Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

43results about How to "Construction noise is small" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

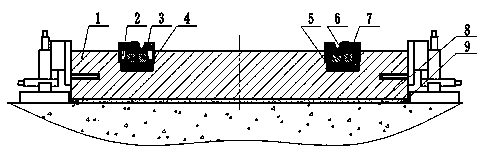

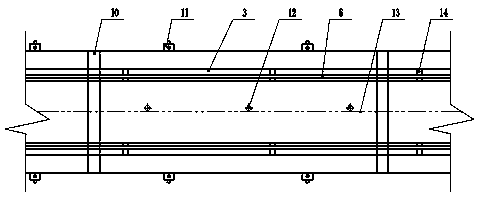

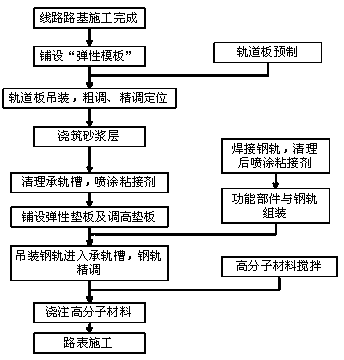

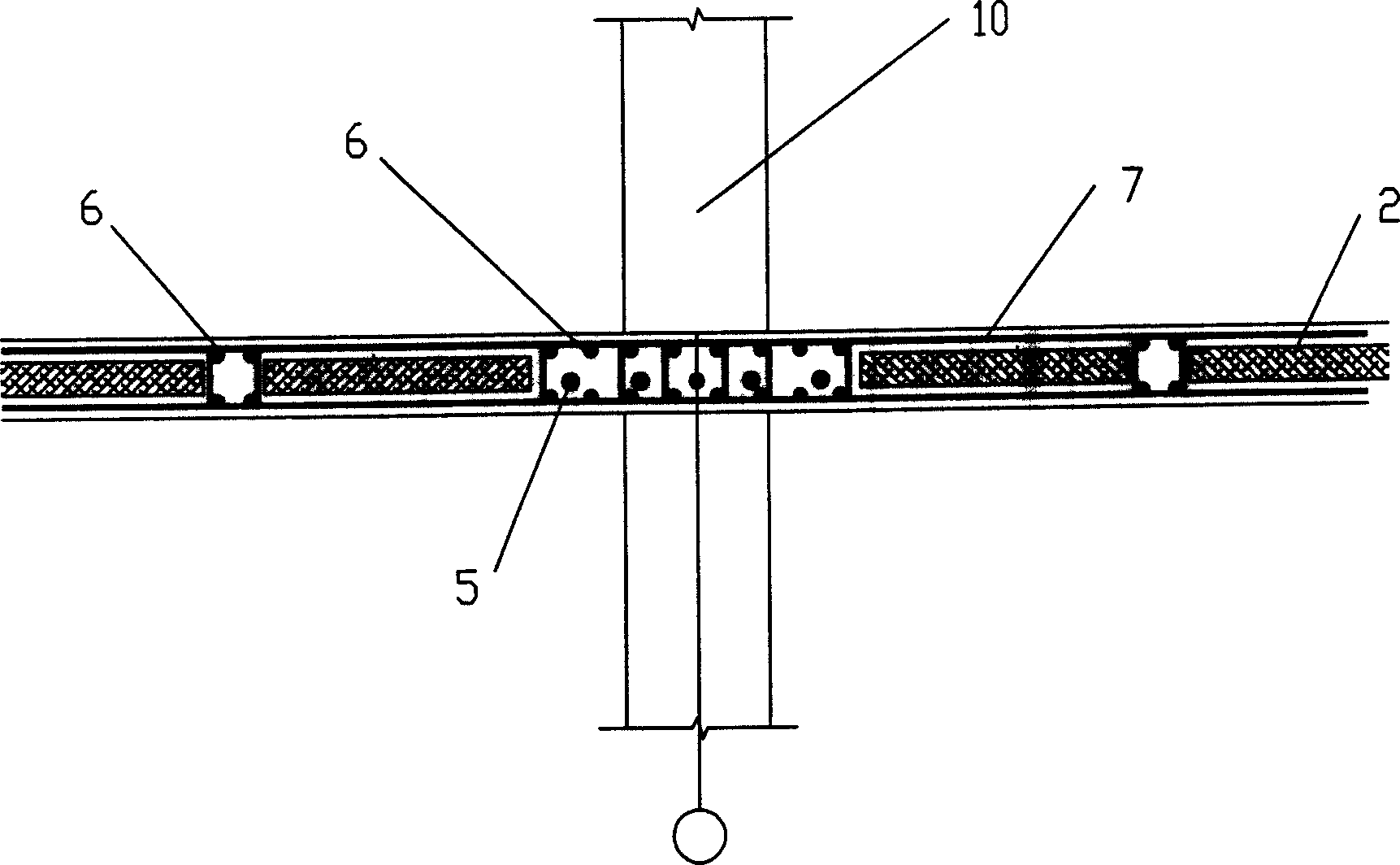

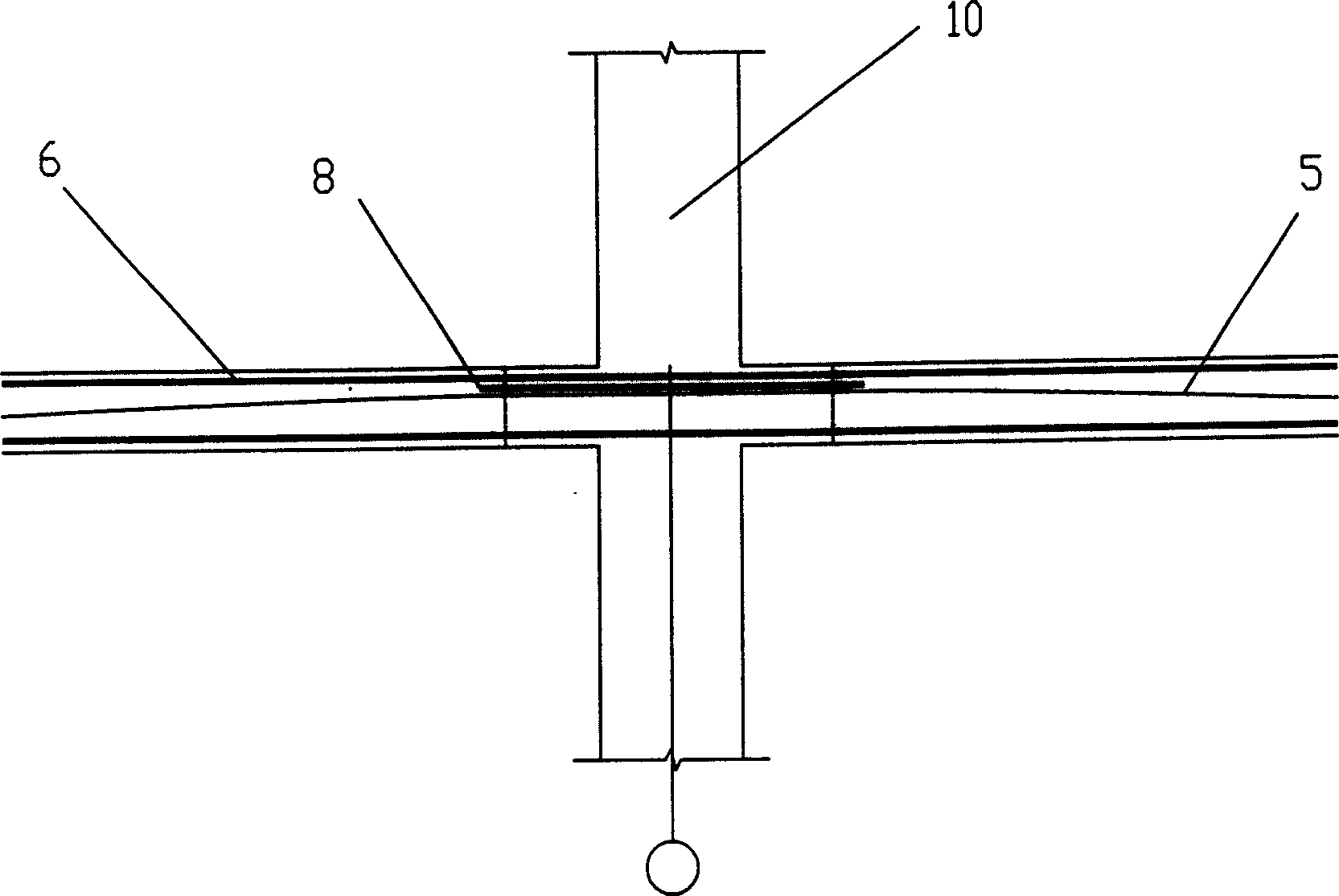

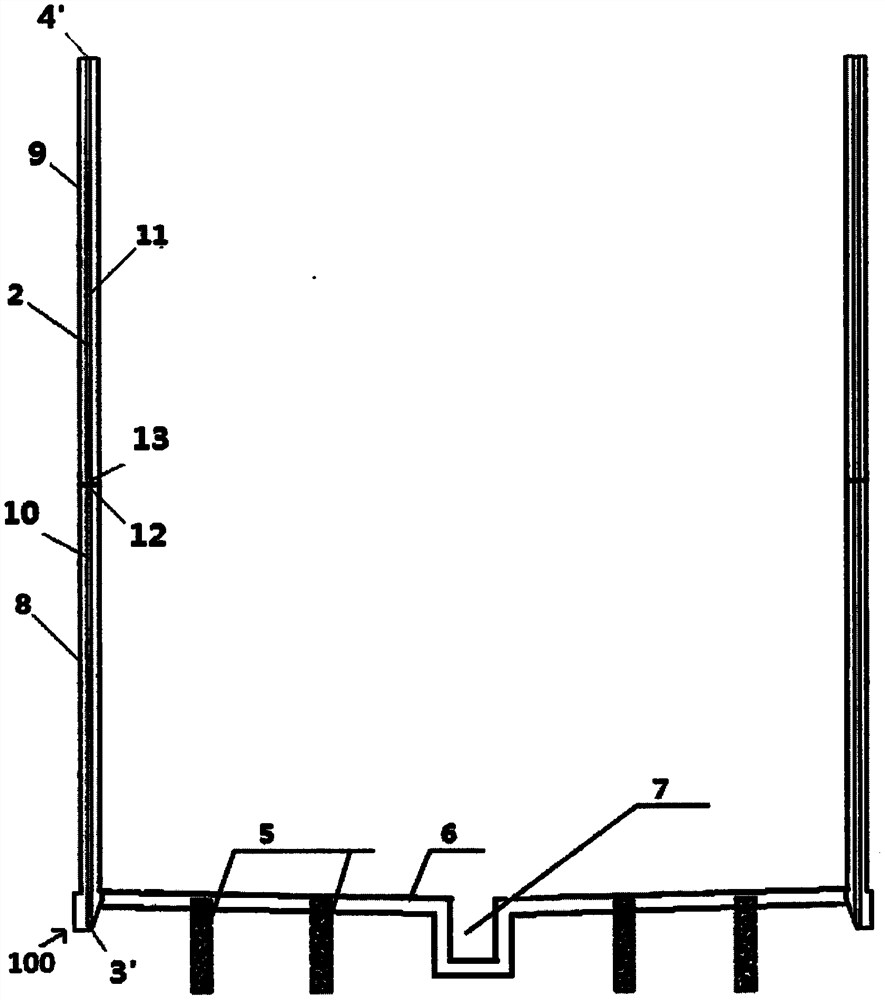

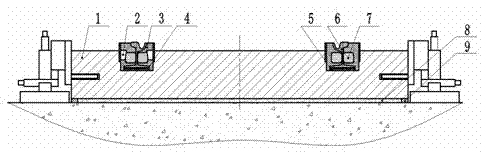

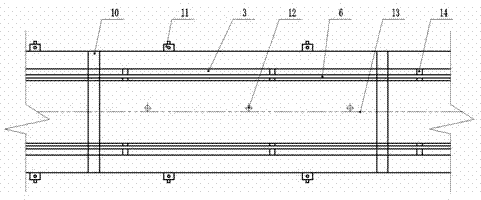

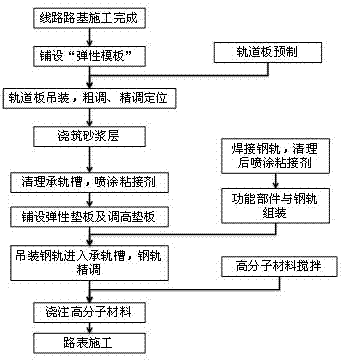

Quick construction method of embedded rail system

ActiveCN103362036ANovel construction methodReasonable construction methodRailway tracksHardnessPlastic film

The invention discloses a quick construction method of an embedded rail system. The quick construction method comprises the following construction steps: performing construction preparation; paving a template; paving rail plates; casting a mortar layer; performing rail bearing groove pretreatment; welding a steel rail; adjusting the steel rail finely; performing antipollution protection and partitioning the rail bearing groove; casting the rail bearing groove; uniformly stirring high polymer material; casting material to the partitioned rail bearing groove with special equipment; clearing plastic films or adhesive tapes after the high polymer material achieves required hardness; and paving on the surfaces of the top surfaces of the rail plates according to construction requirements. Through being combined with prefabricated rail plates, the quick construction method has the characteristics of being quick in construction, high in efficiency and little in influence on surrounding environment, and is a green and environment-friendly construction method.

Owner:CHENGDU XINZHU ROAD & BRIDGE MASCH CO LTD

Construction method for assembling light energy-saving composite wallboards on separation wall

InactiveCN102777045ALight in massQuality improvementWallsBuilding material handlingLight energyChisel

The invention discloses a construction method for assembling light energy-saving composite wallboards on a separation wall, wherein the light energy-saving composite wallboards have the advantages of high strength, stable seismic performance and reliable quality. The construction method comprises the following steps: firstly laying side lines of the wall body of the separation wall and fixing the positions of openings of doors and windows; drilling holes in a main structure at a mounting face of the separation wall and implanting reinforcing steel bars; drilling holes in side vertical faces of the composite wallboards; after sizing, erecting the composite wallboards in a way of being aligned to mounting lines on the floor, splicing the composite wallboards orderly according to a splicing sequence, driving wooden wedges into the lower part of battens, wherein the wooden wedges are used for adjusting position so that the battens are arranged in place; fixing the composite wallboards firmly and then driving each composite wallboard into a building surface slantwise at the angle of 45 degrees by using a steel chisel, so as to achieving an anchoring effect; applying mortar for flattening; and finally carrying out maintenance.

