Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

107results about How to "Reduce noise emissions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

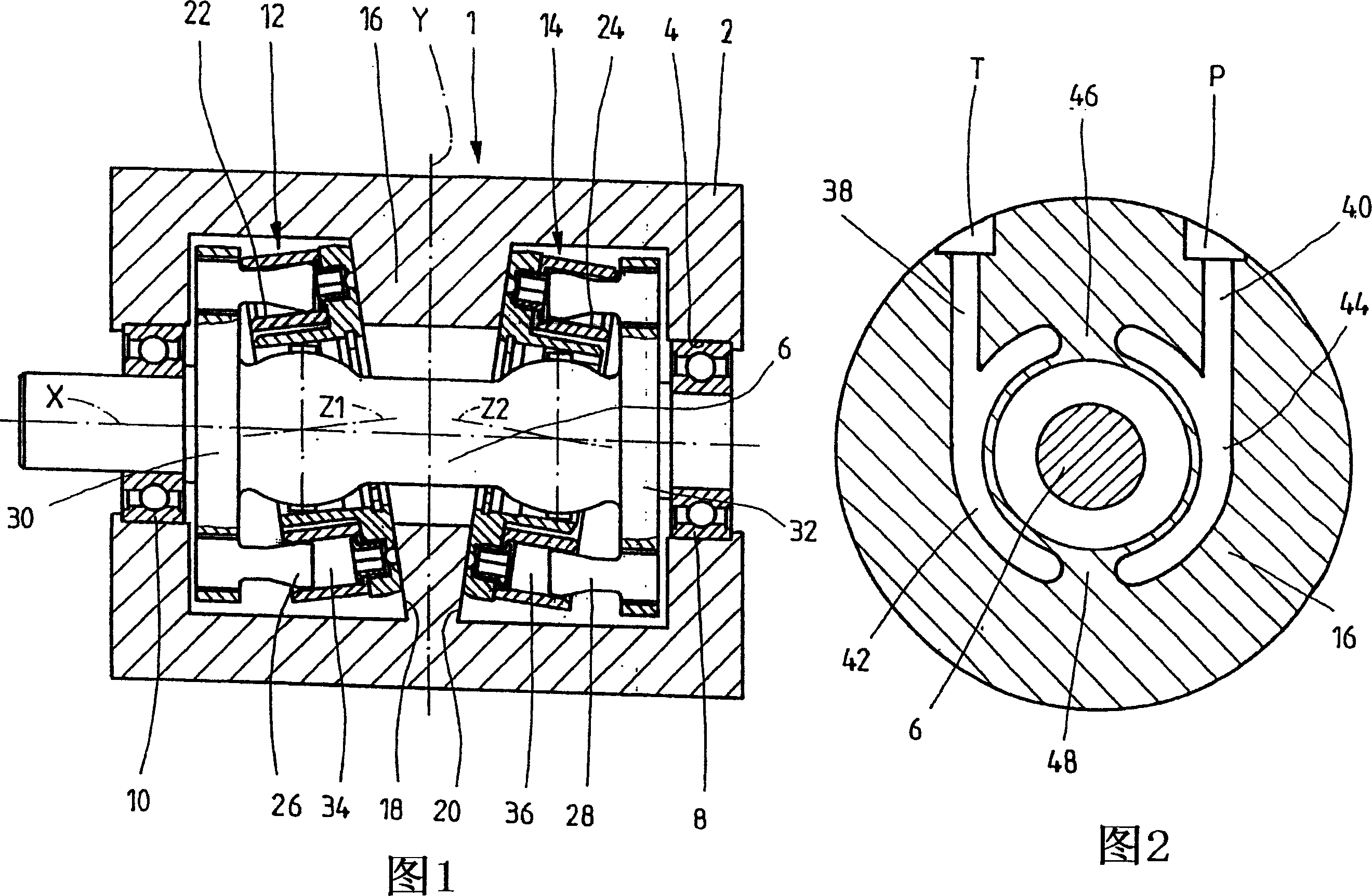

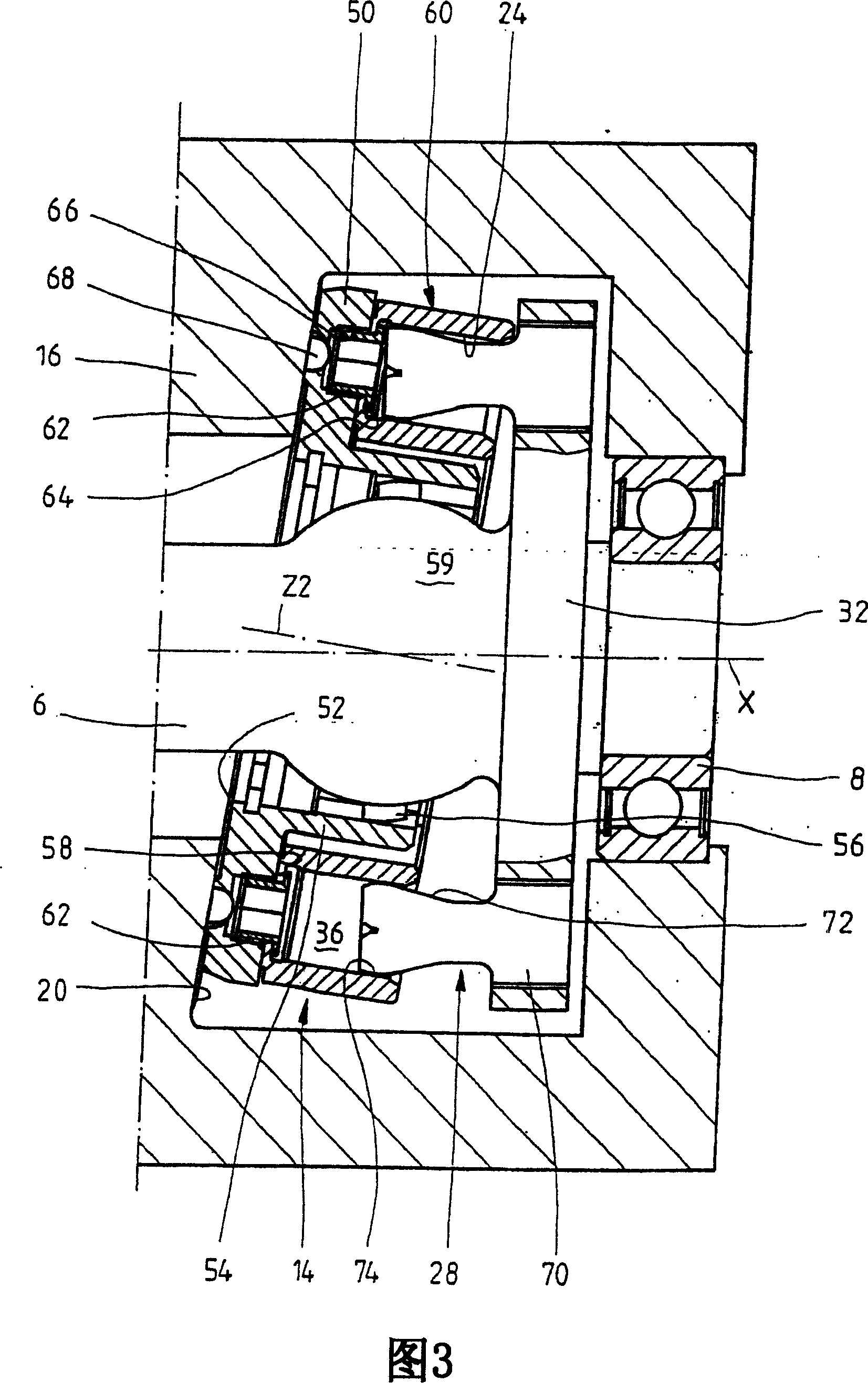

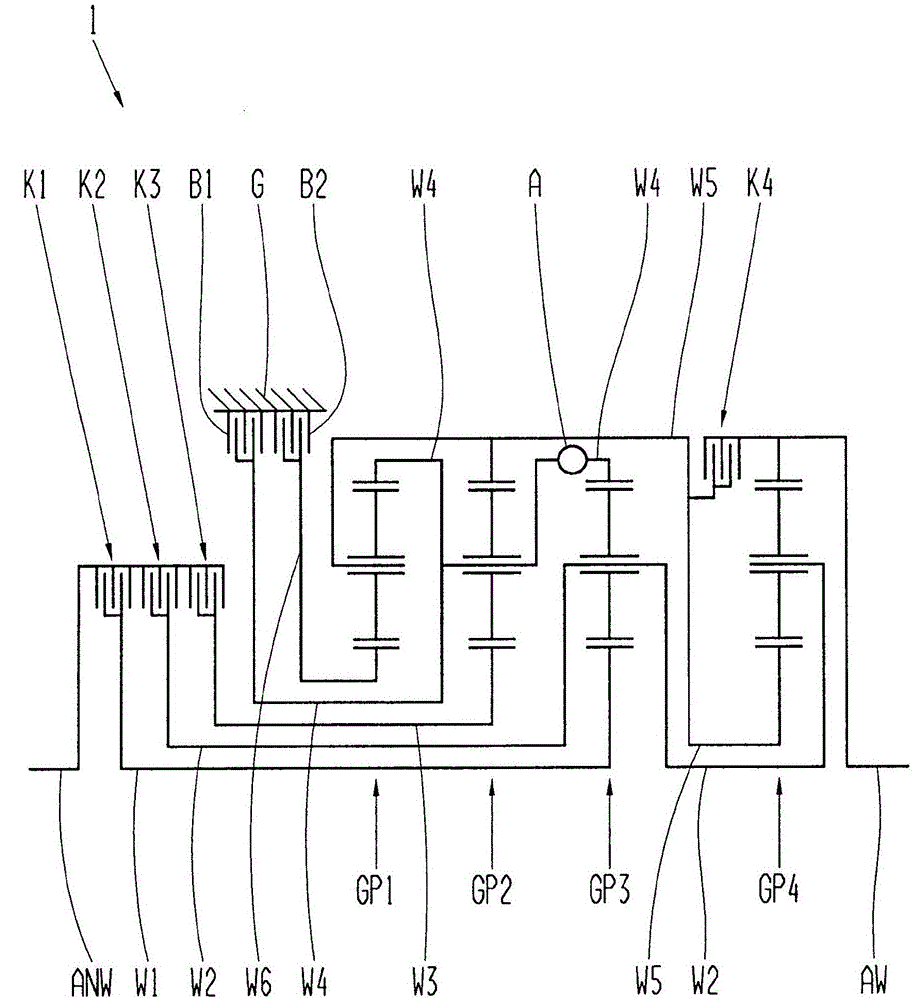

Axial piston machine

InactiveCN1926332ALow costEasy to layPositive-displacement liquid enginesMulti-cylinder pumpsRotational axisEngineering

The invention relates to an axial piston machine comprising two cylinder drums which are guided in a housing, can be respectively rotated about a drum axis, and are respectively supported on an inclined surface arranged in the direction of a shaft rotational axis. According to the invention, said inclined surfaces are located in the region between the two cylinder drums and the channels for supplying and releasing pressure end in said two inclined surfaces, i.e. pressure is supplied and released centrally.

