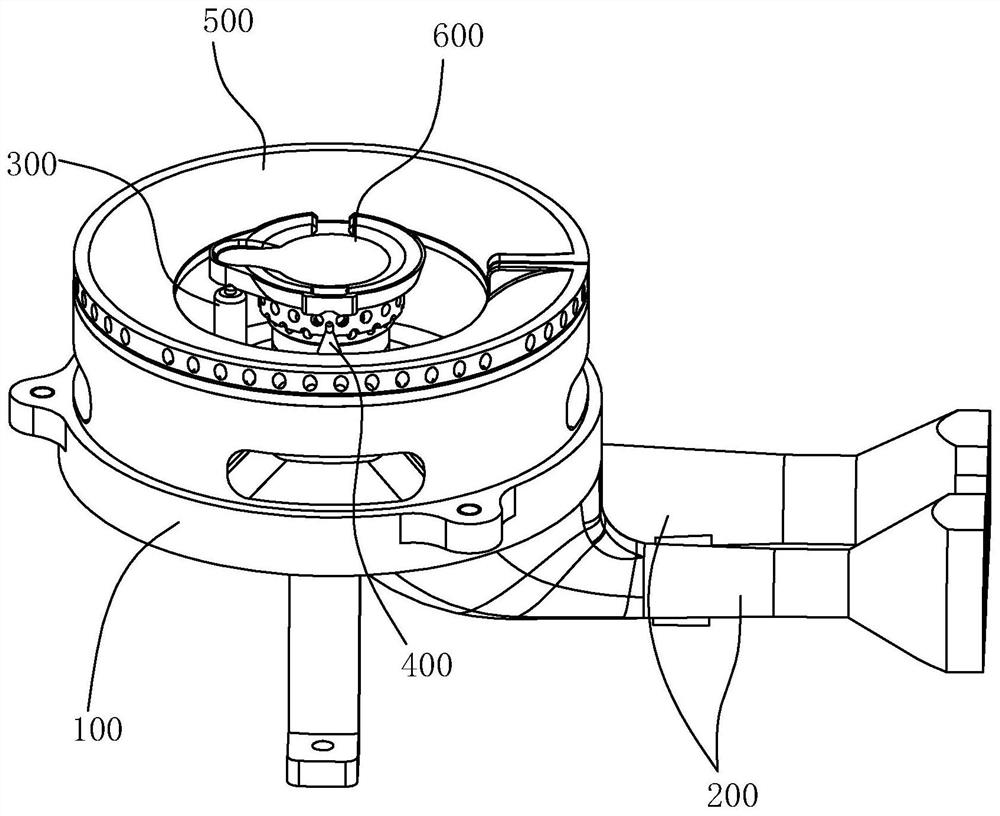

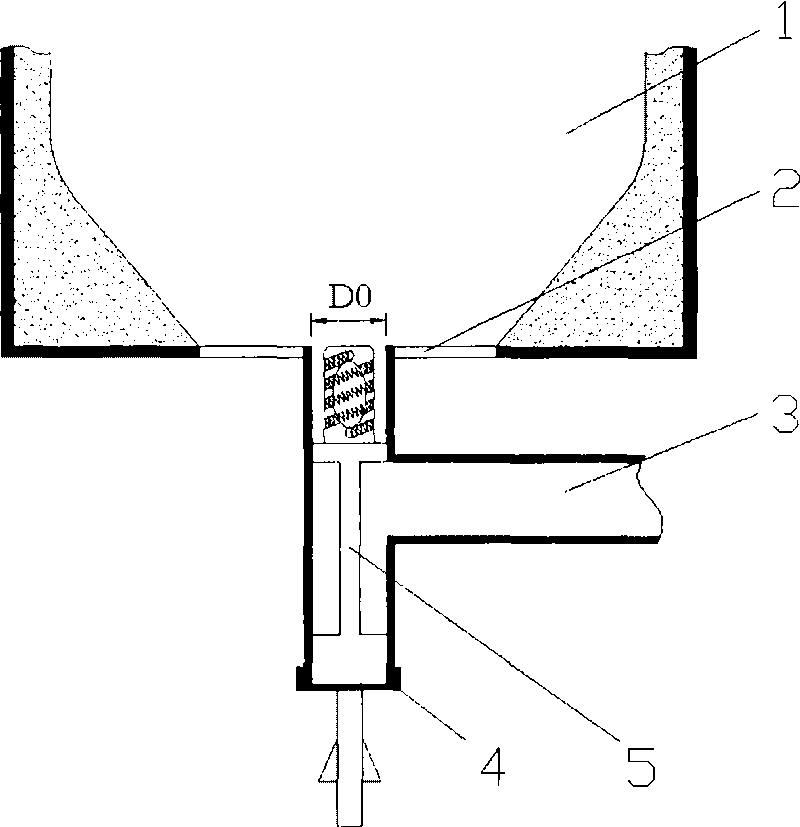

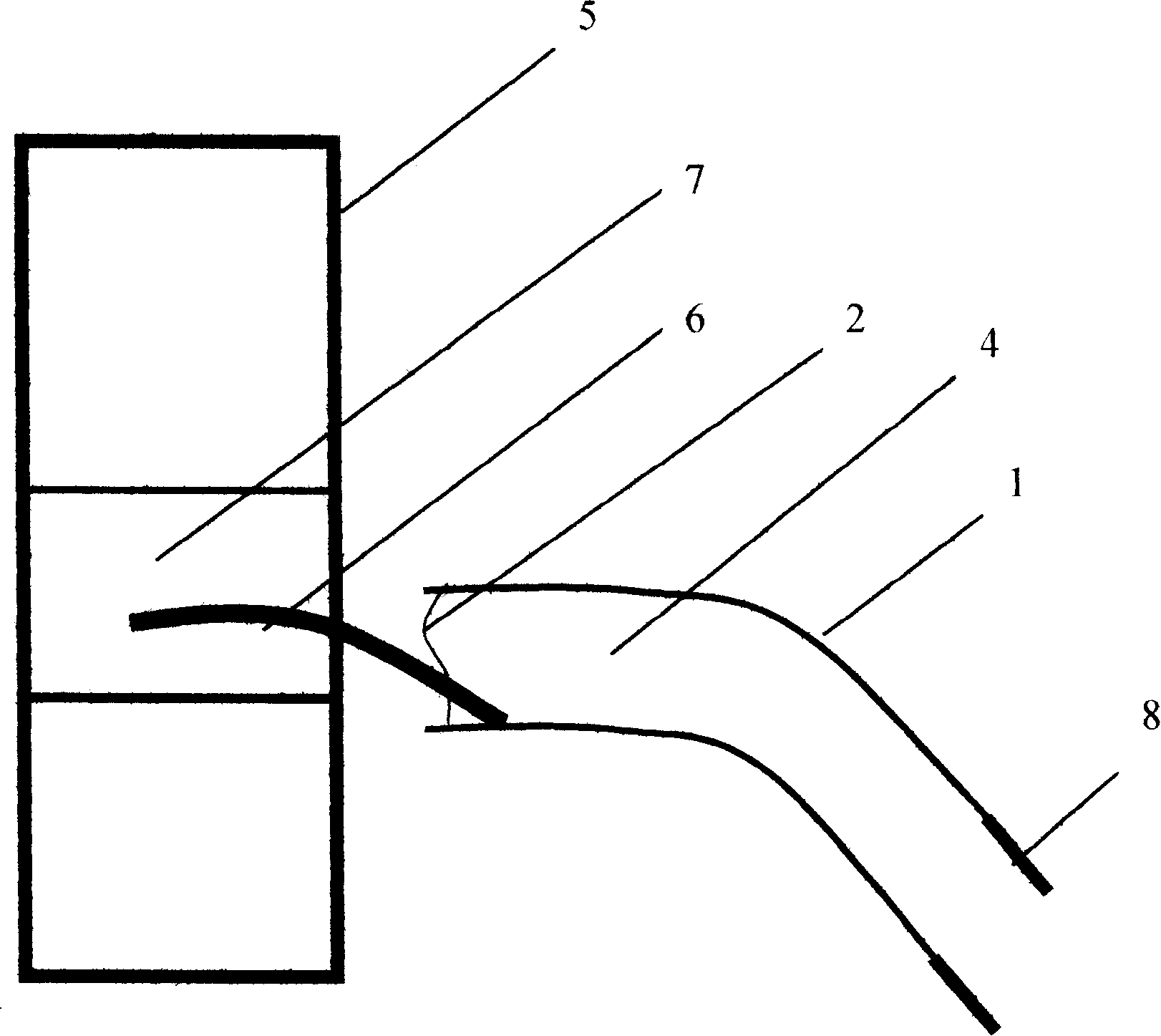

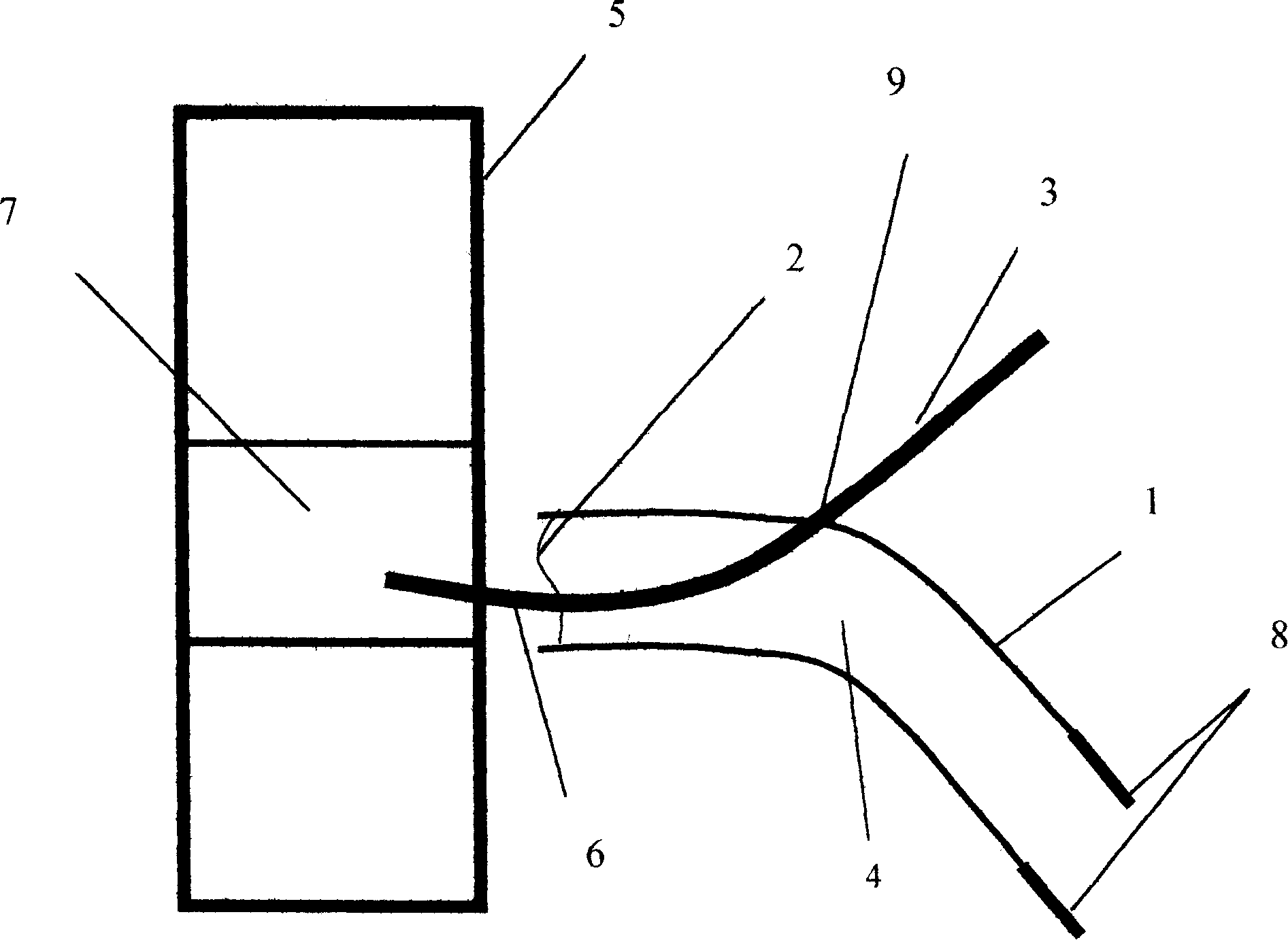

Geometrical variable flame stabilizing device

InactiveCN102607061ALow flow resistanceImprove thrust performanceContinuous combustion chamberCombustion chamberEngineering

The invention discloses a geometrical variable flame stabilizing device and belongs to the technical field of afterburner flame stabilization of aircraft engines. The geometrical variable flame stabilizing device disclosed by the invention utilizes a V-shape as a basic bluff body structure and consists of a main body part and a transmission power part, wherein the main body part is vertically installed in an afterburner cartridge receiver, the afterburner cartridge receiver comprises a front streamline head part, a blade A with a rotating shaft A, a blade B with a rotating shaft B, a rotating shaft supporting plate and a mounting seat, and the two ends of the streamline head part are fixedly connected between the mounting seat and the rotating shaft supporting plate. The geometrical shape of the flame stabilizing device provided by the invention can be changed to effectively reduce the flow resistance of the flame stabilizing device if necessary, or the flow resistance is increased within a short time to improve the ignition success rate, or the geometrical shape of the flame stabilizing device is adjusted to consistently keep the flame stabilizing device at the optimal combination point of the flame stabilization and flow resistance loss so as to obtain the maximal thrust performance of the afterburner.

