Construction method for forming grooves and holes and replacing large-diameter piles with small-diameter piles

A technology for groove-forming construction and construction methods, applied in excavation, sheet pile walls, foundation structure engineering, etc., can solve problems such as high efficiency and low construction difficulty, reduce noise emissions, avoid economic losses, and efficiently form grooves and holes Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

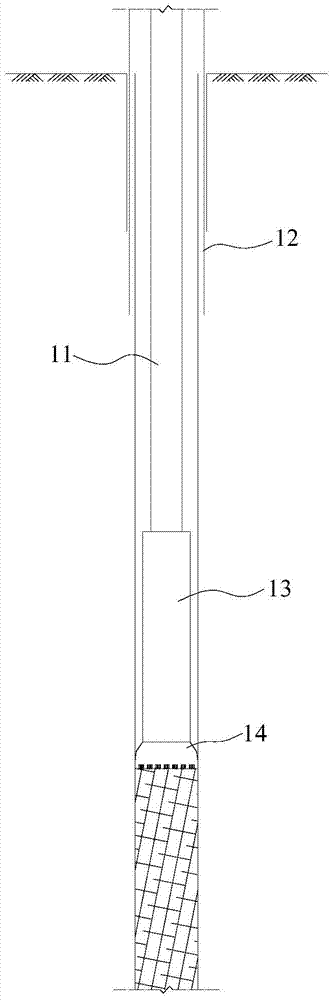

[0039] refer to Figure 1 to Figure 7 , The down-the-hole hammer is a pneumatic impact tool driven by compressed air. The part of the down-the-hole hammer that enters the formation includes a drill pipe 11 , a casing 12 , a hammer body 13 and a hammer head 14 . The air with a certain pressure provided by the air compressor drives the piston in the cylinder of the down-the-hole hammer to move repeatedly in the axial direction, so that the hammer head 14 at the end of the down-the-hole hammer rotates and produces impact effect. The impact energy and impact frequency can be directly transmitted to the hammer head 14, and then driven by the rotation of the drill pipe 11 to form a pulsating crushing ability for the rock, thereby crushing and destroying the rock and soil to achieve the effect of entering the rock and forming a hole. At the same time, the compressed air discharged by the down-the-hole hammer is used to discharge the broken rock particles out of the body, thereby real...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com