Owner:BOSCH REXROTH AG

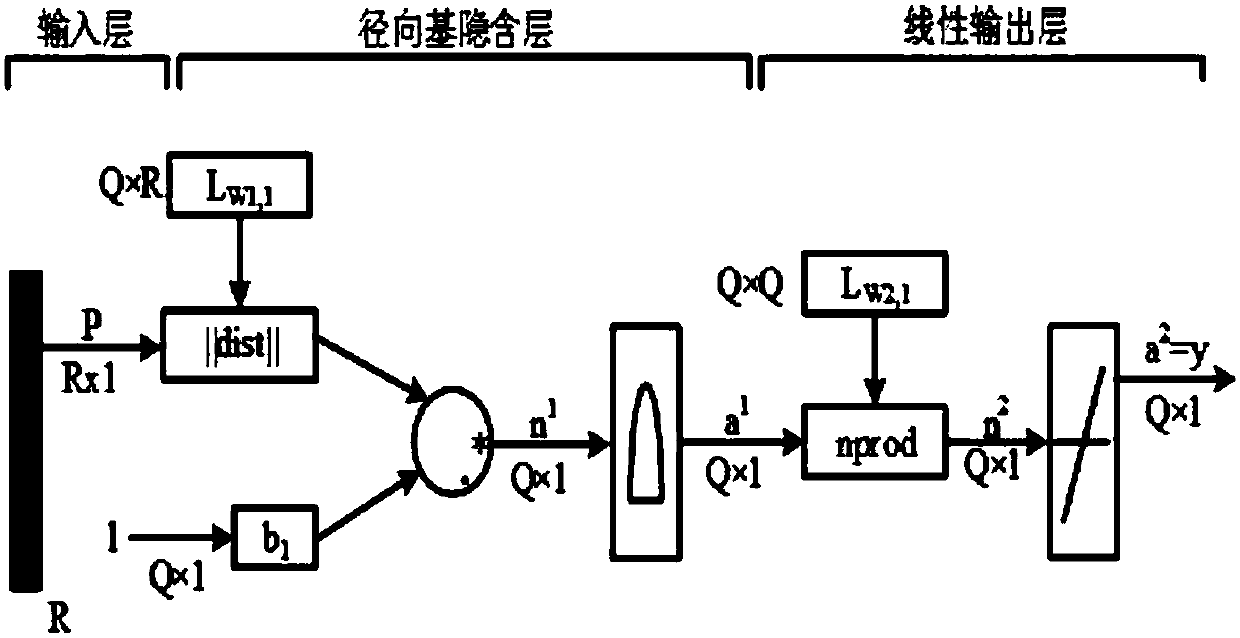

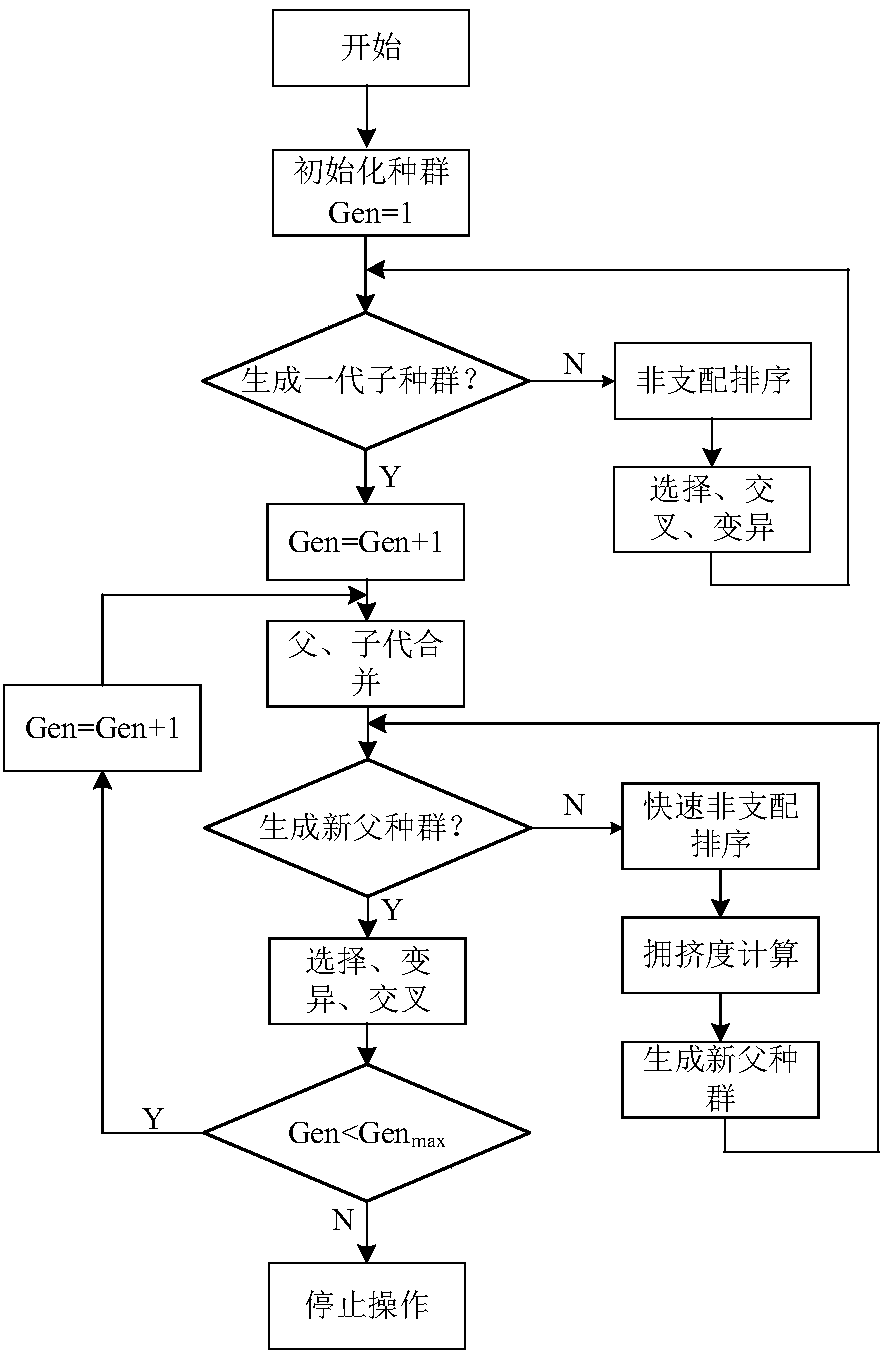

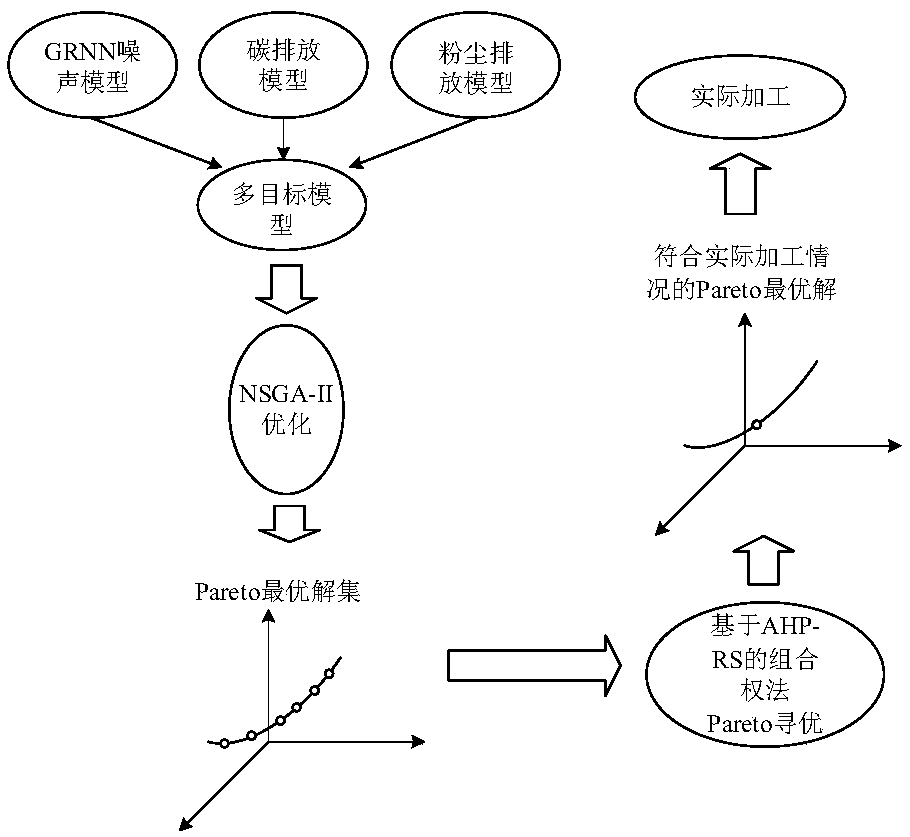

Thread turning process parameter optimization method for green manufacturing

InactiveCN108319223AEmission reductionReduce noiseProgramme controlComputer controlMechanical equipmentGreen manufacturing

The invention discloses a thread turning process parameter optimization method for green manufacturing, which comprises the steps of 1) determining optimization variables such as the cutting speed Vcand the feeding amount f; 2) establishing a multi-objective optimization function; 3) determining constraint conditions; 4) optimizing the objective function to obtain a Pareto optimal solution set thereof; 5) determining the weight of each target attribute according to an AHP (Analytic Hierarchy Process) and RS (Rough Set) based combined weight determination method, and obtaining an optimal solution meeting actual processing requirements from the optimal solution set in the step 4. In the application process of the method disclosed by the invention, parameters in the model can be determined firstly according to the actual condition, then the model is solved by adopting the method so as to obtain the cutting speed Vc and the feeding amount f when the carbon emission, noise emission and dust emission are synthetically optimized, and finally a purpose of reducing the carbon emission, noise remission and dust emission is achieved through controlling mechanical equipment.

Owner:HEFEI UNIV OF TECH

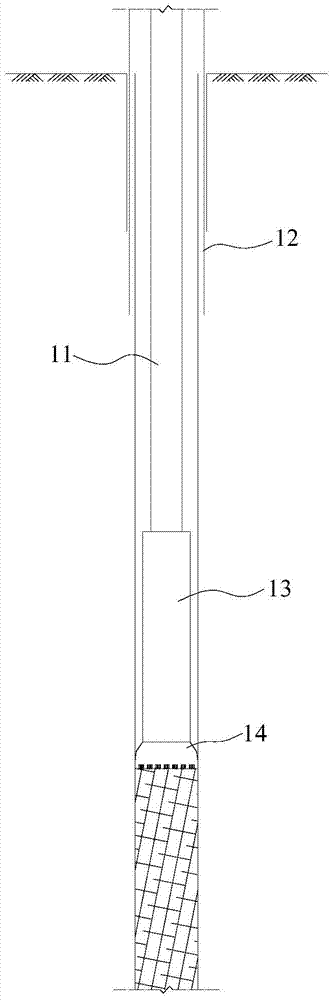

Construction method for forming grooves and holes and replacing large-diameter piles with small-diameter piles

ActiveCN104264689AQuick breakHole forming efficiencyExcavationsBulkheads/pilesSlurry wallSurface layer

The invention discloses a construction method for forming grooves and holes and replacing large-diameter piles with small-diameter piles. The method mainly includes the steps of forming the grooves in an underground continuous wall with the aid of a DTH hammer, forming the holes in the large-diameter piles with the aid of the DTH hammer and replacing the large-diameter piles with the small-diameter piles equivalently through the DTH hammer. Compared with a conventional groove and hole forming method, the construction method has the advantages that the defects that rock entering efficiency is low, holes are deviated, the hammer is stuck and even holes are difficult to form in the construction process under the comprehensive complicated geological conditions such as high-rock surface layers, hard stratums and slope stratums can be effectively overcome, the rock entering construction efficiency during grooving of the underground continuous wall and hole forming of the large-diameter piles can be greatly improved, the technical problems of the rock entering groove and hole forming construction under the complicated geological conditions such as high rock surface layers and hard stratums are solved, the construction quality is stable and reliable, the requirements for safety civilization and environmental construction are met, and economic loss and construction time loss of a project can be effectively avoided.