Owner:BEIHANG UNIV

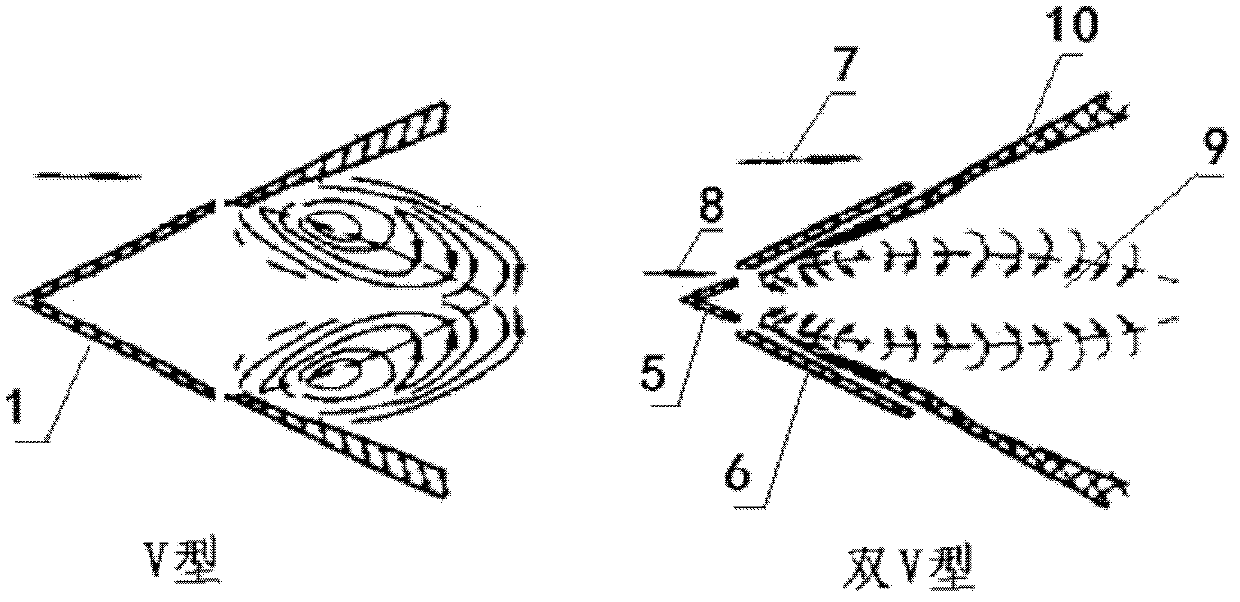

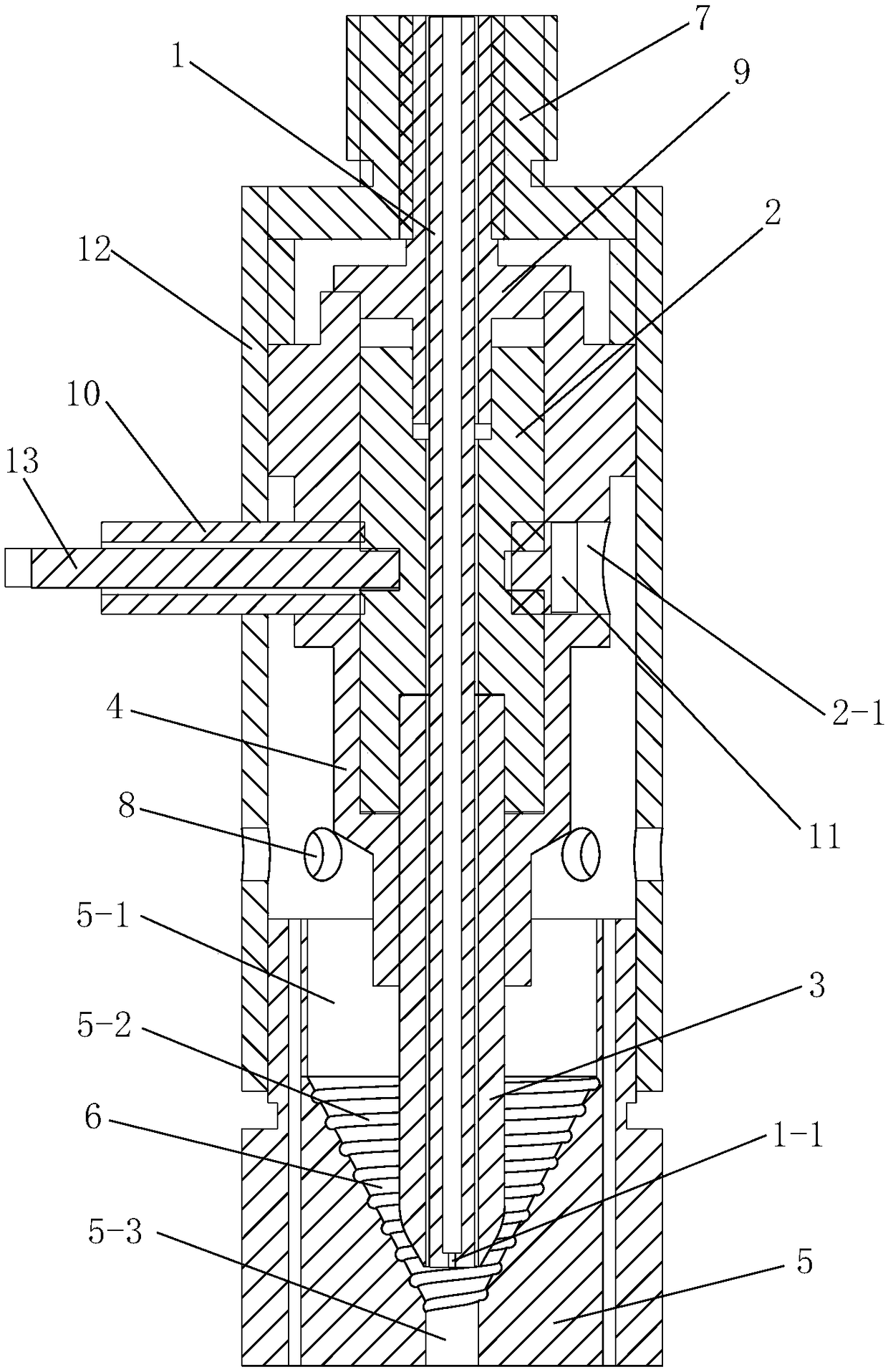

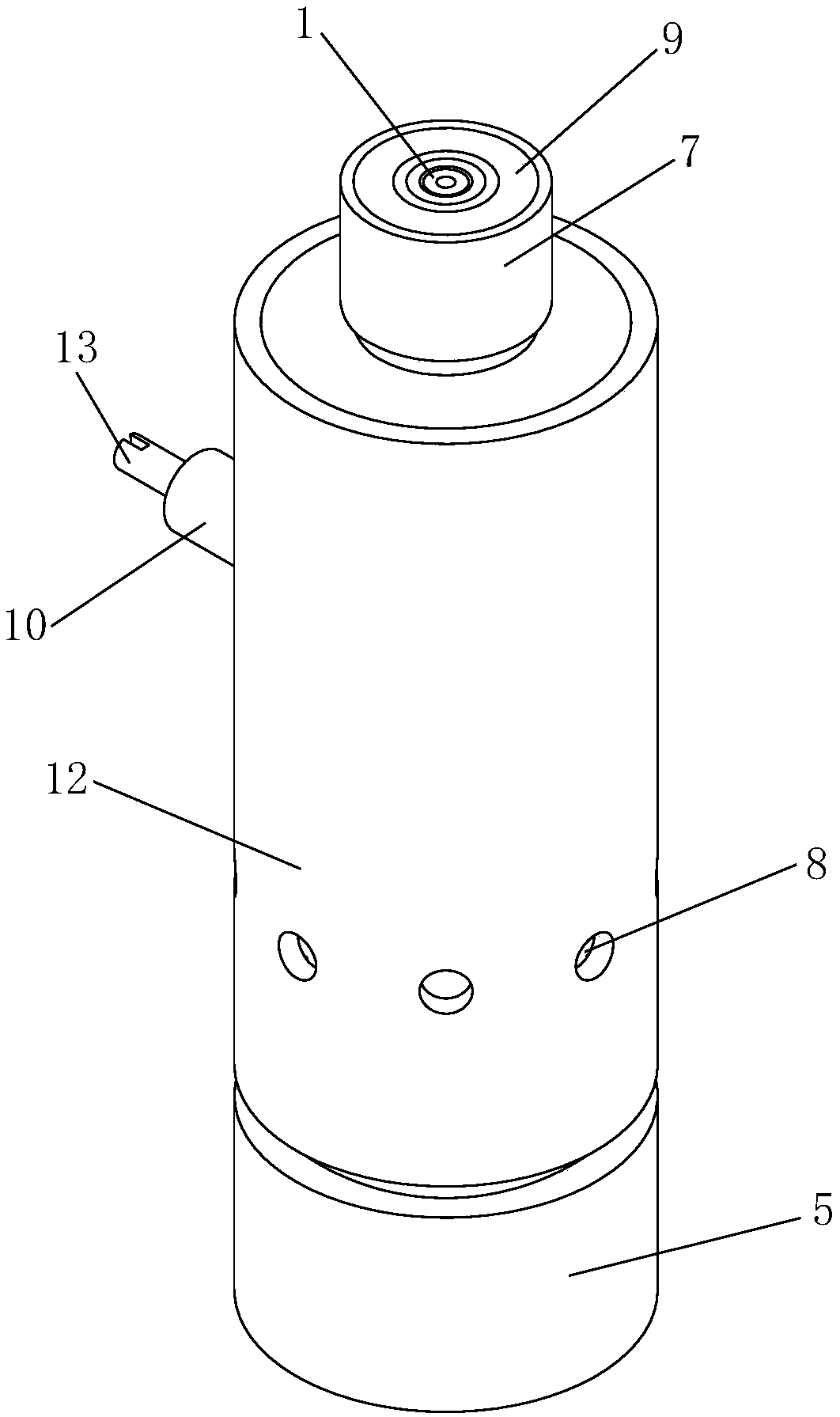

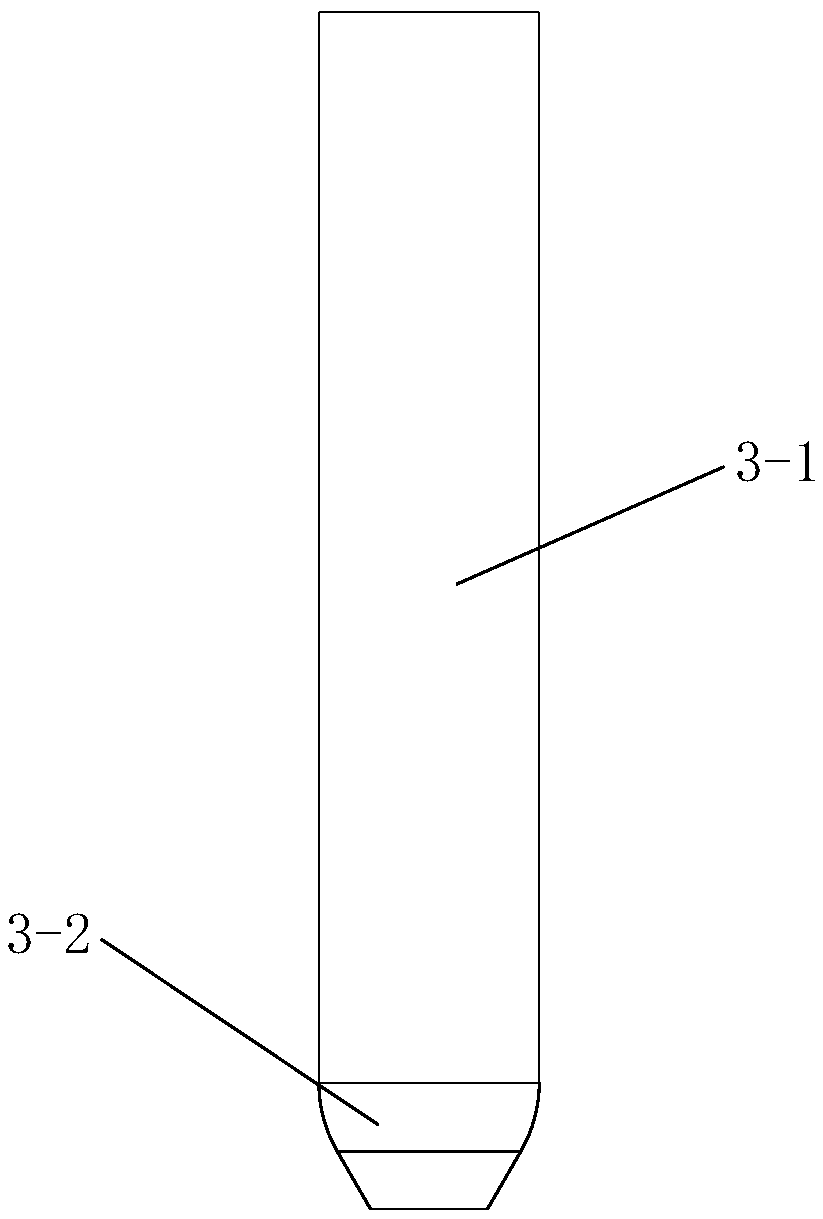

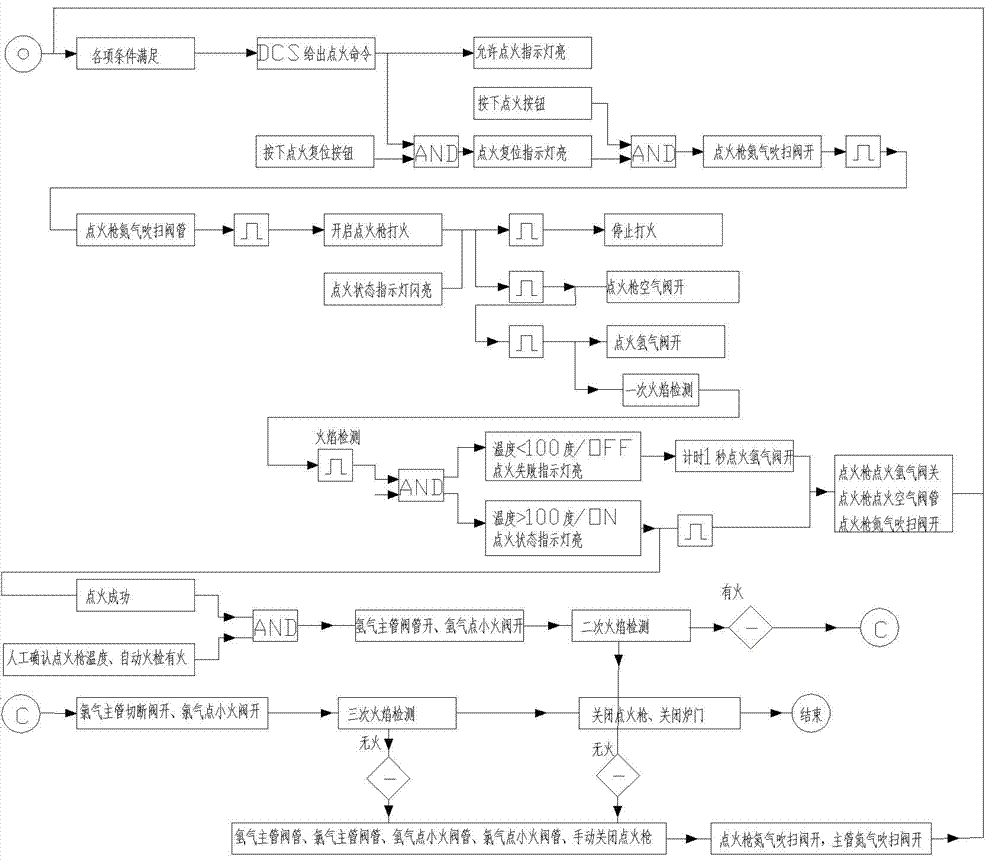

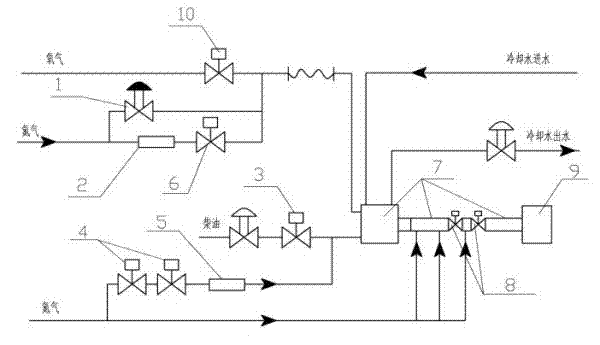

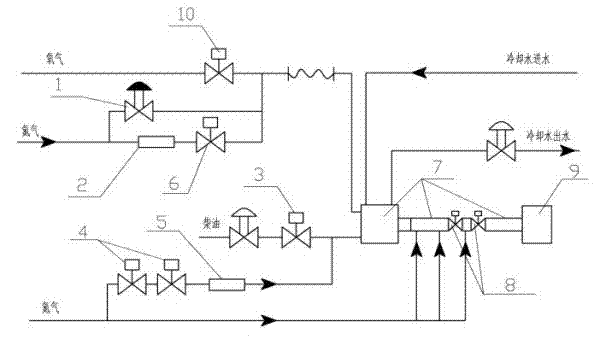

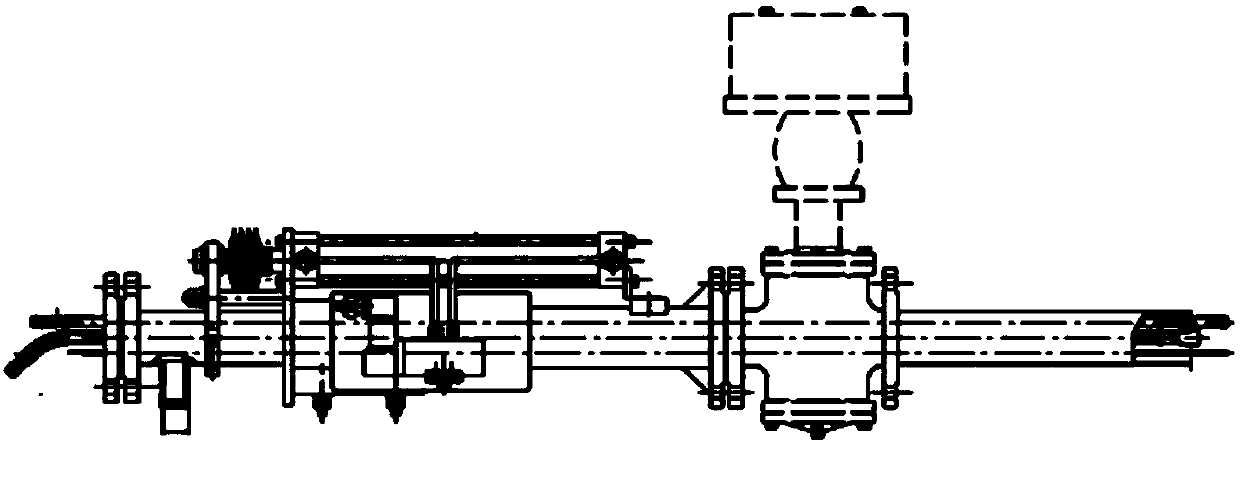

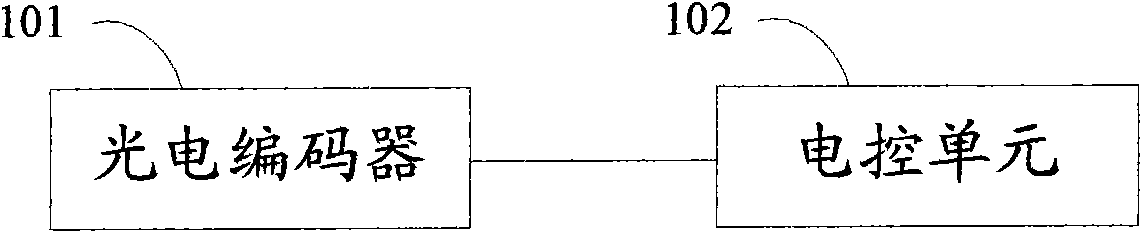

Method for controlling igniter burner of powdered coal pressurized gasifier

ActiveCN104449867AImprove ignition success rateImprove securityGasification processes detailsCombined combustion mitigationWarming processProcess engineering

The invention discloses a method for controlling an igniter burner of a powered coal pressurized gasifier and provides a method for logic control of an igniter burner of a multi-nozzle counter-position type powdered coal pressurized gasifier. According to the technical scheme, the method comprises the following steps: 1, 'initializing' the igniter burner; 2, 'resetting' the igniter burner in the following way: (1) performing nitrogen sweeping, (2) establishing emptying flows of fuel gas and factory air, and (3) switching on inlet fuel gas and inlet oxygen flow adjusting valves according to a preset valve opening and flow relationship; 3, 'igniting' by the igniter burner in the following way: (1) introducing ignition fuel gas and ignition factory air into the gasifier in sequence and discharging by the igniter, wherein the igniter successfully ignites when a flame detector of the igniter detects a flame signal; (2) introducing heating fuel gas and oxygen into the gasifier in sequence, wherein the ignition of the gasifier is successful when the flame detector detects a flame signal and the hearth temperature of the gasifier is of a rising trend; (3) exiting the igniter and introducing protective nitrogen gas, and (4) switching the fuel gas and oxygen during a heating process; 4 'exiting' the igniter burner; and 5, introducing steam to protect the igniter burner. By adopting the method disclosed by the invention, a logic control scheme and a detection manner are reasonably optimized according to technological requirements of a powdered coal gasification production device, the ignition success rate and security of a water cooled wall gasifier are improved, and the driving time and cost are saved.

Owner:水煤浆气化及煤化工国家工程研究中心

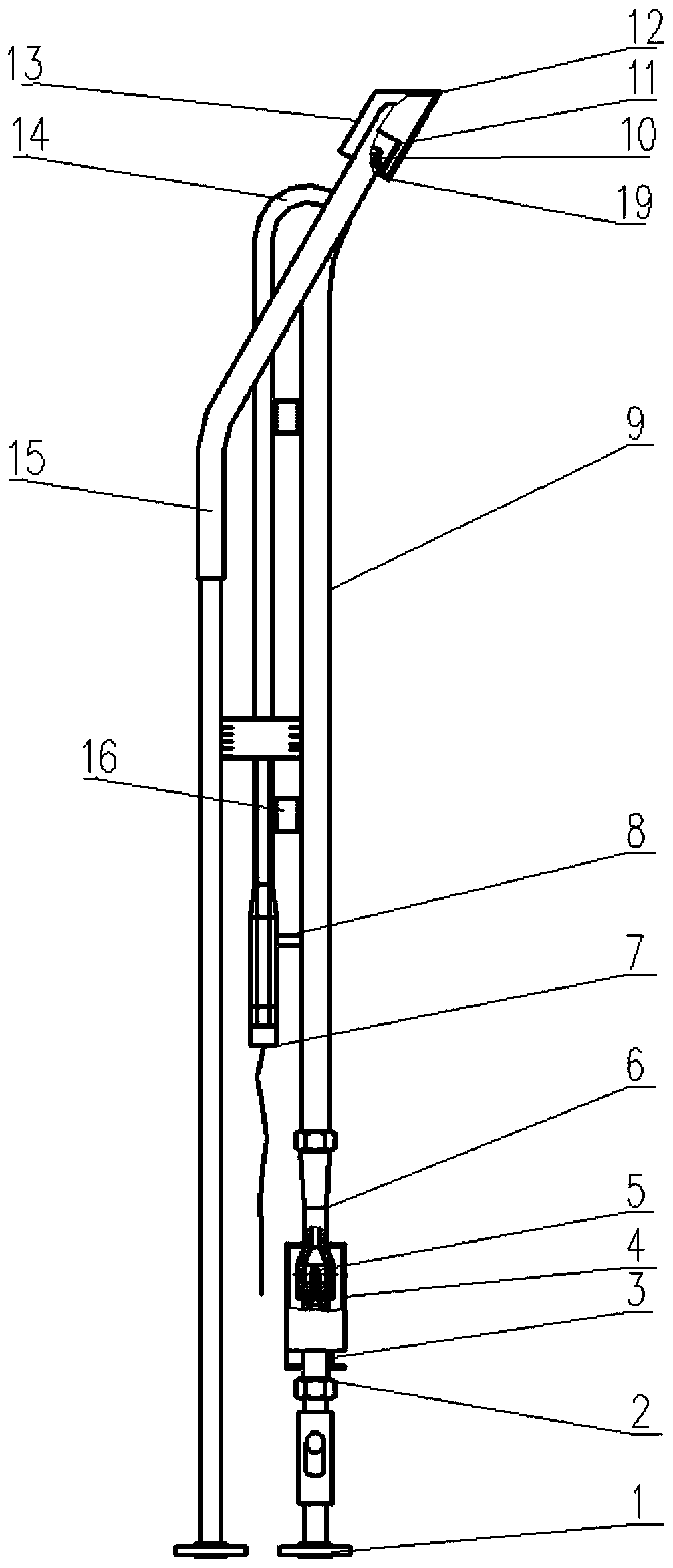

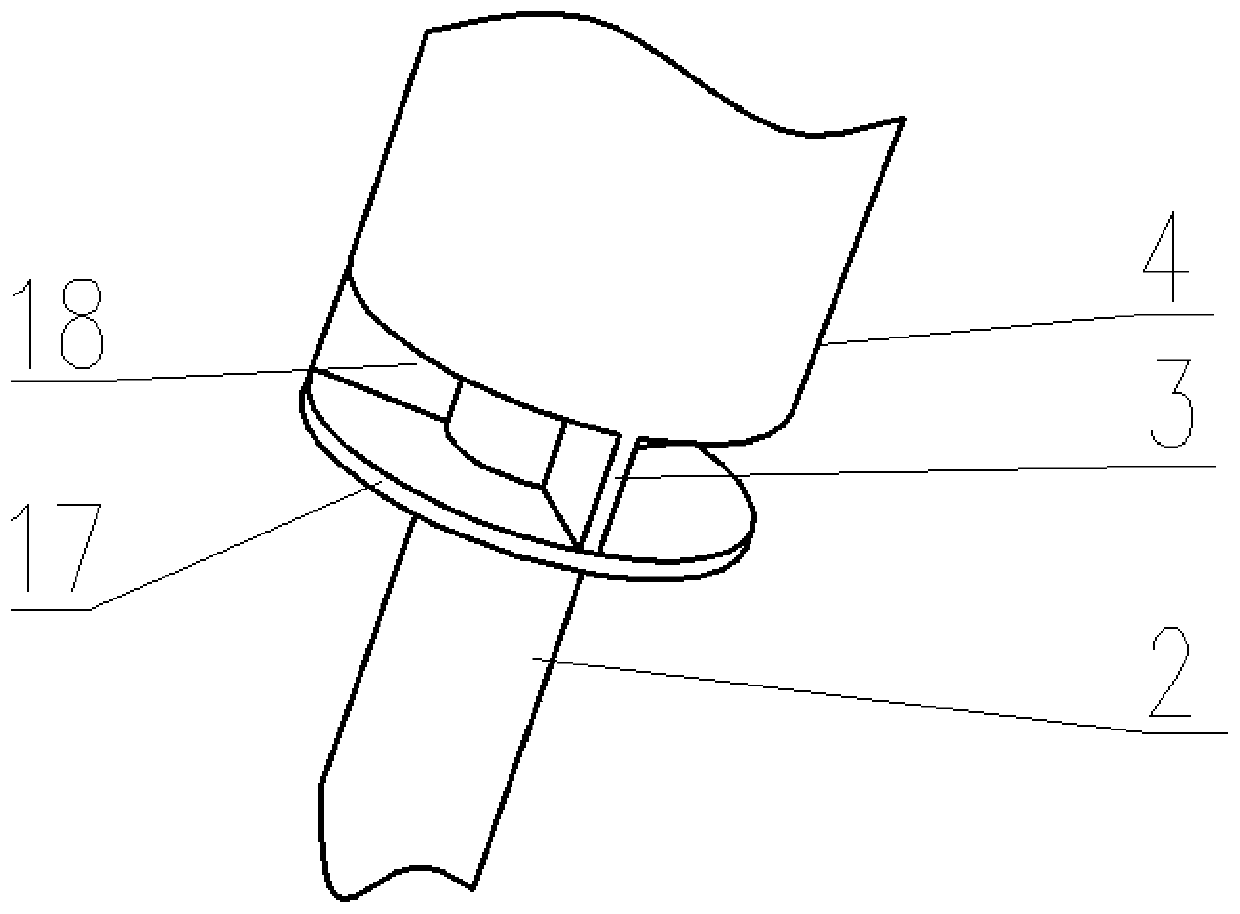

Pre-combusted aircraft engine plasma igniter

ActiveCN109057972ASimplify the intake structureSlender head of igniterGas turbine plantsJet propulsion plantsAero engineIGNITOR

The invention discloses a pre-combusted aircraft engine plasma igniter. The pre-combusted aircraft engine plasma igniter comprises an outer tube, a ceramic tube fuel channel, a cathode portion, an anode, an insulation sleeve, a bushing and a top cover; the cathode portion is installed on the middle-lower portion of the ceramic tube fuel channel in a sleeving mode, and a nozzle is arranged at the front end of the ceramic tube fuel channel; the insulation sleeve is installed on the middle-upper portion of the cathode portion in a sleeving mode and arranged in the outer tube; air inlet holes areformed in the outer wall of the lower portion of the outer tube, the anode is arranged under the air inlet holes, the upper portion of the anode is located in the outer tube and is in threaded connection with the outer tube, and the anode is a hollow revolving body; the cathode portion comprises a cathode base and a cathode, the upper portion of the cathode is in threaded connection with the lowerportion of the cathode base, and a spiral groove is formed in the middle of the inner wall of the anode; the lower end of the bushing is fixedly connected with the upper end of the cathode base; andthe top cover is installed outside the bushing in a sleeving mode, and the lower portion of the top cover is fixedly connected with the upper end of the outer tube. According to the pre-combusted aircraft engine plasma igniter, the ceramic tube fuel channel is additionally installed in the cathode portion, a reaction occurs outside the anode, therefore, electrodes are protected, the safety is improved, and the insulating problem is well solved.