Owner:LONGXIN CONSTR GRP

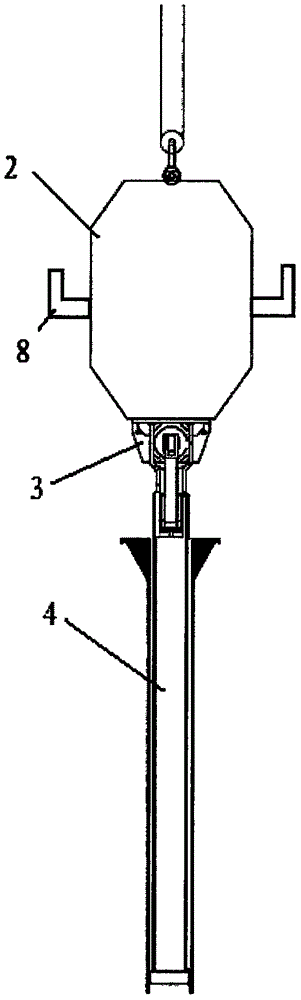

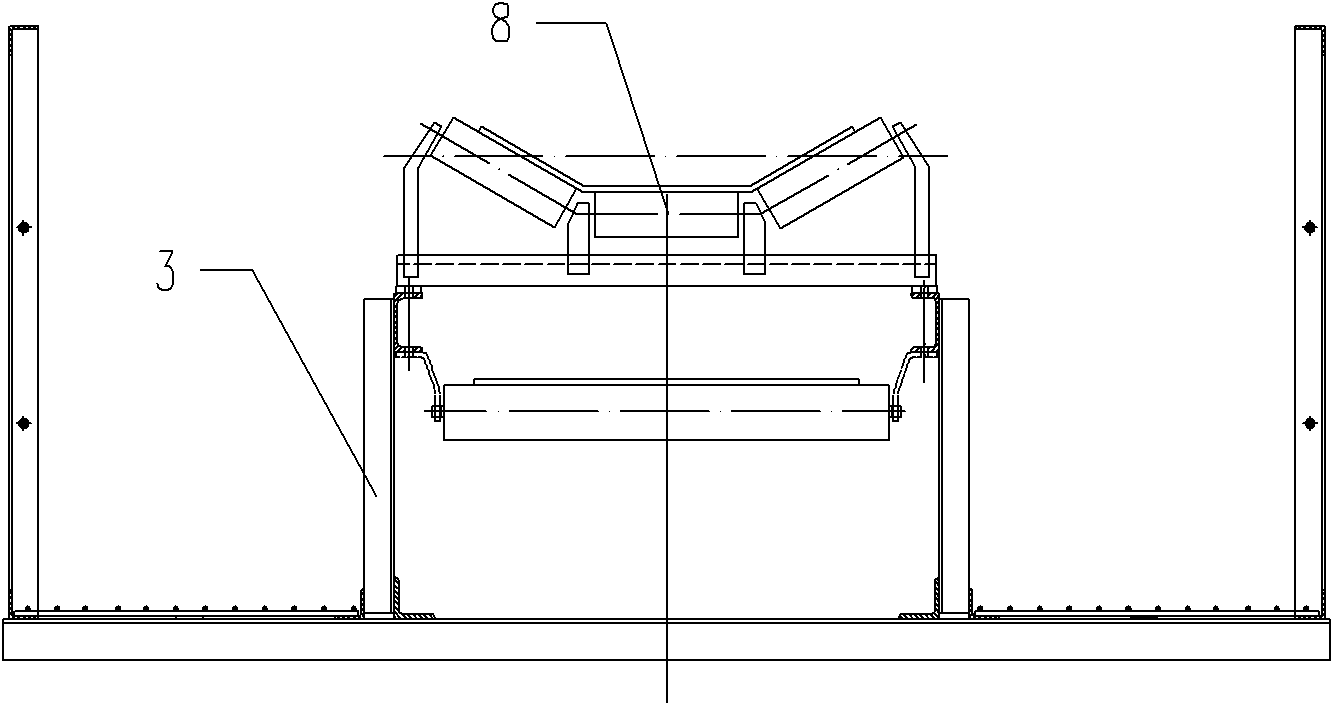

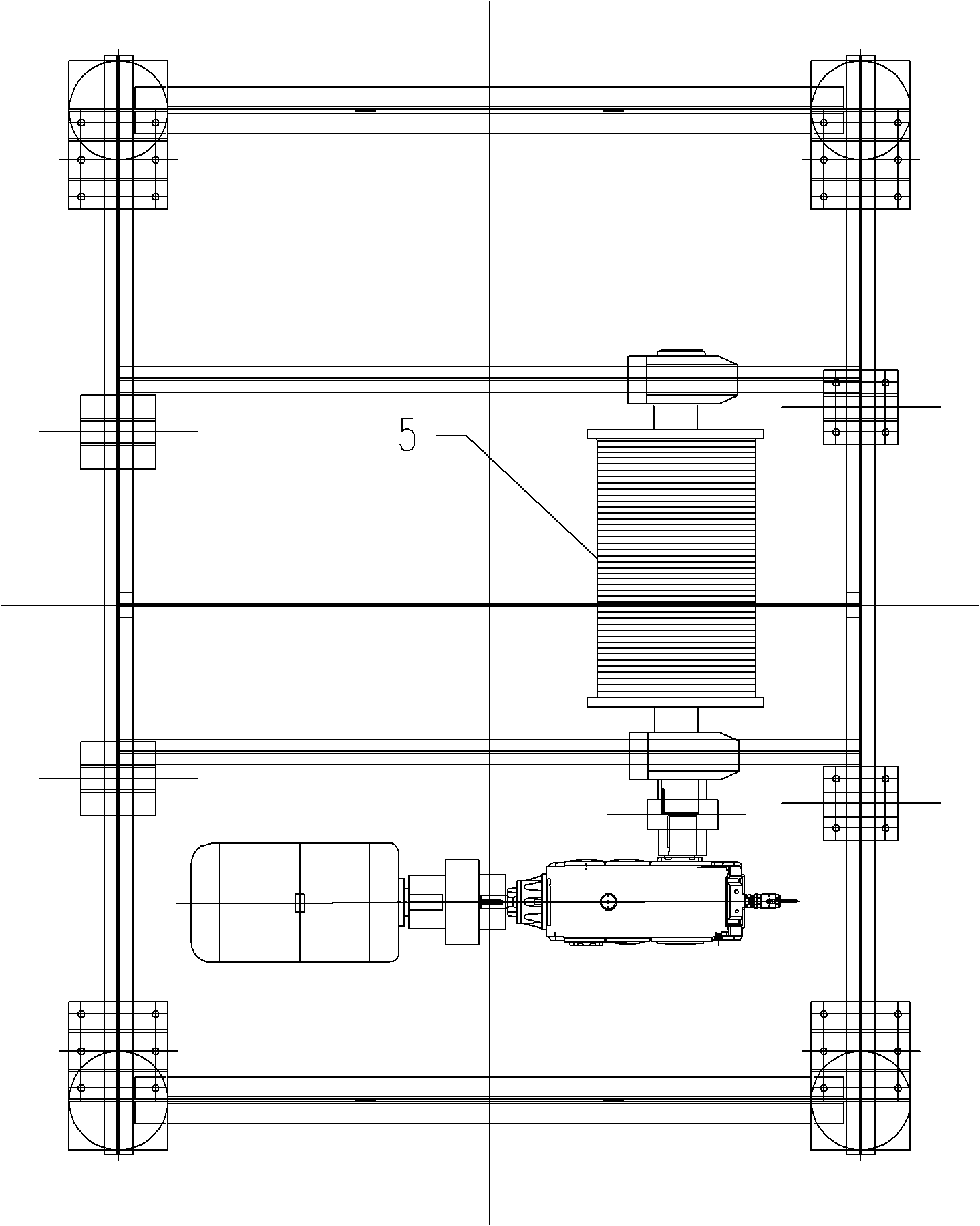

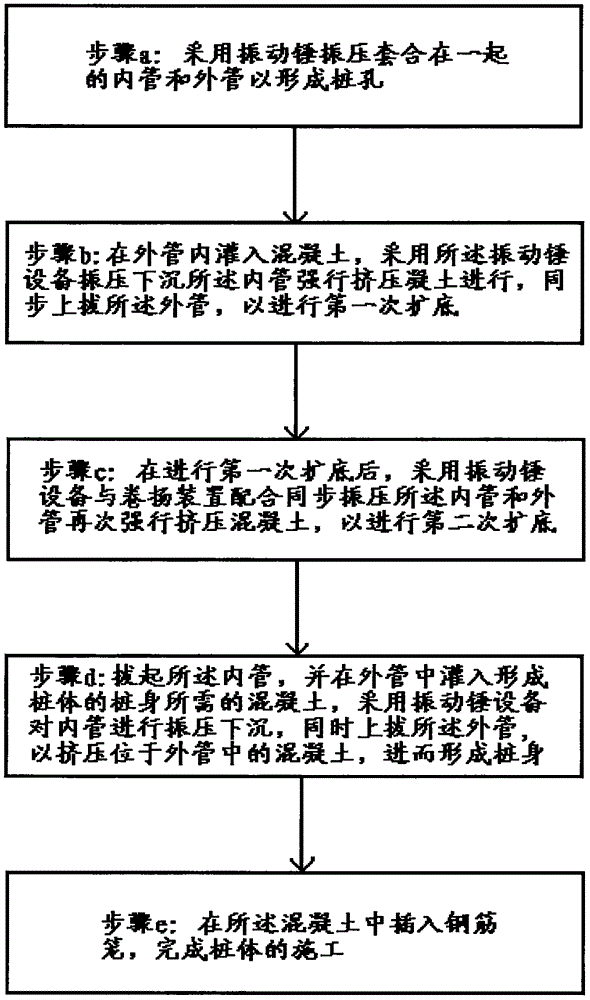

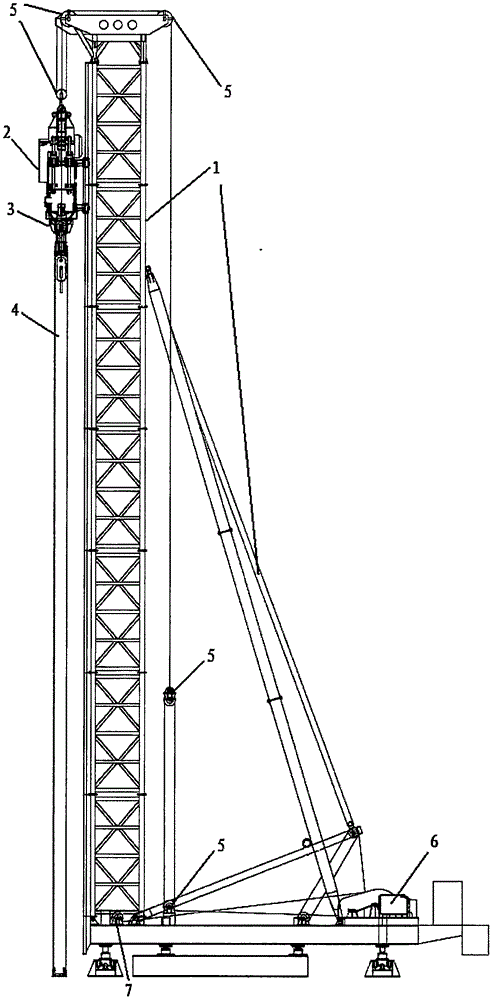

Vibratory hammer device and shaking press type pile body construction method adopting same

InactiveCN106168027AVibration pressure increasedFlexible adjustment of self-weightBulkheads/pilesArchitectural engineeringPulley

The invention discloses a vibratory hammer device. The device comprises a support, a vibratory hammer, a second pulley component, a winding plant and a balancing weight, wherein a first pulley component is installed on the support, the first end of the vibratory hammer is connected with the first pulley component, and the second end of the vibratory hammer is provided with a fixing structure used for fixing an inner pipe and an outer pipe; the second pulley component is installed on the support, the winding plant is installed on the support and connected with the vibratory hammer through the second pulley component and can apply a vertically downward force to the vibratory hammer, and the balancing weight is detachably connected to the vibratory hammer. In this way, construction noise is low, construction efficiency is high, and the dead weight of a hammer body can be adjusted flexibly to meet the requirement for pile forming. The invention further discloses a shaking press type pile body construction method adopting the vibratory hammer device.

Owner:刘献刚

Construction method for forming grooves and holes and replacing large-diameter piles with small-diameter piles

ActiveCN104264689AQuick breakHole forming efficiencyExcavationsBulkheads/pilesSlurry wallSurface layer

The invention discloses a construction method for forming grooves and holes and replacing large-diameter piles with small-diameter piles. The method mainly includes the steps of forming the grooves in an underground continuous wall with the aid of a DTH hammer, forming the holes in the large-diameter piles with the aid of the DTH hammer and replacing the large-diameter piles with the small-diameter piles equivalently through the DTH hammer. Compared with a conventional groove and hole forming method, the construction method has the advantages that the defects that rock entering efficiency is low, holes are deviated, the hammer is stuck and even holes are difficult to form in the construction process under the comprehensive complicated geological conditions such as high-rock surface layers, hard stratums and slope stratums can be effectively overcome, the rock entering construction efficiency during grooving of the underground continuous wall and hole forming of the large-diameter piles can be greatly improved, the technical problems of the rock entering groove and hole forming construction under the complicated geological conditions such as high rock surface layers and hard stratums are solved, the construction quality is stable and reliable, the requirements for safety civilization and environmental construction are met, and economic loss and construction time loss of a project can be effectively avoided.

Owner:GUANGDONG FOUND ENG GRP CO LTD

Industrialization energy-saving building house

ActiveCN101353929AAchieve aestheticsReduce consumptionFloorsDwelling buildingArchitectural engineeringShock resistance

The invention discloses an industrialized energy-saving building which comprises a load-carrying frame, an enclosing exterior wall, a floor cover slab and a roof cover plate; the enclosing exterior wall is formed by the assembly of entirely prefabricated composite exterior wall boards and fixed on the load-carrying frame of a main body by a shock-resistance and energy-dissipation connecting part. The building is an industrialized energy-saving building which lessens construction energy consumption, water consumption and work area, saves construction material, reduces construction noise and the influence of dust on the environment and the ecology, shortens the construction period, has function of shock resistance and energy dissipation and is capable of saving energy, material, water, land and protecting environment.

Owner:黄涛 +1

Boring-tamping lime-soil compacting pile construction process

InactiveCN1676762AConstruction noise is smallReduce vibrationBulkheads/pilesSoil preservationUltimate tensile strengthPile driver

The invention refers to a construction technique, which has a good effect for the drilling ram enlarge the gray soil and the stake. The concrete process is that perching the drill, vertical revising, drilling, milling the material, perching the pile driver, empty ram, filling in material, covering the top and moving the pile driver. The technique has the merits that it having small noisy, light vibration, can avoid the damp sinking efficiently, has a strong stake, the base can bear more weight, has the low cost of the project, project can be constructed in the city and has a broader application among the damp and sink loess areas.