Owner:GUANGDONG FOUND ENG GRP CO LTD

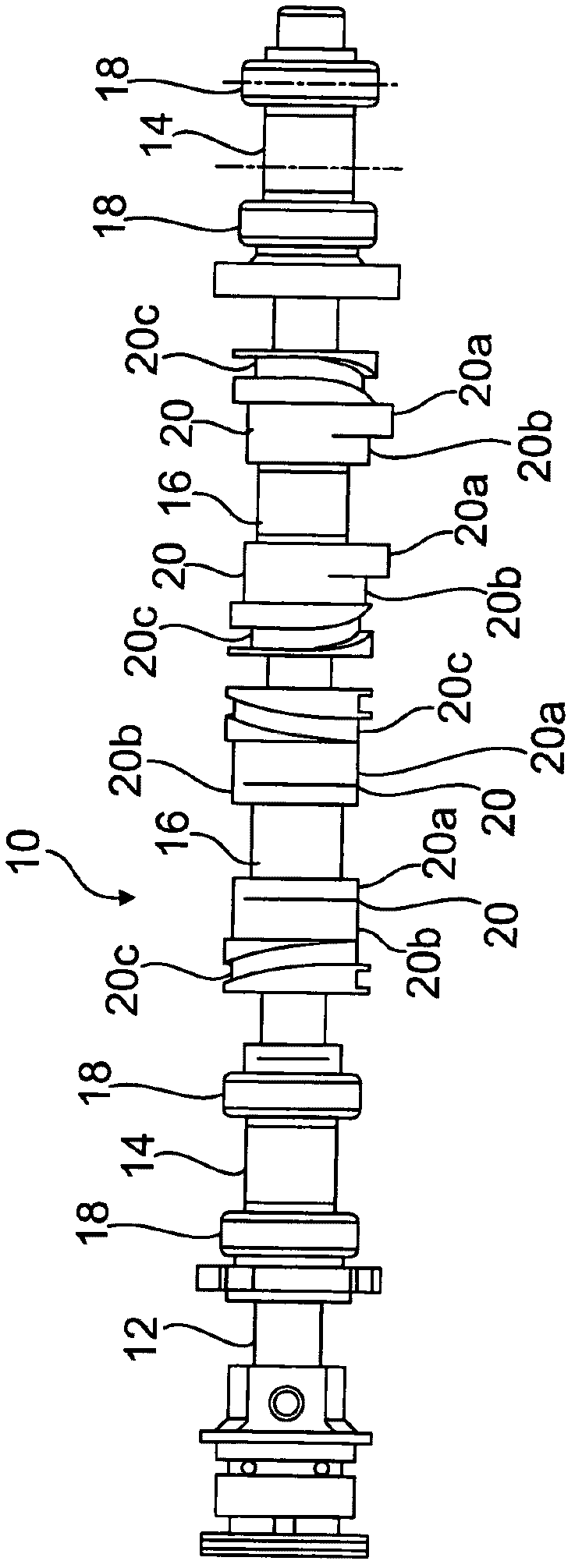

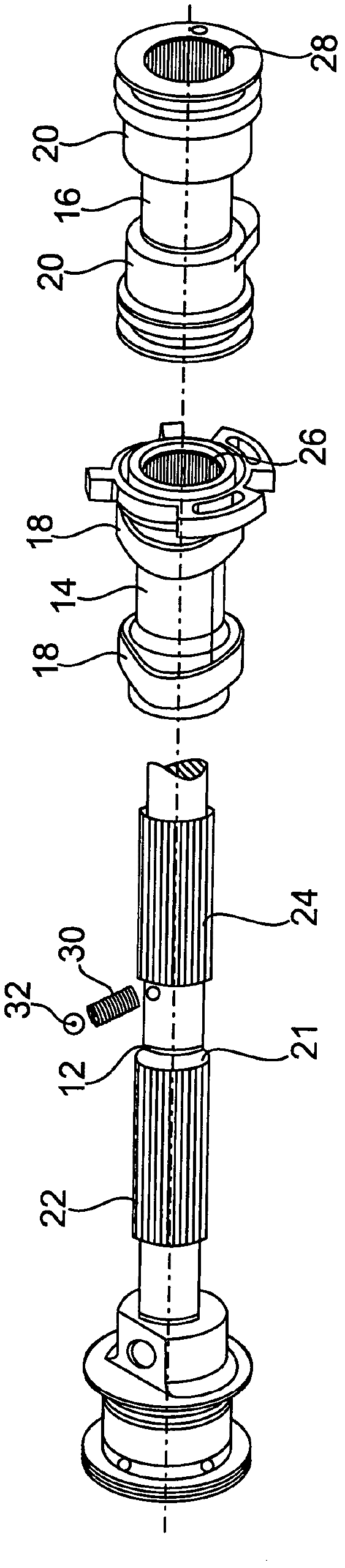

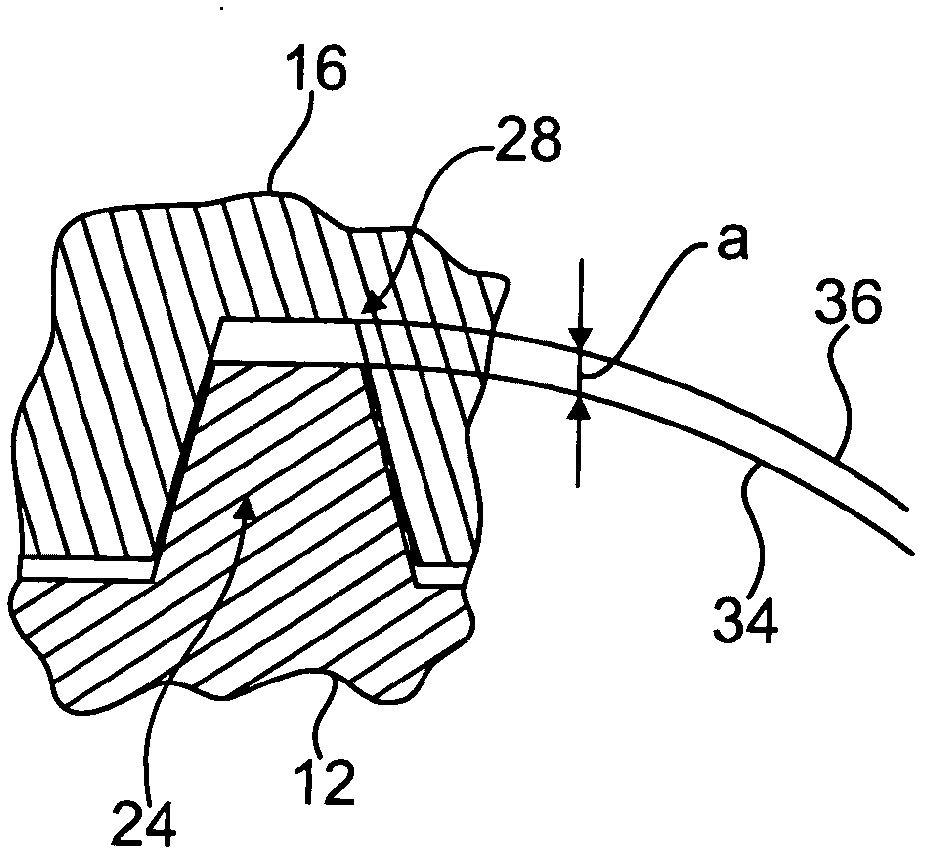

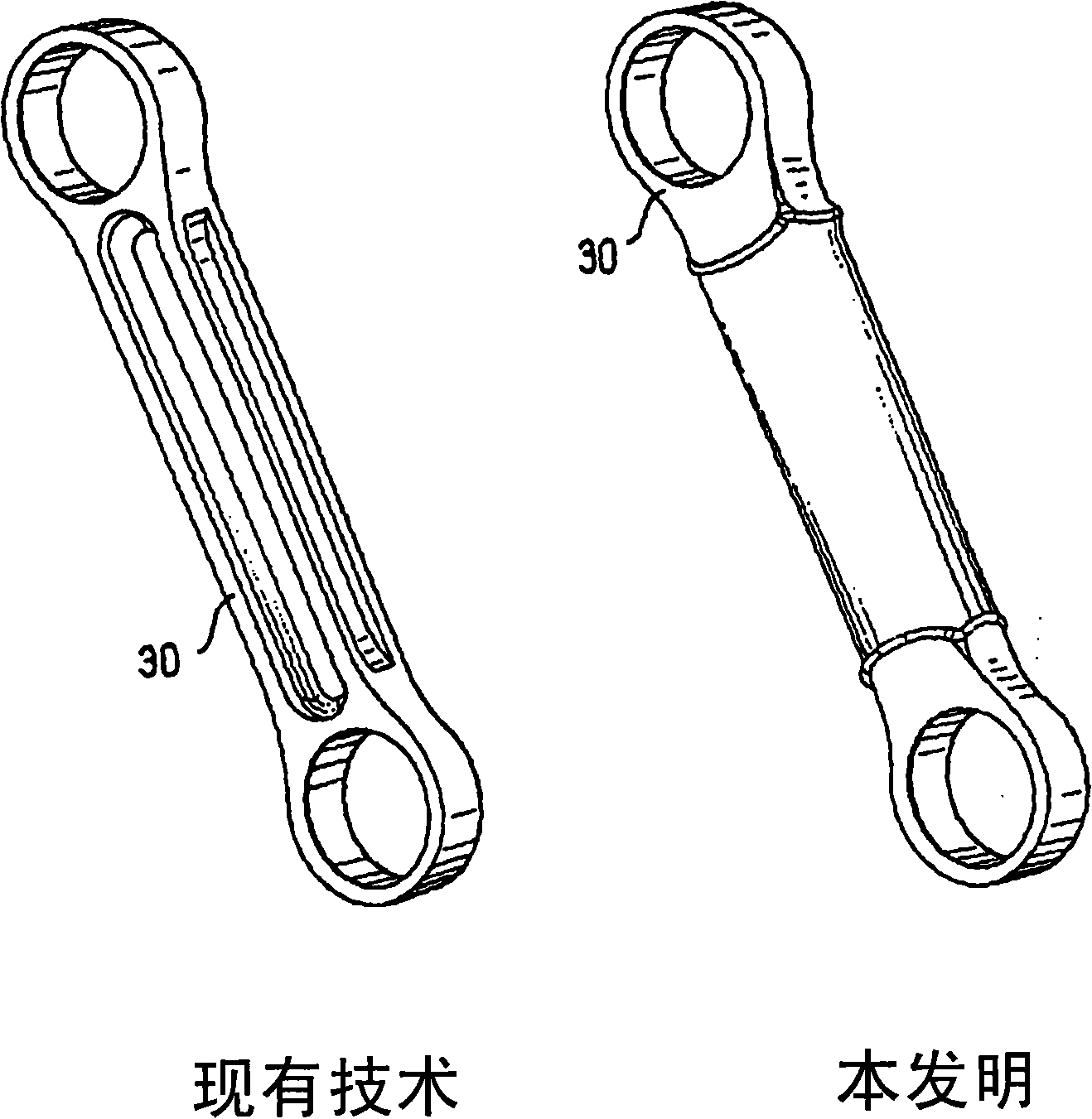

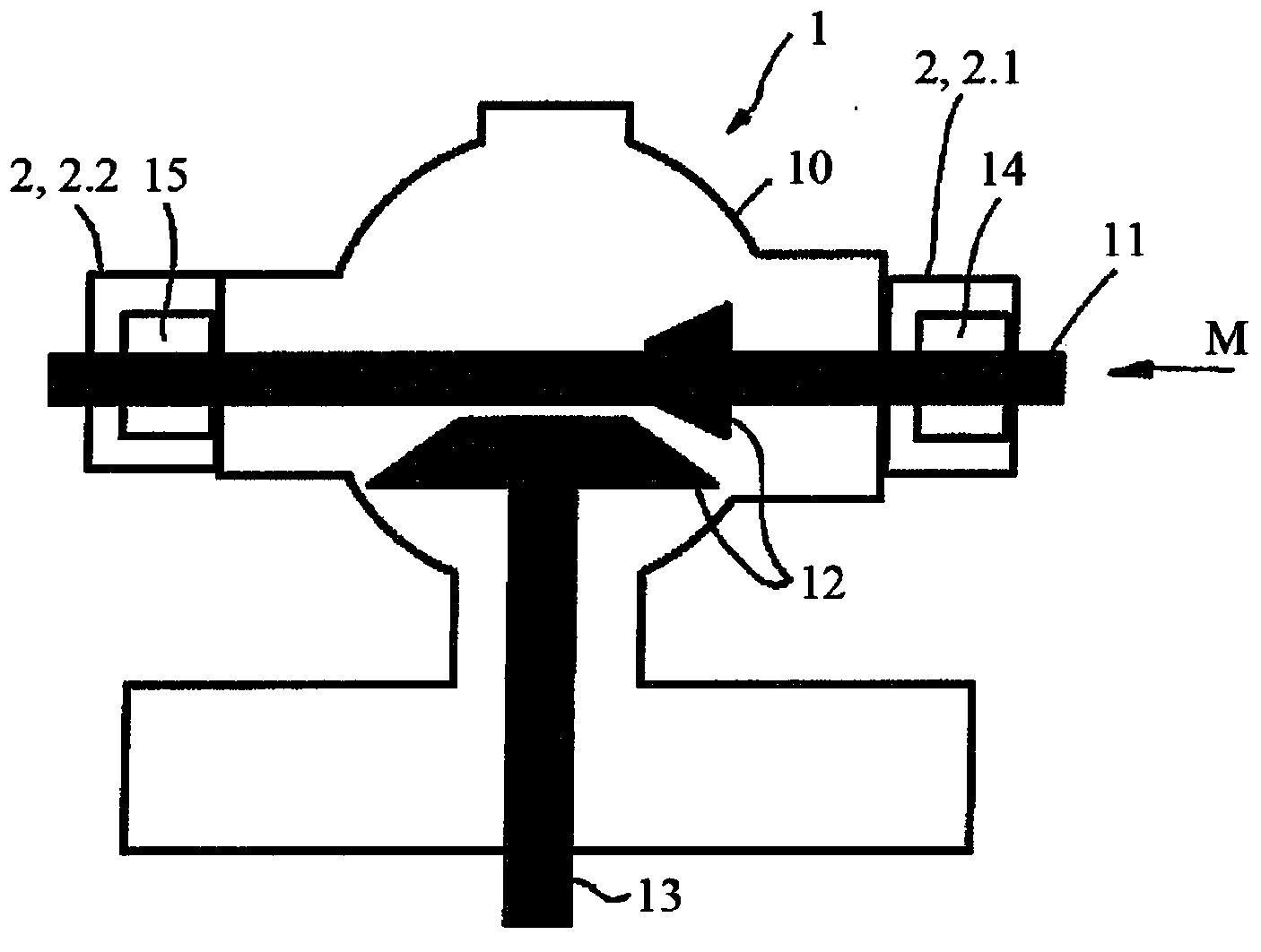

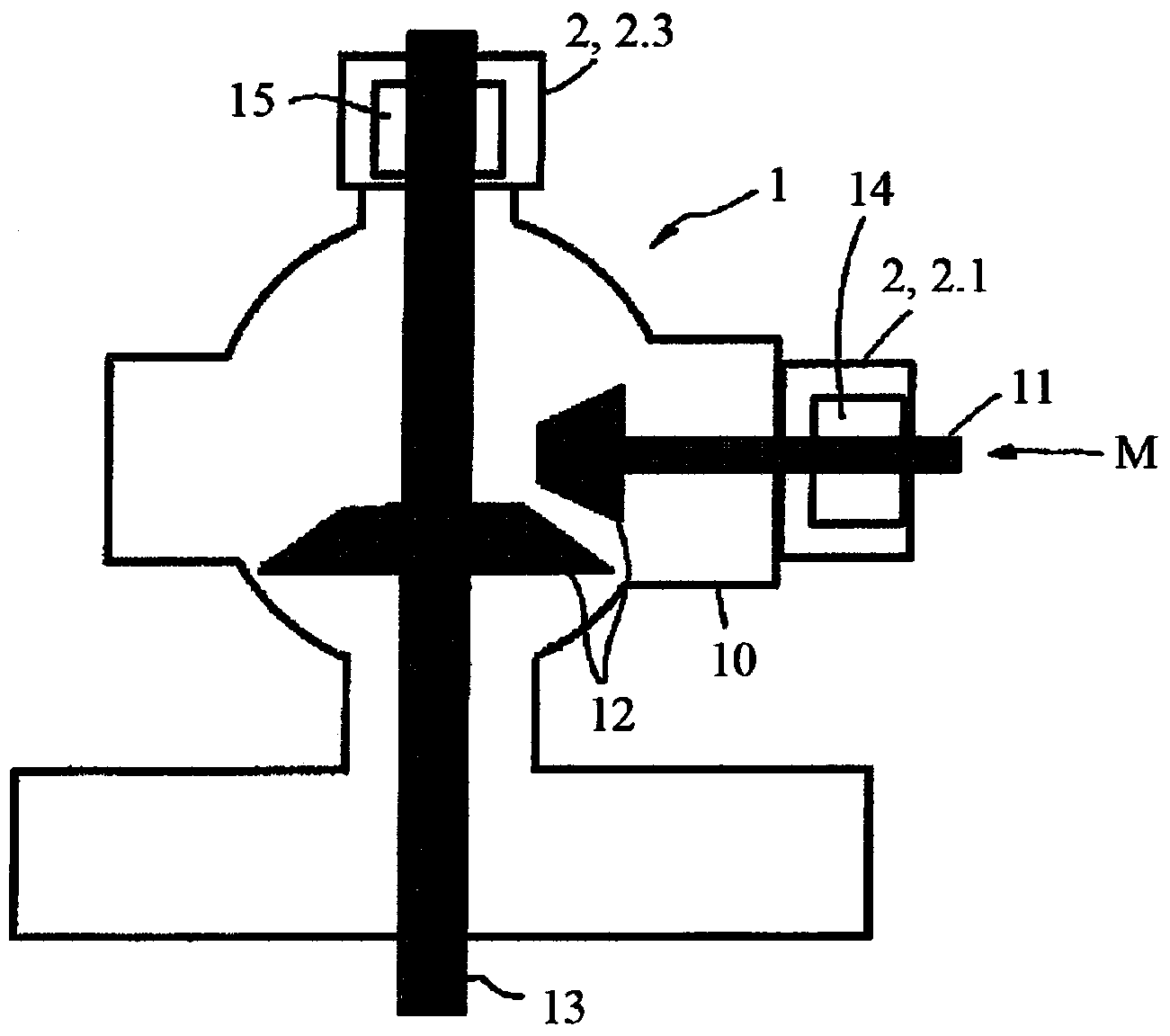

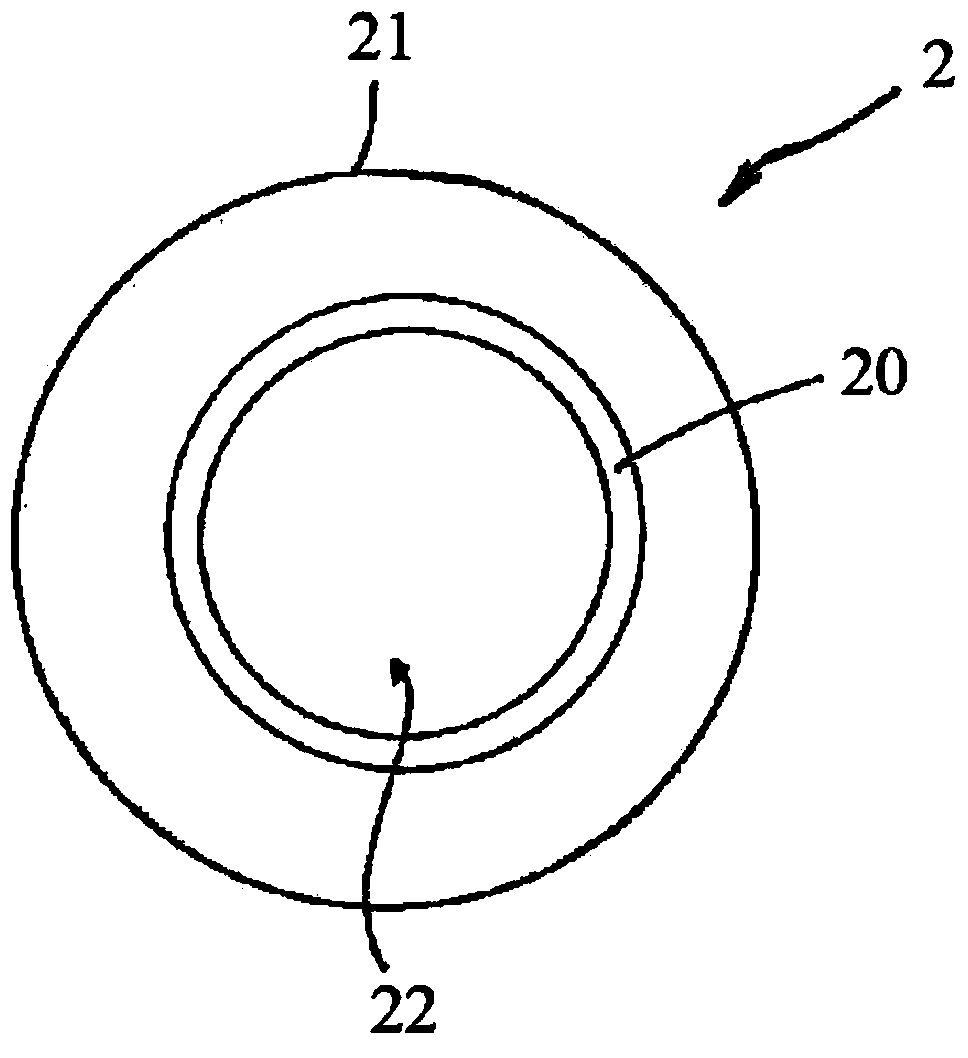

Constructed shaft element, particularly a constructed camshaft for valve controlled internal combustion engines

ActiveCN102459826AAdd supportReduce noise emissionsValve arrangementsCouplings for rigid shaftsCombustionInternal combustion engine

The present invention relates to a constructed shaft element, particularly a constructed camshaft for valve controlled internal combustion engines, wherein a hub body comprising at least one functional part, particularly at least one cam, is held on a shaft by a form fit connection by means of insertion teeth in the circumferential direction, wherein the insertion teeth comprise shaft teeth formed on the shaft and interacting with hub body teeth formed in a hub body recess. According to the invention, the at least one hub body (14) is held in addition to the circumferential form fit connection by a fixed seat on the shaft (12) implemented by a press fit between a tooth circle of the shaft teeth (22) and a root circle of the hub body teeth (26). The invention further relates to a method for producing a constructed camshaft for valve controlled internal combustion engines.

Owner:AUDI AG

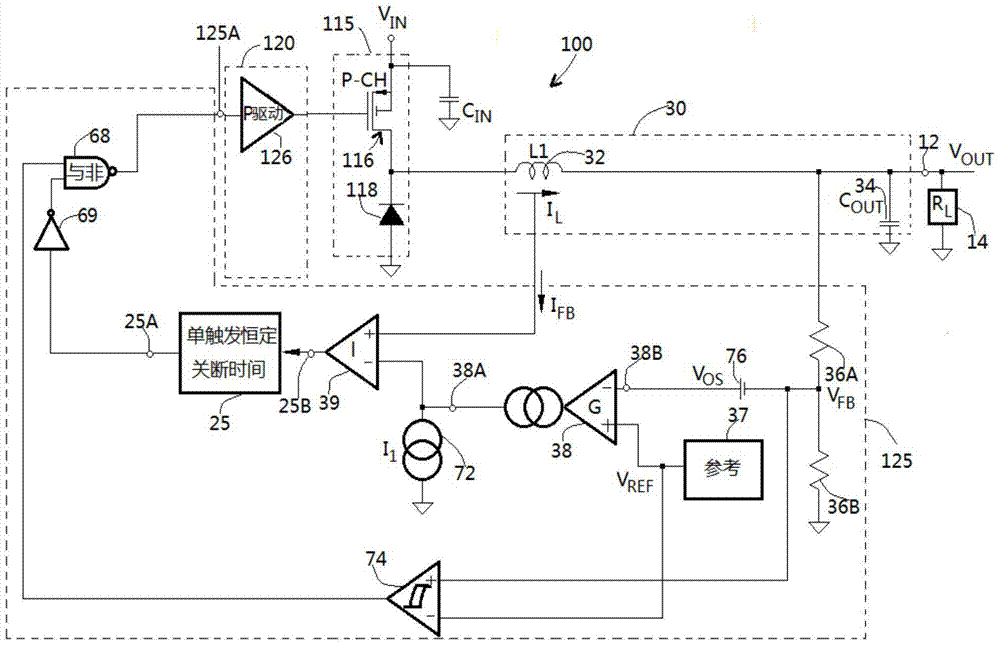

Control circuit enabling switch voltage stabilization circuit to keep high efficiency within wide current range

InactiveCN103618437AReduce noise emissionsReduce the possibilityDc-dc conversionElectric variable regulationEngineeringControl switch

The invention provides a control circuit enabling a switch voltage stabilization circuit to keep the high efficiency within a wide current range. The circuit for controlling a switch stabilizer comprises a switch (1) which comprises an output end comprising one or more switch transistors (2) and is used for providing a current for a load with a steady voltage, wherein the load comprises an output capacitor. When the voltage of the output end can basically keep the steady voltage of the output capacitor, a control signal can be generated according to the circuit and a method, and therefore the switch transistors can be stopped. According to the circuit and method, the efficiency of the stabilization circuit can be improved especially under the condition that the average current is low.