Owner:AIR FORCE UNIV PLA

Automatic ignition system of chlorine hydride synthesis furnace and control method of automatic ignition system

ActiveCN104501206ACompact structureOperational securityChlorine/hydrogen-chloridePilot flame ignitersNitrogenEngineering

The invention relates to an automatic ignition system of a chlorine hydride synthesis furnace and a control method of the automatic ignition system. The automatic ignition system comprises an ignition gun, a flame monitor, a chlorine inlet pipeline, a hydrogen inlet pipeline and a nitrogen inlet pipeline, wherein the ignition gun and the flame monitor are arranged on the side edges of the opening of the chlorine hydride synthesis furnace; the chlorine inlet pipeline, the hydrogen inlet pipeline and the nitrogen pipeline are simultaneously and parallelly connected in series with the bottom of the opening of the chlorine hydride synthesis furnace; the air inlet of the ignition gun is connected in series with an ignition air pipeline; the hydrogen inlet of the ignition gun is connected in series with an ignition hydrogen pipeline; and the input end of the ignition hydrogen pipeline is simultaneously connected with the those of the hydrogen inlet pipeline and the nitrogen inlet pipeline. The automatic ignition system provided by the invention has the advantages as follows the structure is compact; the operation is safe and reliable; the system doesn't need to be in direct contact with hydrogen when the furnace is ignited, can automatically detect and finish the whole ignition process so long as an ignition key is pressed, and thus is very safe and convenient.

Owner:NANTONG STAR GRAPHITE EQUIP CO LTD

Igniting method for gasification furnace start-up burner

The invention relates to an igniting method for a gasification furnace start-up burner. The method comprises the following steps of: before ignition, putting a start-up burner into a hearth of a gasification furnace and purging the start-up burner with nitrogen; and in the ignition process, introducing pure oxygen and diesel into the start-up burner, adjusting nitrogen flow, wherein the pure oxygen flow is 1.15-1.40kg / s, the diesel flow is 0.3-0.45kg / s, and the nitrogen flow is 0.01-0.05kg / s. According to the invention, through introducing certain nitrogen in the ignition process and replacing pure oxygen combustion with oxygen enriched combustion, the phenomenon that the start-up burner is easy to damage because of partial overheating is avoided effectively, and the phenomenon that the start-up burner is damaged by the greater temperature fluctuation of the start-up burner caused by the frequent adjustment of the flow of the fuel diesel in the start-up burner is avoided simultaneously; the ignition success rate of the gasification furnace is improved, the labor intensity is reduced, the production cost is saved, and the maintaining expense is reduced.

Owner:HENAN LONGYU COAL CHEM

Sliding arc combustion supporting device producing atmospheric pressure non-equilibrium plasmas

The invention provides a sliding arc combustion supporting device producing atmospheric pressure non-equilibrium plasmas. The sliding arc combustion supporting device producing the atmospheric pressure non-equilibrium plasmas comprises a pressure gas pipeline, a center electrode pipe, a Laval spraying pipe, a cyclone and the like; a plurality of small holes are formed in the tail end of the center electrode pipe, fuel is sprayed out of the small holes to be atomized, and is fully mixed in the Laval spraying pipe with combustion-supporting gas rectified by the cyclone. The left end of the center electrode pipe is connected with a high voltage power source to serve as an anode; the Laval spraying pipe is grounded to serve as a cathode; the center electrode pipe and the wall face of the Laval spraying pipe perform discharging to generate the plasmas; arc columns of sliding arcs generate a catalysis reaction in a gas mixing area to perform combustion; and flames are sprayed out of the Laval spraying pipe to act on an external connection device. The sliding arc combustion supporting device producing the atmospheric pressure non-equilibrium plasmas is compact in structure, convenient to machine, high in combustion supporting efficiency and capable of being used for combustion supporting of a matched combustion device.

Owner:航天神洁(北京)科技发展有限公司 +1

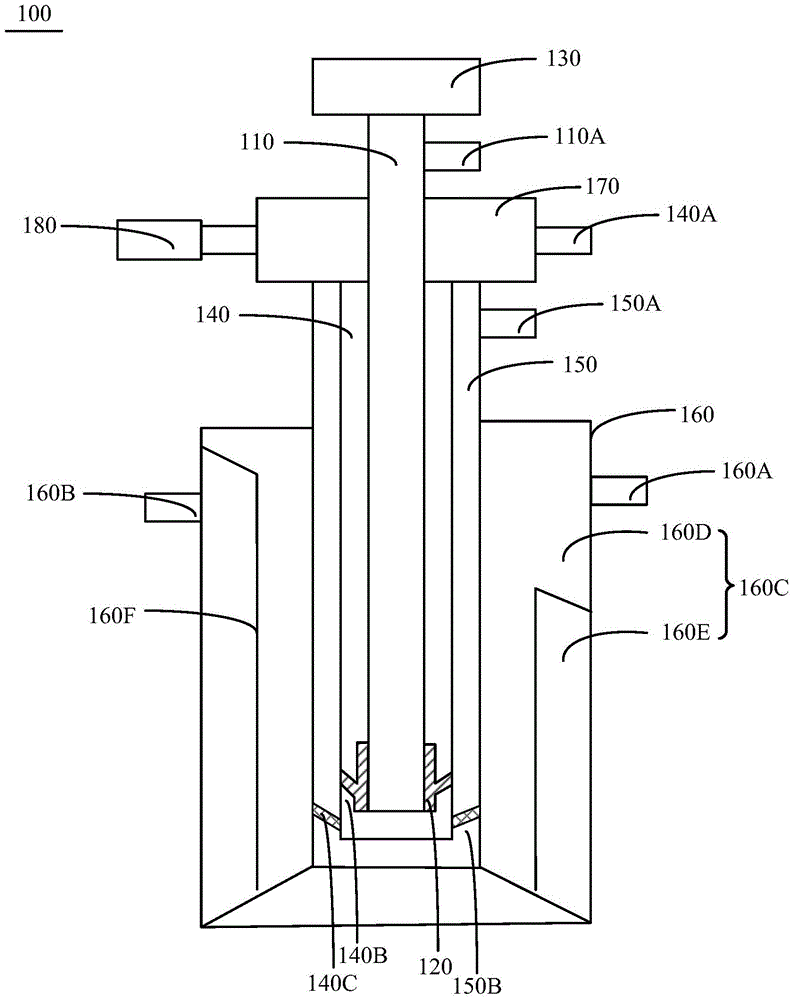

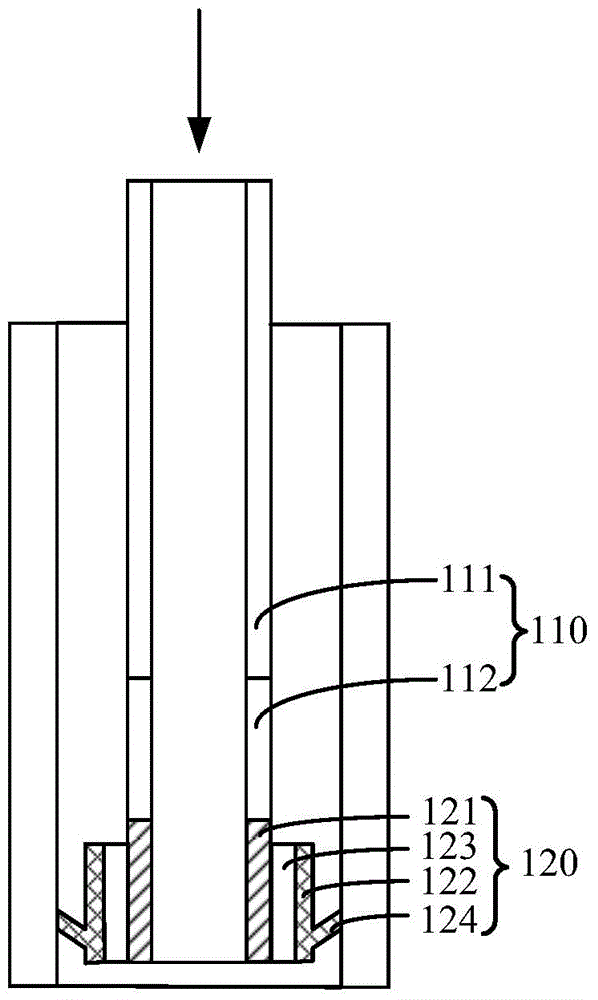

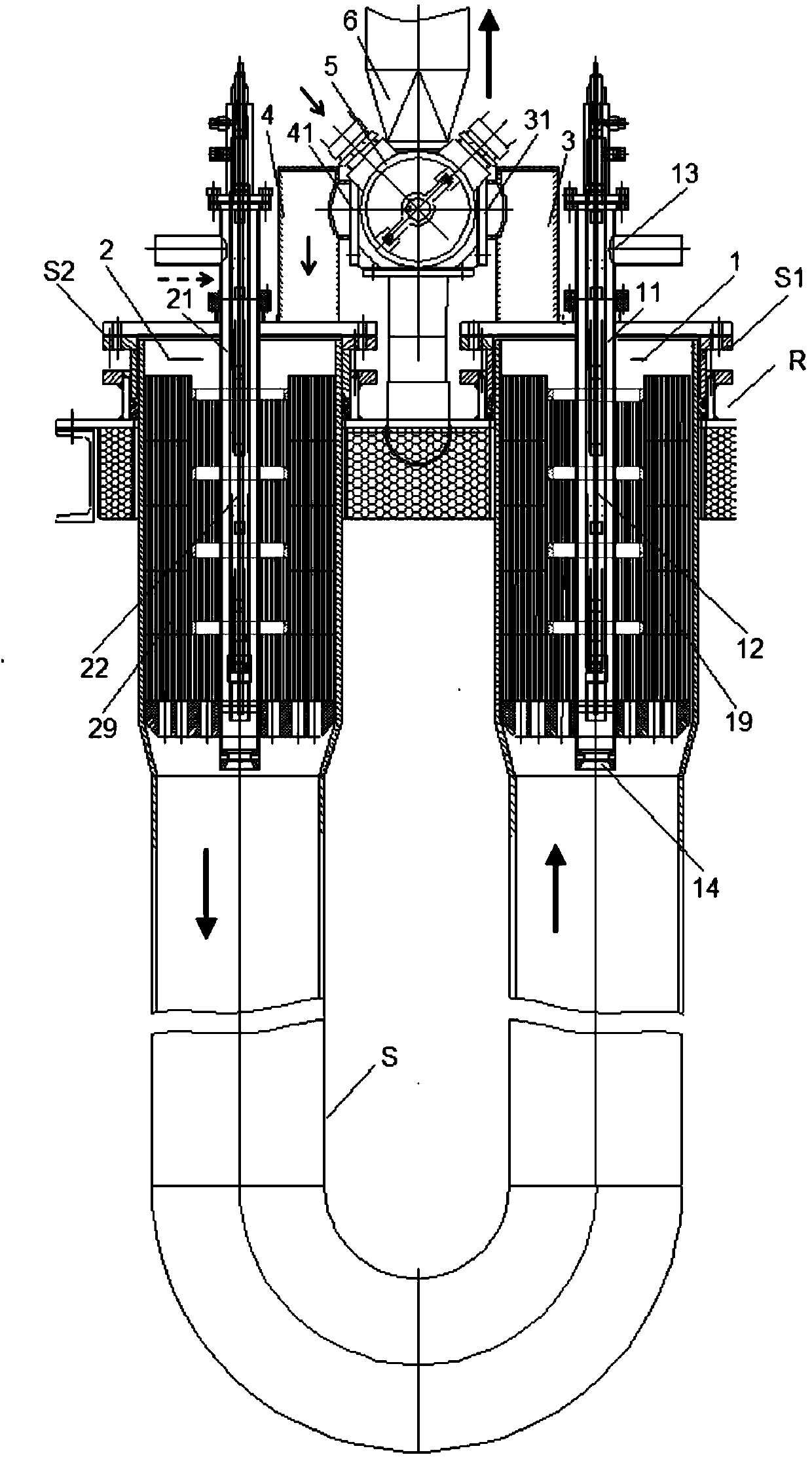

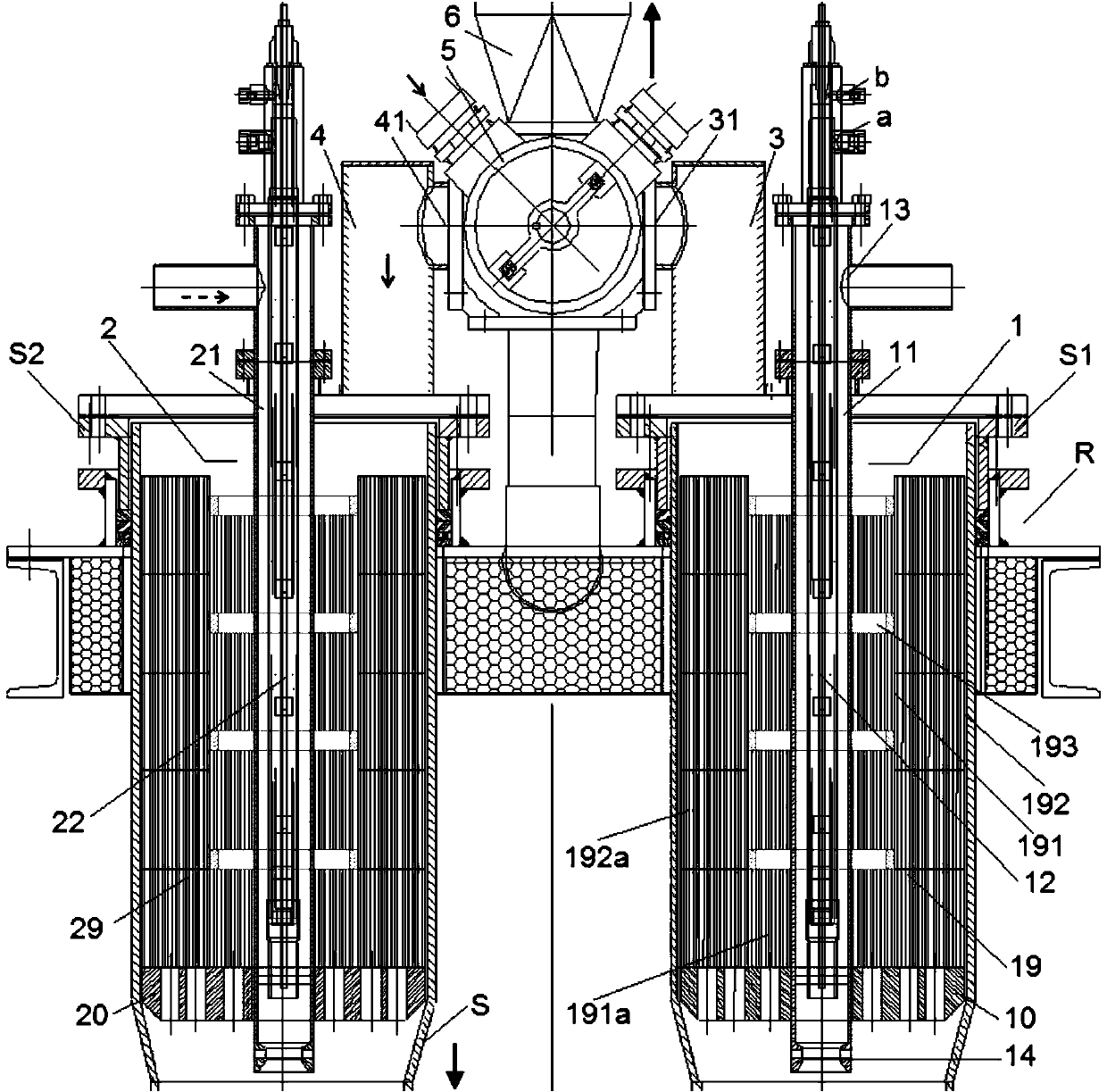

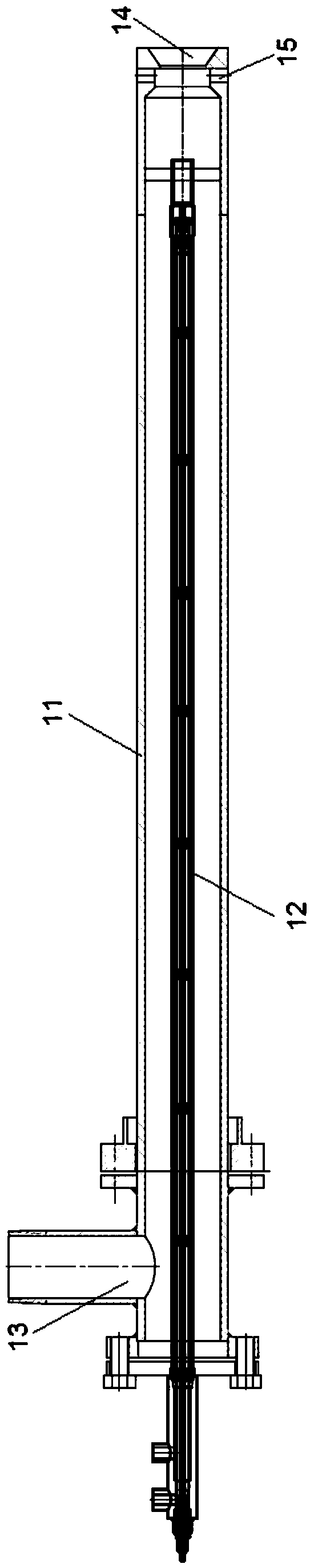

Burner ignition device and high-energy igniter

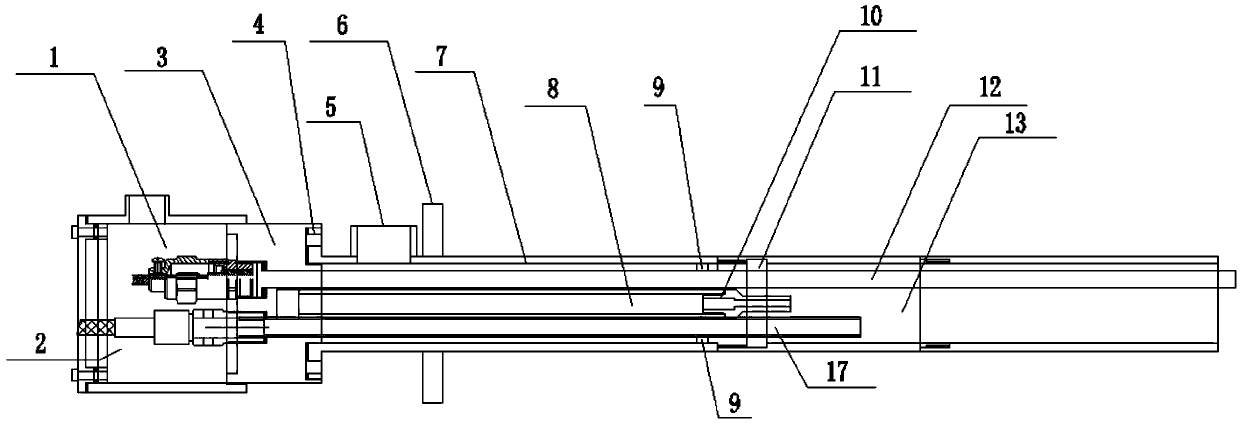

InactiveCN105783028AImprove ignition success rateImprove flame stabilityElectric spark ignitersChamber safety arrangementCombustorInsulation layer

The invention discloses a burner ignition device and a high-energy igniter. The burner ignition device comprises a hollow pipe, the high-energy igniter, a flame monitor, a fuel conveying pipe, a fuel inlet, a combustion improver conveying pipe, a combustion improver inlet and a cooling water conveying pipe. The high-energy igniter is arranged at a first end of the hollow pipe, and includes an anode, a cathode arranged out of the anode and an insulation layer from insulating the anode from the cathode; and a hollow structure communicated with the hollow pipe is formed in middle of the anode. The flame monitor is arranged at a second end of the hollow pipe for monitoring the flame conditions through the hollow pipe and the hollow structure. The fuel conveying pipe coats the hollow pipe and the cathode, and is at least partially separated from the hollow part. The combustion improver conveying pipe coats the fuel conveying pipe, and is at least partially separated from the fuel conveying pipe. The cooling water conveying pipe coats the combustion improver conveying pipe, and two end parts are closed; and the cooling water conveying pipe includes a water inlet, a cooling water circulating channel and a water return port. The device can improve the ignition success rate.