Owner:祁春伟

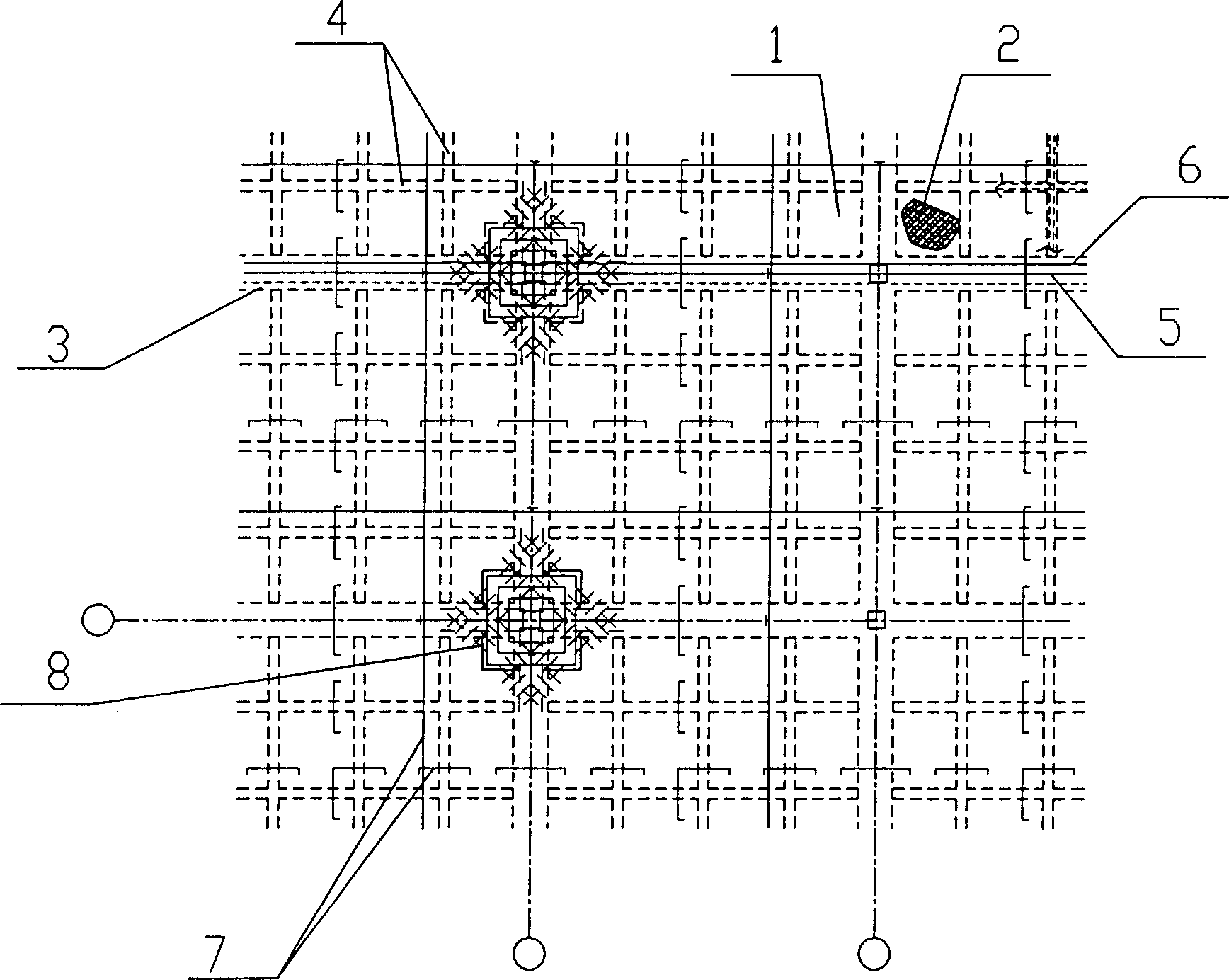

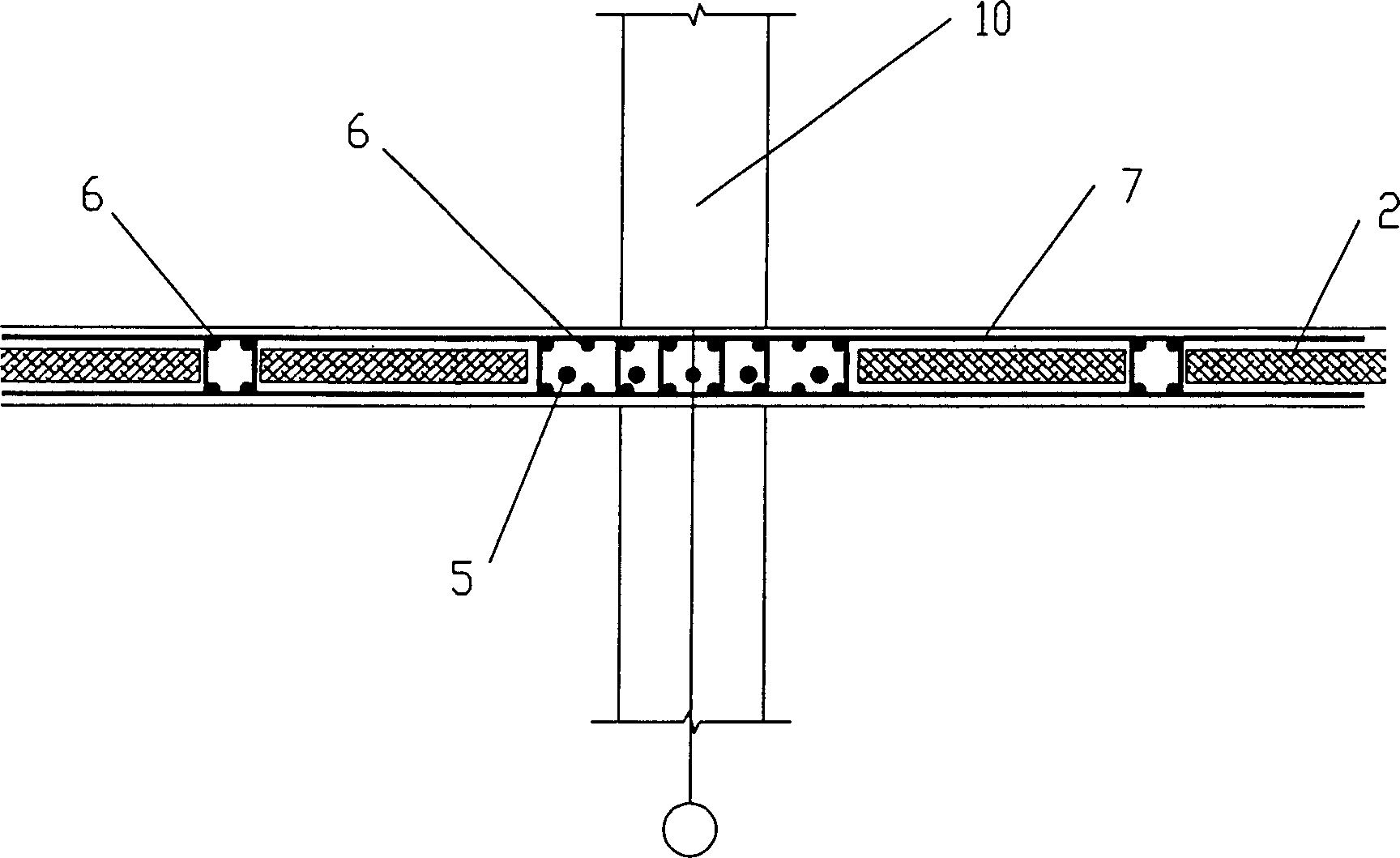

In-site prestressed concrete sandwiched composite beamless floor structure system and construction method

This invention discloses a kind of sandwich and compound beamless slab construction of watering prestress concrete and its constructing method. This construction includes beamless slab body, ribs of inner main and dark slabs and ribs of inner secondary dark slabs with cross arranged. The prestess and stress concrete reinforced bars are arranged in the ribs of main and dark slabs, and the stress concrete reinforced bars are laid out in the upper and lower crust of beamless slab body and in the inner secondary dark slabs with cross arranged. The inner space of the body is stuffed with polystyrene foam sandwich boards. In the job site, first, the form board is propped up and the prestress bars are arranged and stretched and drawn; second, the polystyrene foam sandwich boards should be laid out and fastened and the stress bars are arranged; then the concrete is poured and shaped into the construction, which can satisfy the constructing load-bearing requirements like fireproofing, sound insulation, heat insulation, high-intensity and light quality. Such beamless slab can be used in civilian and various industries construction.

Owner:胡战波

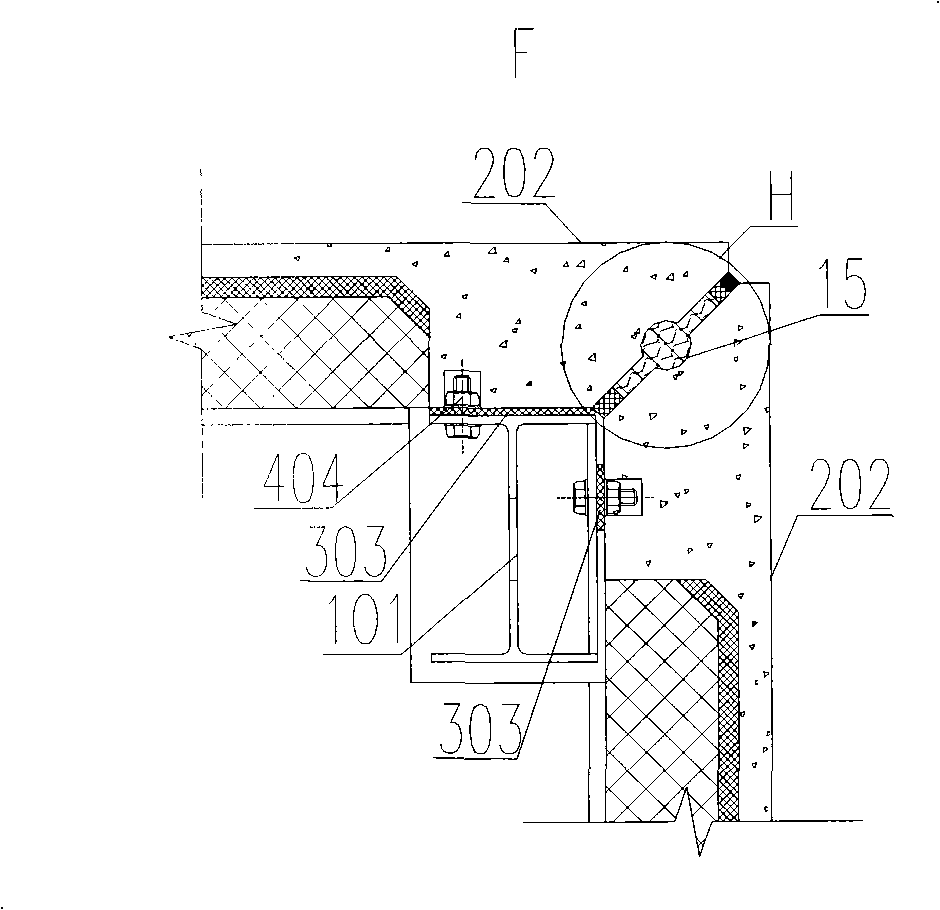

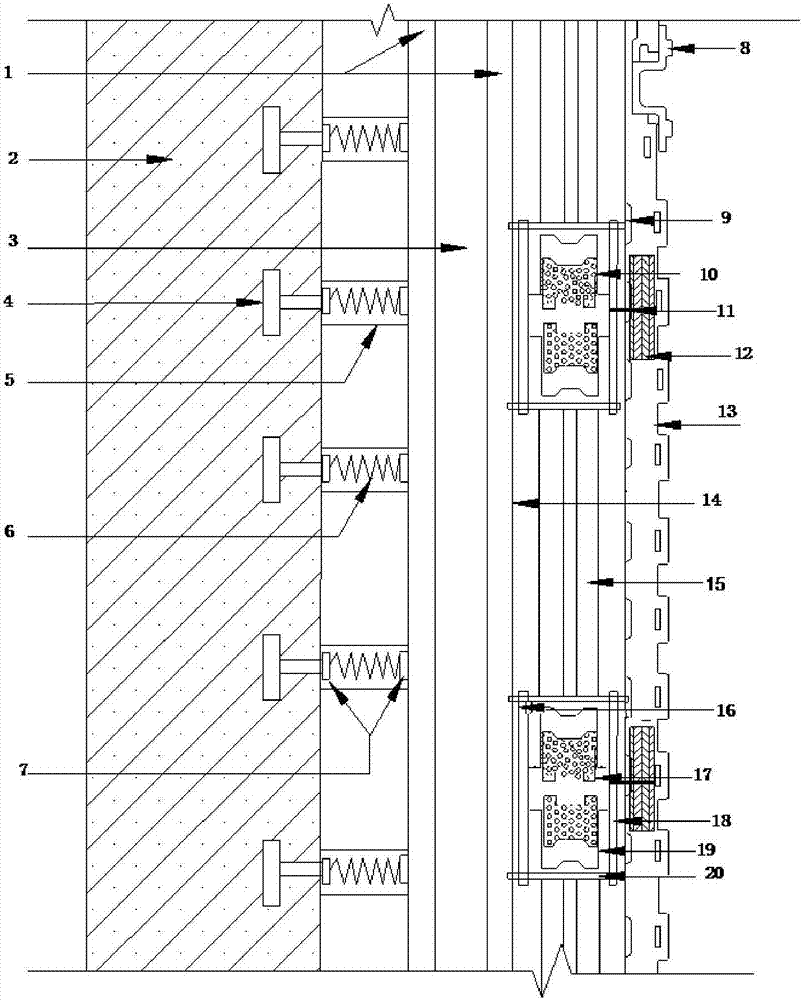

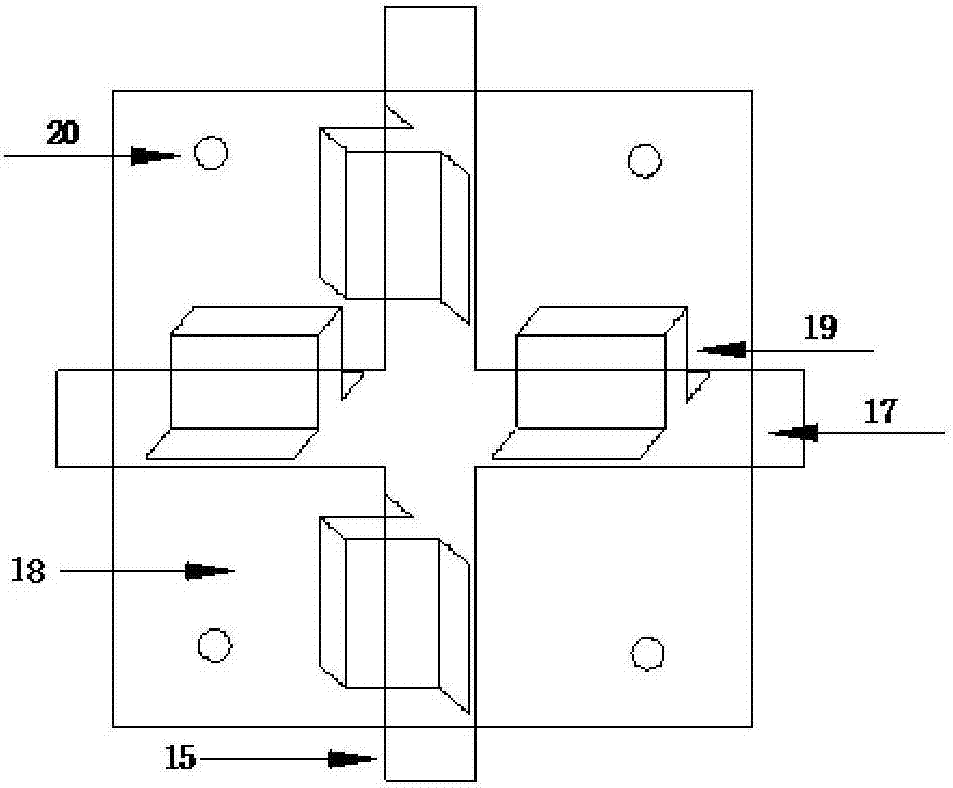

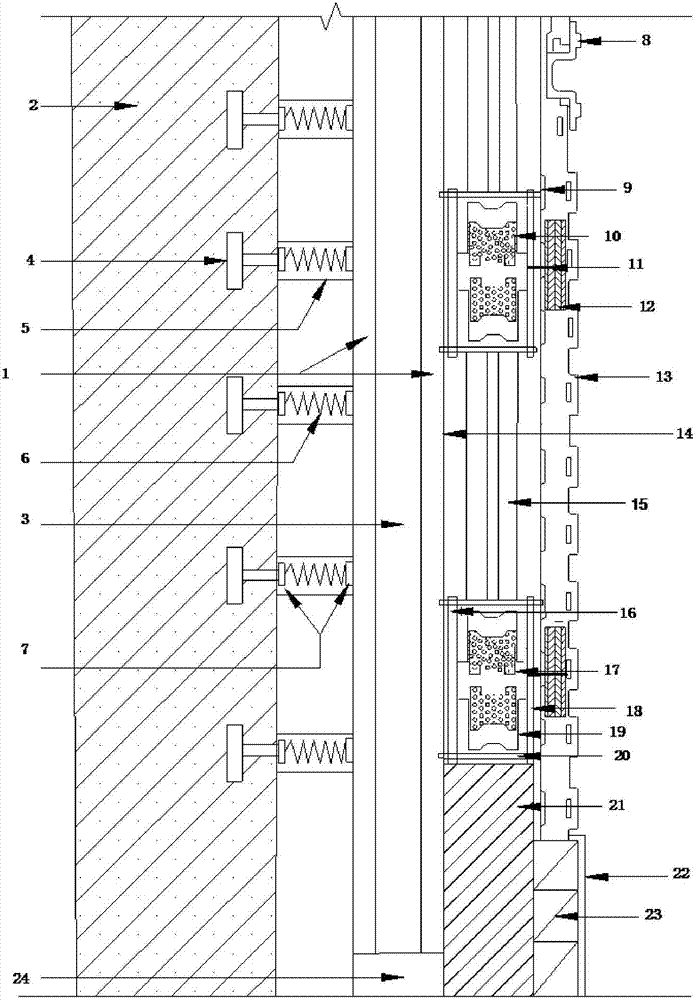

Cavity-type common vibration sound absorption board wall structure and construction method

ActiveCN107143053ABlock deliveryImprove sound insulationWallsSound proofingEngineeringNonwoven fabric

The invention discloses a cavity-type common vibration sound absorption board wall structure and construction method. The structure comprises a wall body, an I-beam layer, a steel wire net and a light steel dragon skeleton from inside to outside, wherein a plurality of spring isolators are arranged between the wall body and the I-beam layer, the wall body is provided with a plurality of embedded parts, and both ends of each spring isolator are fixedly connected with the embedded parts and the I-beam layer respectively; the I-beam layer comprises a plurality of vertical I-beams arranged along the surface of the wall body in order, and the I-beam layer is fixedly connected with the light steel dragon skeleton through a fixing device; a shock absorbing rubber pad is arranged between the bottom of the I-beam layer and the ground, and a cement sound insulation board is arranged between the light steel dragon skeleton and the ground; the lattice of the light steel dragon skeleton is stuffed with environment-friendly and waterproof sound absorbing cotton, and the sound absorbing cotton is wrapped with sound absorbing nonwoven fabrics; a sound absorbing board is fixed on the outer side of the sound absorbing non-woven fabrics, and a fireproof board is arranged on the light steel dragon skeleton. The cavity-type common vibration sound absorption board wall structure has the advantages of a good sound insulation effect, a wide sound absorption range, small environmental pollution, convenient construction, a high utilization ratio of unit material, high overall cost performance, and energy saving and environmental protection.