Owner:SUZHOU BATELAB MICROELECTRONICS

Device having a hydraulic drive for civil engineering

ActiveUS20130036727A1Improve efficiencyReduce hydraulic volume streamRotary clutchesServomotorsHydraulic circuitHydraulic pump

A device having a hydraulic drive for civil engineering work has least one shaft that can be rotated by a hydraulic motor. The hydraulic motor is operated by fluid of a hydraulic circuit that is supplied by a hydraulic pump. The hydraulic motor has a changeable displacement, and means for changing the volume stream are provided. A sensor for measuring the fluid pressure is disposed in the hydraulic circuit, and is connected with a control and regulation unit, by way of which the displacement of the hydraulic motor is adjustable, and by way of which the means for a change in the volume stream can be turned on. The control and regulation unit is set up so that in the event of a pressure drop in the hydraulic circuit, a reduction in the displacement of the hydraulic motor as well as a reduction in the volume stream is brought about.

Owner:ABI ANLAGENTECHN BAUMASCHEN INDBEBEDARF

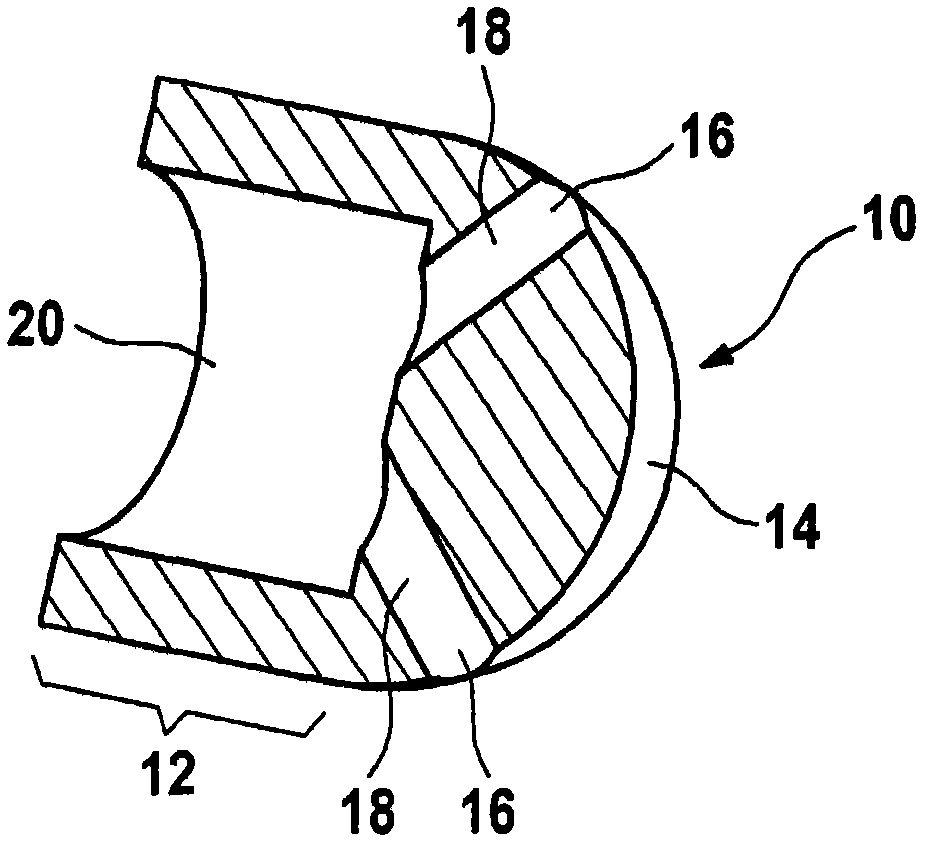

Valve with valve closure body

InactiveCN102072146AReduce manufacturing costEasy to integrateOperating means/releasing devices for valvesPositive displacement pump componentsEngineeringValve seat

The invention relates to a valve for a piston pump, wherein the valve (22) comprises a valve closure body (10) and a valve seat (26) disposed longitudinally facing to the valve closure body (10); the valve closure body (10) comprises a cylindrical guide section (12) and a hemispheric sealing section (14) longitudinally facing to the cylindrical guide section (10) and facing to the valve seat (26); the sealing section is used for selectively closing and opening a hole (30) enclosed by the valve seat (26); according to the invention, the sealing section (14) comprises at least one channel opening (16) which is located out of the hole (30) enclosed by the valve seat (26) under the state that the valve (22) is closed, and extended into a channel (18) in the valve closure body (10) substantially extending along a flow direction.

Owner:ROBERT BOSCH GMBH

Method of reducing the aerodynamic noise generated by an aircraft landing gear

InactiveCN101279645AReduce noise emissionsThin material handlingUndercarriagesVolumetric Mass DensityAircraft landing

The present invention relates to a method of reducing the noise generated when an aircraft landing of flying device is spread, the method includes at least one part (7, 13, 21) of the landing device is coated with materials (8, 14, 22) whose density is lower than that of elements, thereby the part is suitable for the shape of air mechanics of flowing gaseous current around.

Owner:MESSIER DOWTY

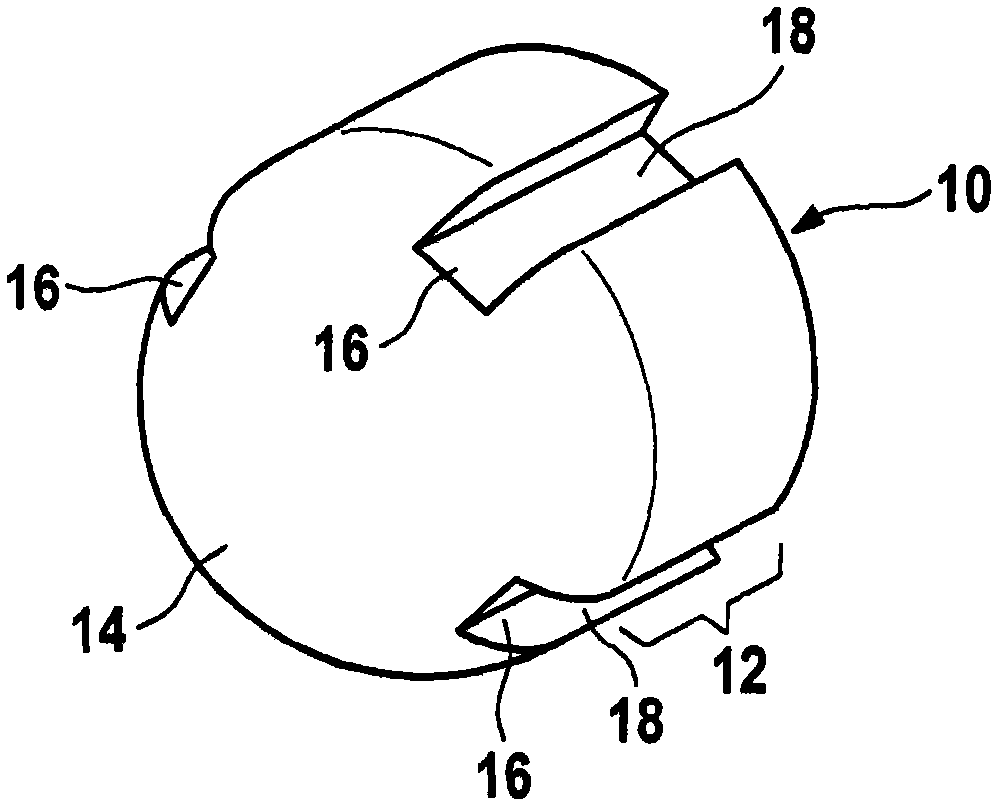

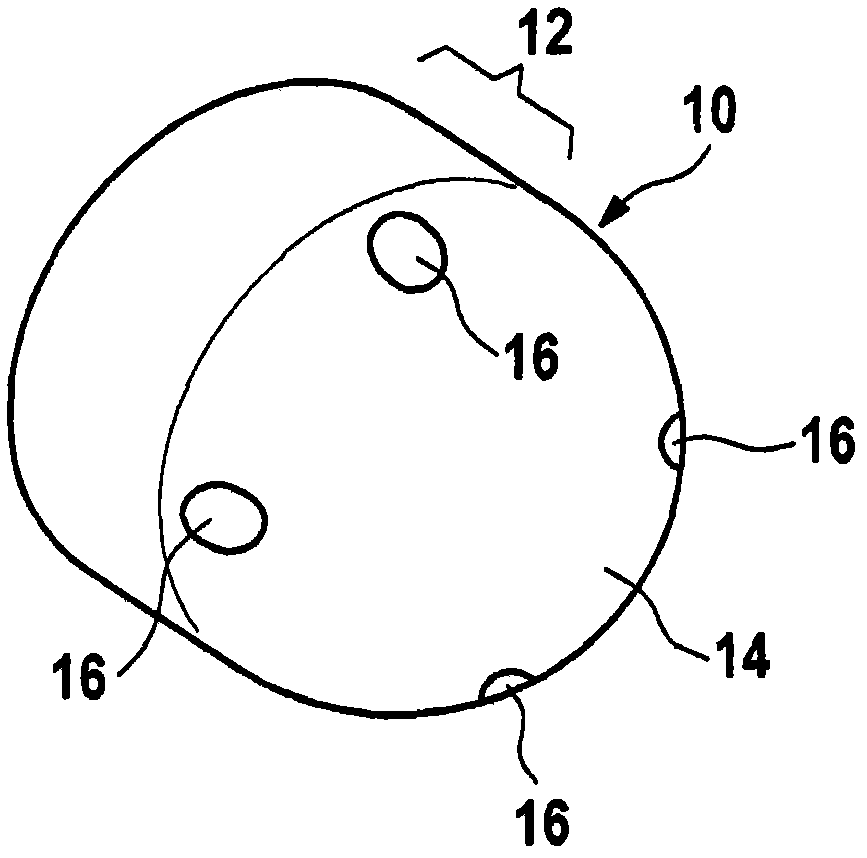

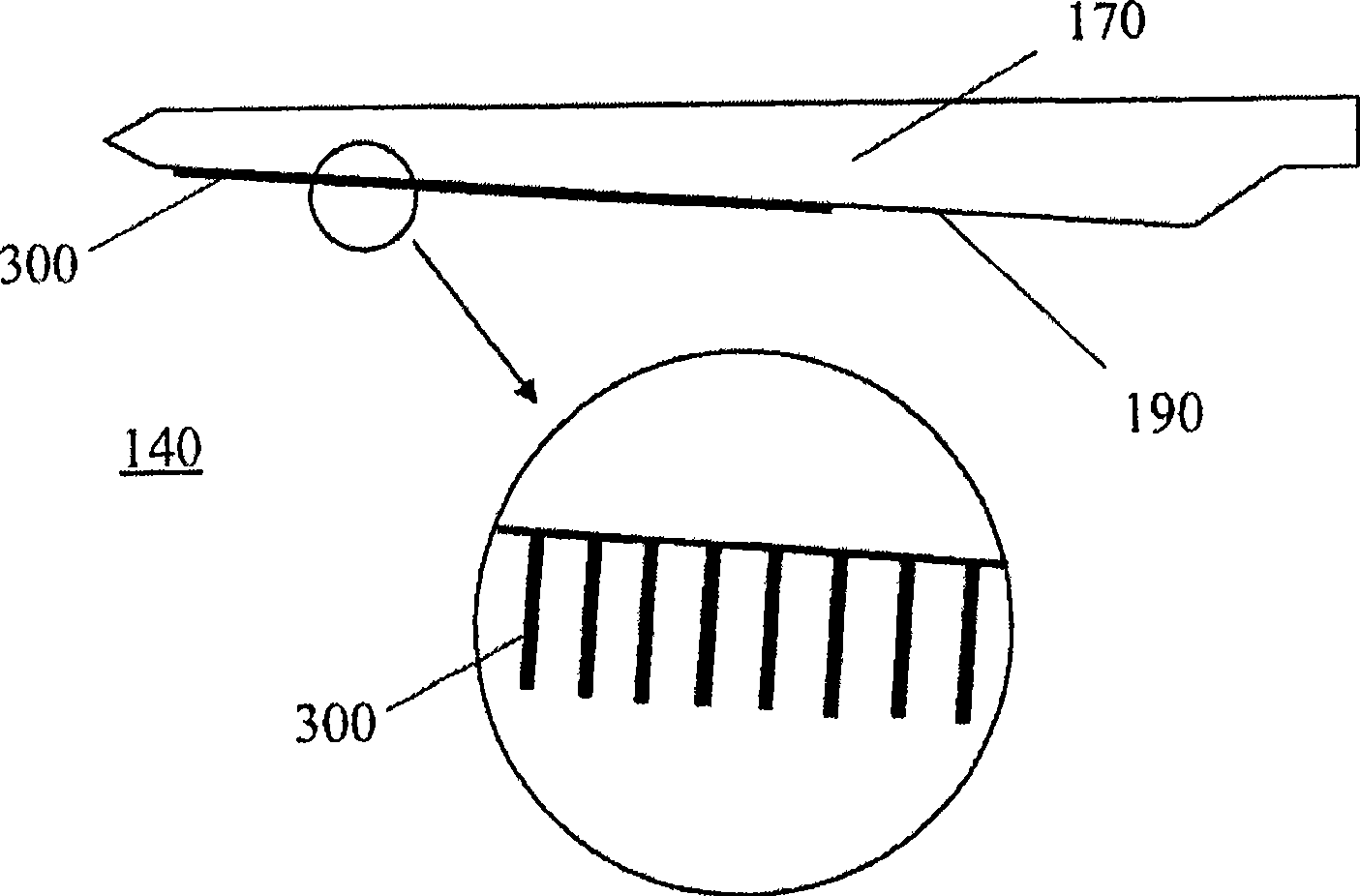

Blade brush of wind turbine

InactiveCN101476537AReduce noise emissionsImproved noise emission performanceMachines/enginesWind energy generationBristleTurbine blade

The invention relates to a wind turbine blade brush and provides a rotor blade for a wind energy system. The rotor blade comprises a blade body with a rear edge and a front edge, and a plurality of bristles on the external surface of the blade body. The bristles are adhered in the vicinity of the rear edge of the blade body under typical circumstances and are used for reducing the noise caused by the air current near the blade during work.