Owner:SHANGHAI QIYAO THERMAL ENERGY ENG CO LTD

Vertical shaft and horizontal shaft joint ignition method in underground coal gasification mining

ActiveCN106194147AIncrease the storage volumeImprove ignition success rateConstructionsCoal gasificationCombustionEngineering

The invention relates to a vertical shaft and horizontal shaft joint ignition method in underground coal gasification mining. In order to solve the problems that according to an existing ordinary ignition method, due to the fact that the initial underground space is small, ignition is difficult, and the ignition time is long, perforation and fracturing are conducted on a coal bed, and a mixed combustion improver and oxygen-rich ignition gas are added, so that the fracturing success rate is increased, ignition can be conducted effectively, the time is shortened, and the human cost is reduced.

Owner:中嵘能源科技集团有限公司

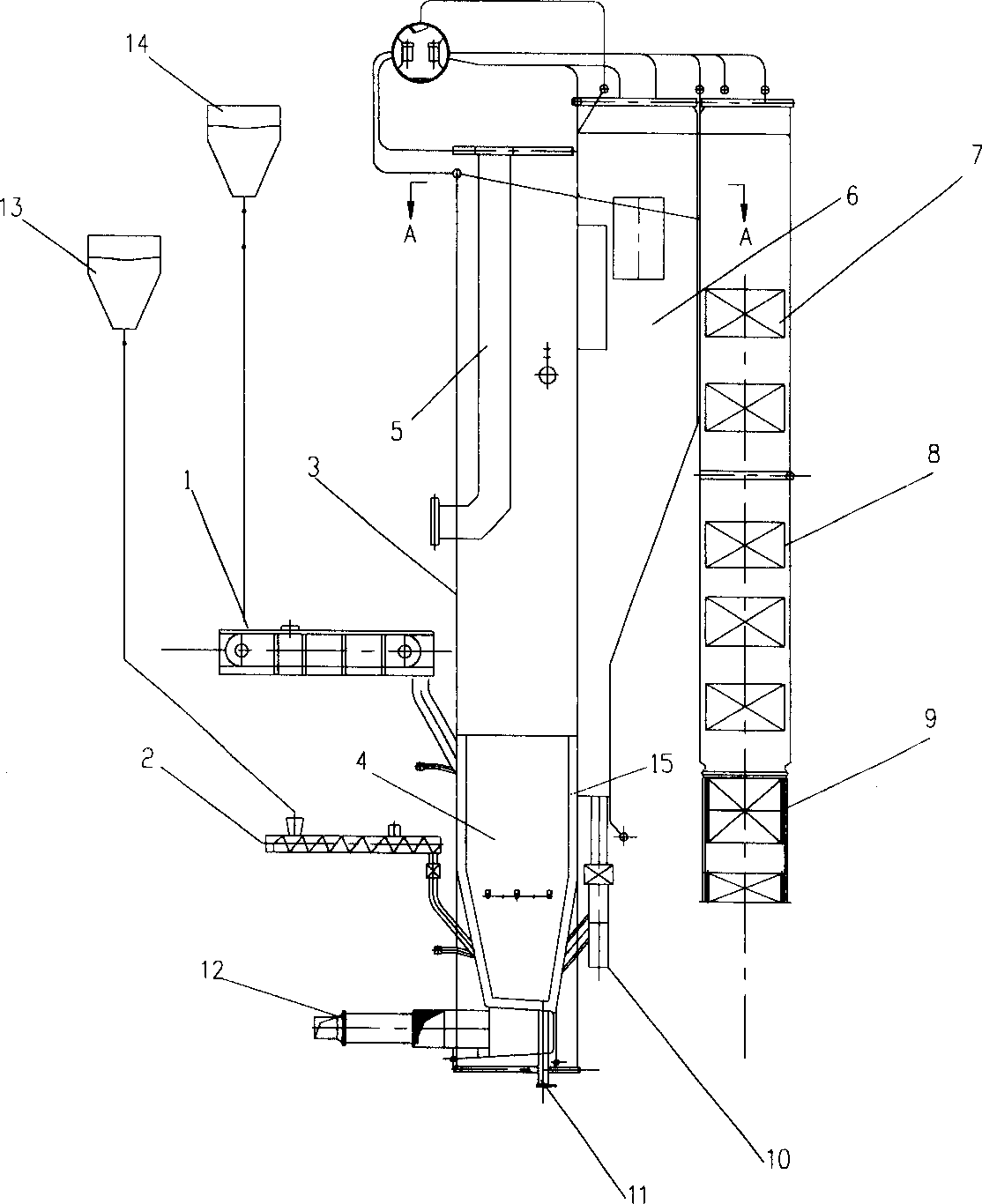

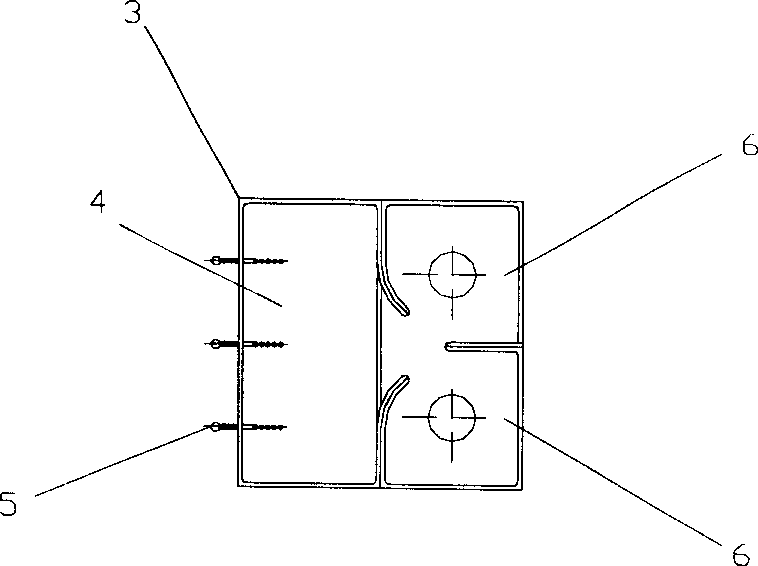

Boiler of circulating fluid bed for burning household garbage

InactiveCN1696569AAvoid cokingAvoid timeFluidized bed combustionIncinerator apparatusBoiler furnaceCombustion chamber

The present invention relates to a circulating fluidized bed boiler for incinerating domestic refuse. Said invention includes the following components: boiler furnace body, combustion chamber, air chamber, air-distributing plate, air channel, lighting-up burner, water-cooling separator, superheater, coal-saving device, air preheating device, refuse feeder and fuel / auxiliary material feeder, etc.

Owner:TSINGHUA UNIV +1

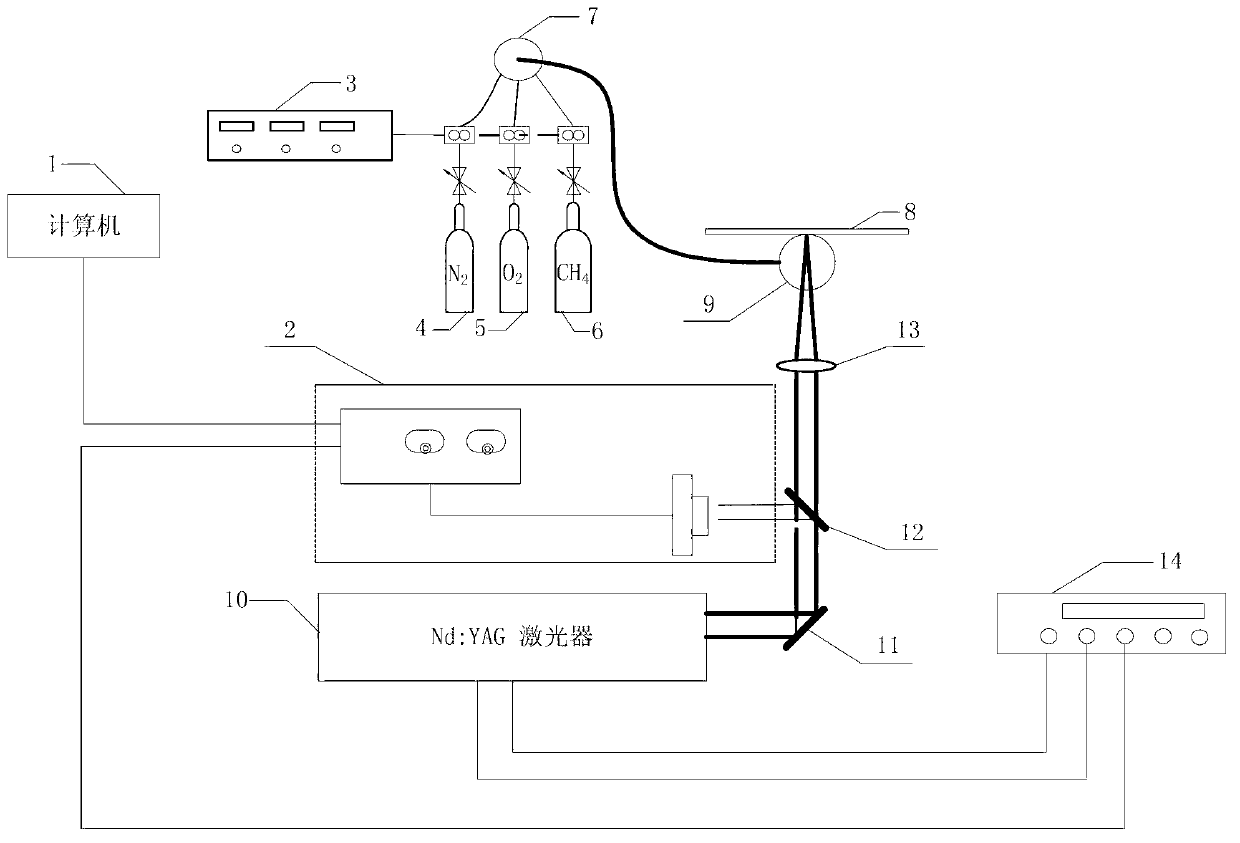

Method for enabling laser to induce metal target plasma to achieve ignition of flammable gas and device for achieving same

InactiveCN103343982AMiniaturizationPromote engineering applicationCombustion ignitionLight beamCombustible gas

The invention provides a method for enabling laser to induce metal target plasma to achieve ignition of flammable gas and a device for achieving the method, and relates to the method for achieving ignition of the flammable gas and the device for achieving the method. The method and the device for achieving the method solve the problem that an existing method for enabling laser to directly breakdown the gas to induce the plasma to conduct ignition is high in minimum ignition energy, low in ignition success rate and high in requirement for laser output energy. The method includes the steps of enabling premixed gas to enter a quartz tube, emitting a laser bundle through a Nd:YAG laser, focusing the bundle on the surface of a metal target, inducing the metal target to produce the plasma and igniting the premixed gas in the quartz tube. According to the device, the gas outlet of a premixing tank is communicated with the tail end of the quartz tube, the metal target is arranged on the side face, above the tube opening of the quartz tube, of the quartz tube, laser produced by the Nd:YAG laser is reflected to a spectroscope through a mirror and divided into reflected light and transmission light through the spectroscope, the first reflected light is emitted outward, and the transmission light penetrates through a lens and is focused on the metal target through the lens. The method and the device are suitable for situations where flammable gas ignition is needed.

Owner:HARBIN INST OF TECH

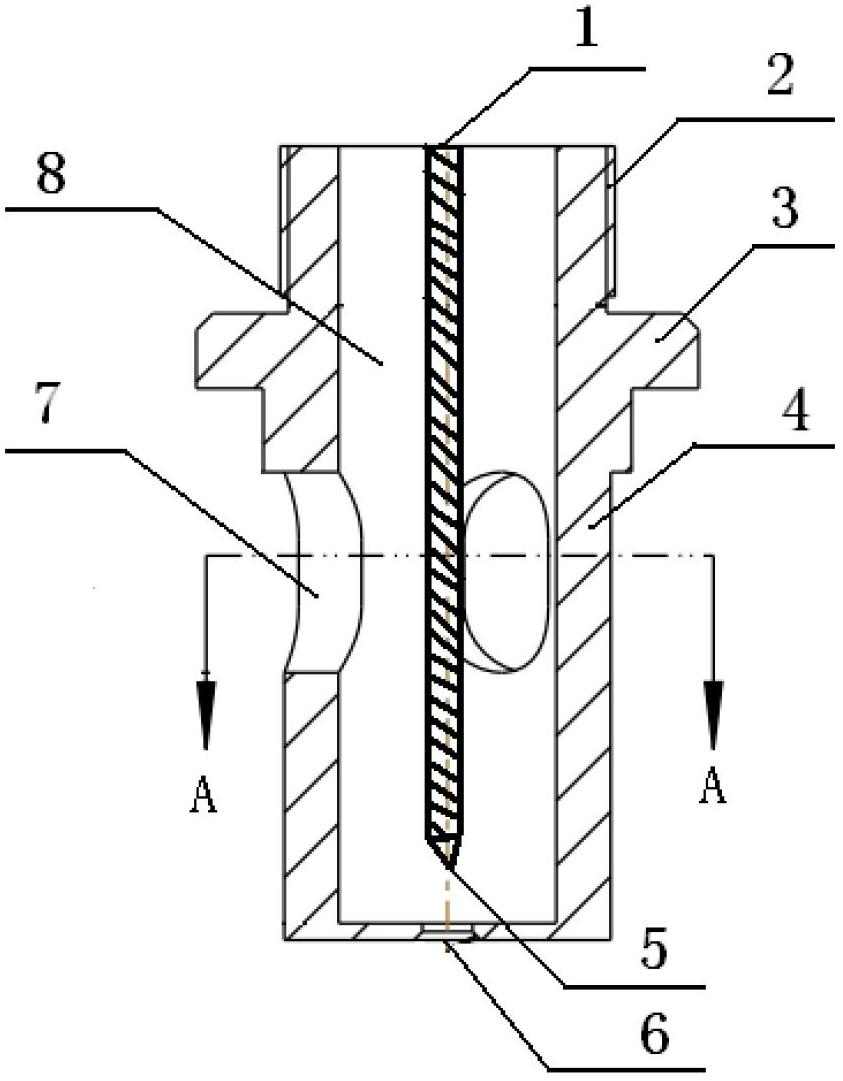

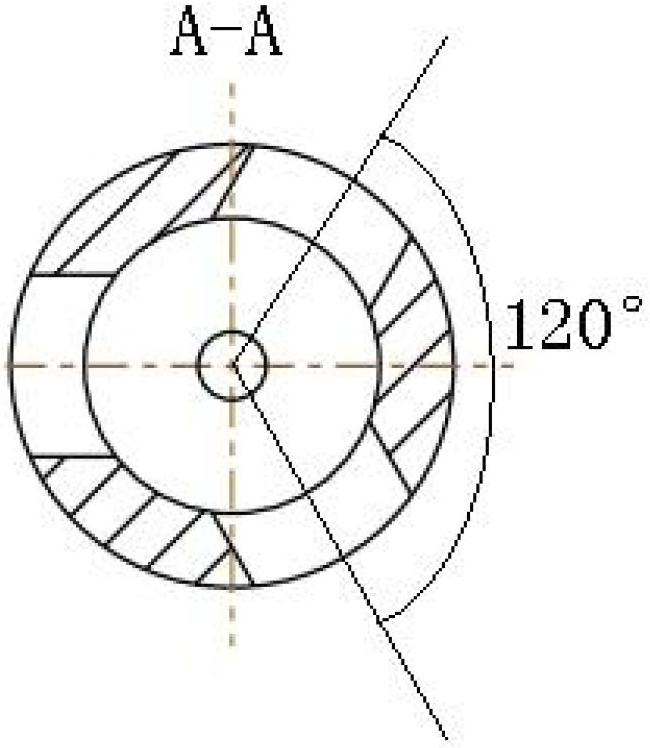

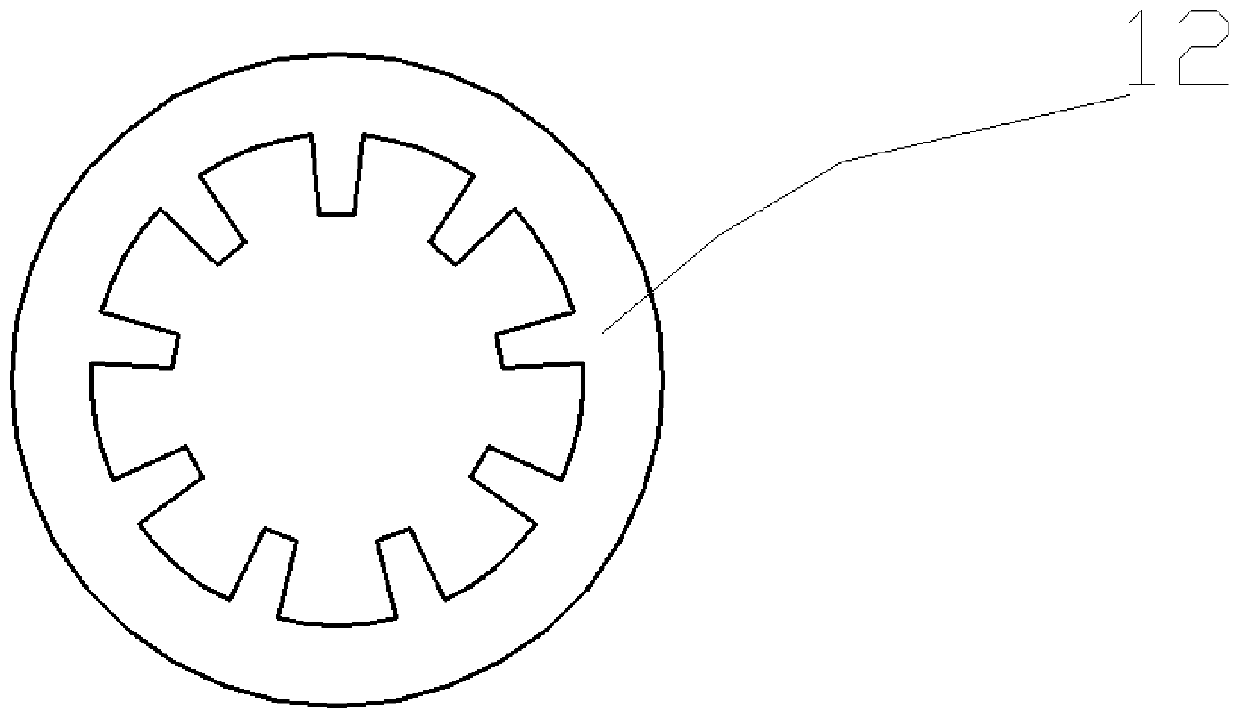

Ignition device of hydrogen chloride synthetic furnace and ignition method thereof

ActiveCN103629694AImprove ignition success rateImprove corrosion resistanceElectric spark ignitersElectric arcHydrogen chloride

The invention relates to an ignition device of a hydrogen chloride synthetic furnace. The ignition device is characterized in that the ignition device comprises a tubular housing, the tubular housing is divided into an in-furnace segment and an out-furnace segment, the in-furnace segment and the out-furnace segment are connected through a flange, and an air connector is arranged on the out-furnace segment of the tubular housing; an electric arc ignitor, a gas pipe and a flame probe are arranged in parallel inside the tubular housing, the flame probe is longer than the gas pipe and the electric arc ignitor, and a thermocouple is installed on the head portion of the flame probe in a sheathed mode; the in-furnace segment of the tubular housing comprises a front sleeve and a rear sleeve, and the front sleeve and the rear sleeve are in threaded connection; a vortex board is arranged between the front sleeve and the rear sleeve in a pressed and fixed mode, the vortex board is of a circular shape, a hole is formed inside the vortex board, six to ten identical arc grooves are evenly distributed in the hole at the same angle, the cross section of each arc groove is formed by two arcs with different radii, the vortex board corresponds to a nozzle of the gas pipe in position, and a check ring is fixedly arranged on the inner wall, on the rear portion of the vortex board, of the front sleeve.