Owner:华神建设集团有限公司

Track deformation adjusting device and magnetic levitation railway tracks applying same

InactiveCN107905046APlay a corrective roleReduce adjustment and re-construction worksBallastwayTrack superstructureEngineeringRetaining wall

The invention discloses a track deformation adjusting device and magnetic levitation railway tracks applying the same. The track deformation adjusting device comprises a track plate base, a track plate, a boss and an adjusting unit module. The track plate is arranged on the track plate base and provided with track bearing ditches which are used for mounting the steel tracks and fastener systems. The magnetic levitation railway tracks comprise a first side edge retaining wall and a second side edge retaining wall which are fixed to the railway track surface of a bearing beam, and the first sideedge retaining wall, the second side edge retaining wall and the railway track surface of the bearing beam form a U-shaped structure. According to the track deformation adjusting device and the magnetic levitation railway tracks applying the same, the track journey and the track gauge of the steel tracks at the laying stage are adjusted, the tracks are corrected during subgrade settlement at theoperating stage, and thus the laying construction cost and the later-period operating managing cost of the steel tracks are reduced; and noise can be reduced, escape tunnels and maintenance tunnels can be additionally formed, a magnetic levitation railway track traffic system is improved, and the safety guarantee capacity and the maintenance efficiency are improved.

Owner:成都天府轨谷科技有限公司

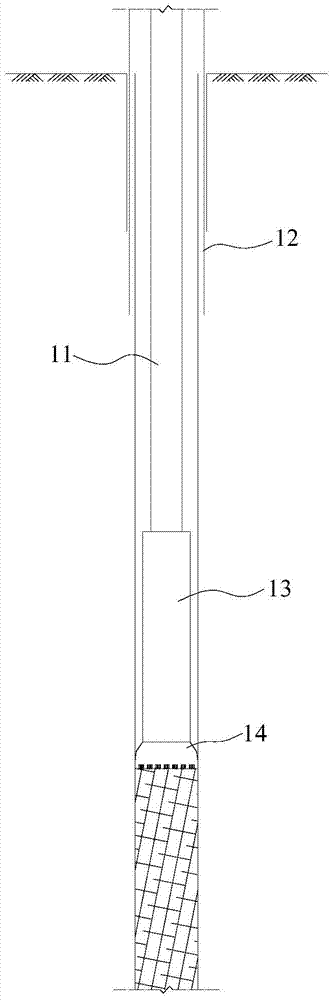

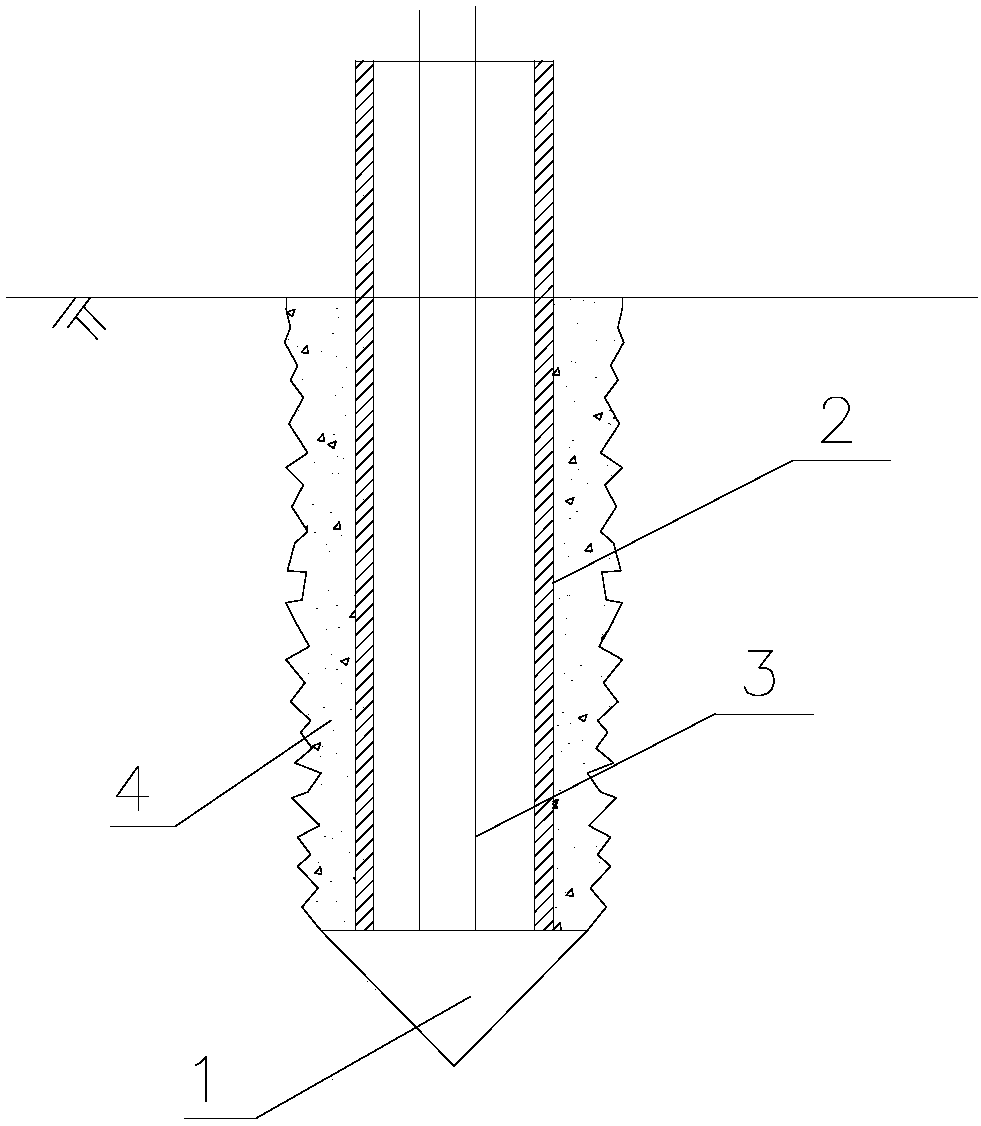

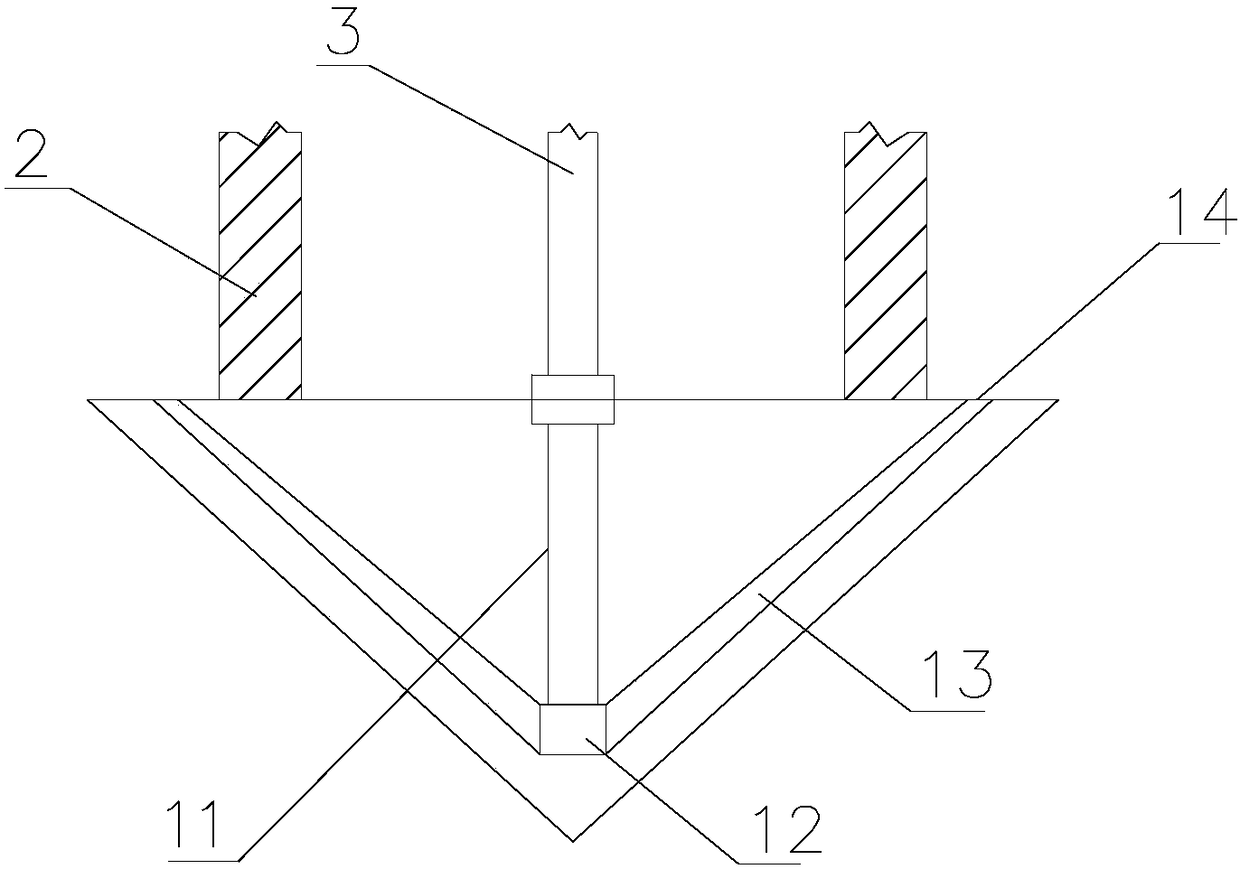

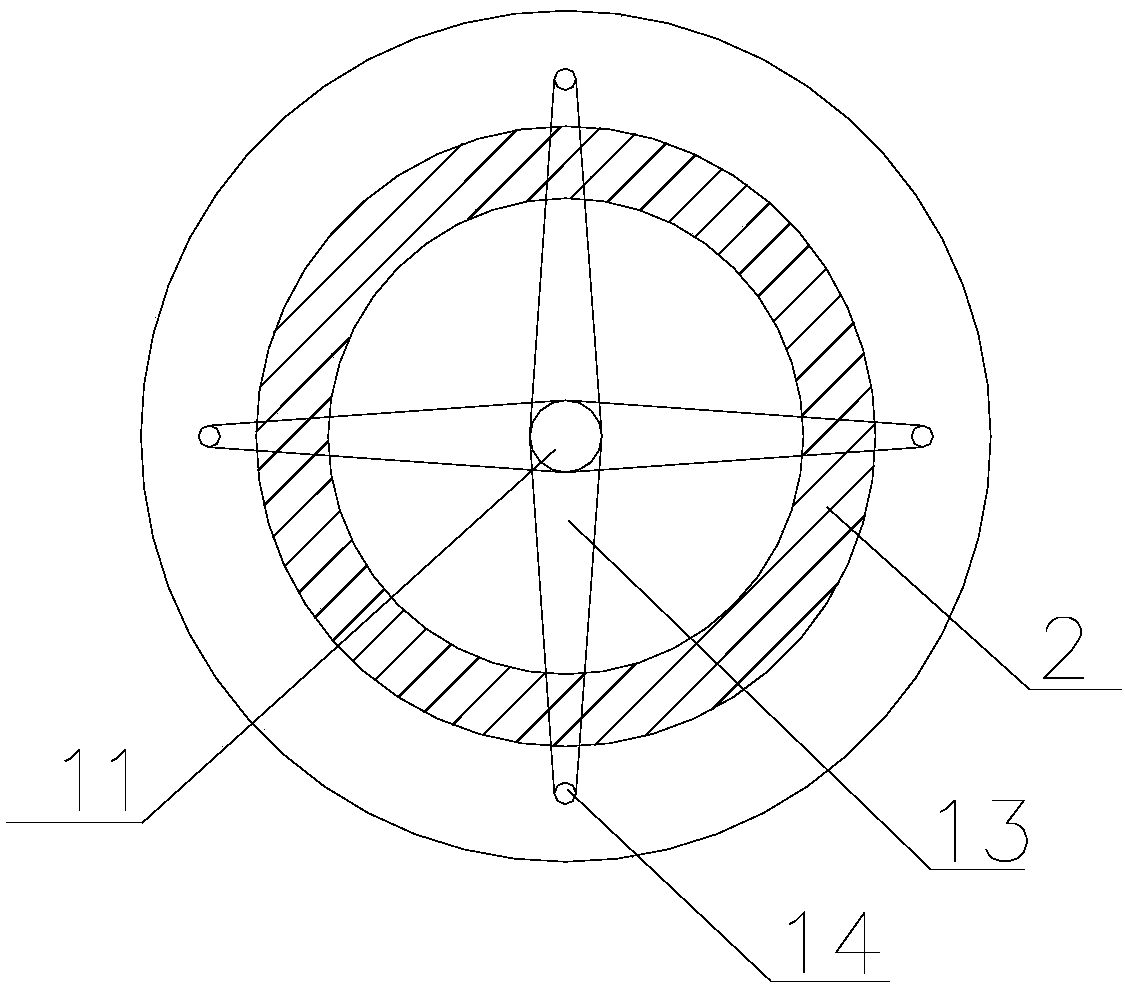

Synchronous-grouting pre-stressed pipe pile and construction method thereof

PendingCN108179743AReduced bearing capacity requirementsReduce the difficulty of pile pressingBulkheads/pilesPre stressPre stressing

The invention relates to a synchronous-grouting pre-stressed pipe pile. The synchronous-grouting pre-stressed pipe pile comprises a special pile shoe device, a prefabricated pipe pile, a grouting pipedevice and a grouting layer; the special pile shoe device comprises a main grouting pipe, branch pipe joints, branch pipes and grout discharging holes; the upper end of the main grouting pipe is connected with the grouting pipe device; the lower end of the main grouting pipe is connected with the branch pipes via the branch pipe joints; each branch pipe is connected with the corresponding grout discharging hole; the grout discharging holes are uniformly distributed at an equal interval in the outer side of a pipe pile juncture at the edge of a pile shoe; the grouting pipe device is arranged inside a cavity of the prefabricated pipe pile; and the grouting pipe device comprises a four-claw hook, an upper end interface, a grouting pipeline and a lower end interface. The synchronous-groutingpre-stressed pipe pile provided by the invention has the beneficial effects that the synchronous-grouting pre-stressed pipe pile is a novel pile foundation which is formed by adopting a pile jacking-in method and is additionally provided with a special pile shoe based on an original pre-stressed pipe pile; by synchronous grouting, the sidewall of the pipe pile can be lubricated by grouting liquid,so the difficulty of pile pressing is reduced, and the requirements on the bearing capacity of a place and the requirements on pile pressing equipment are reduced.

Owner:ZHEJIANG UNIV CITY COLLEGE

Super-long floor concrete post-pouring seam design and construction process

ActiveCN105863088ASave secondary setupImprove construction efficiencyBuilding insulationsRebar corrosionSocial benefits

The invention belongs to the field of structural design and construction and particularly relates to a super-long floor concrete post-pouring seam design and construction process. The design and construction process mainly includes the following steps of 1, determining of a beam and slab post-pouring seam sideline; 2, mounting of a beam slab panel; 3, determining of a beam and slab unbonded rebar area; 4, binding of beam steel and filling of a beam post-pouring seam; 5, binding of slab steel and filling of a slab post-pouring seam; 6, pouring of beam and slab concrete; 7, curing of the concrete; 8, pouring of the post-pouring seams; 9, curing of the post-pouring seams. According to the super-long floor concrete post-pouring seam design and construction process, sufficient extension strain capacity of a post-pouring seam unbonded rebar is scientifically utilized, the purpose of releasing temperature stress of floor concrete is achieved, and it is guaranteed that a super-long floor is free of cracking. Compared with a traditional post-pouring belt construction method, phenomena of cracking of floors on the two sides of a post-pouring belt and rebar corrosion are avoided, construction operation is simple, the construction period is greatly shortened, comprehensive cost is greatly saved, remarkable economic and social benefits are achieved, and the design and construction process meets construction requirement of high efficiency, energy conservation and environmentally-friendliness.