Owner:GENERAL ELECTRIC CO

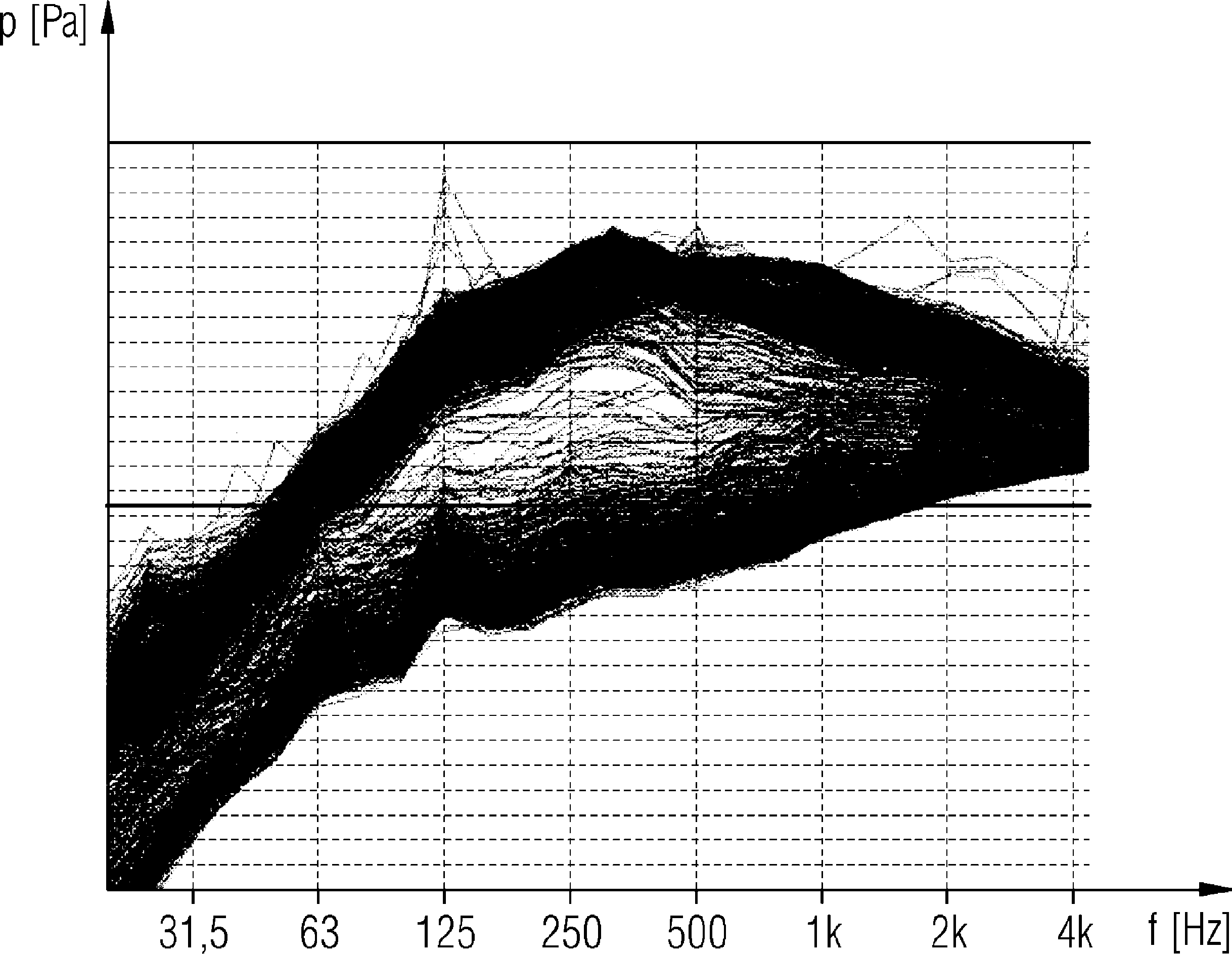

Stall detection of wind turbine blades

InactiveCN103528670AExtend your lifeIncreased power productionSubsonic/sonic/ultrasonic wave measurementWind motor controlFrequency spectrumTurbine blade

The invention provides a stall sensor for a wind turbine, a wind turbine comprising such a stall sensor and a method of operating such a wind turbine. The stall sensor comprises detector means (10) adapted to measure vibration of a rotor blade of the wind turbine and to output a vibration signal representative of the vibration of the rotor blade, conversion means (11) connected to the detector means (10) and adapted to determine a noise figure representative of a spectral signal content within a frequency band of the vibration signal received from the detector means (10) and arbiter means (12) connected to the conversion means (11) and adapted to signal a presence or an absence of stall based on the noise figure received from the conversion means (11).

Owner:SIEMENS AG

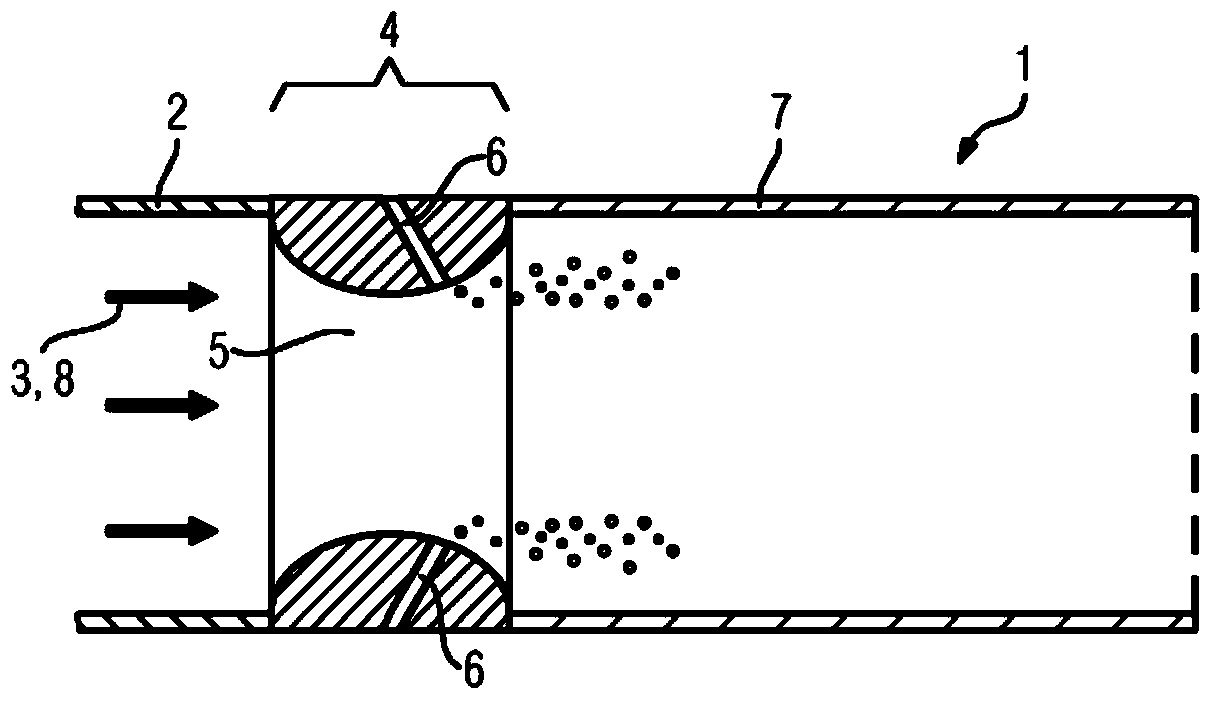

Bypass steam line

InactiveCN103765098AWell mixedReduce noise emissionsSuperheating controlFlow mixersSteam lineEngineering

The invention relates to a mixing unit (1) for mixing water with steam in a bypass station, wherein a plurality of Laval nozzles (5, 5a, 5b,...) are arranged in the mixing unit (1), which Laval nozzles (5, 5a, 5b,...) are displaced axially with respect to one another in a water steam direction, with the result that the noise emissions are reduced overall.

Owner:SIEMENS AG

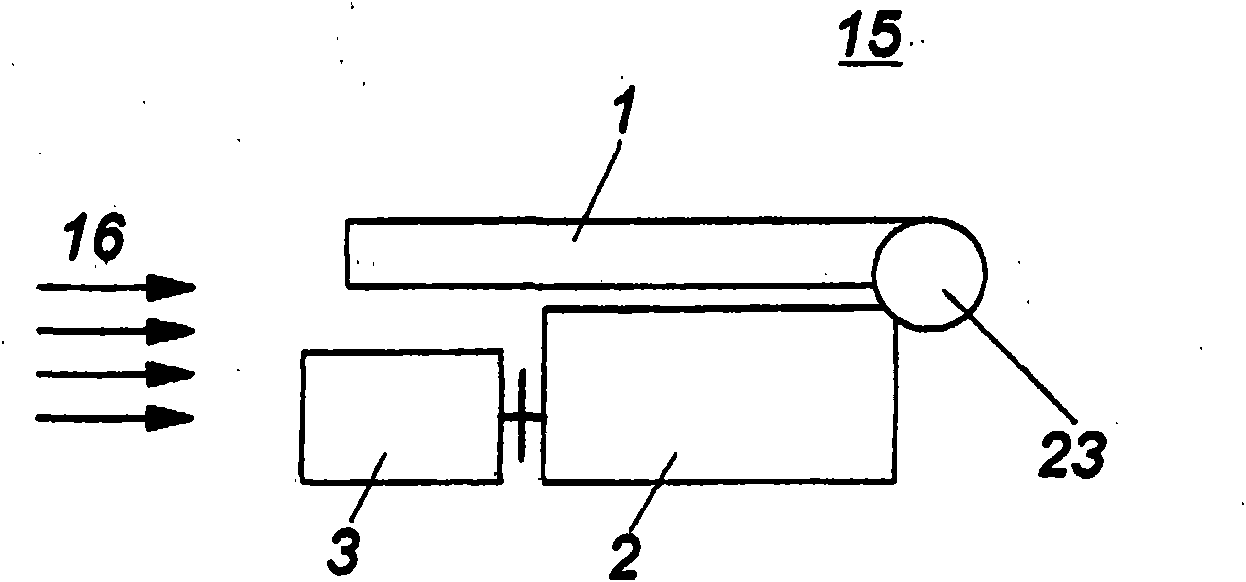

Helicopter with transverse duct

The invention is related to a helicopter with a longitudinal axis and with a tail portion (1) with a transverse duct (6) and a drive shaft (23) inside a drive shaft fairing (14) for an aerodynamic and acoustic optimized counter-torque device (2) supported within said transverse duct (6).

Owner:AIRBUS HELICOPTERS DEUT GMBH

Air filter for a combustion machine

InactiveCN101634263AImprove sound insulationReduce noise levelGas treatmentDispersed particle filtrationCombustionAir filter

An air filter for a combustion machine including a housing with a flow passage and a filter insert, wherein said filter insert subdivides the flow passage into an intake flow passage with an air inlet opening and into a discharge flow passage with an air outlet opening, wherein the filter insert has an air inlet surface which extends at least region-wise over the length of the filter insert along the air flow direction, wherein said filter insert has at least two successive filter elements, wherein the outside diameter or diameters of said filter elements, is or are different.

Owner:GE JENBACHER

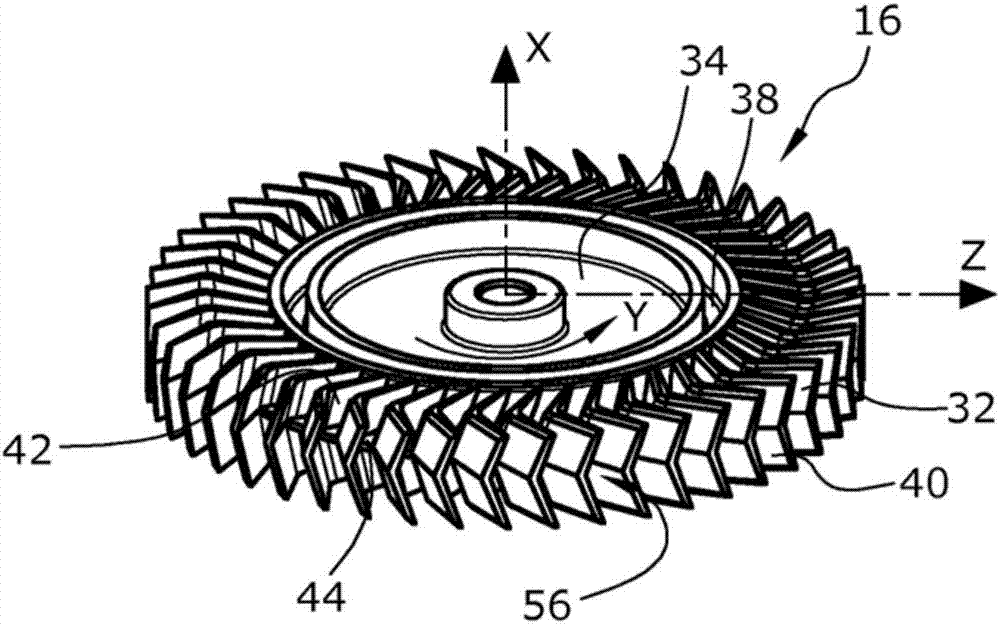

Side-channel blower for an internal combustion engine, comprising a wide interrupting gap

ActiveCN107110169AReduce sensitivityEasy to manufactureEngine manufacturePump componentsImpellerIncreased tolerance

Previously known side-channel blowers for an internal combustion engine comprise a fluid-penetrated housing, an impeller (16) that is rotatably arranged in said housing, impeller blades (32) that are formed in the radially outer region of the impeller (16) and are open in the radially outward direction, a radial gap (52) between the impeller (16) and a housing wall (54) that radially surrounds the impeller (16), an inlet (18), an outlet (30), two gas ducts (20, 22) which connect the inlet (18) to the outlet (30), are formed axially opposite the impeller blades (32) in the housing, and are fluidically connected to one another via intermediate spaces between the impeller blades (32), a drive unit (14) for driving the impeller (16), and an interruption zone (58) which is located between the outlet (30) and the inlet (18) and in which the ducts (20, 22) are interrupted in the peripheral direction. In order to be able to manufacture the blower at a lower cost by increasing tolerances and render the blower less prone to the formation of ice and accumulation of dirt without reducing the delivery rate, according to the invention, a radial interrupting gap (64) between the impeller (16) and the radially delimiting housing wall (54) in the entire interruption zone (58) is 0.005 to 0.03 times the diameter of the impeller.

Owner:PIERBURG GMBH & CO KG NEUSS

Magnetic resonance imaging gradient coil, magnet assembly, and system

ActiveUS20130106420A1Prevents mechanical energyReduce noiseMagnetic measurementsElectric/magnetic detectionSpinsSpatial encoding

A magnetic resonance imaging magnet assembly (100) comprising: a magnet (102) adapted for generating a main magnetic field for aligning the magnetic spins of nuclei of a subject (502) located within an imaging volume (504); and a gradient coil (103) for generating a gradient magnetic field for spatial encoding of the magnetic resonance signal of spins of nuclei within the imaging volume, wherein the gradient coil is adapted to be mounted into the magnet, wherein the gradient coil comprises: a first gradient coil section (112), wherein the first gradient coil section comprises a first rigid element (113), a second gradient coil section (114), wherein the second gradient coil section also comprises a second rigid element (115), a connecting element (116, 300, 302, 304, 400) for joining the two half gradient coils, wherein the connecting element comprises an elastic material (116), wherein the elastic material is in contact with the first rigid element and the second rigid element.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