Owner:SHANGHAI TIANSAN AUTOMATIC CONTROL

Filled aerogel ICF cryogenic target system

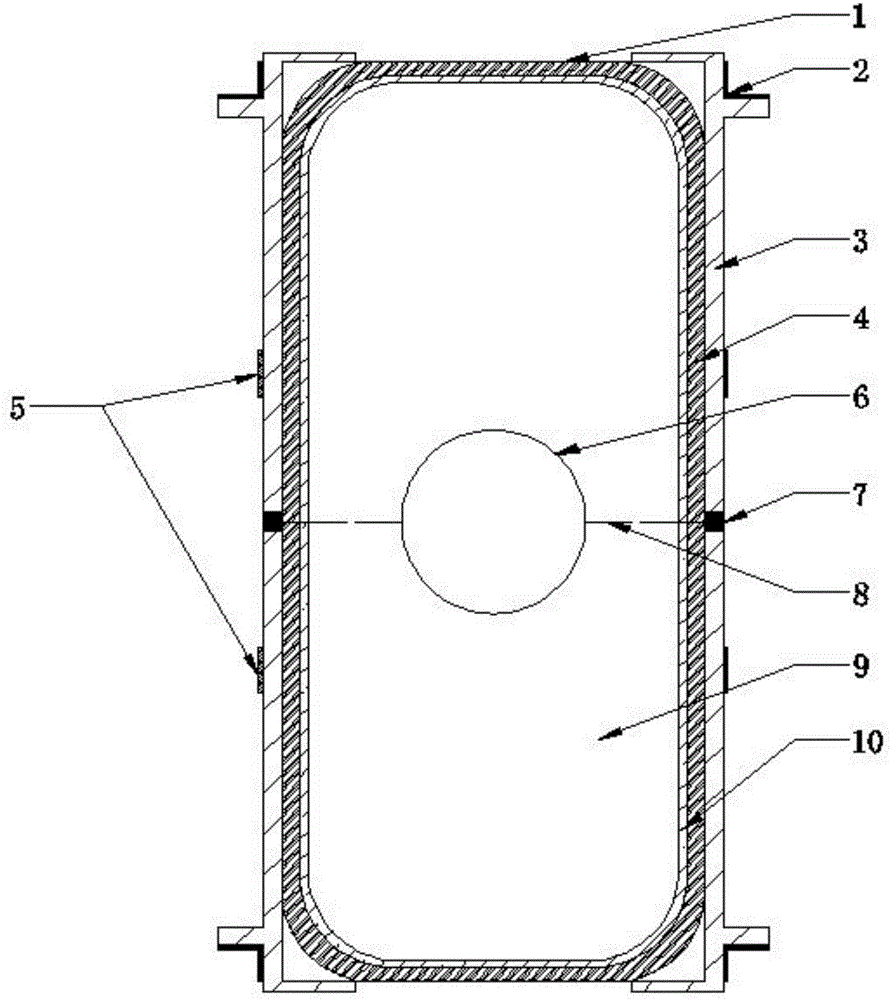

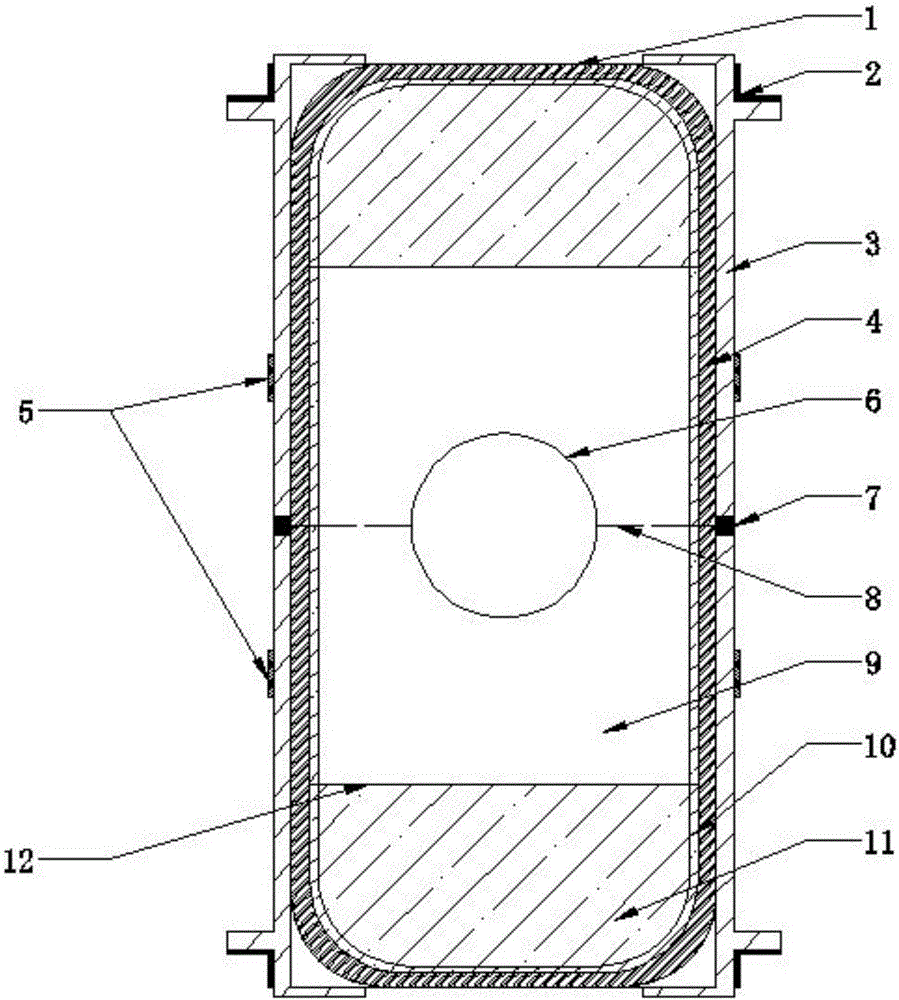

InactiveCN106297902AInhibit swellingReduce contentNuclear energy generationThermonuclear fusion reactorEngineeringNatural convection flow

The invention discloses a filled aerogel ICF cryogenic target system which comprises a gold cavity, wherein a pellet is fixed in the center inside the gold cavity through a support membrane; a fusion material is arranged inside the pellet; a laser incident hole is formed in the top of the gold cavity; a thermal mechanical structure is arranged outside the gold cavity; the upper part and the lower part of the thermal mechanical structure are integrally connected through a connecting structure; a cryogenic ring is arranged on the thermal mechanical structure; a thin aerogel layer is arranged on the inner wall of the gold cavity; the cavity of the thin aerogel layer is filled with a filling gas; filling aerogel is arranged at the upper end and the lower end of the thin aerogel layer; the filling aerogel is fixed through fixing membranes; a cavity of the thin aerogel layer between the upper filling aerogel and the lower filling aerogel is filled with the filling gas. Due to existence of the thin aerogel layer and the filling aerogel, gold plasma expansion can be inhibited, the content of the filling gas inside can be reduced, and the influence of natural convection flow can be reduced, so that the temperature uniformity of the temperature of the pellet can be optimized, and the ignition success rate can be increased.

Owner:深圳市开迩文科技有限公司

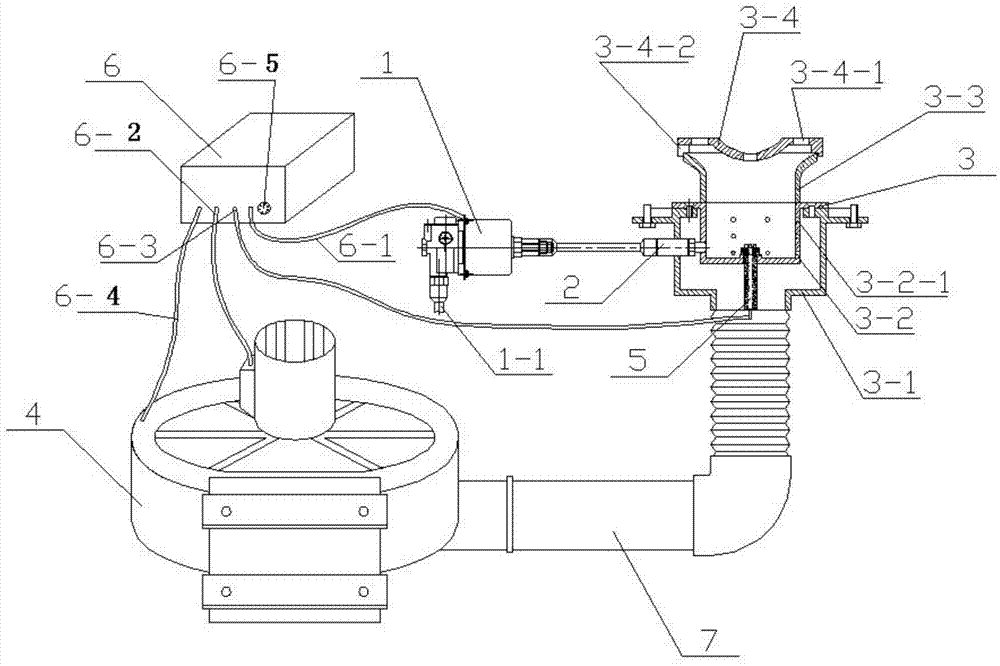

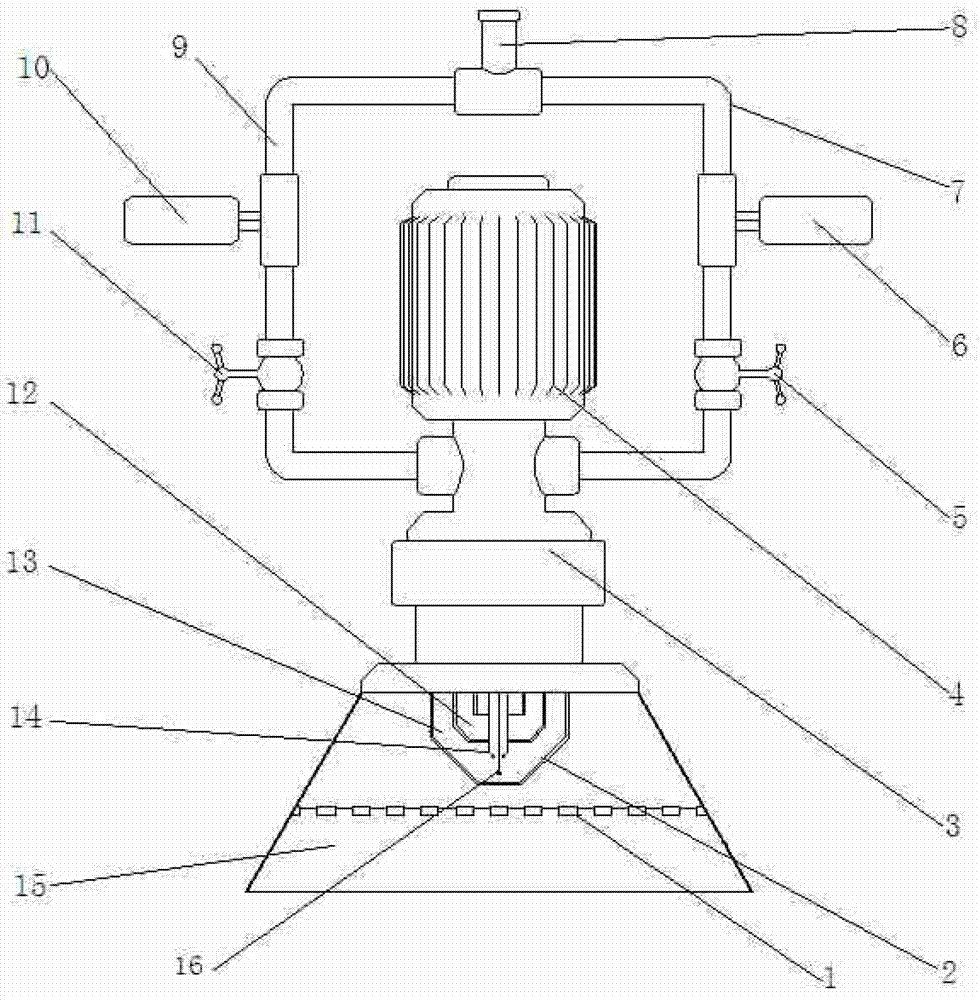

Novel alcohol group fuel cyclone atomizing burner

ActiveCN104776429AImprove ignition success rateUniform thermal field distributionFuel supply regulationLiquid fuel burnerCycloneAlcohol

The invention relates to a novel alcohol group fuel cyclone atomizing burner, comprising an electromagnetic pump, an atomizing oil nozzle, an intelligent burning control system, a burner group, a blower and an ignition flame ion probe; the automatic proportion of air and fuel in the burner is realized by controlling the rotary speed of the blower and the fuel oil flow of the electromagnetic pump in real time through the intelligent burning control system, and an excessive air coefficient in the burner is kept within a certain range. The novel alcohol group fuel cyclone atomizing burner has the beneficial effects that 1, the atomizing input ignition successful rate is high; 2, a certain included angle is formed by an air inlet in the side wall of a liner, and air of the blower is converted to cyclone from bottom to top, and the air is vaporized, dissolved and burnt in the rising process and a thermal field is uniformly distributed; 3, a high temperature reaction kettle being above 1000 DEG C is formed in the burner in a burning process, the fuel is more fully burnt and environment protection is facilitated; 4, the system is safe and reliable; 5, radiating is a main heating manner, so the design structure of the whole burner is more compact; 6, the application range of the burner is wider.

Owner:GUILIN GANLONG ENVIRONMENTAL PROTECTION SCI & TECH CO LTD

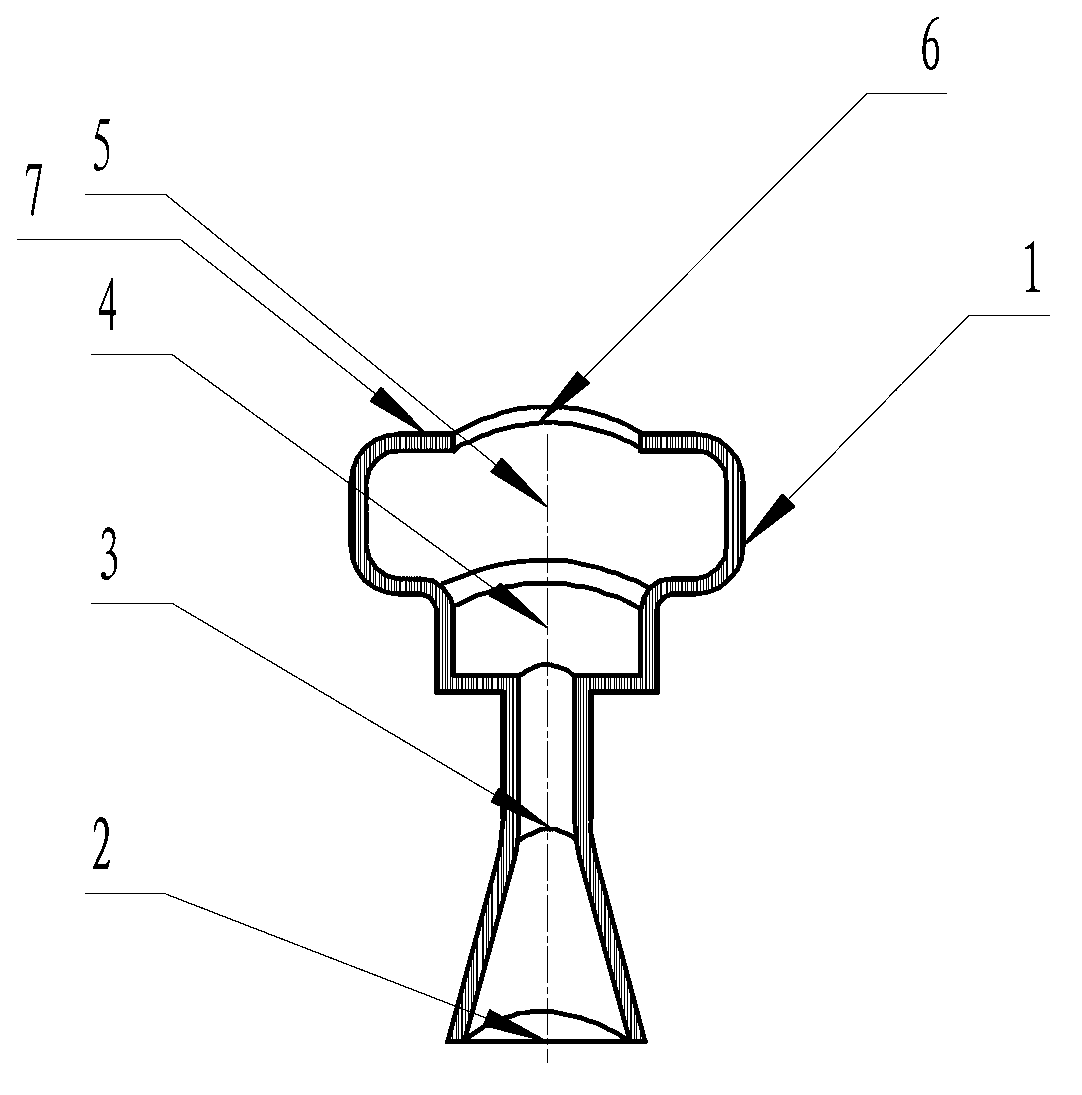

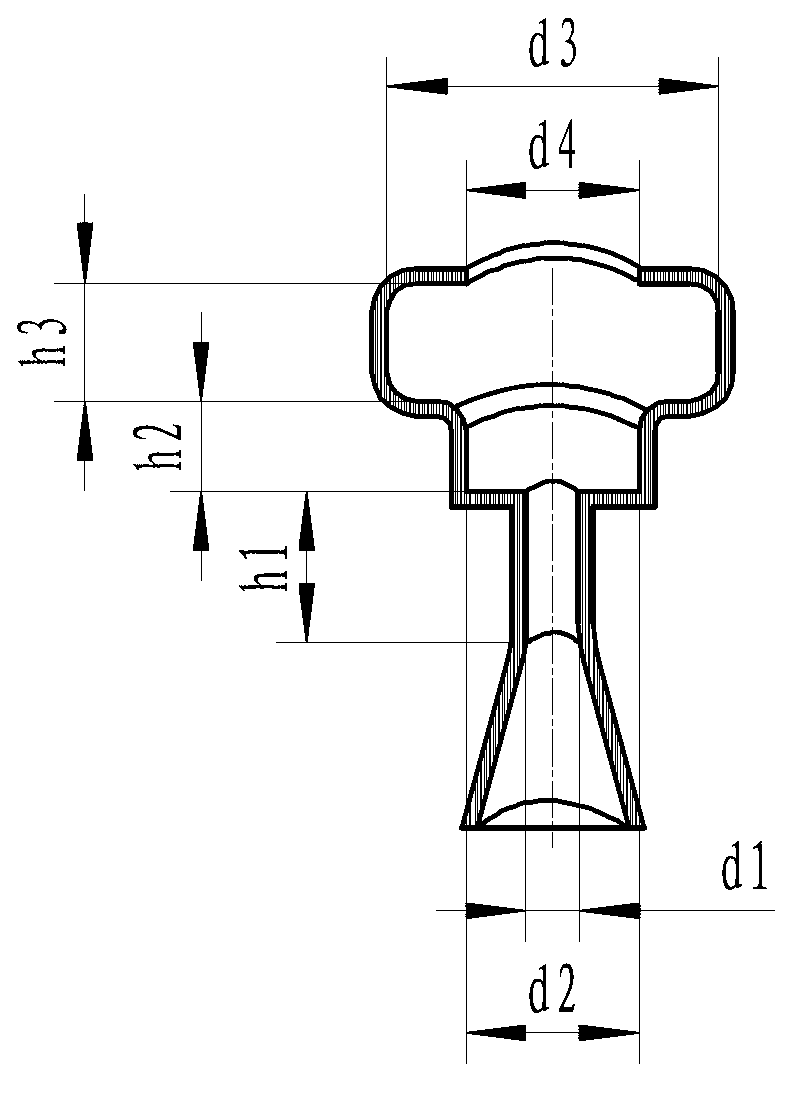

Gas burner with stable flame propagation

InactiveCN102997240ALarge heat-to-gravity ratioHigh heat-to-weight ratioGaseous fuel burnerGas burnerCombustion chamber

The invention discloses a gas burner with stable flame propagation. A gas burner body comprises a gas input port, a gas spray pipe, a primary damp diffusion cavity and a combustion chamber, which are sequentially connected from bottom to top, wherein the diameter of the gas spray pipe is d1, the diameter of the primary damp diffusion cavity is d2, the diameter of the combustion chamber is d3, the diameter of a flame nozzle is d4, d2 is more than d1 and less than d3, and the d3 is more than d4. An annular cavity body is formed inside the combustion body through a vortex stopping sheet at the inner side of the flame nozzle at the upper end of the combustion chamber; and flame is combusted inside the annular cavity body, and the section area of the combustion chamber is increased relatively to the primary damp diffusion cavity, so that secondary speed-reduction effect on a fuel speed is realized, the ignition success rate is high and the combustion is stable. Furthermore, a gas pressure has wide application range. The gas burner can stably combust in working modes, such as ultralow-speed atmosphere combustion, low-speed Bunsen type combustion, secondary mixing combustion, turbulent flow type combustion, high-speed full pre-mixing combustion, oxygen supply type ultrahigh-speed combustion and the like. The gas burner has the characteristics of small size, combustion stability, high ignition success rate, large burner thermogravimetrical ratio, and simple structure.

