Air filter for a combustion machine

An air filter and internal combustion engine technology, applied in the field of fixed power equipment and air filters, can solve the problems of expensive maintenance and repair work, disadvantages, etc., and achieve the effect of small structure volume and flow loss, and reduce noise level.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

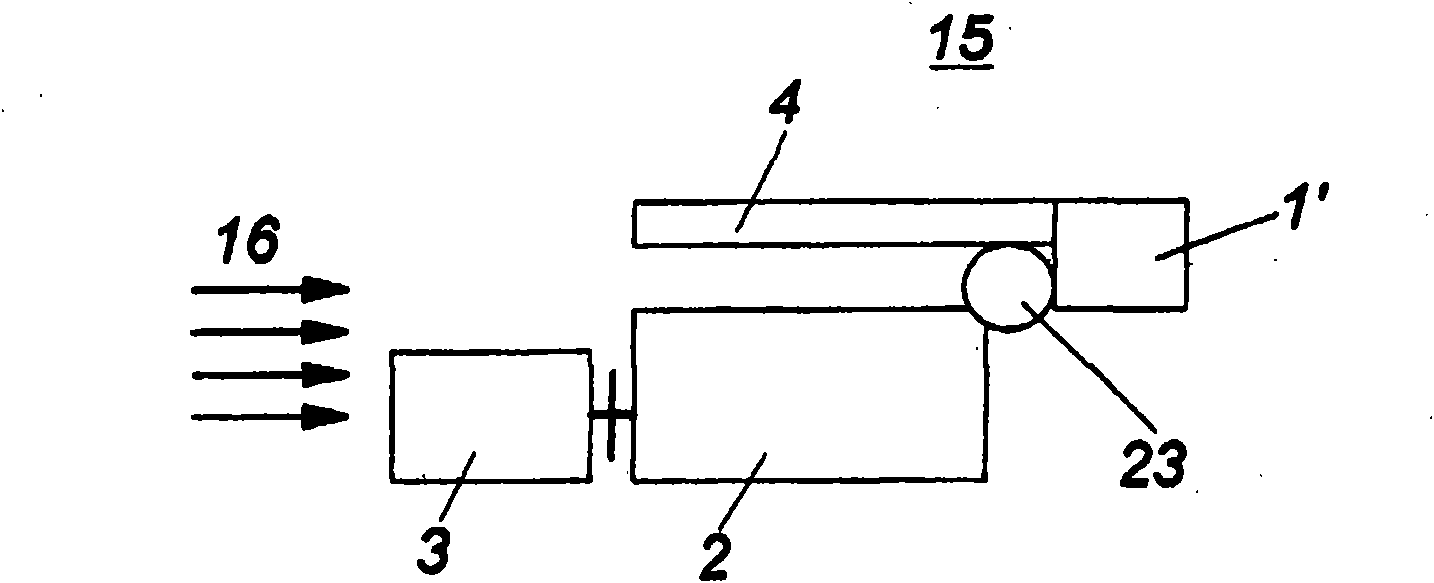

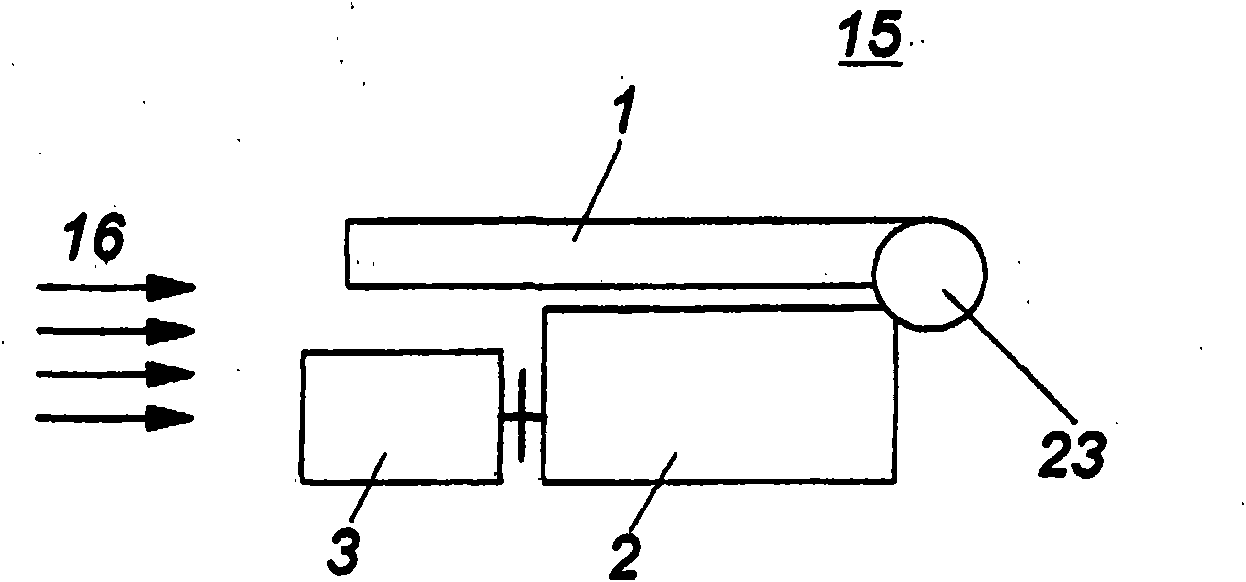

[0026] Figure 1a with 1bIn each case, a stationary power plant 15 according to the prior art is shown, which is arranged in a machine room, not shown in more detail. The stationary power plant 15 includes an internal combustion engine 2 and a generator 3 , the internal combustion engine 2 driving the generator 3 . By way of example, the internal combustion engine is a gas engine. as by Figure 1a As is evident, air 16 (from the left in the plane of the drawing) flows around generator 3 and internal combustion engine 2 . A supercharging device 23 is now arranged on the internal combustion engine 2 , in which the intake air 16 is compressed. If the intake air 16 is now drawn in directly in the area of the supercharging device 23 , the hot air discharged from the generator 3 is also drawn in, which can lead to an increase in the temperature of the air drawn in via the intake duct 4 up to 20°, This results in a severe reduction in power and efficiency of the internal combust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com