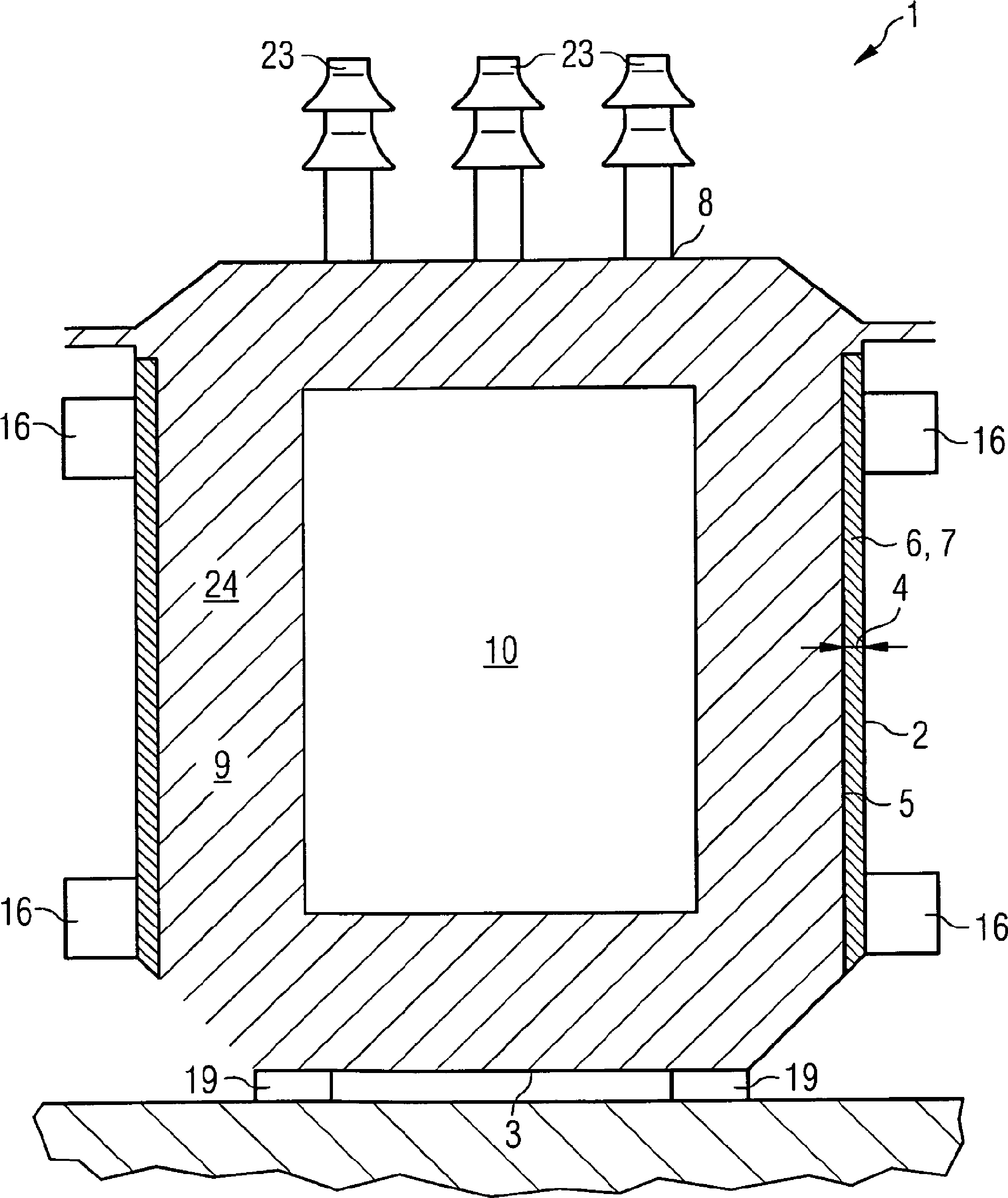

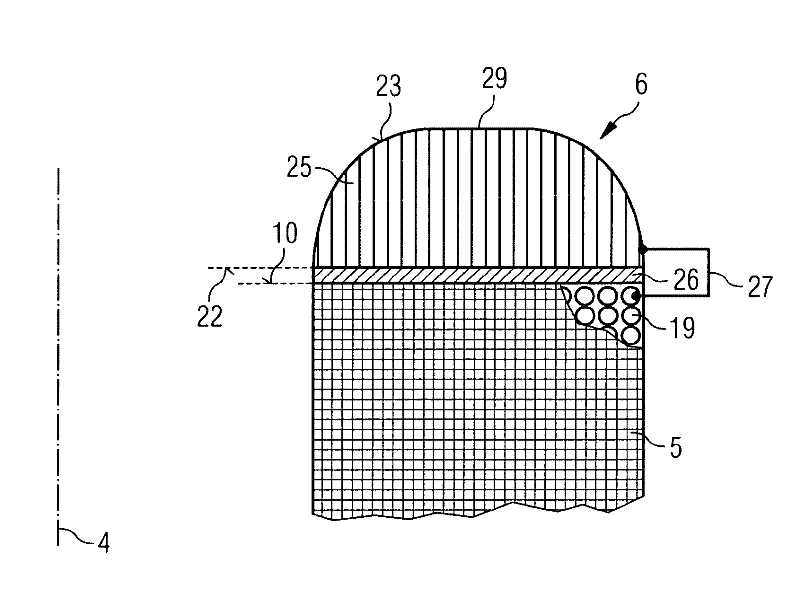

Tank for liquid-filled transformers or inductors

ActiveCN104335301AAids in mechanical stabilityReduce noise emissionsTransformers/inductances coolingTransformers/inductances casingsInterior spaceTransformer

Tank for a liquid-filled transformer or inductor, comprising: a) an outer tank casing (2) comprising a bottom part (3); b) an inner tank casing (5), enclosed by the outer tank casing (2) at a distance (4), wherein the outer tank casing (2) and the inner tank casing (5) are formed from metal; c) a plastic or polymer material (7), which is incorporated in an intermediate space (6), bounded by the inner surface (14) of the outer tank casing (2) and the inner surface (13) of the inner tank casing (5), and at least partially fills this intermediate space (6), wherein the plastic or polymer material and the adhesion thereof to the inner surfaces (13, 14) is designed such that d) shearing forces are transmitted between the inner and outer tank casings (2, 5) and that e) the transmission of structure-borne sound that is generated in the case of operation of an active part (10) arranged in the interior space (9) of the tank between the inner tank casing (5) and the outer tank casing (2) is inhibited.

Owner:西门子能源全球两合公司

A method for operating a wind turbine, a wind turbine and use of the method

InactiveCN101680424AReduce noise emissionsWind motor controlMachines/enginesTurbine bladeConstant angle

Owner:VESTAS WIND SYST AS

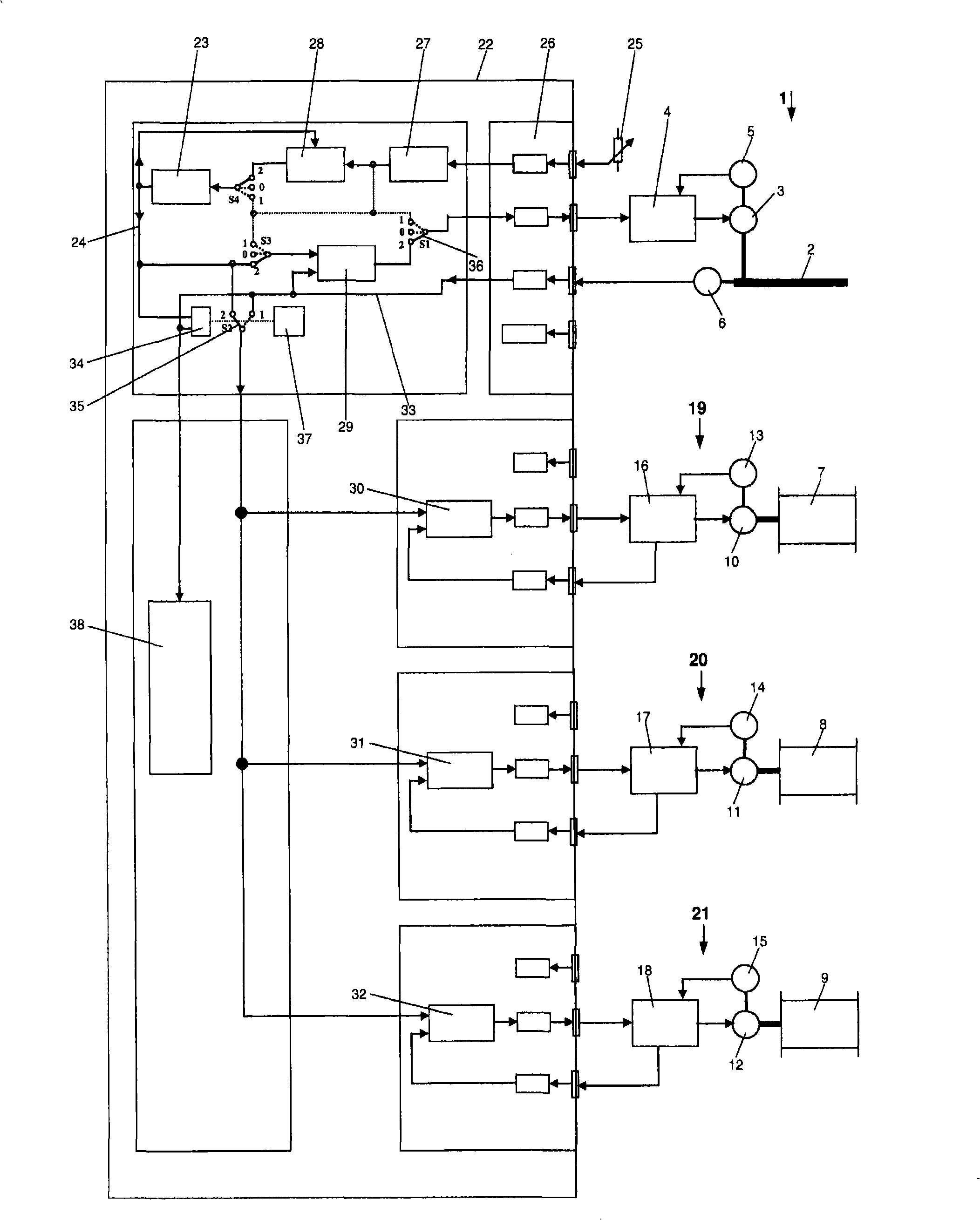

Method for operating a warp knitting machine and warp knitting machine

InactiveCN101339425AHigh mechanical loadIncrease the mechanical loadWarp knittingNumerical controlProduction rateEngineering

The invention provides a warp knitting machine (1) and its operation method. The warp knitting machine comprises a main axle (2) driven by main axle driving device (3), at least a following drive device (19-21) and a controller for controlling following drive device according to capstan. In addition controller (22) comprises a capstan generator (23) for forming virtual capstan. The invention is to provide a high yield warp knitting machine.

Owner:KARL MAYER TEXTILMASCHFAB GMBH

Pump unit driven by an electric motor

ActiveCN104093980AReduce sound transmissionImproved Acoustic DecouplingPositive displacement pump componentsEngine fuctionsInlet channelInlet valve

The invention relates to a pump unit (1) that can be driven by an electric motor, in particular for providing vacuum for a pneumatic brake booster, comprising a pump housing (3) that can be closed by a working-chamber cover (2) and at least one elastic displacement element (4), wherein a working chamber (5) is bounded between the displacement element (4) and the working-chamber cover (2) and wherein inlet valves (6) and outlet valves (7) and inlet channels (8) and outlet channels (9) associated with the valves are associated with the working chamber. According to the invention, in order to reduce noise emissions, means for reducing a contact surface between the working-chamber cover (2) and the pump housing (3) are provided.

Owner:CONTINENTAL AUTOMOTIVE TECH GMBH

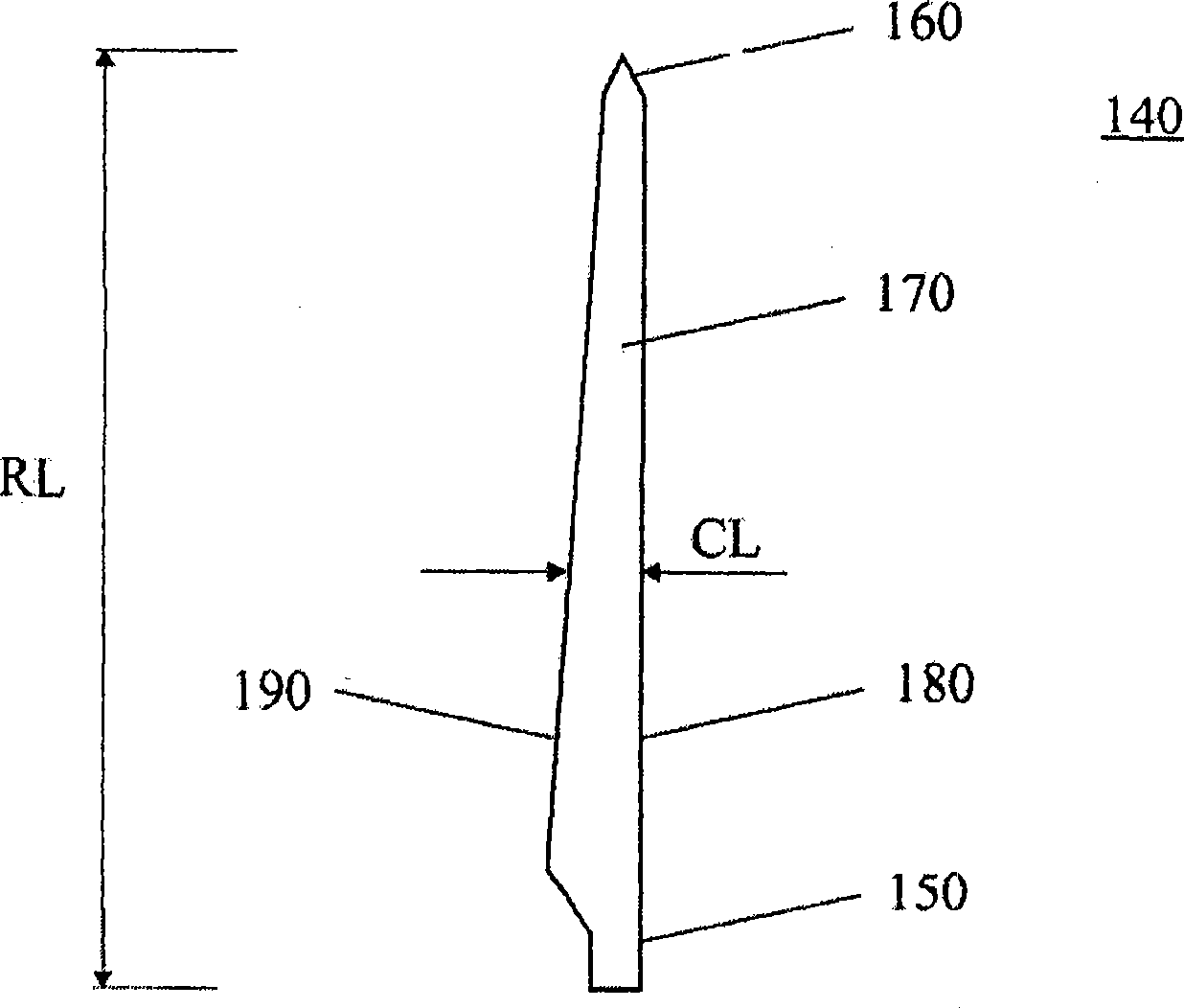

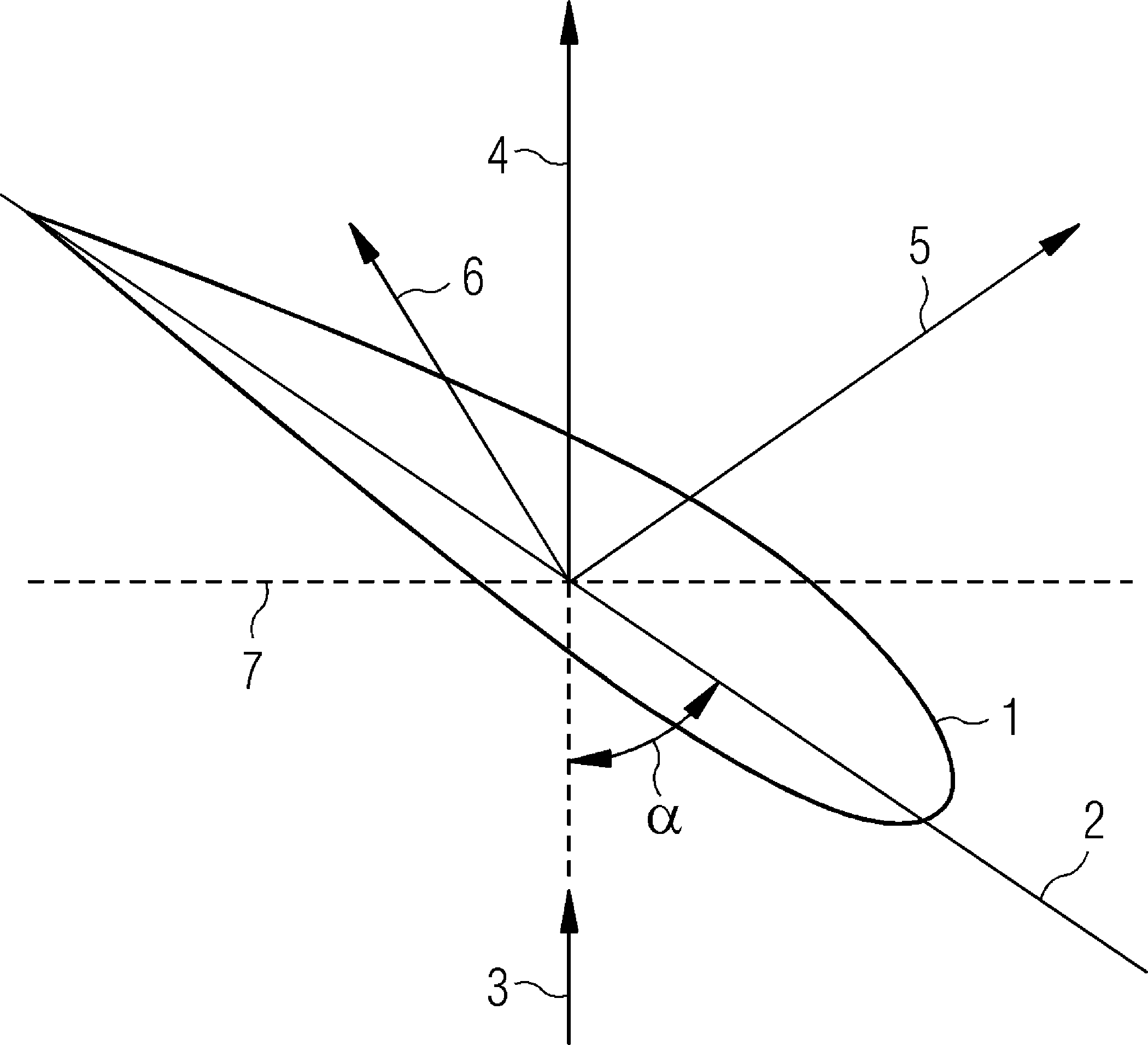

Aeroacoustic rotor blade for a wind turbine, and wind turbine equipped therewith

InactiveCN102102623AMade preciselyGood geometric contour accuracyEngine fuctionsMachines/enginesAcoustic emissionEngineering

A rotor blade and a wind turbine is provided that has such a rotor blade, wherein the absolute length of the rotor blade extends from the blade attachment to the blade tip and the relative blade length proceeds from the blade attachment. The rotor blade is divided into an inner longitudinal section associated with the blade attachment and an outer longitudinal section associated with the blade tip, wherein the transition from the inner longitudinal section to the outer longitudinal section defines the cross-sectional plane E0, and the blade tip defines the cross-sectional plane EE. As a function of the relative blade length, the rotor blade has a specific aerodynamic profile with a chord t, a twist theta, a relative thickness d / t, a relative curvature f / t, and a relative trailing edge thickness h / t. In order to reduce acoustic emissions without having to accept appreciable losses in performance, it is proposed according to the invention that the cross-sectional plane E0 is located at a relative blade length in the range between 0.80 and 0.98, the blade chord of the aerodynamic profile in the cross-sectional plane EE is at least 60% of the blade chord t of the aerodynamic profile in the cross-sectional plane E0, and the blade twist of the aerodynamic profile in the cross-sectional plane EE is greater than the blade twist - of the aerodynamic profile in the cross-sectional plane E0.