Owner:SHANDONG WANXIN CONSTR

Recoverable and modular deep foundation pit construction process, recoverable module and deep foundation pit support

The invention provides a recoverable and modular deep foundation pit construction process, a recoverable module and a deep foundation pit support and belongs to the technical field of deep foundation pit excavation and supporting. The process comprises the following steps that a foundation pit is dug down; a first anchor cable hole is formed, a first anchor cable is put in, and a grouting stop plug is installed for grouting; a second anchor cable hole is formed, a second anchor cable is put in, and a grouting stop plug is installed for grouting; modules and connecting fasteners are installed; a prestressing force is exerted to the first anchor cable and the second anchor cable to for a first layer of supporting; the operations are repeated to form multiple layers of supporting; modules, anchor cables and connecting fasteners of the last layer of supporting are recovered, soil is backfilled to the bottom surface of the second layer of supporting till the first layer of supporting is recovered. A soil body surrounding a deep foundation pit is supported and retained by adopting the modules and anchor cables jointly, the modules can be recycled, and materials waste and construction cost are reduced.

Owner:河北建科唐秦建筑科技有限公司

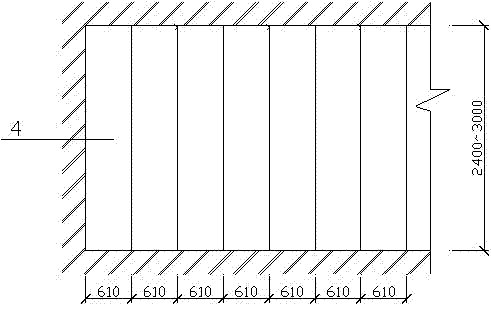

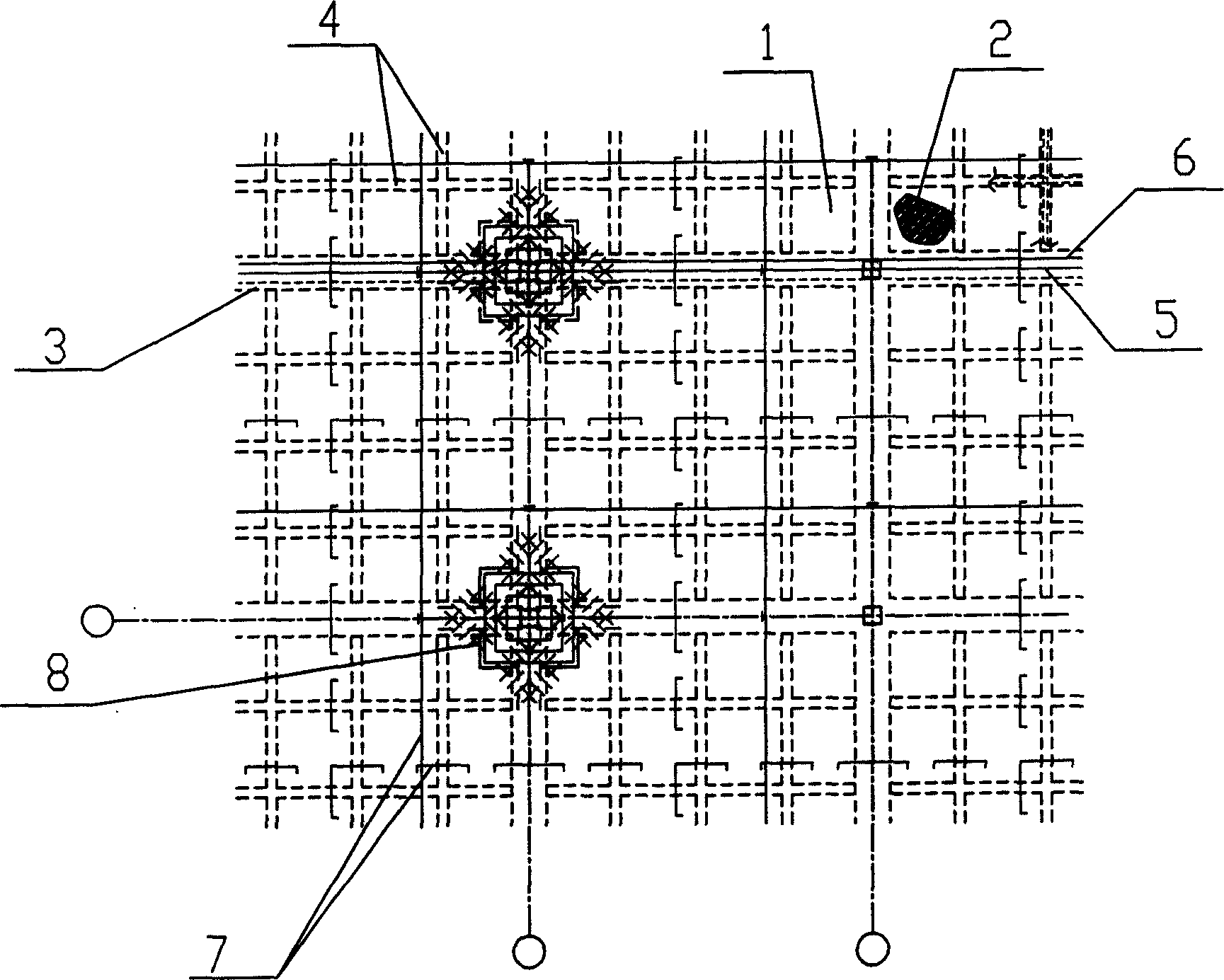

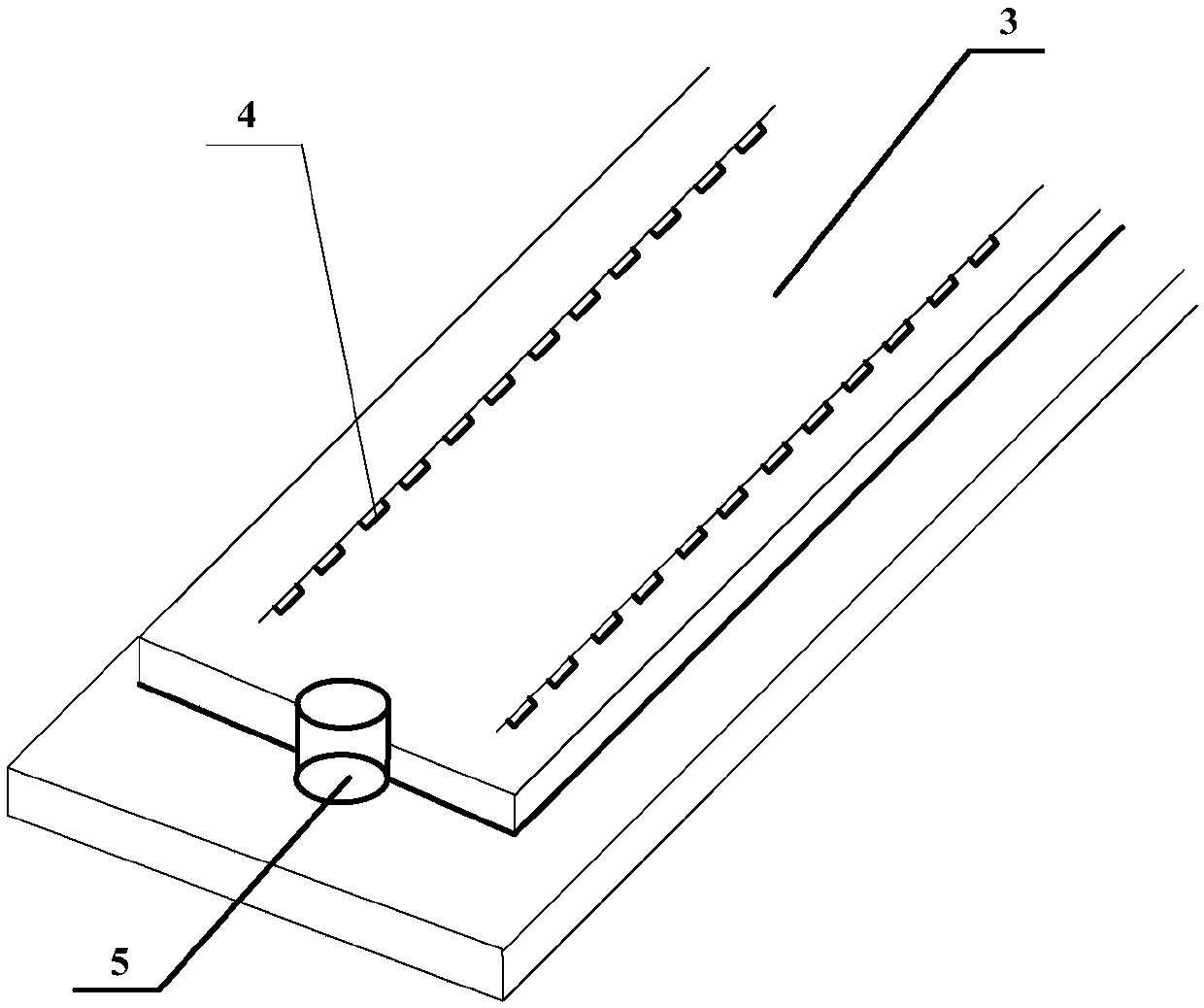

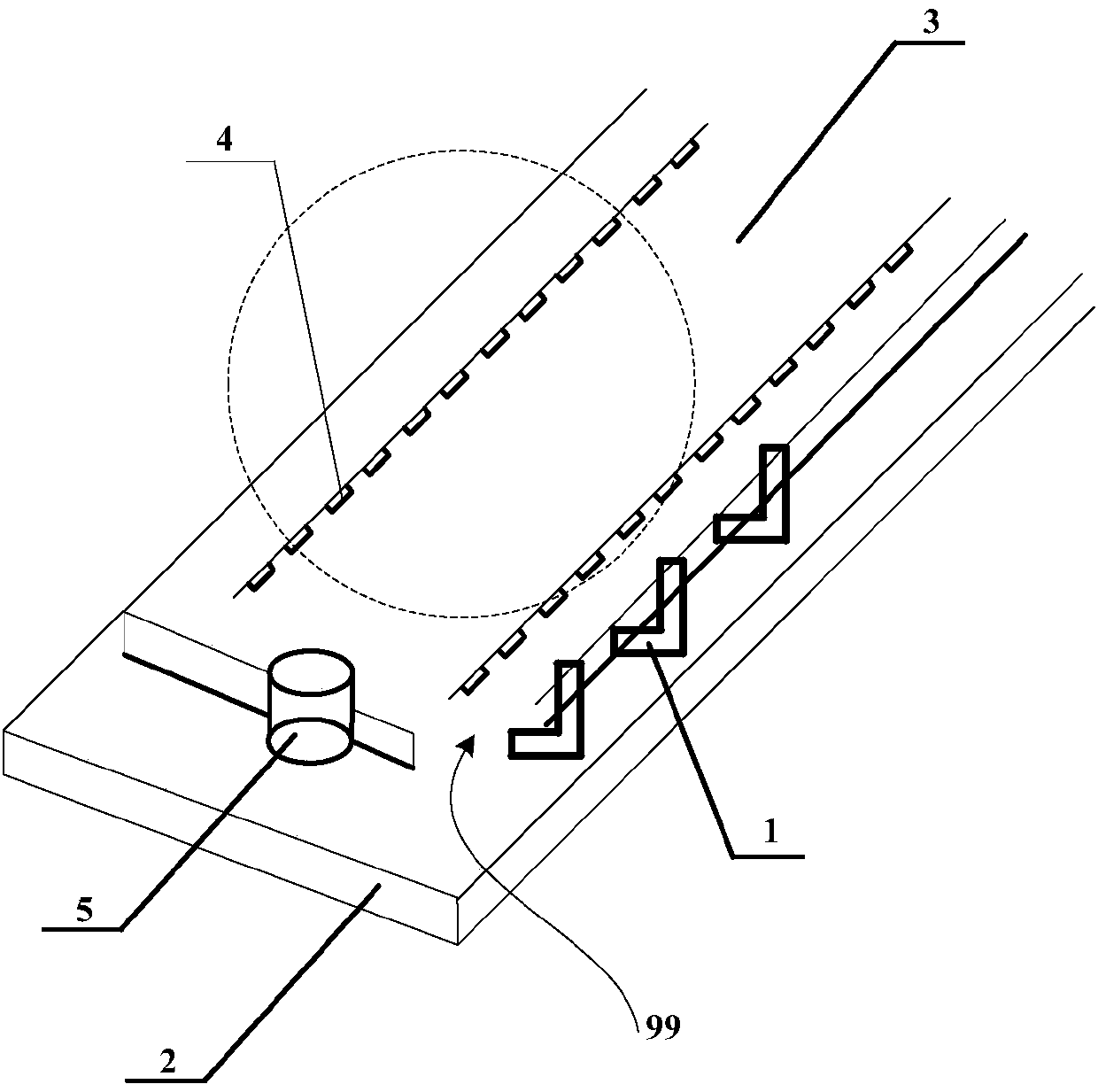

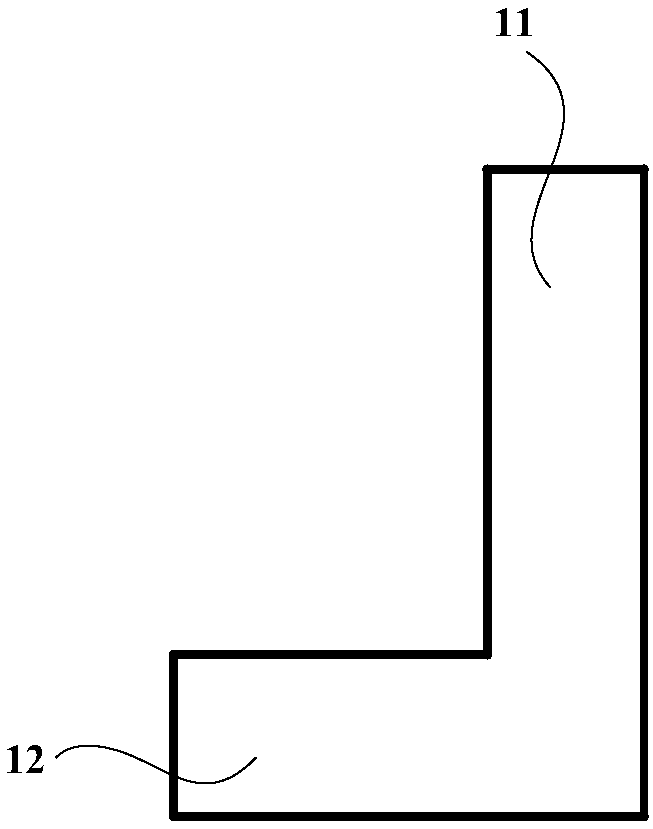

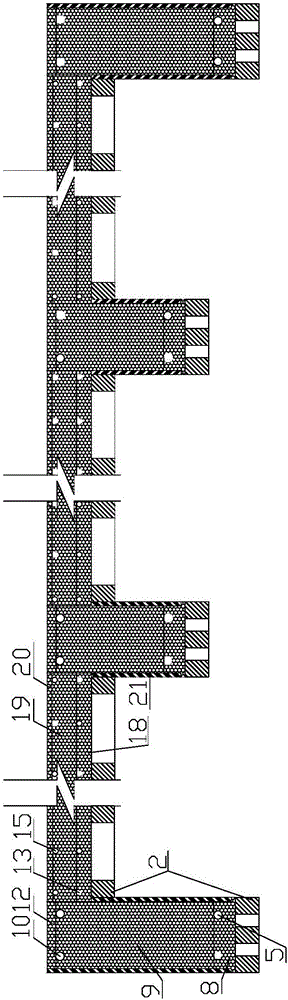

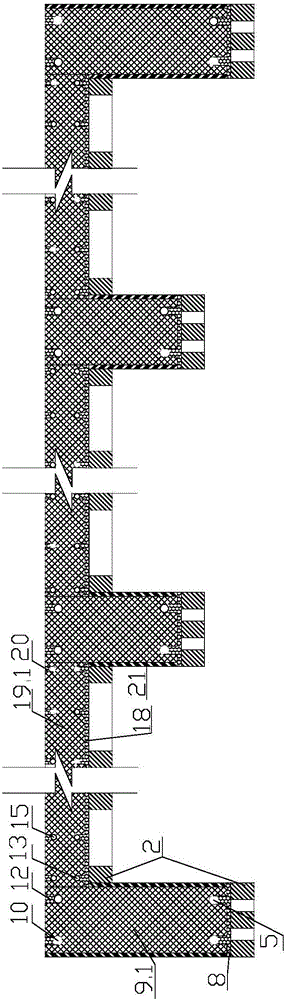

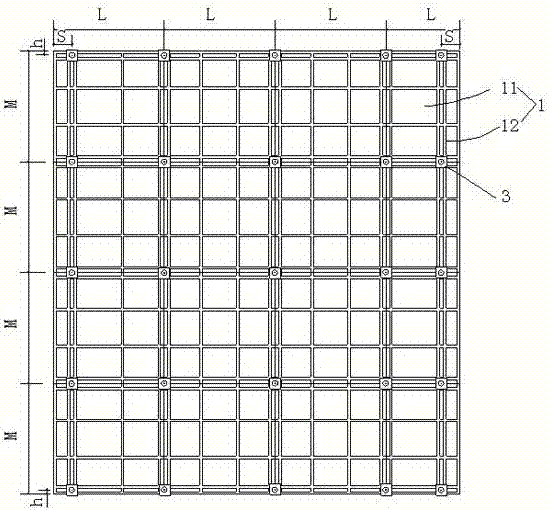

