Uniflow differential pressure type plasma ignition nozzle

A technology of plasma ignition and downstream pressure, applied in combustion ignition, incandescent ignition, combustion method and other directions, can solve the problems of high power requirements, engine deflagration easily, affecting ignition stability, etc., to achieve wide applicability, ignition The effect of strong reliability and ignition stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention is described in more detail below in conjunction with accompanying drawing example:

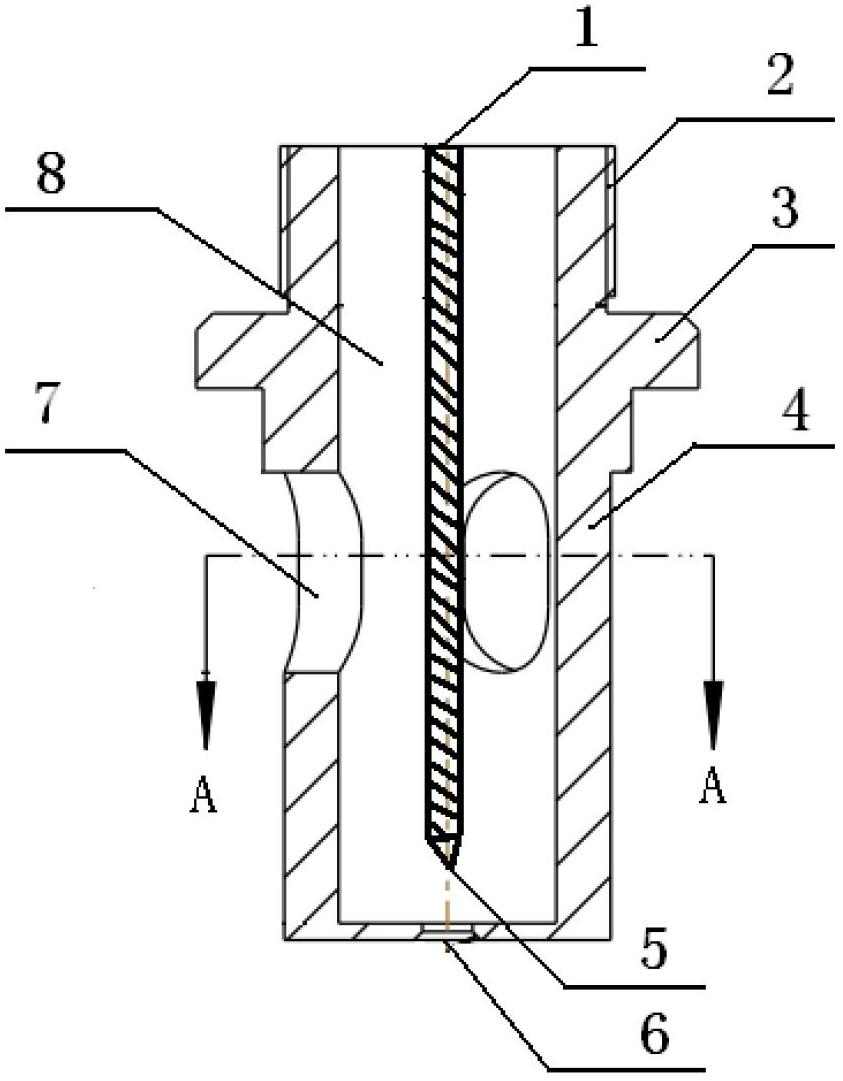

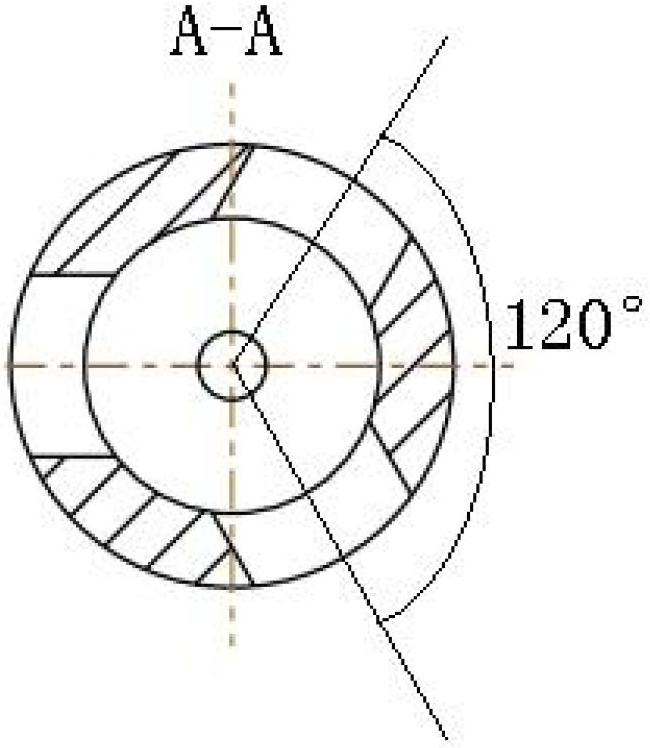

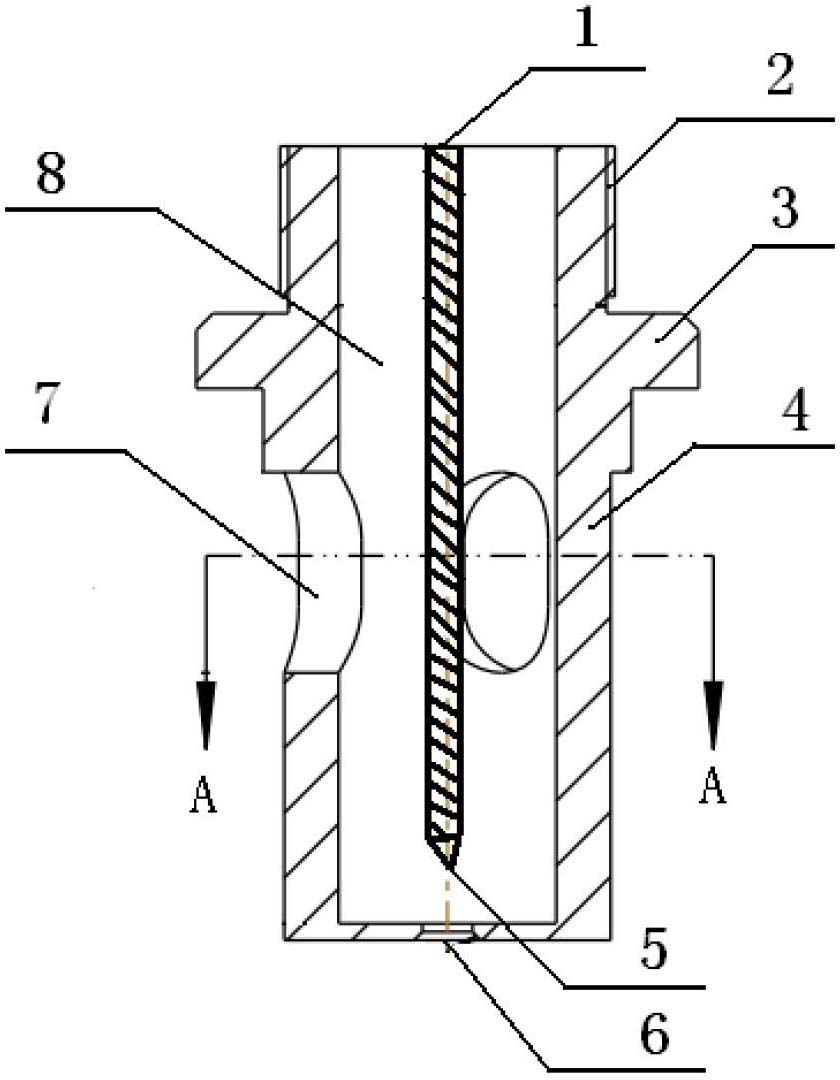

[0015] combine Figure 1~2 , The dual-fuel nozzle designed by the invention is mainly composed of cathode 1, anode 4, thread 2, hexagonal mounting seat 3, cathode head 5, nozzle hole 6, air inlet 7, electric nozzle cavity 8 and other components. When the downstream differential pressure plasma ignition nozzle shown in the present invention starts to work, the air enters the electric nozzle cavity 8 from the air inlet 7, and then moves near the spray hole 6 due to the internal and external pressure difference. Then the air is ionized into an ion state between the cathode head 5 and the nozzle hole 6, and is ejected from the nozzle hole 5 at a higher speed and a higher temperature, so that the high-temperature, high-speed plasma arc can fully interact with the fuel - The air mixture contacts and ignites the fuel-air mixture rapidly, thus ensuring the effective work...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com