Owner:西格弗里德·米克勒 +1

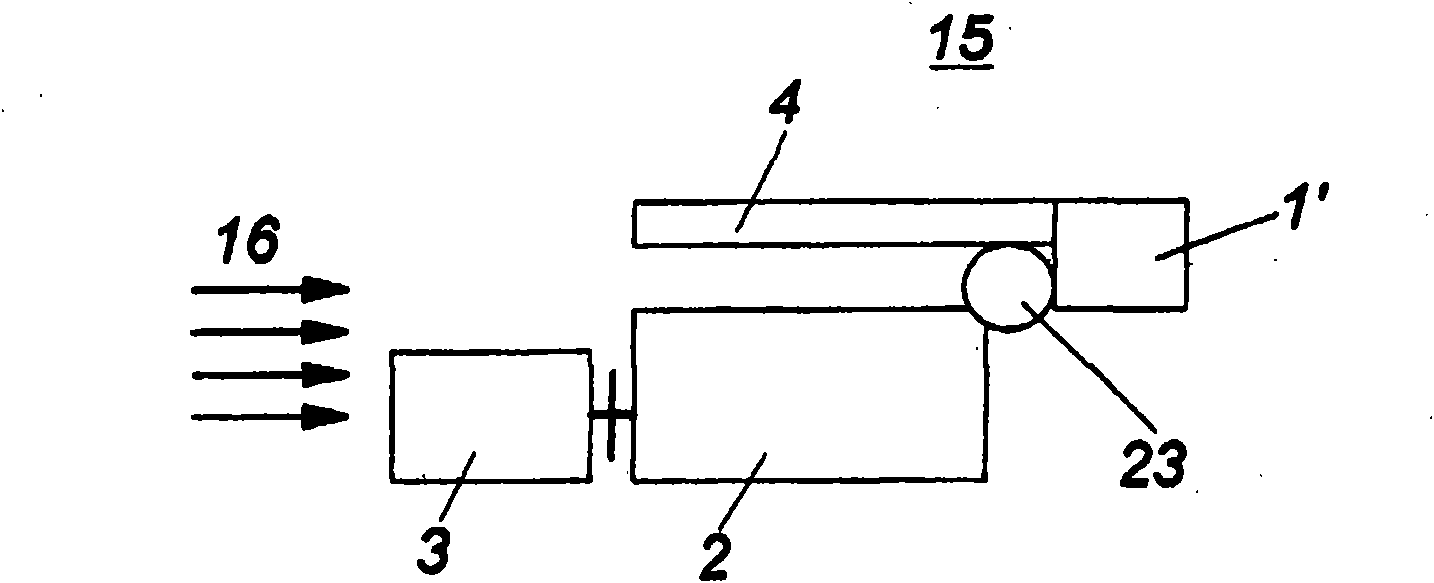

Line routing device for hanging applications, particularly as a service loop for a drill

The invention relates to a line routing device (10) for guiding a plurality of lines, such as cables, hoses, or the like, particularly for hanging applications, such as supplying a vertically traveling power head (3) of a drill (1). The line routing device (10) has a flexible carrying strand (11) and a plurality of guide bodies (14) arranged one behind the other in the longitudinal direction of the carrying strand. According to the invention, adjacent guide bodies (14) can be deflected spatially toward each other and each guide body has a central part (15A) having a center axis (A), which extends coaxially to the carrying strand (11), and an outer part (15B) having at least one circumferential element (17). The outer part (15B) delimits a receiving region (L), which is open in the axial direction, for the lines, radially to the outside.

Owner:IGUS

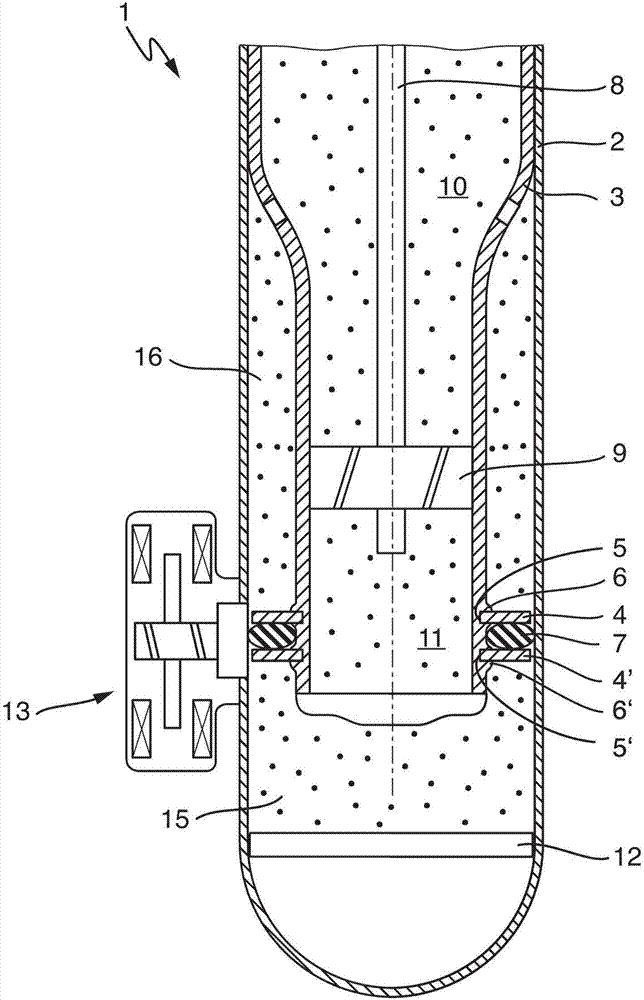

Vibration damper for a motor vehicle and a method for producing a press fit between a damper inner tube and at least one separating plate

ActiveCN107882912AReduce noise emissionsSpringsSprings/dampers design characteristicsMobile vehicleControl theory

The invention relates to a vibration damper for a motor vehicle and a method for producing a press fit between a damper inner tube and at least one separating plate. A vibration damper 1 may comprisea damper outer tube 2, a damper inner tube 2 having a lateral surface of the damper inner tube and arranged coaxially in the damper outer tube, a separating plate 4, 4' arranged coaxially in a regionof the lateral surface of the damper inner tube, and a sealing element 7 arranged coaxially circumferentially on the damper inner tube on the separating plate. In a region of the separating plate arranged coaxially on the lateral surface of the damper inner tube, a groove 5, 5' for the separating plate may be formed on the lateral surface of the damper inner tube. The separating plate may be arranged in the groove, and the connection between the groove and the separating plate may be press fit, at least in the radial direction.

Owner:THYSSENKRUPP BILSTEIN +1

Roots blower pipeline noise reduction device

InactiveCN103244464AReduce noise emissionsSound absorption and noise reduction effect is goodPump componentsPumpsInsulation layerHigh density

The invention discloses a Roots blower pipeline noise reduction device which comprises silencing box and an internal sound absorbing layer wrapped outside a pipeline. The internal sound absorbing layer is disposed in the silencing box. A cavity is formed between the inner wall of the silencing box and the sound absorbing layer. The silencing box, the cavity and the internal sound absorbing layer form a secondary silencing composite structure. The internal sound absorbing layer is three-layered and comprises a galvanized plate, high-density centrifugal glass cotton and low-density centrifugal glass cotton from outside to inside. The silencing box is four-layered and comprises a face protecting layer, a sound insulation layer, a sound absorbing layer and a inner plate form outside to inside. By the secondary silencing composite structure, the problem that inlet-outlet pipeline noise is high and radiation range is wide during operation of a Roots blower is solved, and noise pollution to environments is reduced effectively. The device is suitable for wide popularization in places with severe noise pollution.

Owner:SHANDONG ZHANGQIU BLOWER

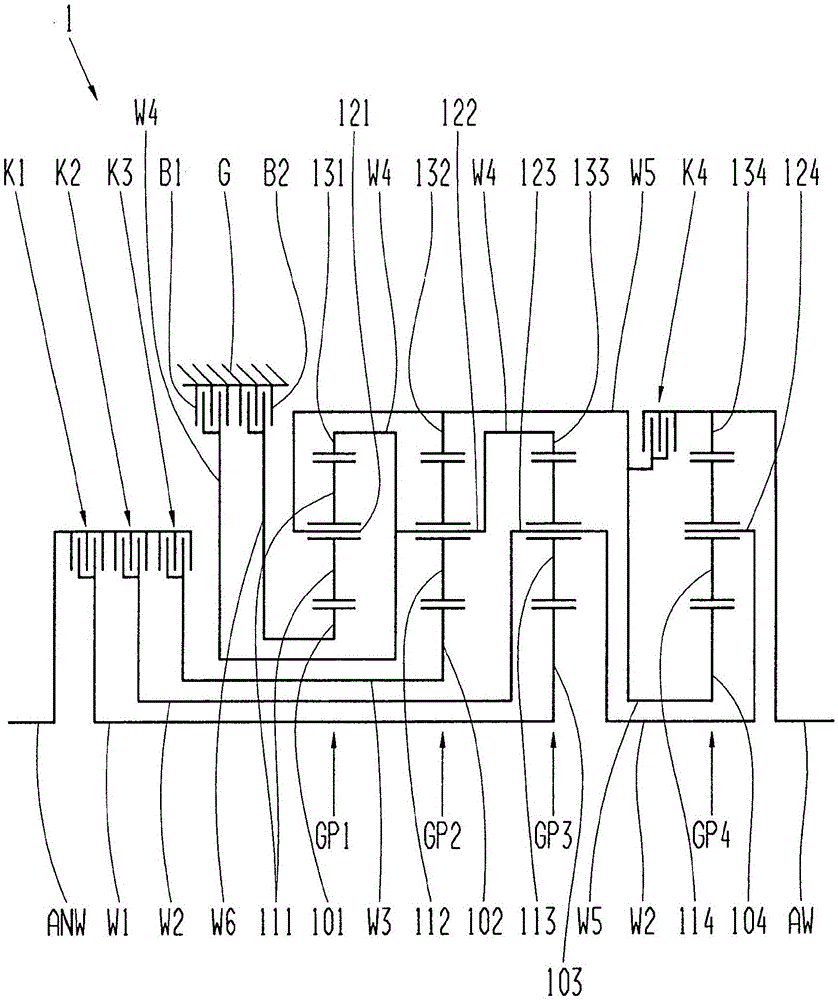

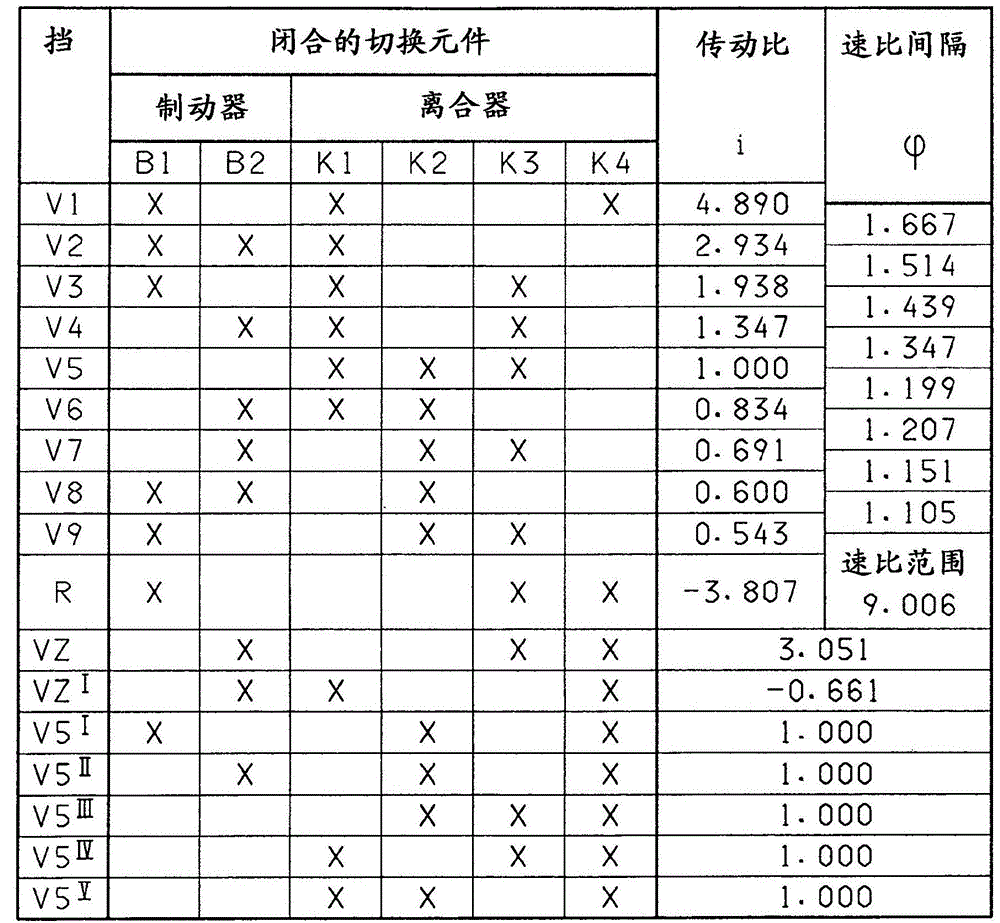

Transmission for motor vehicle

InactiveCN105051417AImprove accessibilityLow costToothed gearingsTransmission elementsDrive shaftEngineering

Transmission, in particular multi-step transmission, for a motor vehicle, comprising a housing, a drive shaft, an output shaft, at least four planetary gear sets, wherein the planetary gear sets in each case comprise a sun gear, a planet, a planetary carrier and an internal gear, and a plurality of shifting elements in the form of at least four clutches and at least two brakes, wherein the drive shaft can be connected via the second clutch to the planetary carrier of the third planetary gear set and the planetary carrier of the fourth planetary gear set, wherein the first brake is connected to the internal gear of the first planetary gear set and to the planetary carrier of the second planetary gear set, wherein the second brake is connected to the sun gear of the first planetary gear set, and wherein the planetary carrier of the first planetary gear set is connected to the sun gear of the fourth planetary gear set.

Owner:ZF FRIEDRICHSHAFEN AG

Transmission punching mechanism of vehicle interior and exterior trimming product die

InactiveCN104890044ALower replacement costsSimple structureMetal working apparatusPunchingEngineering

The invention relates to a transmission punching mechanism of a vehicle interior and exterior trimming product die. The upper end of a trolley is provided with a lower fixing table-board. The lower fixing table-board is fixedly provided with guideposts and interior trim part supporting plate. The upper ends of the guideposts are provided with an upper fixing table-board. The upper fixing table-board is fixedly provided with a motor through a motor fixed base. The output shaft of the motor is fixedly provided with a transmission lead screw. A puncher pin fixing plate is arranged between the upper fixing table-board and the lower fixing table-board. The puncher pin fixing plate is provided with a guide sleeve. The puncher pin fixing plate is provided with an inner threaded hole. The guide sleeve is cooperated with the guidepost. The inner threaded hole and the transmission lead screw are cooperated. The lower surface of the puncher pin fixing plate is fixedly provided with a holddown spring and a puncher pin. The puncher pin is in the holddown spring. The transmission punching mechanism is simple, compact, and reasonable in structure. The transmission punching mechanism can ensure to complete hole site punching, reduce noise emission, reduce equipment investment, reduce maintenance and component changing cost.