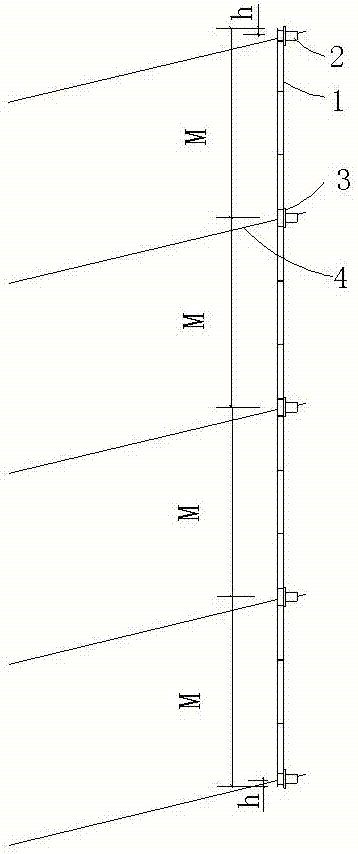

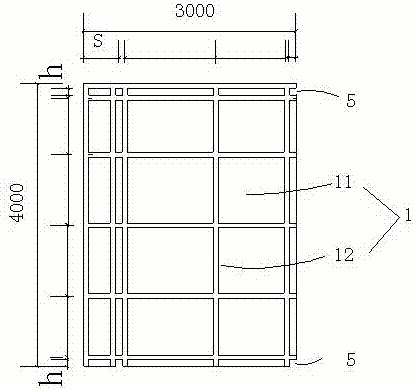

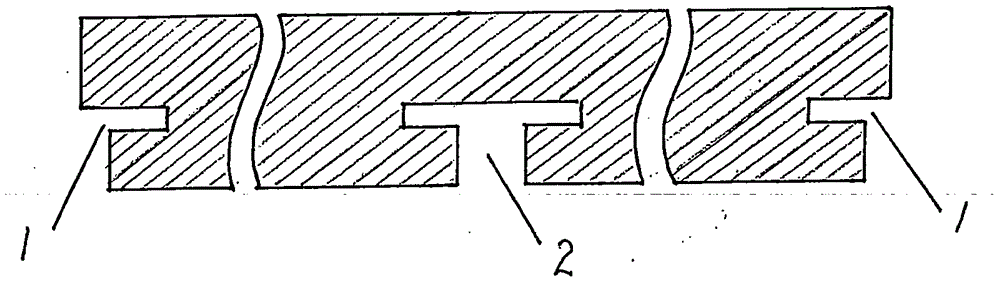

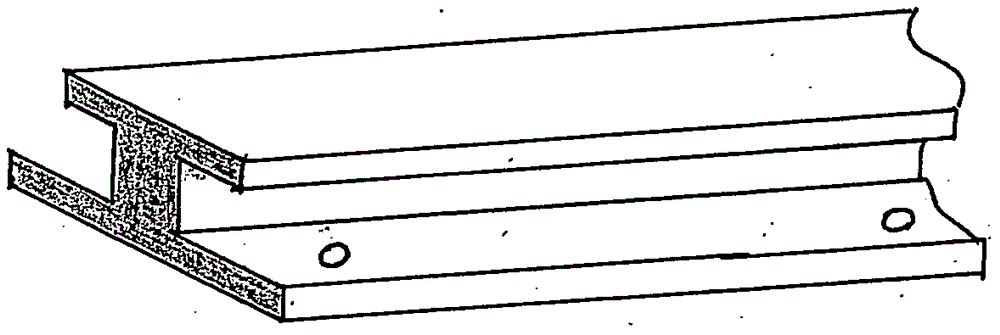

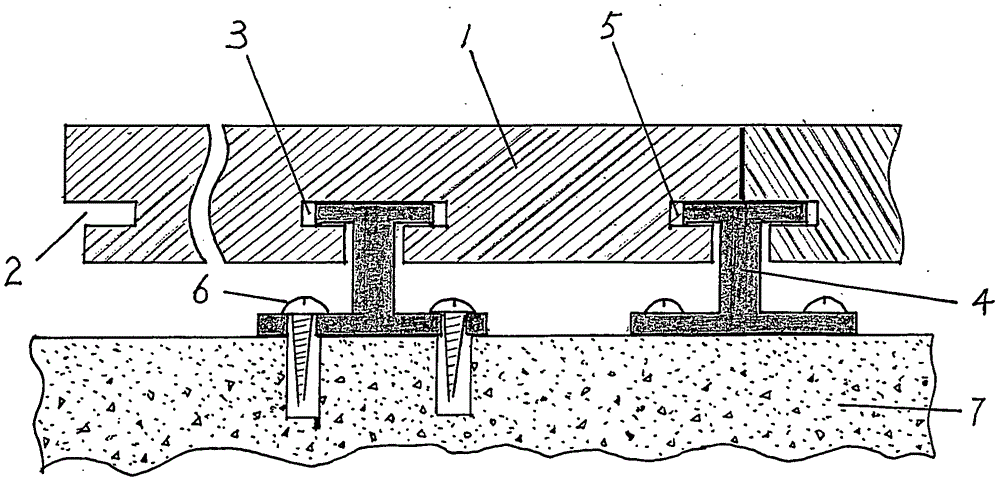

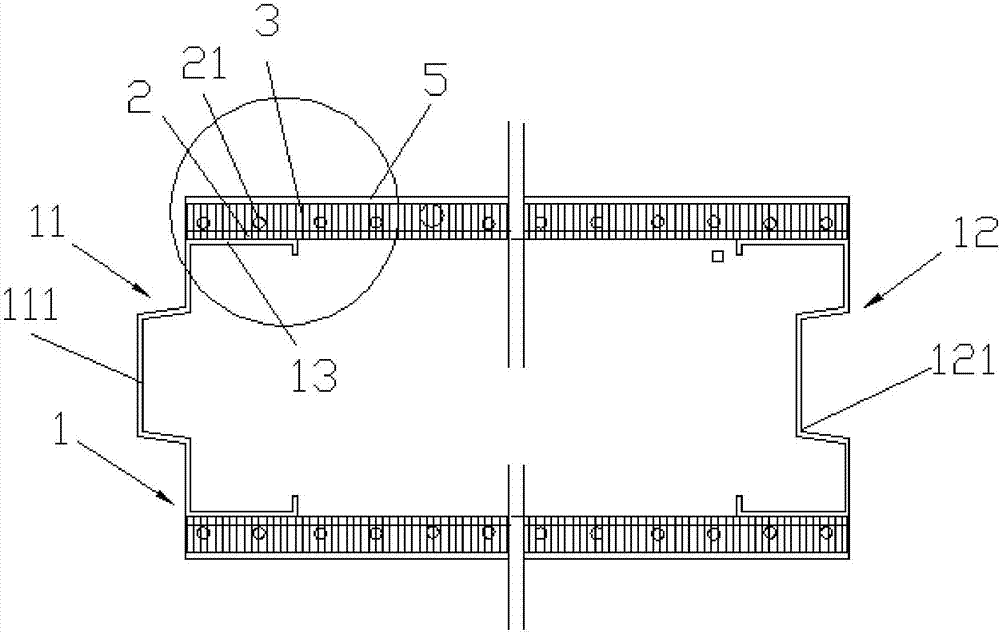

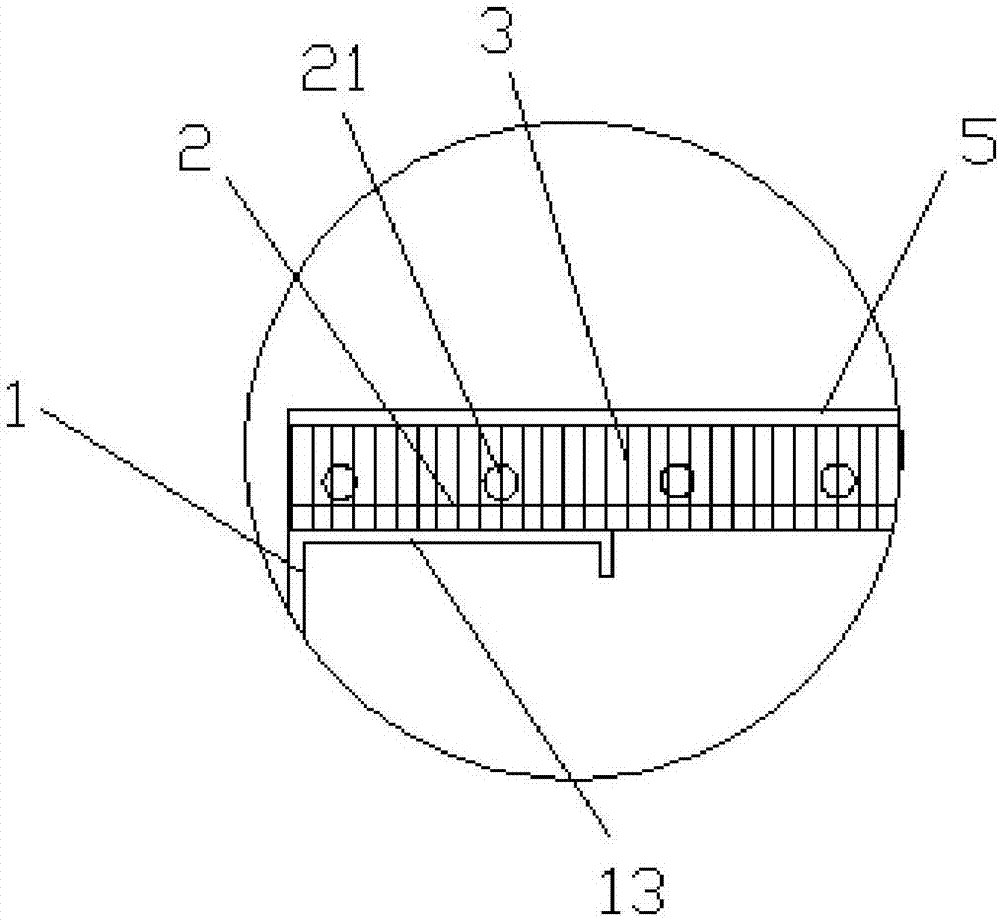

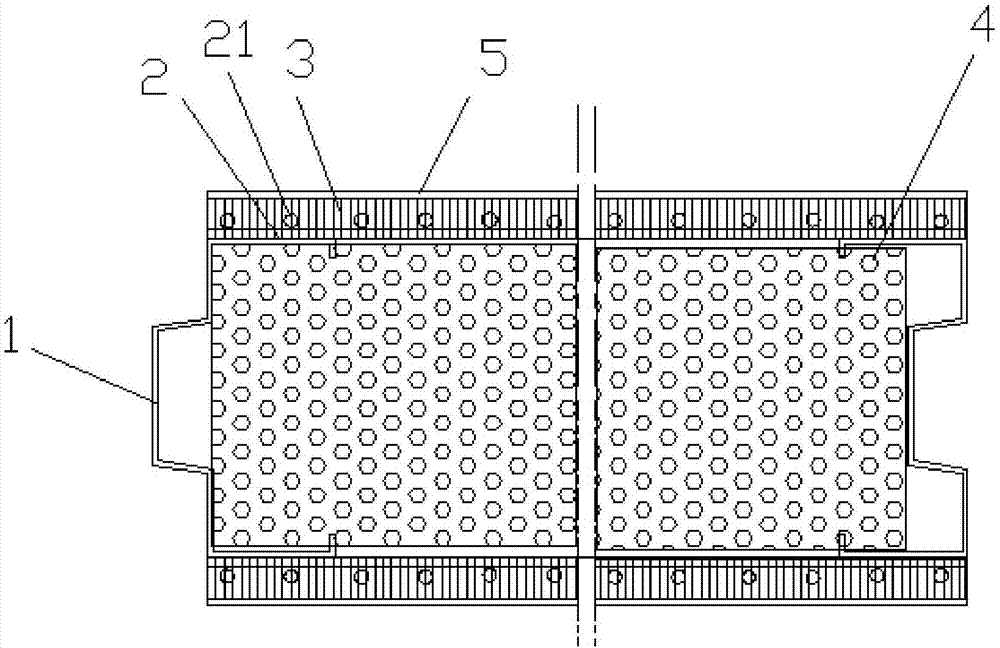

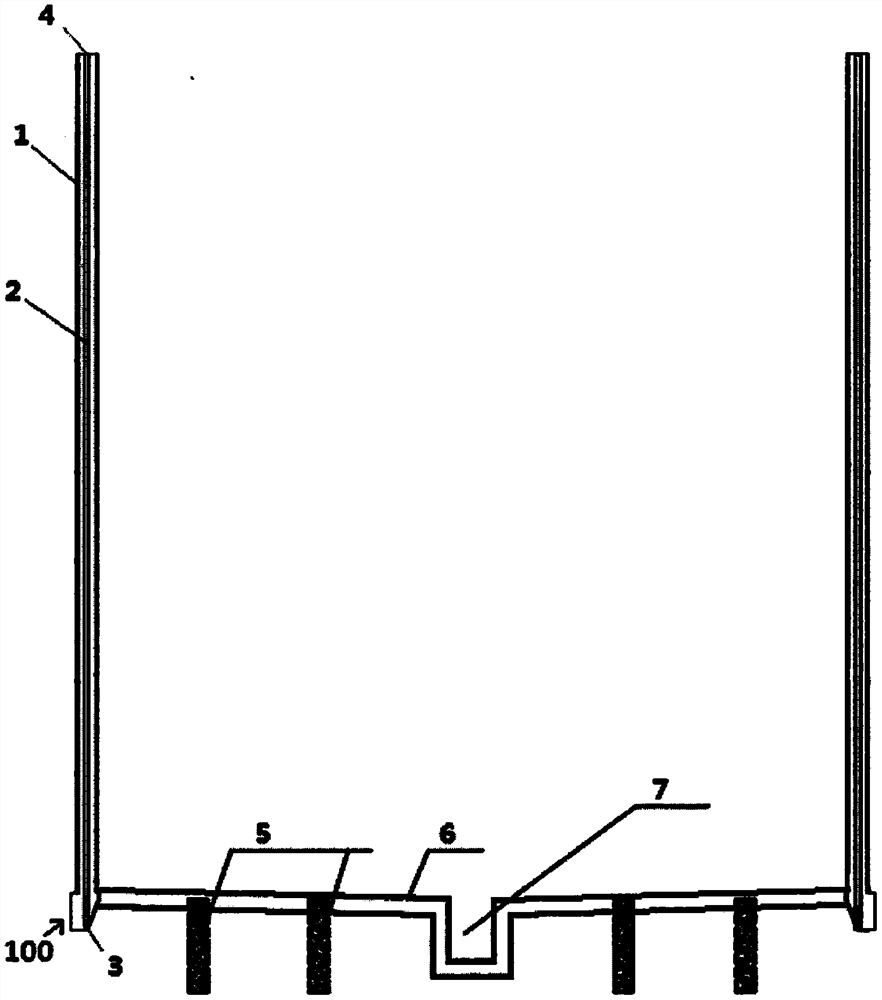

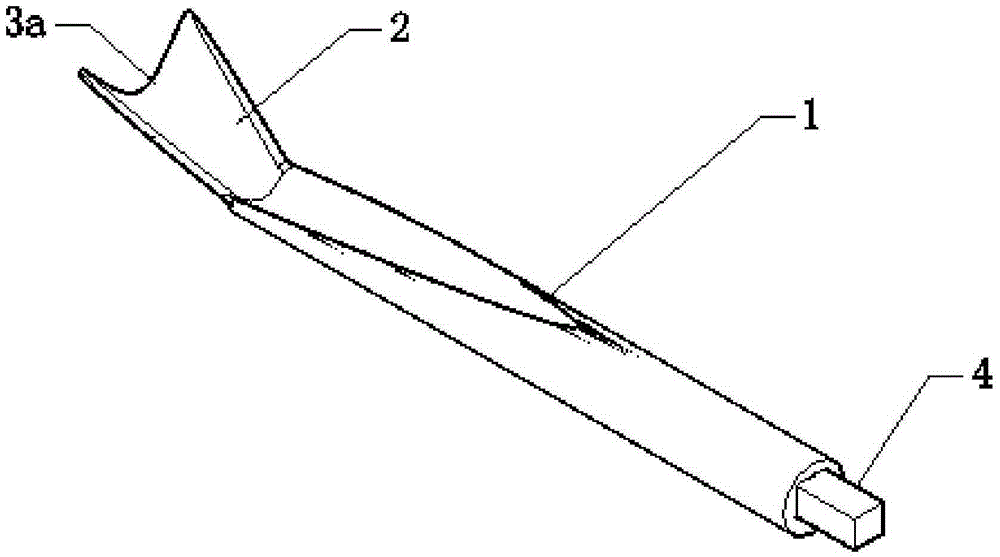

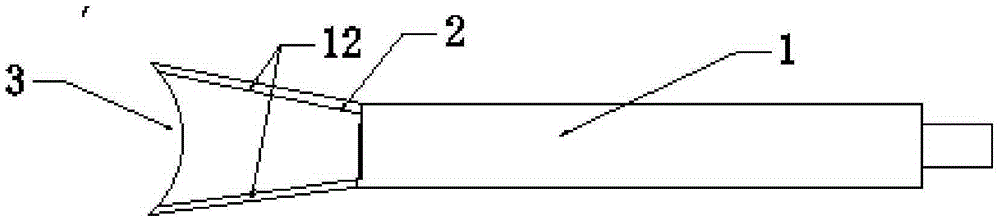

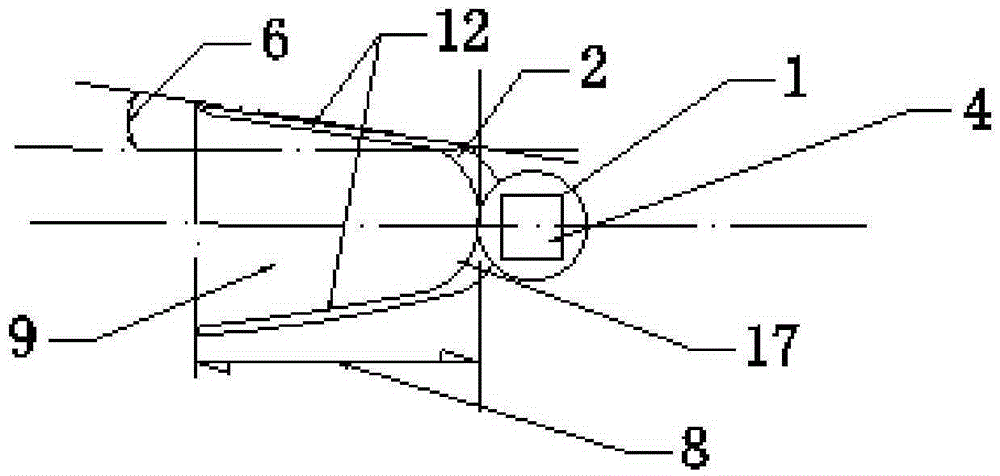

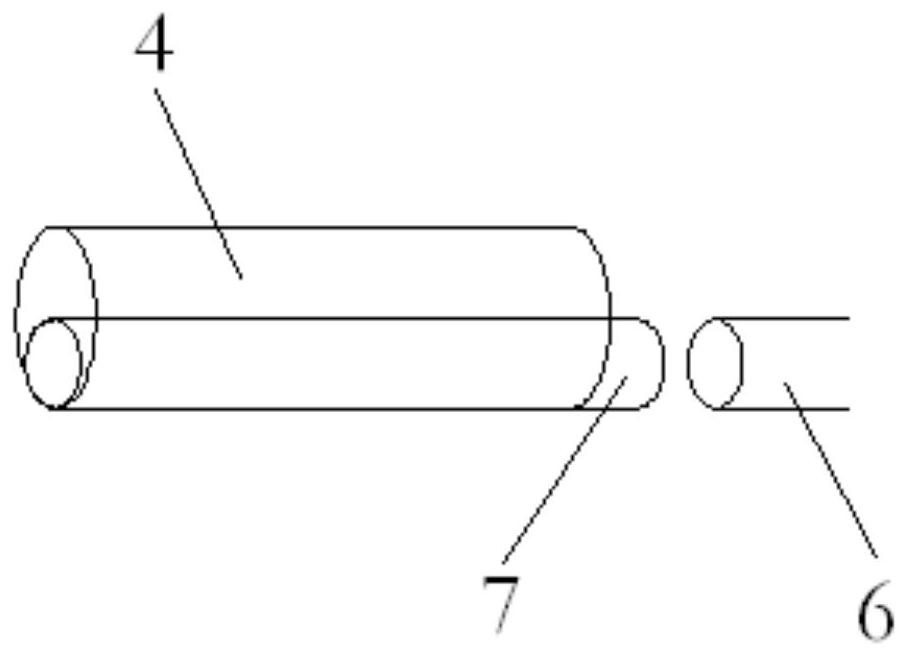

Guide rail type detachable floor

The invention provides a guide rail type detachable floor which is a brand new floor assembling structure. At present, most solid wood floors adopt the mode of assembling wood keels with steel nails and cannot be detached and reused, wood is wasted, and the net height is further lost. In order to overcome the defects, the guide rail type detachable floor changes rabbets at the two ends of a floor body (1) into two symmetrical half T-shaped notches (2) meanwhile retaining the rabbets on the two sides of the floor body (1) according to the mortise and tenon principle. One (or several) T-shaped groove (3) parallel to the two ends of the floor body is milled in the reverse surface of the floor body, and then an I-shaped metal profile serves as a guide rail (4). The upper half part of the guide rail is exactly embedded in the T-shaped groove of the floor body or a T-shaped groove (5) formed by splicing the two half T-shaped notches, and the lower half part of the guide rail is fixed to the ground (7) through a screw (6). The guide rail type detachable floor is convenient to install, can be detached and moved, and can be returned to a factory for refurbishment; wood is saved; and the nation and the people are benefited. The method is mainly applicable to solid wood floors and also can be used for solid wood composite floors.

Owner:卢伟民

Composite air-drying hardened wallboard and manufacturing method and using method thereof

The invention provides a composite air-drying hardened wallboard and a manufacturing method and using method thereof. The wallboard comprises a rectangular frame, a rebar combination net and an air-drying face layer, and the rebar combination net and the air-drying face layer are sequentially located on the front side and the rear side of the frame from inside to outside. The air-drying face layercomprises a honeycomb weave layer and light dry-mixed mortar, the honeycomb weave layer is attached to or mounted on the rebar combination net, the honeycomb weave layer is provided with densely-covered honeycomb holes, the honeycomb holes of the honeycomb weave layer are filled with the light dry-mixed mortar, and paster is attached to the outer side of the air-drying face layer. The wallboard is low in weight and convenient to transport, the transporting cost is reduced, the labor intensity of workers in the mounting process is relieved, the mounting efficiency is improved, and the mountingmanpower cost is decreased. After the wallboard is mounted and hardened with water, the wallboard has the advantages that compactness and strength are good, and a wall face layer is not prone to cracking. Mechanized, standardized and large-scale production of the wallboard can be achieved in a factory, the production efficiency is improved, and the production cost is lowered.