Owner:VATTI CORP LTD

Rotation speed synchronizing signal-based spark plug sparking control device

InactiveCN101915194AAvoid ineffective flashoverFire jumping energy is largeIgnition automatic controlAutomatic controlIgnition coilWork cycle

The invention discloses a rotation speed synchronizing signal-based spark plug sparking control device. The device comprises a photoelectric encoder and an electric control unit, wherein the photoelectric encoder is arranged on a cam shaft of an engine for acquiring a rotation speed synchronizing signal and a top dead centre signal of the engine and outputting the signals to the electric control unit in real time; and the electric control unit is connected with the photoelectric encoder for counting interruption signals produced by overflowing by using a counter according to the received rotation speed synchronizing signal and top dead centre signal, so that preset periodic sparking of a spark plug of the engine is realized, and a multi-pulse sparking control signal is output to an ignition coil of the spark plug to control the spark plug to perform sparking for several times. The spark plug sparking control device of the invention can prevent ineffective sparking, realize the sparking close to the end point of a compression travel of a working cycle of the engine for several times and has the advantages of high sparking energy, high success rate of ignition and high timing accuracy of sparking, so the device is particularly suitable for spark ignition type natural gas engines requiring high ignition energy and is favorable for broad production and application.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

Pressurization and ignition device and method

ActiveCN106051820AMeet the process requirementsStability is not affectedCombustion ignitionGranular/pulverulent flues gasificationCombustible gasSolid particle

The invention discloses a pressurization and ignition device and method. The ignition device comprises a burner, a rectification furnace and a reaction furnace. The burner is connected with the rectification furnace through a flange. The rectification furnace is connected with the reaction furnace through a tee joint. The rectification furnace is provided with an annular air distribution pipe. The reaction furnace is internally filled with solid particles in advance. According to the pressurization and ignition device and method, on one hand, a certain pressure and solid material cycle is established for a system, and the phenomena of fluctuation of system parameters and nonuniform temperature distribution of the reaction furnace are avoided; and on the other hand, by calibrating action of an adjustment valve, the purpose of precisely controlling the mixing ratio of natural gas to air required in the ignition process is achieved, ignition efficiency is improved, and meanwhile, by means of the tee joint, excessive combustible gas can be prevented from entering the rectification furnace and the reaction furnace.

Owner:SHAANXI YANCHANG PETROLEUM GRP

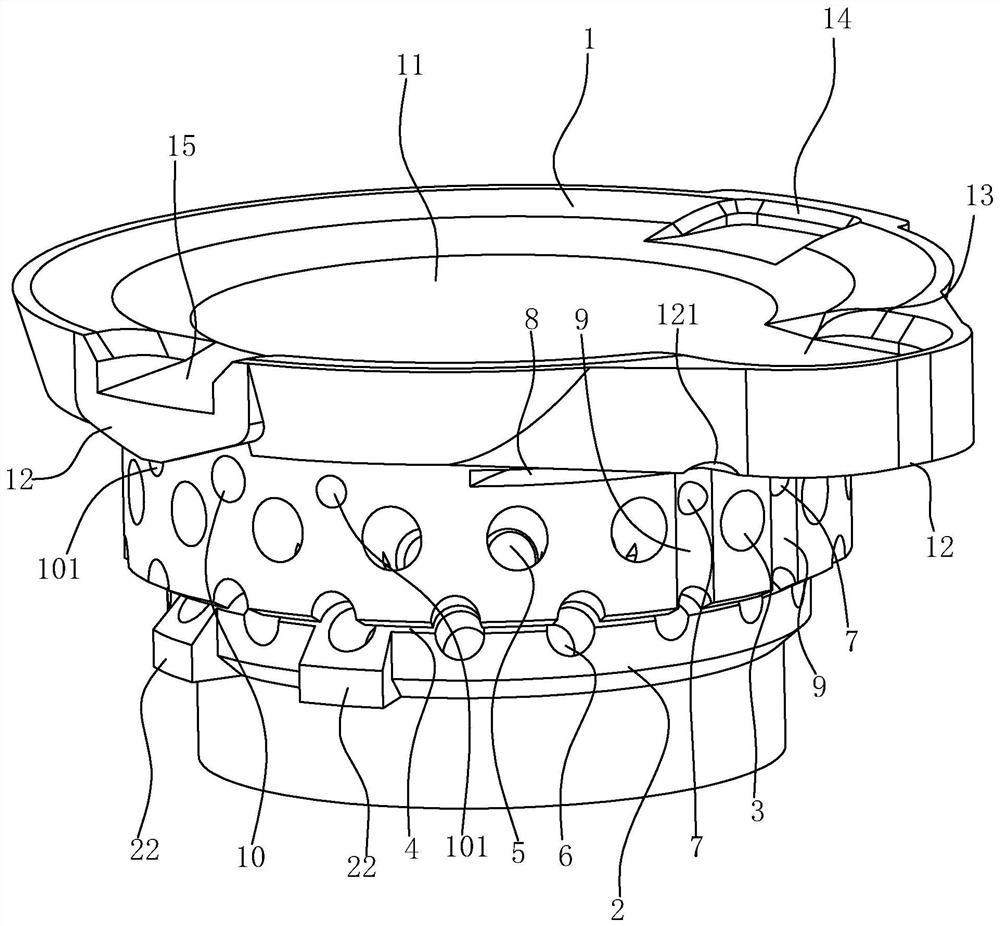

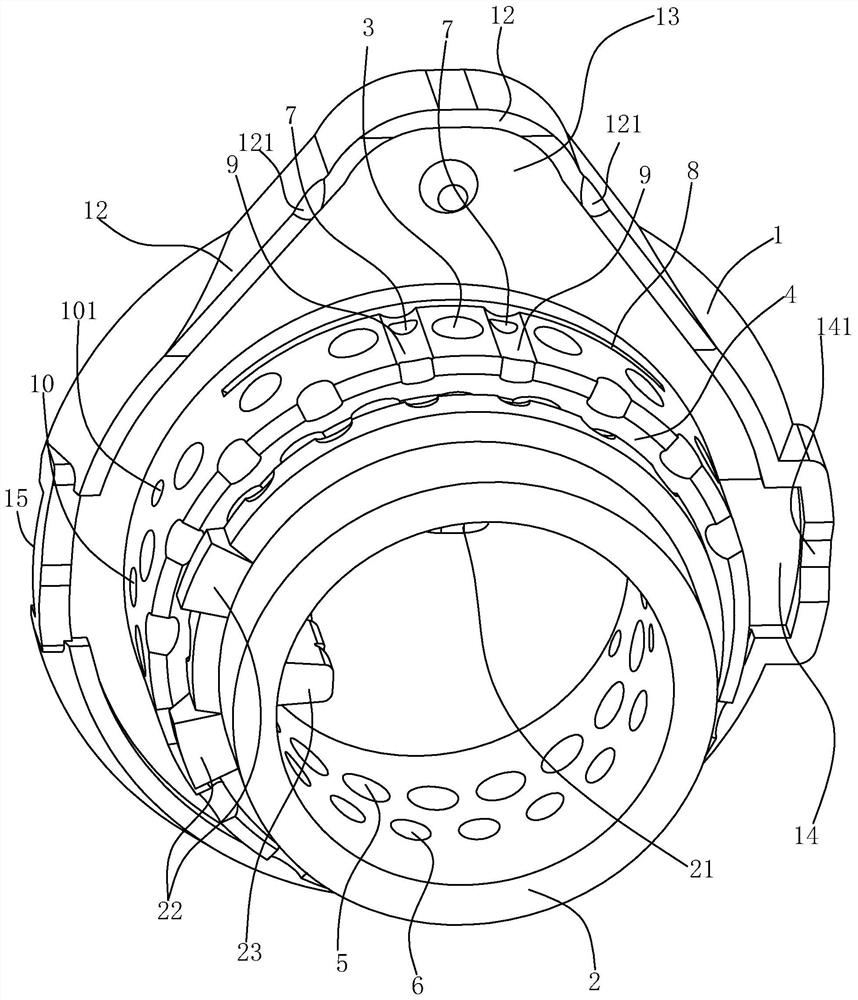

Fire cover and combustor using same

ActiveCN111998342AGood flame stabilization effectIncrease success rateDomestic stoves or rangesGaseous fuel burnerThermodynamicsCombustor

The invention relates to a fire cover, and further relates to a combustor. The fire cover comprises a top cover and an annular wall extending downwards in the circumferential direction of the top cover. Fire holes are formed in the annular wall. A main ignition hole is formed in a position, corresponding to an ignition needle, in the annular wall. The aperture of the radial inner end of the main ignition hole is smaller than the aperture of the radial outer end of the main ignition hole. According to the fire cover, a better flame stabilizing effect can be played when ignition is conducted, and the success rate of ignition is greatly improved. The combustor comprises a base, an ejection guiding pipe, an ignition needle and a thermocouple. The base is provided with an outer ring gas mixingchamber and an inner ring gas mixing chamber which communicate with the ejection guiding pipe. An outer ring fire cover is arranged on the outer ring gas mixing chamber in a matched mode. The ignitionneedle and the thermocouple are close to the inner ring gas mixing chamber and are arranged on the periphery of the inner ring gas mixing chamber. An inner ring fire cover is arranged on the inner ring gas mixing chamber in a matched mode. The fire cover is adopted as the inner ring fire cover. The combustor is higher in ignition success rate, working reliability and stability, and the service life is effectively prolonged.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

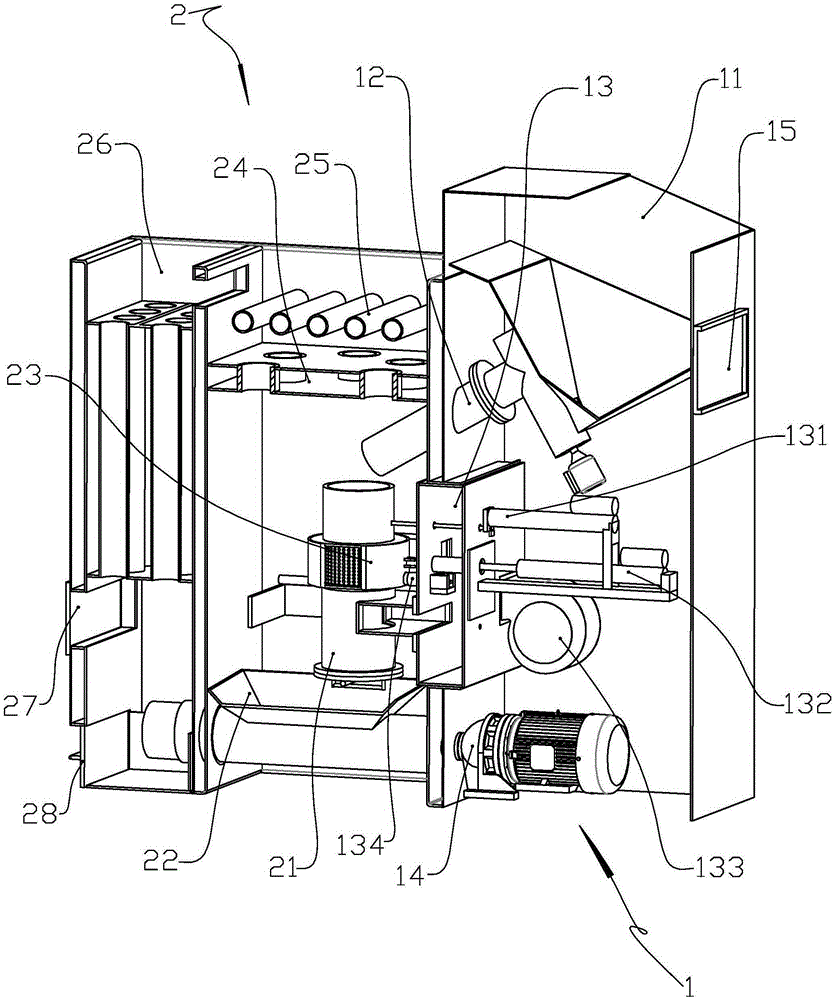

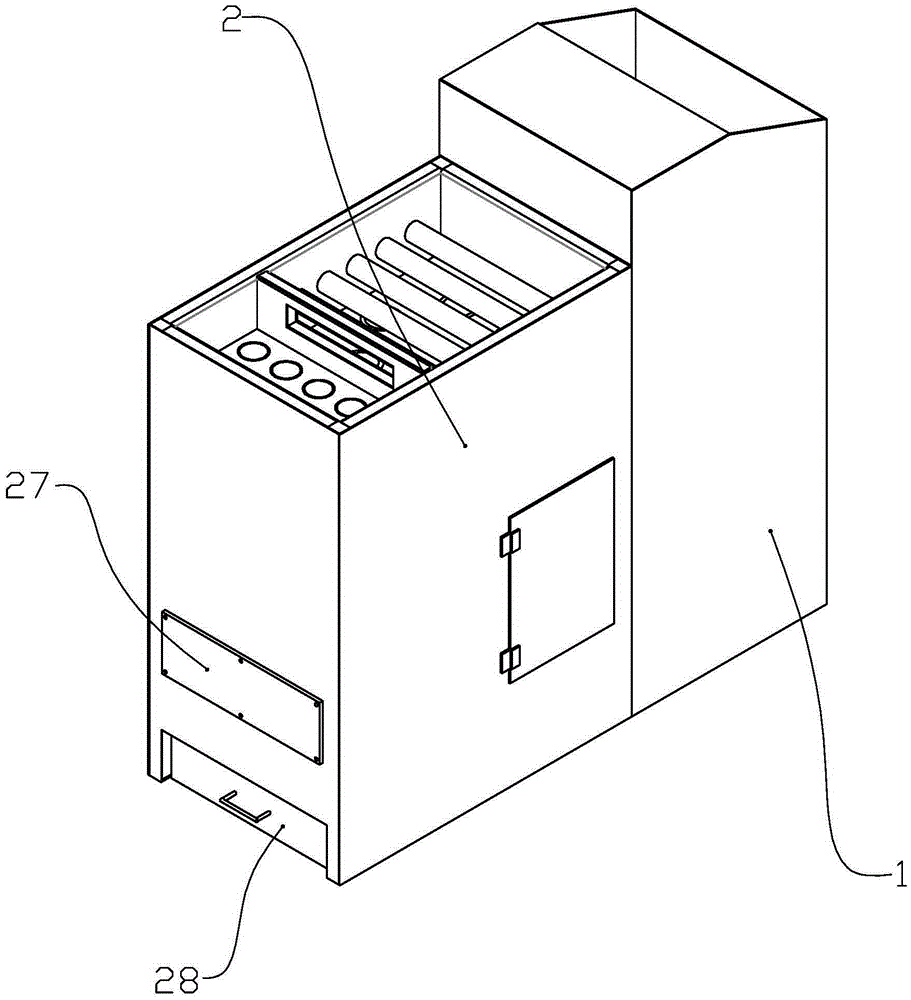

Automatic biomass particle heating stove and ignition method thereof

InactiveCN105180217AWith automatic feedingNo black smokeLighting and heating apparatusStove/ranges for heating waterAutomatic controlCombustion chamber

The invention discloses an automatic biomass particle heating stove. According to the automatic biomass particle heating stove, a combustion chamber and a feeding auger are arranged in a spaced mode, a feeding cylinder corresponding to the combustion chamber is arranged at the tail conveying end of the feeding auger, and thus the problem of carbonization of participating fuel in the feeding auger is solved; through the additional arrangement of a control panel, a driving device, a temperature measurement device, a deslagging auger and the like, automatic control over feeding, ignition, deslagging and the air volume is achieved, and automation is achieved; a vertical and tangential bidirectional air inlet mode is adopted, in this way, oxygen-enriched and suspension combustion is achieved, and sufficient fuel is guaranteed; a two-stage dedusting channel is arranged for smoke, in this way, the degree of pollution of exhausted smoke can be lowered, and the environmental friendless effect is achieved; both the deslagging portion and the dedusting portion are arranged in a stove body and are sealed relative to the indoor space when the heating stove operates, and thus indoor cleanliness can be guaranteed when the heating stove is in use; a time-control ignition mode and a temperature-control ignition mode are adopted, and the ignition mode can be selected according to different times; meanwhile, in the temperature-control ignition mode, the success rate of ignition can be greatly increased, the flameout situation can be found in time and ignition can be started immediately.

Owner:山东宇龙机械有限公司

Uniflow differential pressure type plasma ignition nozzle

InactiveCN102679395ALow flow lossImprove ignition success rateIncandescent ignitionCombustion chamberLow demand

The invention aims to provide a uniflow differential pressure type plasma ignition nozzlewhich comprises a cathode and an anode, wherein the cathode is mounted in the anode; the cathode and the anode form an inner cavity of a sparking plug; the anode is provided with an air inlet along the circumferential direction; and an injection hole is arranged on the position of the end part of the anode corresponding to the head part of the cathode. According to the invention, the plasma ignition nozzle has the advantages of small flow loss and local loss, high ignition success rate, strong ignition stability, short delay time, simple structure, strong ignition reliability, and relatively low demands on power supply power and the space size in a combustion chamber; in addition, the plasma ignition nozzle is also used for igniting liquid fuel and gaseous fuel and has wide applicability.