Owner:WUXI GISSING AUTO ACOUSTIC PARTS TECH CO LTD

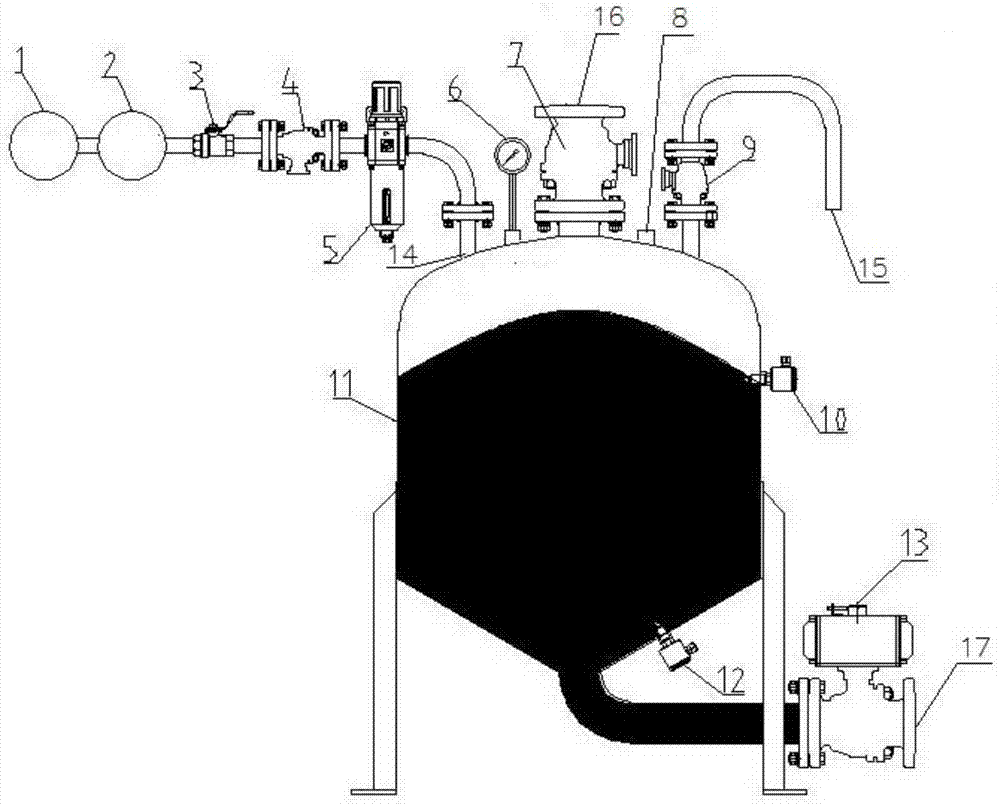

Particle conveying mechanism

The invention relates to the solid-phase material conveying technology, in particular to a particle conveying mechanism. The particle conveying mechanism comprises a storage tank. An air source assembly, a pressure gage, a feed valve, a pressure switch and an exhaust valve are arranged above the storage tank. The air source assembly comprises an air compressor, an air storage tank, a hand valve, an inlet valve and a pressure regulating valve, all of which are connected in sequence. One end of the pressure regulating valve is connected with the storage tank. A first material level induction switch is arranged on the side face of the storage tank. A second material level induction switch and a discharge valve are arranged at the bottom of the storage tank. The particle conveying mechanism is larger in conveying height, the requirement for a special plant structure can be better met, meanwhile, noise discharge is reduced, the impact generated on products is small, and conveying of diverse products can be better achieved; and material conveying can be finished within short time, the conveying amount is large, manual operation is not needed in the whole conveying process, and automation can be completely achieved.

Owner:南京法宁格节能科技股份有限公司

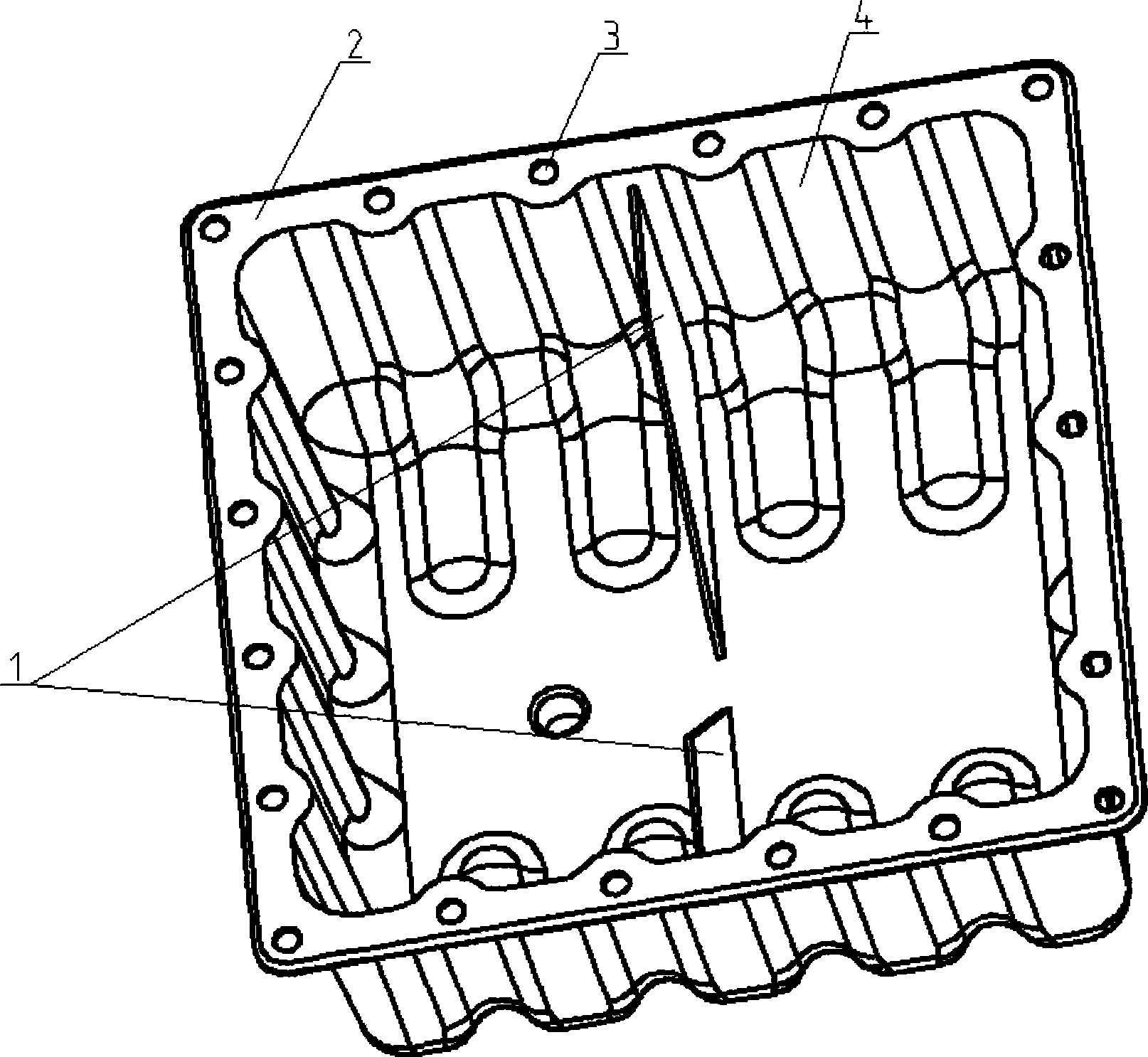

Oil sump for horizontal diesel engine

InactiveCN101363342AHigh strengthIncrease stiffnessMachines/enginesEngine lubricationOil separationCylinder block

The invention relates to an oil sump of a horizontal diesel engine, belonging to the parts of the diesel engine. The oil sump is essentially used for solving the technical problems of cylinder body sealing and engine oil loading in the horizontal diesel engine. The technical proposal is as follows: the invention is composed of the oil sump and a mounting surface of the oil sump, the cavity of the oil sump is internally provided with a plurality of oil separation plats of the oil sump to separate the cavity of the oil sump into a plurality of sub-cavities, the sub-cavities are communicated with each other, and the oil sump is provided with an oil drain bolt seat and an arc concave reinforcing rib. The oil sump can be applied to horizontal single-cylinder or double-cylinder diesel engines.

Owner:KUNMING UNIV OF SCI & TECH +1

An electric transformer with improved cooling system

InactiveCN102349122ASmall radial componentReduce lossTransformers/inductances coils/windings/connectionsTransformers/inductances magnetic coresTransformerEngineering

An electric transformer comprising: a magnetic core; at least one coil assembly which is positioned around a portion of the magnetic core and comprises a plurality of windings; a structure adapted for applying a clamping force on the magnetic core and / or the windings; and a cooling circuit adapted for conveying cooling fluid directly inside the coil assembly.

Owner:SIEMENS AG OESTERR

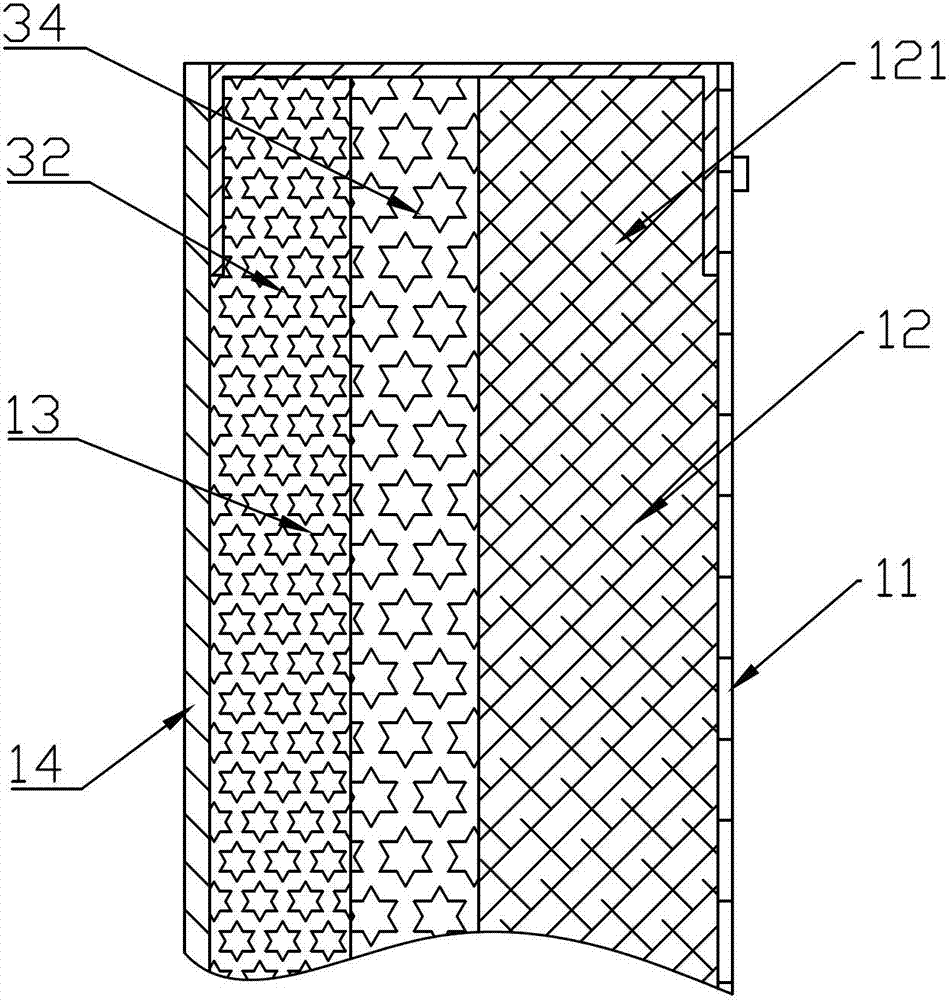

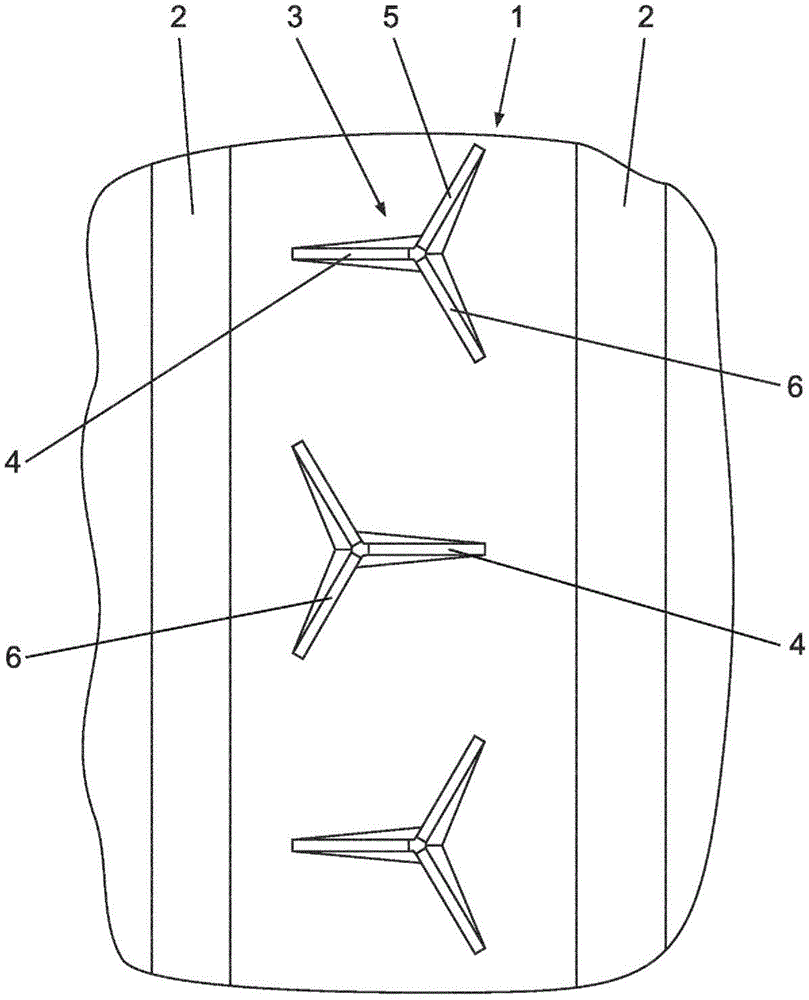

Vehicle pneumatic tyre

ActiveCN104619523AReduce noise emissionsAvoid Simultaneous ShocksTyre tread bands/patternsEngineeringTread

Pneumatic vehicle tyre with a tread which are divided by circumferential grooves (2) and by tread lugs extending in the circumferential direction, at least one profile strip (1, 1', 1 ") being part of said profiles. In the profile strip (1, 1', 1 "), respectively three grooves (4, 5, 6, 4', 4 ", 5 ", 6 ") having a width of 0.8 mm to 1.5 mm form a groove group (3, 3', 3 "). Said grooves (4, 5, 6, 4', 4 ", 5 ", 6 ") form stars, starting from a recessed central region (7), and at least two grooves (5, 6, 5 ", 6 ") of the groove group (3, 3', 3 ") end within the profile strip (1, 1', 1") and a groove (4, 4', 4 ") extends axially or essentially in the axial direction of the running strip.

Owner:CONTINENTAL REIFEN DEUTSCHLAND GMBH

Hybrid drive for water vehicle

InactiveCN104284834ASimple structureReduce noise emissionsHybrid vehiclesPropulsion based emission reductionDrive shaftWatercraft

A hybrid drive for a watercraft, including a primary drive motor, which is situated inside the watercraft and drives a drive shaft, and an above-water transmission, which is situated after the drive shaft and has a transmission housing, for driving a vertical shaft branching off from the above-water transmission, as well as an electric secondary drive motor, which has a stator and a rotor and is able to drive the vertical shaft in addition to or alternatively to the primary drive motor. The secondary drive motor can be embodied with a hollow shaft and the stator of this motor can be coupled in a torsionally rigid fashion to the transmission housing of the above-water transmission.

Owner:SCHOTTEL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com