Owner:HARBIN ENG UNIV

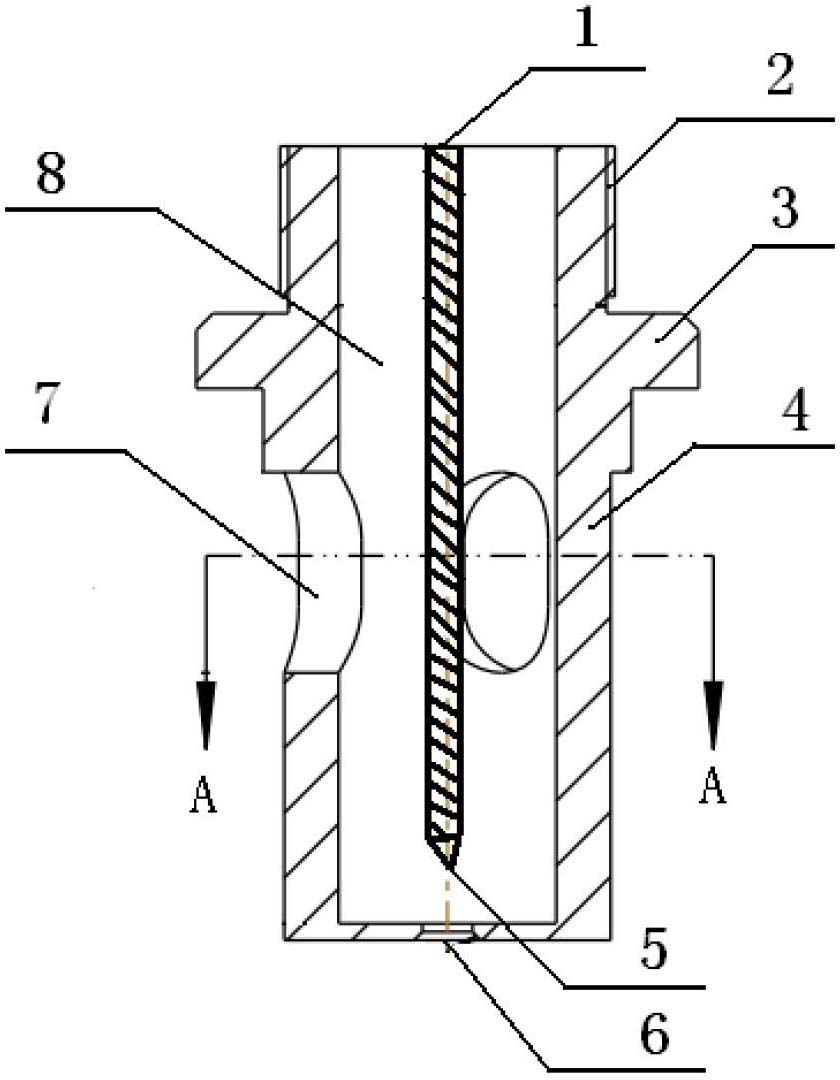

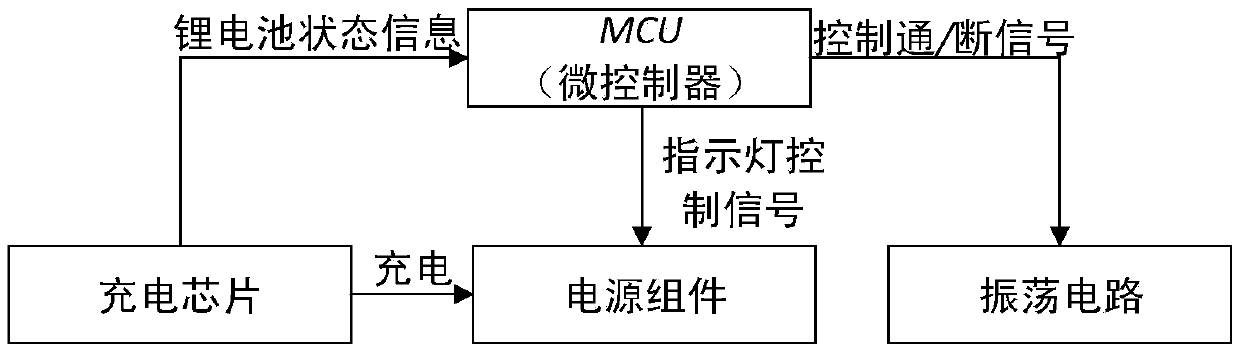

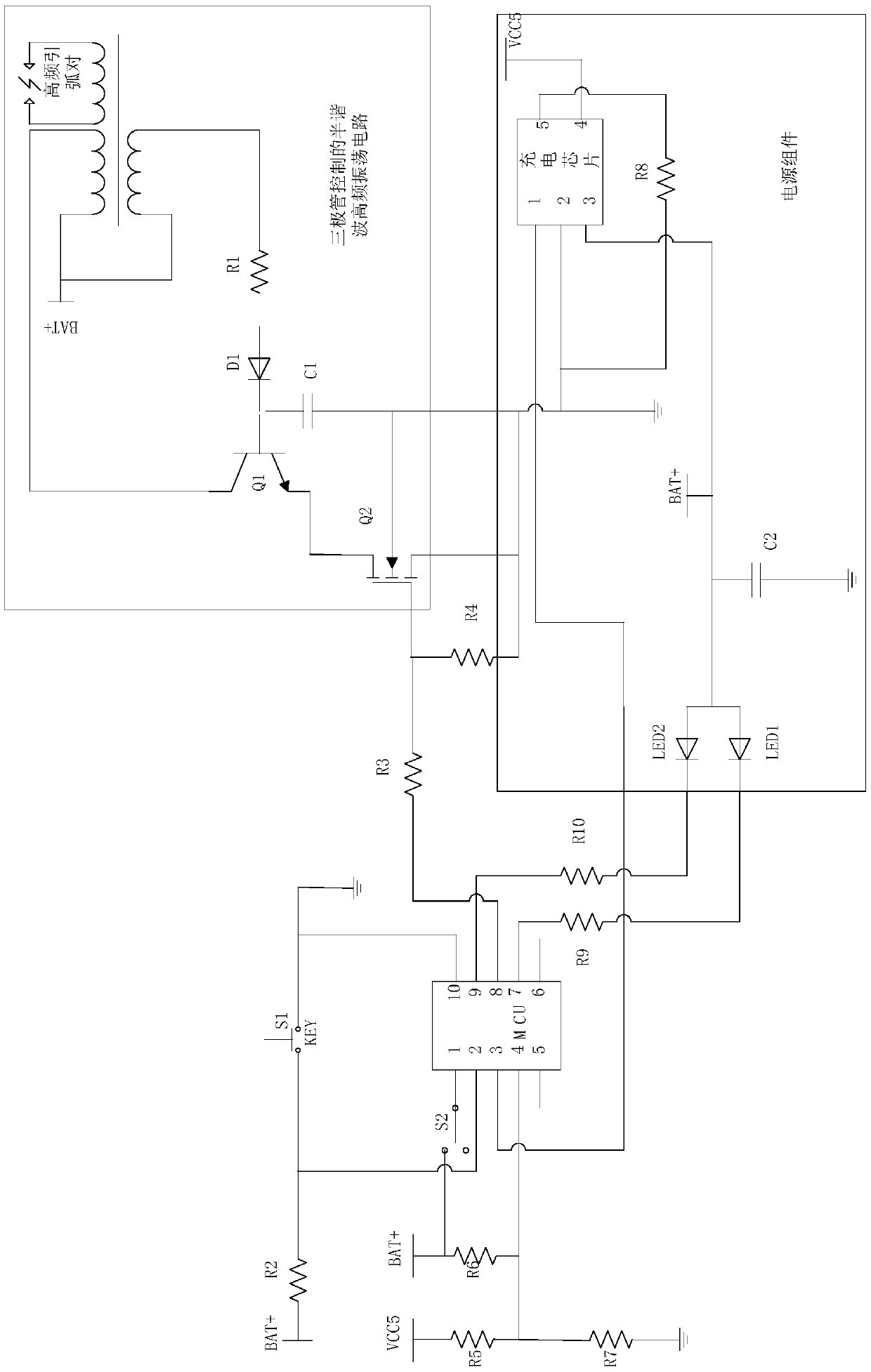

Low-power-consumption intelligent arc lighter and ignition method

InactiveCN105509093ANot easy to damageWith windproof abilityCircuit monitoring/indicationElectric spark ignitersCapacitanceMicrocontroller

The invention relates to a low-power-consumption intelligent arc lighter and an ignition method. The low-power-consumption intelligent arc lighter comprises a power supply component, a triode controlled semi-harmonic high-frequency oscillating circuit, a high-frequency arc ignition pair and an MCU (microcontroller unit), and a connection relation of the power supply component, the semi-harmonic high-frequency oscillating circuit, the high-frequency arc ignition pair and the MCU is displayed in a diagram of the abstract. The triode controlled semi-harmonic high-frequency oscillating circuit comprises a power field-effect transistor switch, a triode, a rectifier diode, a feedback resistor, a voltage stabilizing capacitor and a boosting transformer. The boosting transformer comprises a primary winding, a secondary winding and a positive feedback winding. The power supply component comprises a lithium battery, a constant-current constant-voltage linear charging chip of the single lithium battery and two LED (light emitting diode) indicating lights. On the basis of an existing arc lighter, the MCU is arranged additionally to realize intelligent control of charging and discharging processes of the circuit, monitoring of conditions of the lithium battery is realized, and a user can be prompted through the LED indicating lights. The low-power-consumption intelligent arc lighter has the advantages of low power consumption, intelligence, simple structure, high safety, energy saving, environment friendliness and the like.

Owner:常州矽能电子科技有限公司

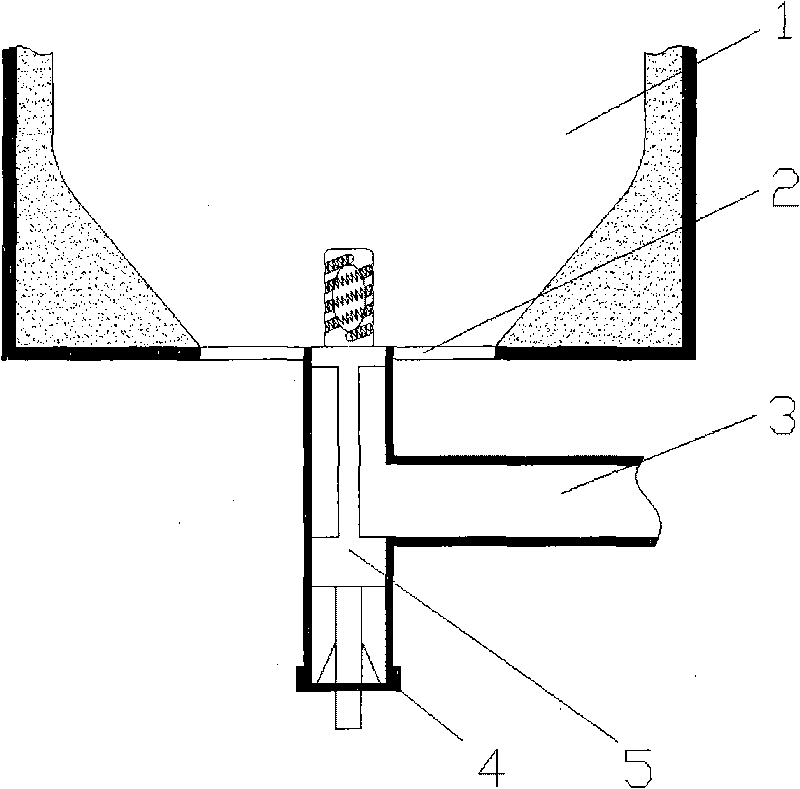

Ignition device for biomass gasification furnace and using method thereof

InactiveCN101726002APromote combustionImprove ignition success rateIncandescent ignitionCombustible gas productionElectricityEngineering

The invention relates to an ignition device for a biomass gasification furnace and a using method thereof. In the device, an ignition bar formed by a heating wire and a ceramic tube element is vertically arranged in a three-way inlet tube of the biomass gasification furnace; the upper end of the ceramic tube element wound with the heating wire is positioned above a grate; the biomass gasification furnace are filled by granular biomass materials and compacted; the biomass materials are closely contacted with the heating wires; after the ignition bar is electrified, the biomass materials at the periphery of the ignition bar is directly heated; a draught fan is opened after 10 to 20 seconds of heating, air is introduced to the bottom of the gasification furnace from the lateral side of the upper section of the ignition bar; the power supply of the ignition bar is closed after the electrification lasts for 10 to 20 seconds; and the ignition bar is twitched downwards and is rotated to ensure that the ignition bar is retracted inside the three-way inlet tube, the ignition bar is separated from the biomass material subjected to high-temperature gasification reaction with the ignition bar, and the air is introduced into the biomass gasification furnace from clearance between the upper end of the ignition bar and the inlet tube to maintain constant performance of the gasification reaction. The ignition device has the advantages of high success rate of ignition, short ignition time, simple and convenient operation and safe use.

Owner:JIANGSU UNIV +1

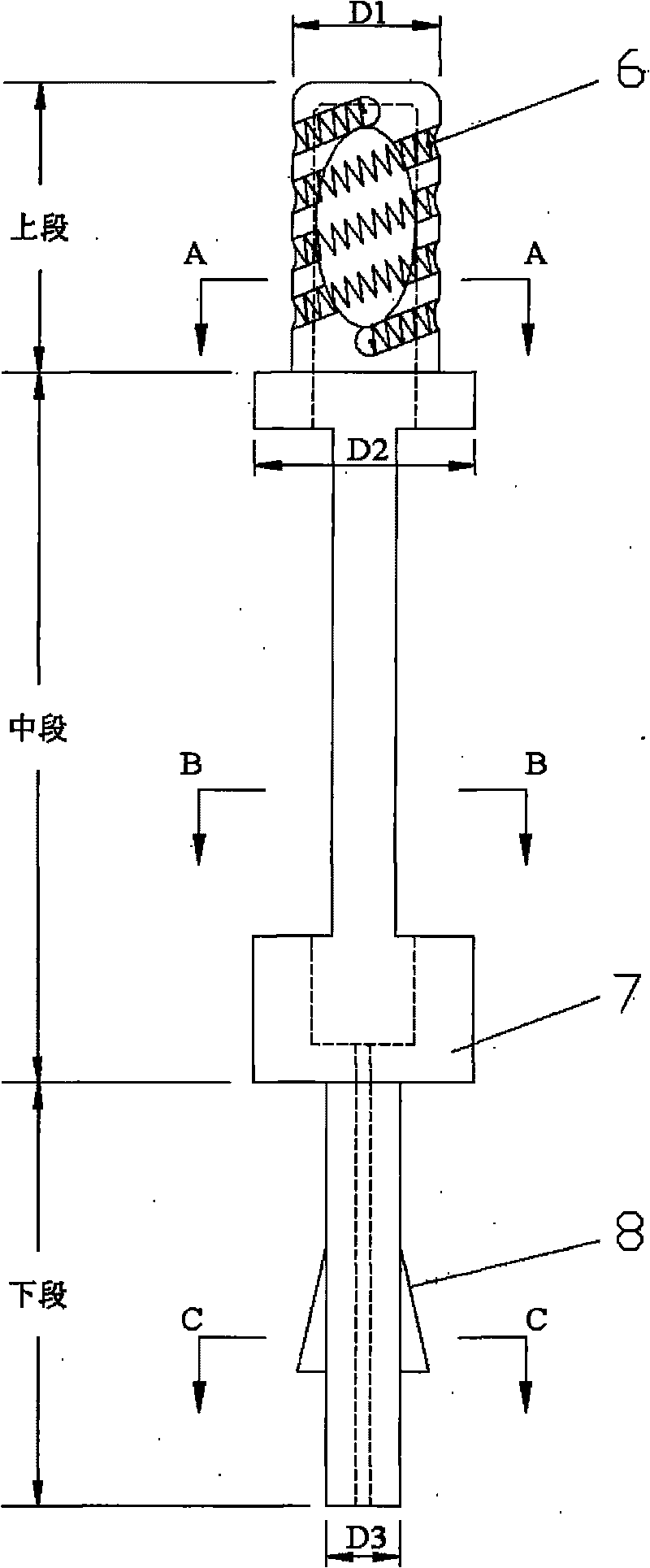

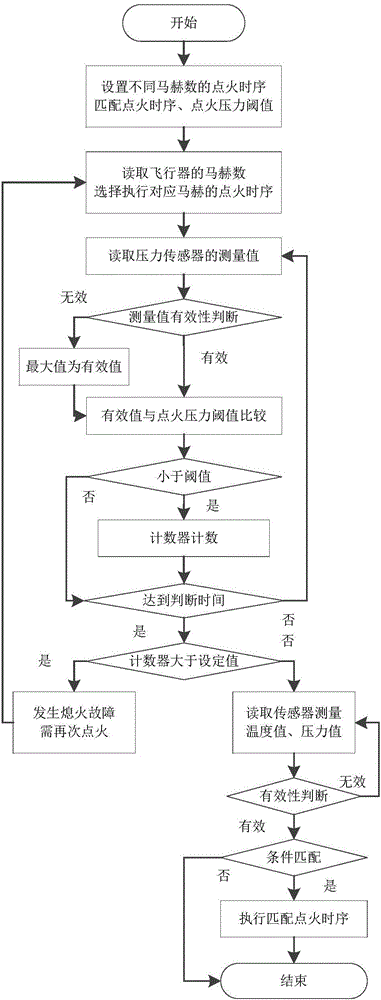

Time sequence control method for increasing ignition success rate of ramjet

ActiveCN105971737AImprove ignition success rateStable combustionGas turbine plantsJet propulsion plantsRamjetCombustion chamber

The invention relates to a time sequence control method for increasing the ignition success rate of a ramjet. Before ignition, according to different aircraft mach numbers, different working time sequences are set for fuel nozzles. During ignition of a combustion chamber, according to the speed of an aircraft, the fuel nozzles execute corresponding actions according to the time sequences, ignition and stable combustion of fuel are guaranteed, and ignition within the wide mach number range is achieved. After ignition, the state of the combustion chamber is monitored in real time, and whether ignition succeeds or not and whether a flameout fault occurs or not are judged. If ignition fails or flameout occurs, reignition operation is executed, and the ignition success rate of the ramjet is increased. The proper temperature and pressure are key factors for stable combustion of the fuel in the combustion chamber. According to the method, after ignition, the temperature and the pressure of the combustion chamber are detected in real time, when the pressure and the temperature are matched with corresponding conditions, the corresponding matching ignition time sequences are executed, that is, matching control is achieved, stable combustion of the fuel is guaranteed, and the flameout fault is avoided.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Firework firecracker with two fuze and manufacturing method therefor

The invention relates to a fireworks and firecrackers, in particular to a safe ignition fireworks and firecrackers with electric heating fuze or with powder fuze and electric heating fuze and a manufacturing method thereof. Heating material fuze is directly connected to the powder of the fireworks and firecrackers through the powder fuze or through no powder fuze. After the single fireworks and firecrackers with the electric heating fuze or with the electric heating fuze and powder fuze, a long metal conducting wire is connected to a power supply operation control box by the heating material fuze of the fireworks and firecrackers through connecting points. When the bunchy fireworks and firecrackers are spliced, the electric heating material fuzes of the fireworks and firecrackers are respectively connected to the power supply control box, and the powder fuzes are spliced together along the arranged firecrackers, or the heating material of the heating fuze is connected to the powder fuzes of the fireworks and firecrackers or the naked flame igniting ends of the powder fuzes of the bunchy firecrackers, and a section of powder fuze is also remained outside the connecting points.

Owner:王辉

Integrated automatic ignition eternal flame lamp

PendingCN110566983AStable combustionGuaranteed ignition success rateIncinerator apparatusCombustion ignitionIgnition coilControl engineering

The invention discloses an integrated automatic ignition eternal flame lamp. The integrated automatic ignition eternal flame lamp comprises a mixed fuel gas pipe and an ignition pipe, wherein a burning mouth is connected to the upper end of the mixed fuel gas pipe, a flame stabilizing cover and a windproof cover are arranged on the outer side of the burning mouth in sequence, and the bottoms of the burning mouth, the flame stabilizing cover and the windproof cover are supported by a windproof cover bottom plate; the lower end of the mixed fuel gas pipe is connected with an ejector, a fuel gasnozzle and a fuel gas nozzle seat, and the fuel gas nozzle seat is connected with a fuel gas pipe through a pipeline; and the upper end of the ignition pipe is connected with the inlet end, close to the burning mouth, of the mixed fuel gas pipe, the lower part of the ignition pipe communicates with the mixed fuel gas pipe through a flow induction pipe, and an ignition rod is inserted from the lower end of the ignition pipe and seals the lower end of the ignition pipe. According to the integrated automatic ignition eternal flame lamp, built-in ignition is kept, light ignition of the eternal flame lamp is not influenced by external weather conditions, and the air consumption is small; meanwhile, the ignition rod is far away from the burning mouth so as to be prevented from being placed in ahigh-temperature region, so that the service life of the ignition rod is prolonged; and finally, a special air inducing and flame stabilizing structure is matched with a semi-premixed combustion mode,so that flames can still form a stable combustion region on the head part of the eternal flame lamp even under weather conditions of heavy rain and strong wind.

Owner:JIANGSU SUNPOWER TECH

Heat storage type burner used for radiant tube

InactiveCN105509053AImprove ignition success rateExtended service lifeIndirect carbon-dioxide mitigationGaseous fuel burnerThermal energyCombustion

The invention discloses a heat storage type burner used for a radiant tube. The heat storage device is arranged in the radiant tube which is provided with two end parts; the two end parts of the radiant tube are respectively provided with a first burner assembly and a second burner assembly correspondingly; each of the first burner assembly and the second burner assembly comprises a heat storage body; the two end parts of the radiant tube are respectively provided with a first air pipeline and a second air pipeline which are communicated with the radiant tube correspondingly; each of the first air pipeline and the second air pipeline is provided with an air inlet; a reversing valve is connected to the first air pipeline and the second air pipeline; the reversing valve is stopped between a first station and the first air pipeline, and is communicated with the second air pipeline; the reversing valve is communicated with the first air pipeline at a second station, and is stopped between the second station and the second air pipeline; and a gas exhaust pipeline is communicated with the reversing valve. The heat storage type burner disclosed by the invention is high in ignition success rate and is good in combustion stability after ignition; a heat storage body is not liable to damage, heat storage capacity is high, and a waste gas heat utilization rate is high.

Owner:宝钢日铁汽车板有限公司

Ignition device and ignition method for sinter pot test

ActiveCN102829487AImprove combustion effectReasonable structural designIncandescent ignitionAutomatic controlEngineering

The invention provides an ignition device and an ignition method for a sinter pot test. The ignition device is composed of a flame uniform distribution plate, a blast blower, an air tube, a gas valve, an electromagnetic valve, a primary gas tube, a secondary gas tube, a premixing cavity, a connection seat, an electronic igniter, a protective cover, a flame detector and a computer; the computer starts the blast blower, the electronic igniter, the flame detector and the secondary electromagnetic valve in a programmable manner for pre-igniting, and judges whether the pre-igniting is successful according to a set temperature; if the pre-igniting is not successful, the computer stops the secondary electromagnetic valve, and re-ignites; if the pre-igniting is successful, the computer starts the primary electromagnetic valve for formal igniting, and the computer times; and when the ignition time reaches a set time, the computer stops the primary electromagnetic valve, the secondary electromagnetic valve and the blast blower in a programmable manner. The ignition device and the ignition method for the sinter pot test provided by the invention can economize on manpower and space, ensure uniform and stable flame temperature at the outlet of the protective cover, and realize an automatic ignition control process; and with the ignition device and the ignition method, a combustion effect of fuel can be improved, and the accuracy rate of the sinter pot test can be ensured.

Owner:ANGANG STEEL CO LTD

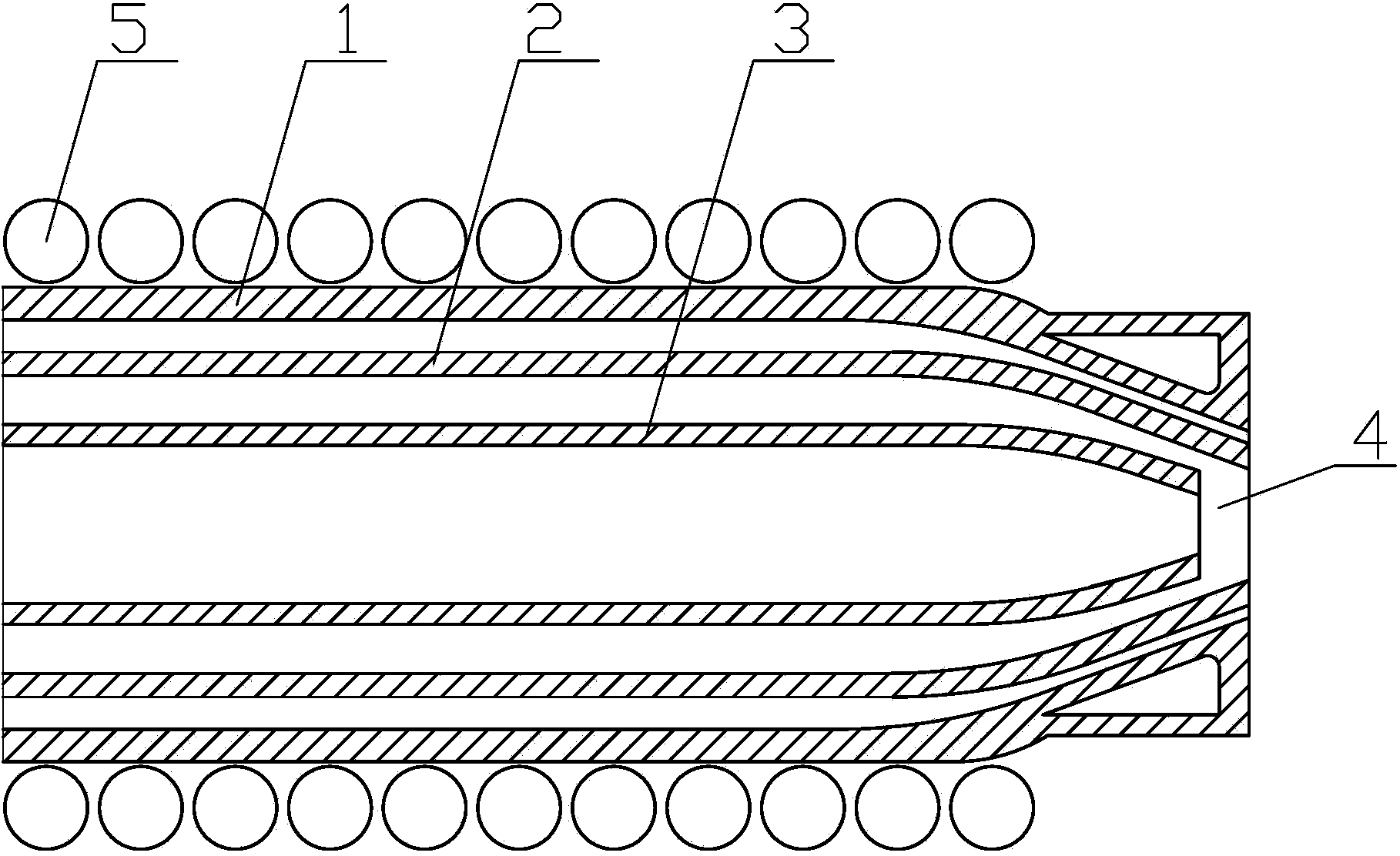

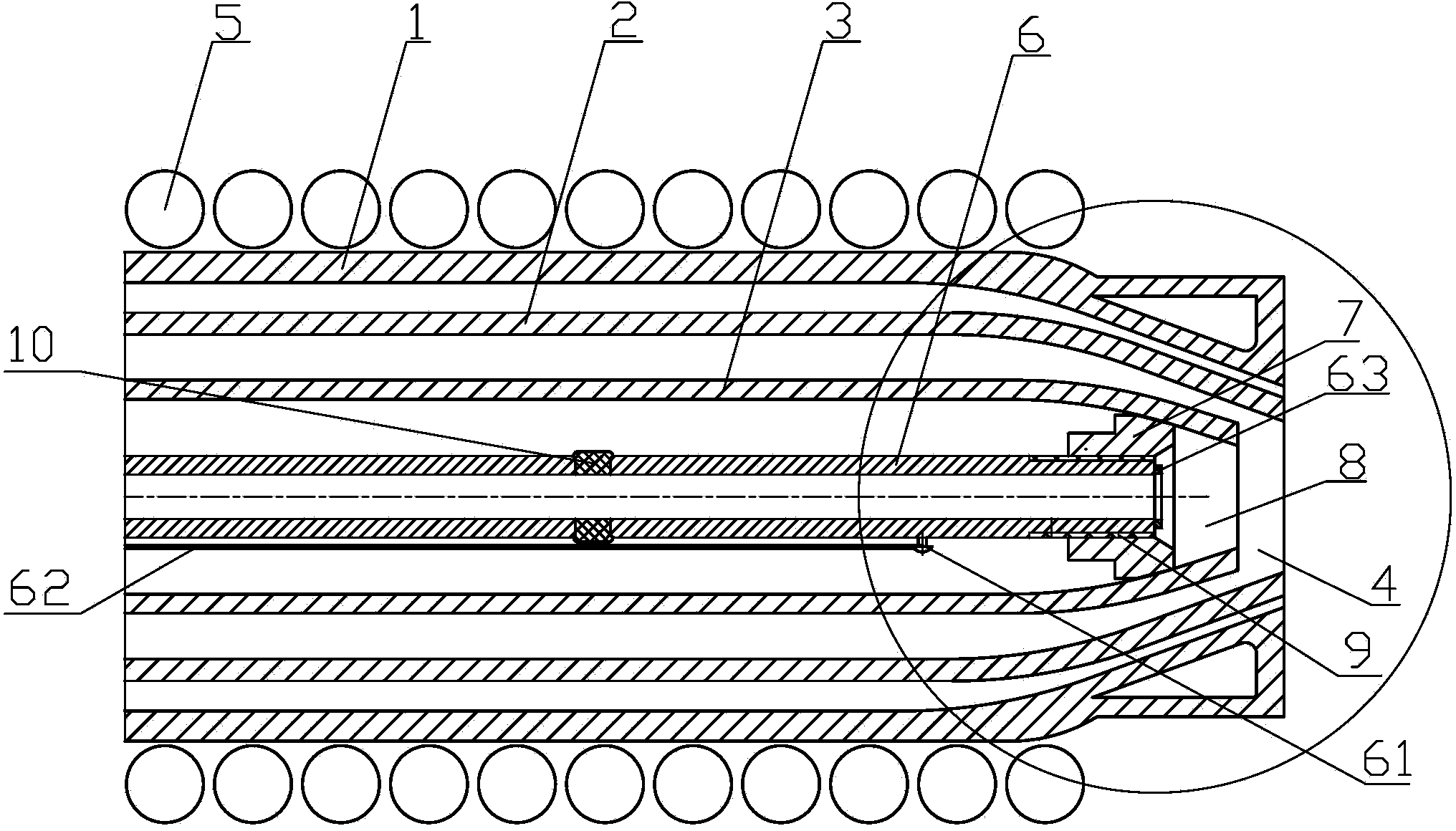

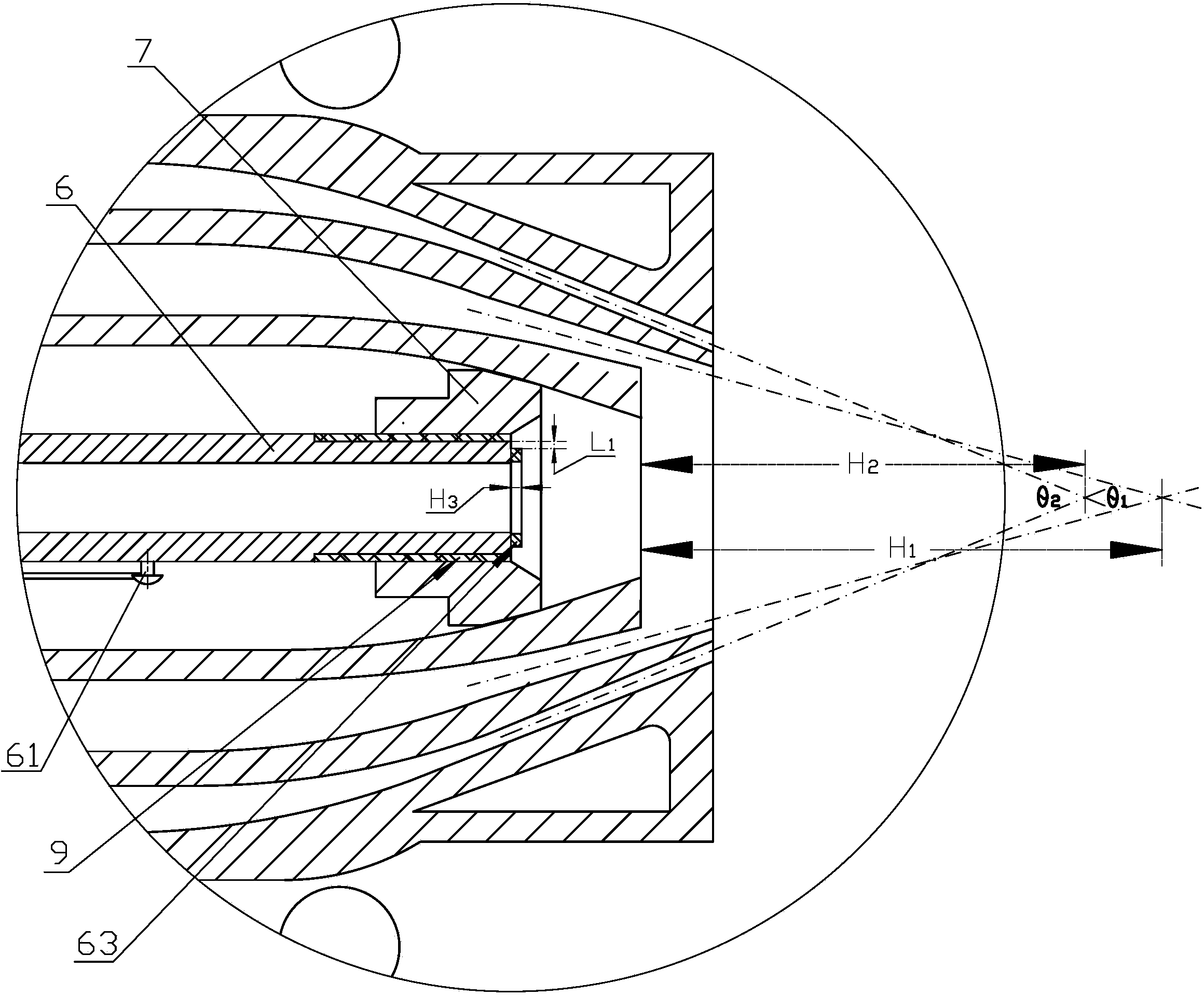

Combined type coal water slurry nozzle provided with ignition device

InactiveCN103849434AImprove flammabilityRealize two functions in oneBurnersGranular/pulverulent flues gasificationCoal waterPower flow

The invention relates to a combined type coal water slurry nozzle provided with an ignition device. The combined type coal water slurry nozzle provided with the ignition device comprises an outer sprayer, a middle sprayer, an inner sprayer and a center pipe which are coaxially arranged, wherein an ignition cable is arranged on the outer wall of the center pipe, a hydrocyclone which can form rotary jet is arranged at the front end of the center pipe, an axial through hole is formed in the hydrocyclone, certain shrinkage is formed at the front end of the center pipe relative to the front end of the through hole of the hydrocyclone, part of or all the circumferential edge of the hydrocyclone is contacted with the inner cavity wall of the front end of the inner sprayer; certain retraction is formed in the front end face of the hydrocyclone relative to the end face reference surface of the inner sprayer, so that a premixing cavity B is formed. The combined type coal water slurry nozzle provided with the ignition device has the advantages that functions of an ignition nozzle and a technological nozzle in a gasifier are combined into one, so that the ignition nozzle and the technological nozzle can not be switched again and again in the whole gasification process, and complex operation in the gasification process is simplified; meanwhile, current required for ignition is small, so that the combustible effect on coal water slurry is improved, the ignition success rate is high, and the produced flame is stable.

Owner:杜建吉

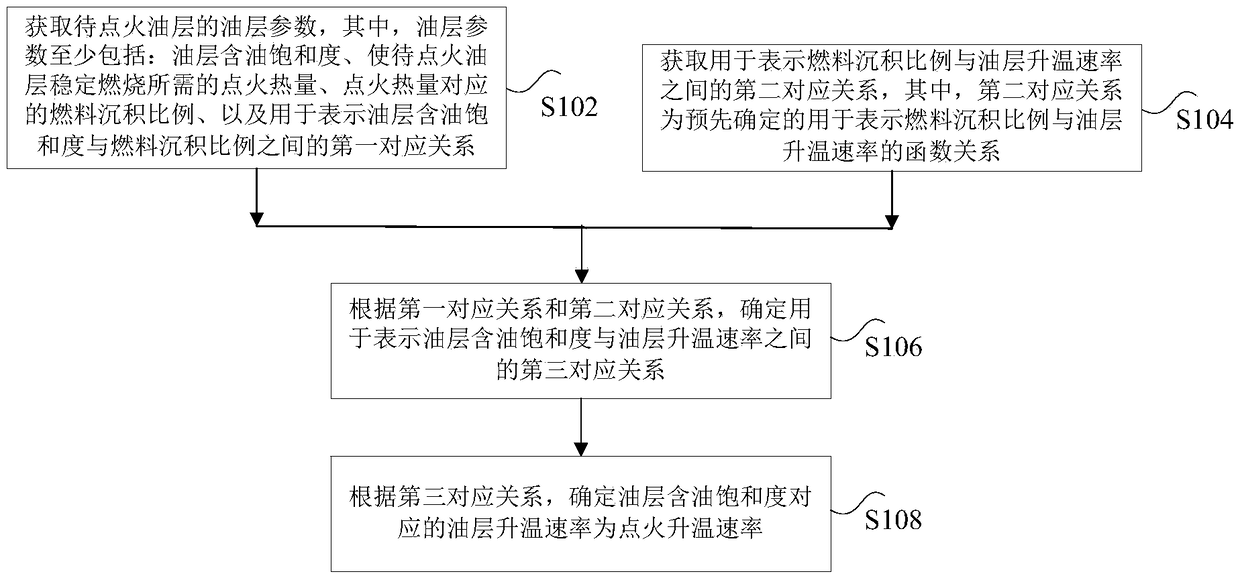

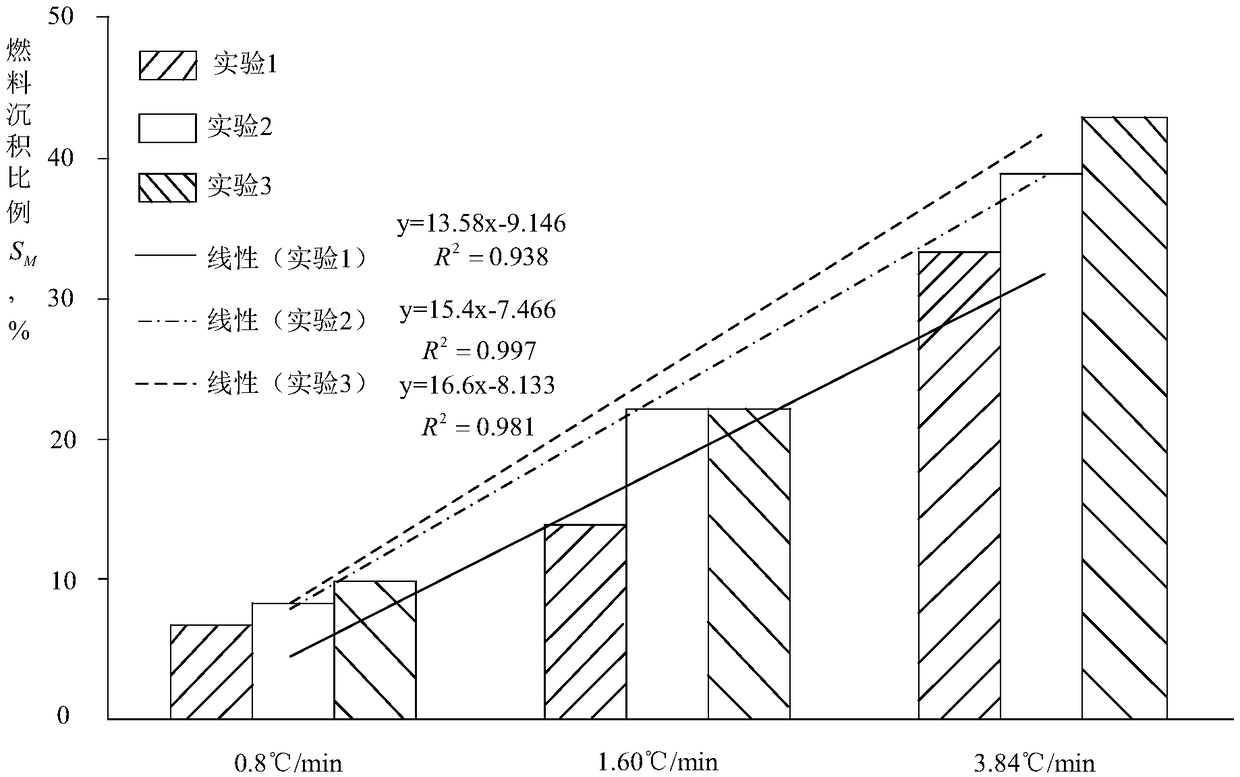

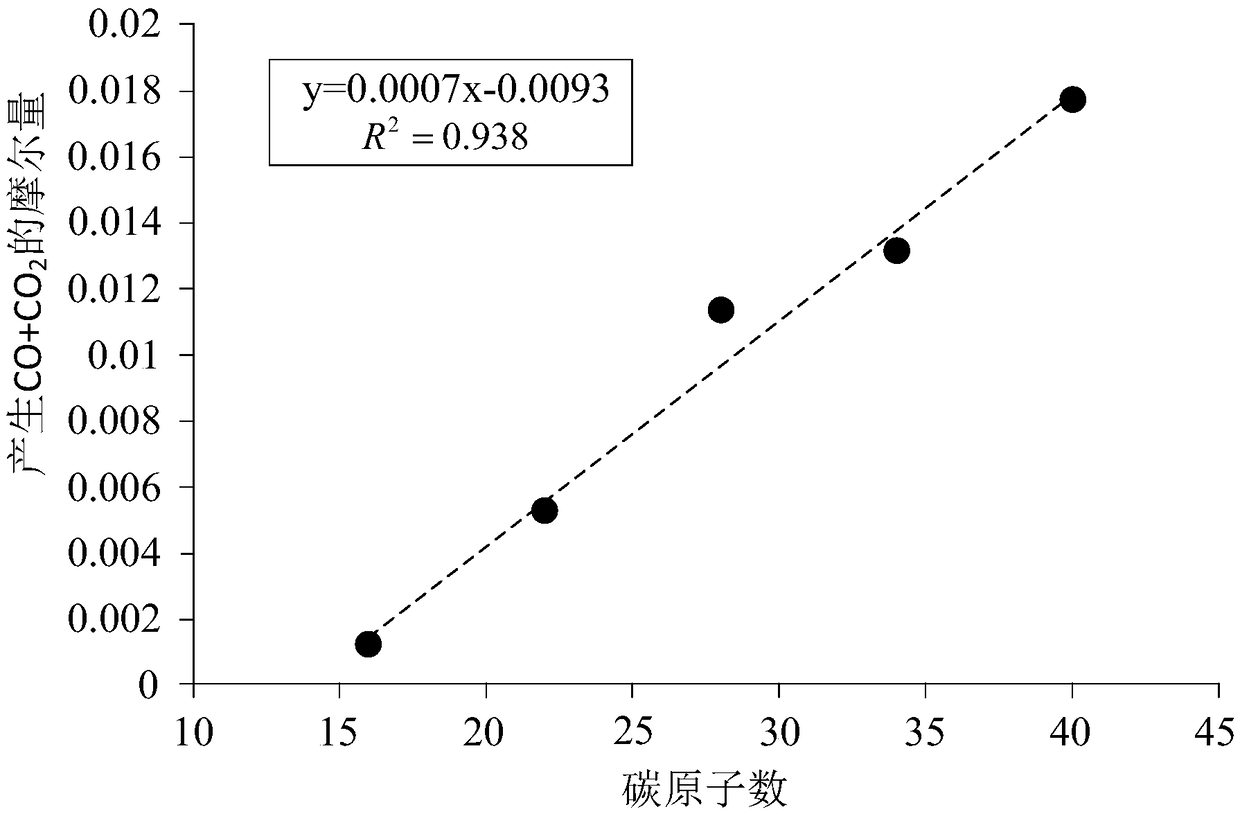

Oil layer ignition method and device, storage medium and processor

ActiveCN109469467ASolve the technical problem that the ignition is not easy to succeedImprove ignition success rateFluid removalCombustionPetroleum engineering

The invention discloses an oil layer ignition method and device, a storage medium and a processor. The method comprises the steps that oil layer parameters of a to-be-ignited oil layer are acquired, wherein the oil layer parameters at least comprise the oil saturation of an oil layer, the ignition heat required for stable combustion of the to-be-ignited oil layer, the fuel deposition ratio corresponding to the ignition heat and a first corresponding relation used for representing the oil saturation of the oil layer and the fuel deposition ratio; a second corresponding relation used for representing the fuel deposition ratio and the heating rate of the oil layer is acquired; according to the first corresponding relation and the second corresponding relation, a third corresponding relation used for representing the oil saturation of the oil layer and the heating rate of the oil layer is determined; according to the third corresponding relation, it is determined that the heating rate of the oil layer corresponding to the oil saturation of the oil layer is ignition heating rate. The oil layer ignition method and device, the storage medium and the processor solve the technical problem that the ignition of the oil layer with the low oil saturation does not succeed easily.

Owner:PETROCHINA CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com