Owner:唐方方

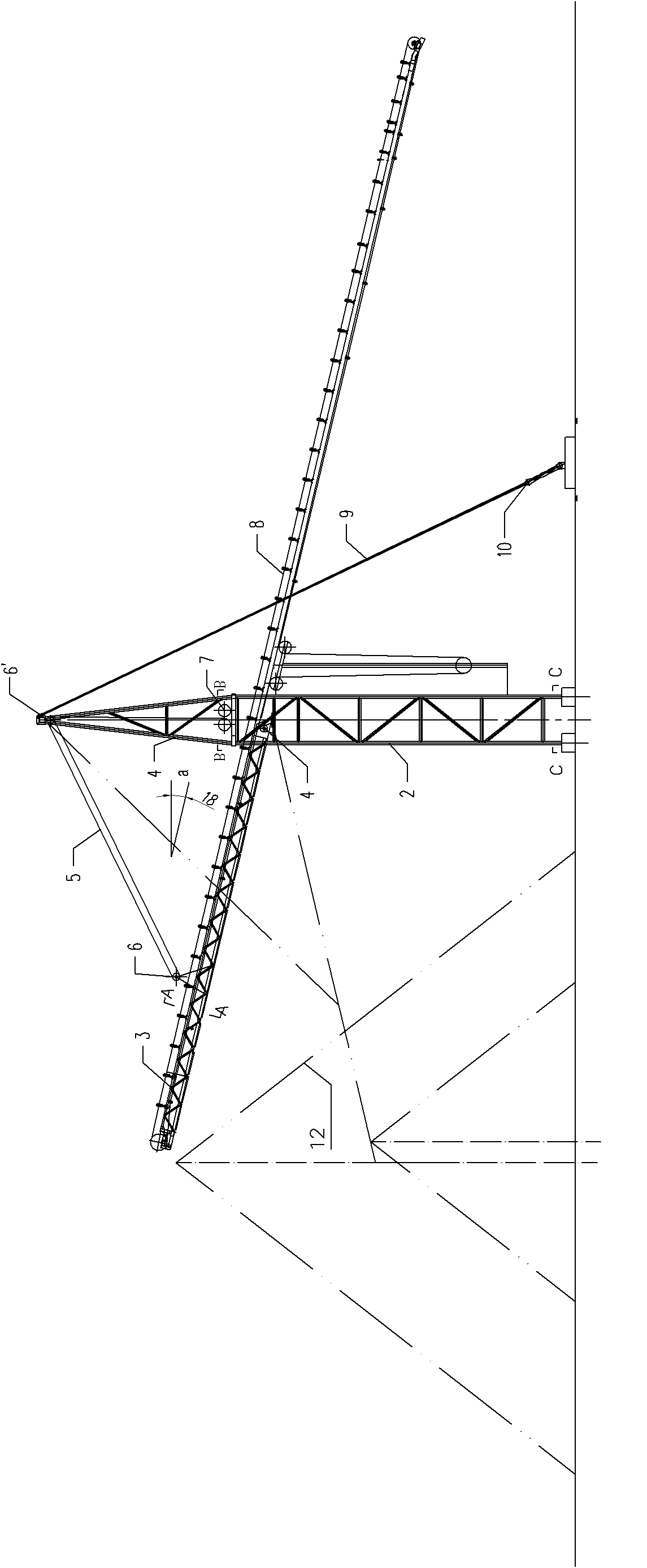

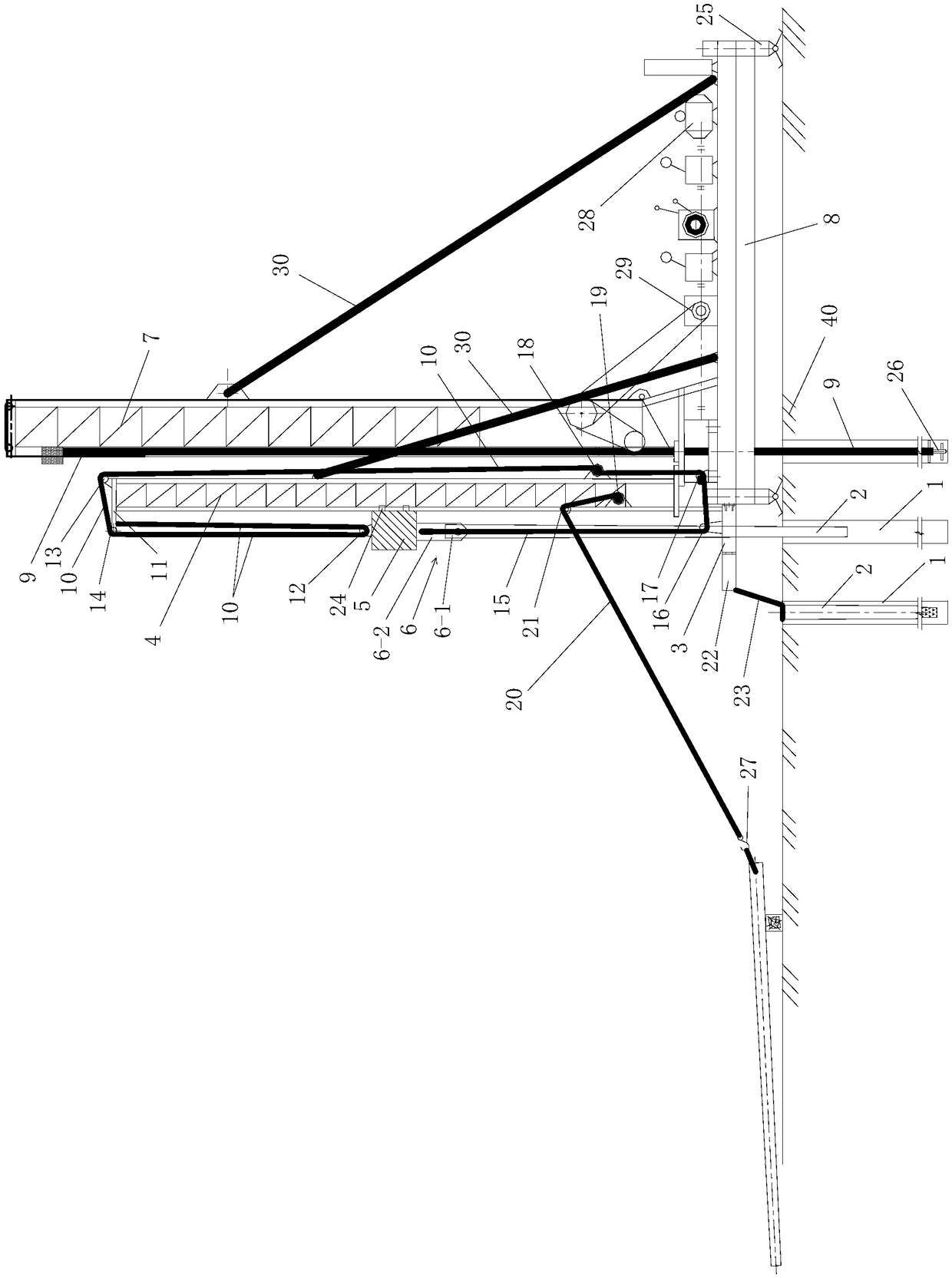

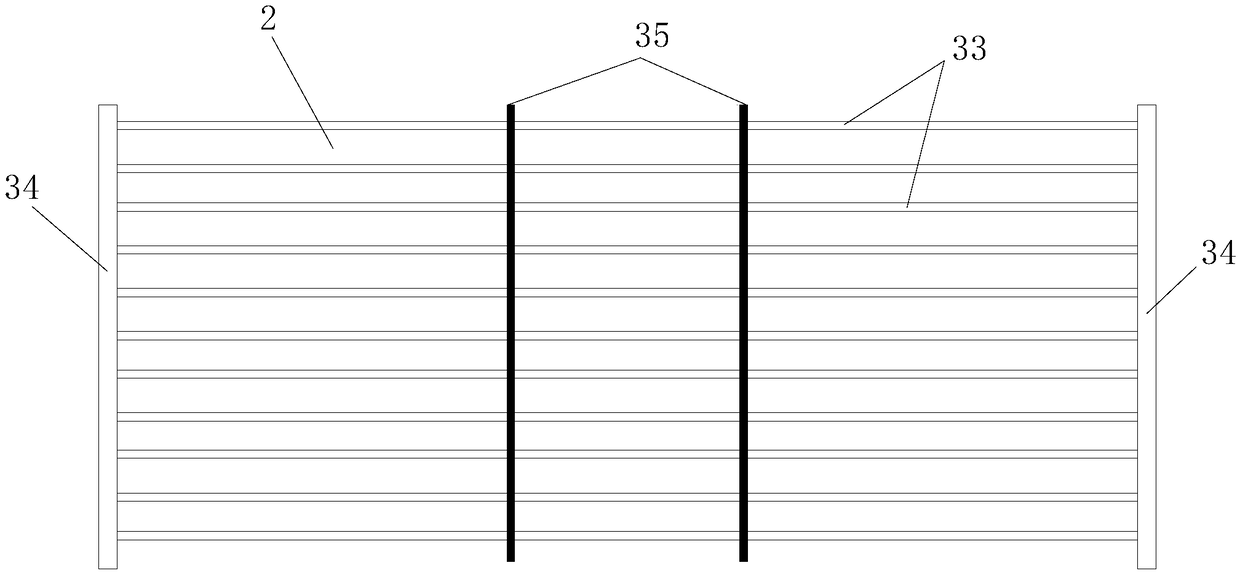

Device for composting concrete aggregate with large particle diameter

Device for composting concrete aggregate with large particle diameter comprises a tower, a steel upright column and a backstay cable, wherein the steel upright column is provided with a hoist workbench, two hinge supports are arranged on the hoist workbench, and a movable cantilever truss girder is connected with the hinge supports via axle pins; a hoist is equipped on the hoist workbench, a sealing-tape machine is arranged on the movable cantilever truss girder, and a steel wire rope of the hoist is connected with the movable cantilever truss girder via two assembly pulleys. Compared with the current scheme of adopting a stocker, the device provided by the invention saves the cost of purchasing stocker equipment, and reduces construction land occupation and civil engineering expense; and compared with the scheme of adopting a sealing-tape machine for blanking and stockpiling at fixed point, the device of the invention can maximally avoid second fragmentation of the aggregate with large particle diameter in stockpiling, and reduces the undersize index of the particle diameter aggregate by 8% to 18%, at the same time, guarantees continuous aggregate grading, avoids aggregate separation, and solves concrete separation problem caused by unreasonable particle diameter of coarse aggregate, so as to reach the quality requirement of concrete aggregate.

Owner:CHINA GEZHOUBA GROUP NO 5 ENG

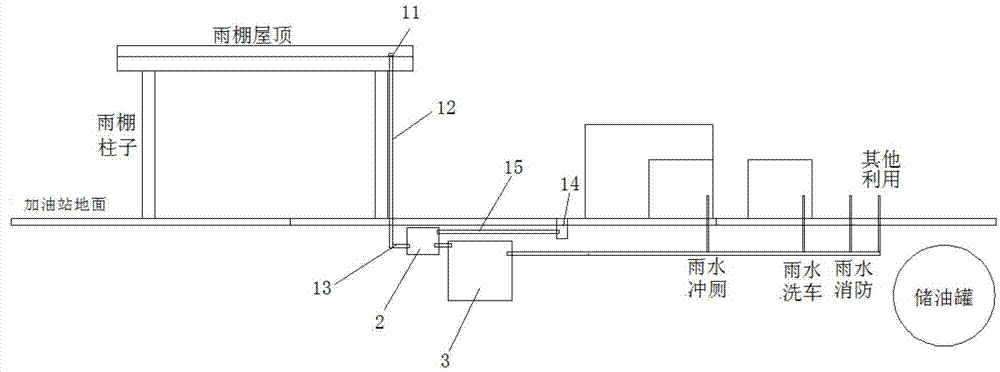

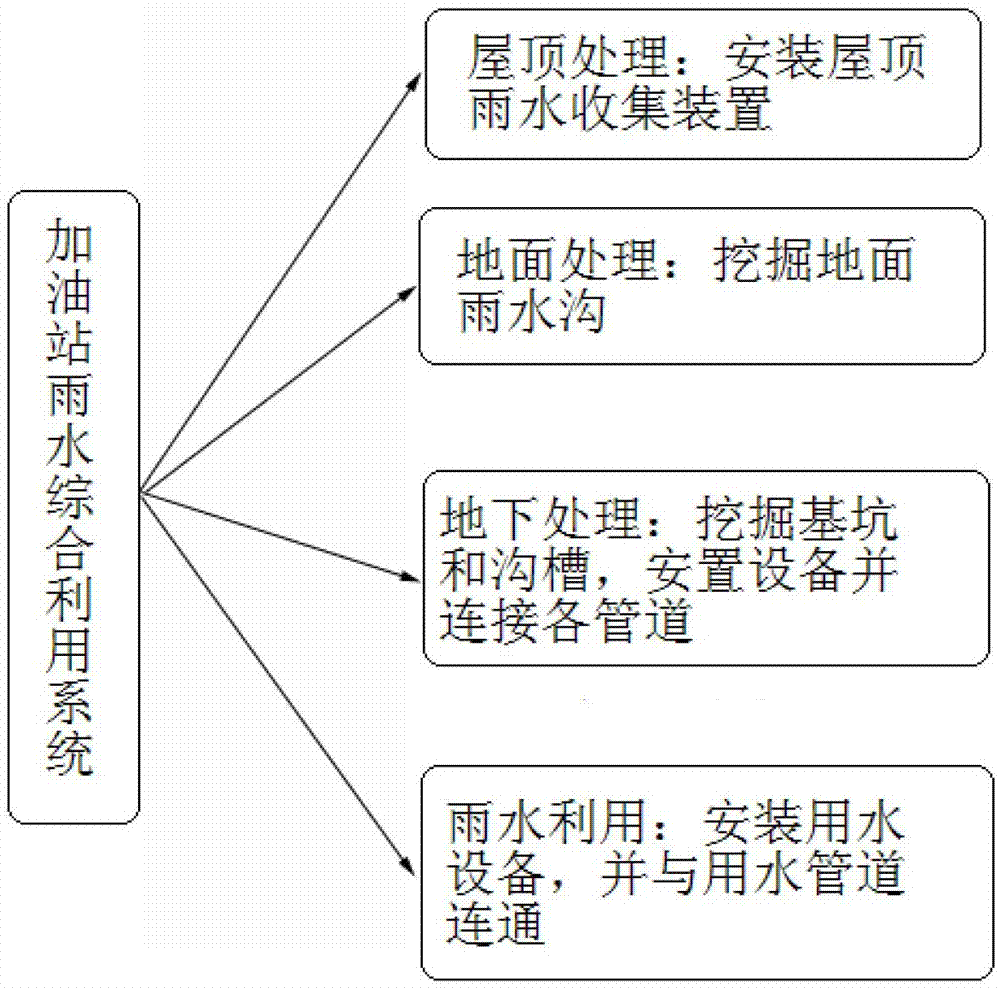

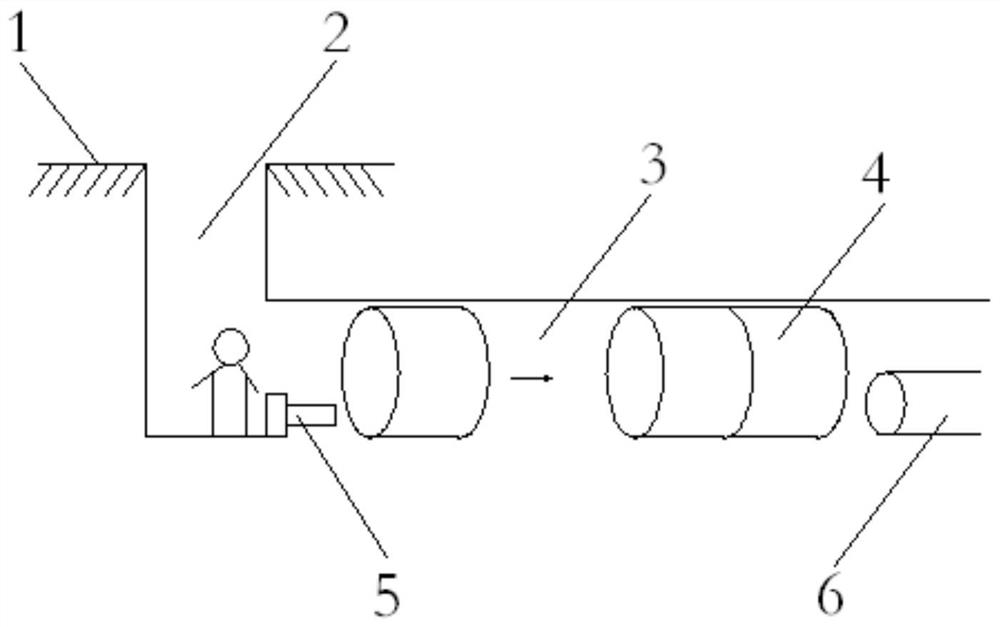

Rainwater comprehensive utilization system for gas station and construction method

InactiveCN102877535ARelieve drainage pressureSolve drainage problemsSewerage structuresRoof drainageEngineeringRainwater harvesting

A rainwater comprehensive utilization system for a gas station comprises a rainwater collection device, an underground rainwater storage tank, a rainwater treatment device and a rainwater utilization subsystem, wherein the rainwater collection device is connected with the rainwater treatment device which is connected with the underground rainwater storage tank, and the underground rainwater storage tank is connected with the rainwater utilization subsystem. By the rainwater comprehensive utilization system, rainwater resources are sufficiently utilized, water drainage pressure of the gas station is alleviated, and main products and facilities which are arranged below a freezing line are not affected in use; further, rainwater storage facilities and rainwater gutters and the like can be preformed parts, so that the rainwater comprehensive utilization system has the advantages of low economic cost, short construction period, low construction noise, high environmental applicability, low affection on the surroundings, superior comprehensive cost performance, recyclability of products and materials and the like when being assembled and constructed on constriction site, and is an ideal scheme for solving the problems of water drainage and using of the gas station.

Owner:BEIJING TIDELION S&I RAINWATER HARVESTING TECH CO LTD

Vibrating-press-type pile construction method and vibrating hammer equipment therefor

The invention discloses a vibrating-press-type sinking construction method. The vibrating-press-type sinking construction method is characterized in that according to the compactness of soil, vibrating hammer equipment is adopted, and by use of the self-weights of a hammer body of the vibrating hammer equipment and a balancing weight detachably mounted on the hammer body and corresponding to the compactness of the soil, at least one of an inner pipe and an outer pipe which are nested together is subjected to vibrating-press operation to the designed standard height so as to realize pipe sinking. According to the design, the self-weight of the corresponding balancing weight is increased or adjusted on the basis of the conventional vibrating hammer equipment according to different soil compactness to achieve the purpose that one set of the vibrating hammer equipment adapts to construction in different soil characteristics to meet the design requirements, so that not only is the construction efficiency guaranteed, but also the construction cost is lowered. The invention also discloses a vibrating-press-type pile construction method adopting the vibrating-press-type sinking construction method and the vibrating hammer equipment for the vibrating-press-type pile construction method.

Owner:刘献刚

Soft soil foundation reinforcing method based on cement concrete cored piles

InactiveCN109162270ASimple construction methodReasonable designSoil preservationMaterials sciencePrefabrication

The invention discloses a soft soil foundation reinforcing method based on cement concrete cored piles. Multiple cement concrete cored piles, vertically distributed, are adopted to reinforce a soft soil foundation; and the method comprises the steps of: (1) prefabrication of the cored piles; (2) conveying of the cored piles; and (3) reinforcement of the foundation: the cement concrete cored pilesare constructed by adopting an integrated cored pile machine; and when any one cement concrete cored pile is constructed, six steps of placement of the pile machine in place, construction of cement stirring piles, shifting of the pile machine, installation of the cored piles, vertical placement of the cored piles and pressing of the piles are carried out. The method is simple in step, reasonable in design, convenient for construction, high in construction efficiency and excellent in use effect; after prefabrication of all the cored piles, the integrated cored pile machine finishes the construction of the cement stirring piles in the cement concrete cored piles and the pressing process of the cored piles, so that the construction speed is high; and the verticality of the cored piles in thepile pressing process is easily controlled, so that the quality of the formed cement concrete cored piles can be effectively guaranteed, and the reinforcing effect of the soft soil foundation is guaranteed.

Owner:NO 1 ENG LIMITED OF CR20G

Production method of lightweight concrete prefabricated big panels

ActiveCN105906371AOptimize mix ratioExcellent preparation strengthCeramicwareFoaming agentArchitectural engineering

The invention discloses a production method of lightweight concrete prefabricated big panels. The method comprises the following steps: 1, selecting raw materials according to a case that every cubic meter of lightweight concrete prefabricated big panels contains 450-550kg of cement, 65-195kg of stone flour, 3.25-9.75kg of a water reducer and 0.01-0.05kg of a foaming agent, foaming the foaming agent, uniformly mixing cement, the stone flour and the water reducer to prepare a cement mortar, adding the foamed foaming agent to the cement mortar, and uniformly stirring the foamed foaming agent and the cement mortar to prepare lightweight concrete; and 2, pouring the lightweight concrete in a die, and carrying out demolding treatment and curing to produce the lightweight concrete prefabricated big panels. The method solves the problem of adverseness of too large weight of common prefabricated big panels to transportation and hoisting installation, the weight of the lightweight concrete prefabricated big panels produced in the invention is about 50% lower than that of common concrete prefabricated big panels, and the construction efficiency of prefabricated wallboards is effectively increased.

Owner:GUANGDONG PROVINCIAL ACAD OF BUILDING RES GRP CO LTD

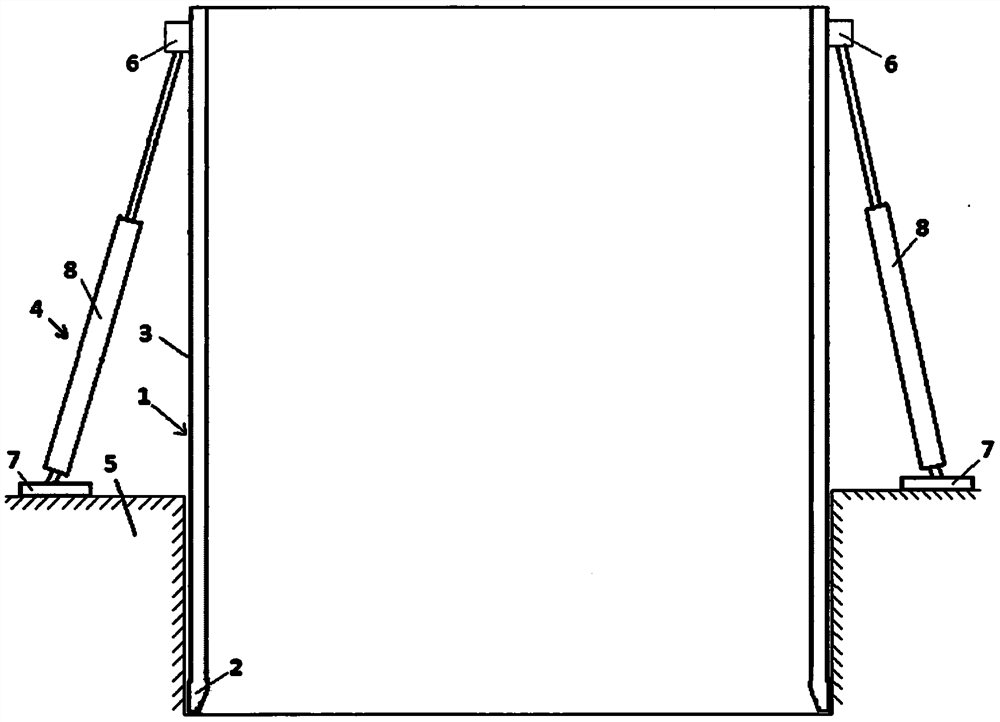

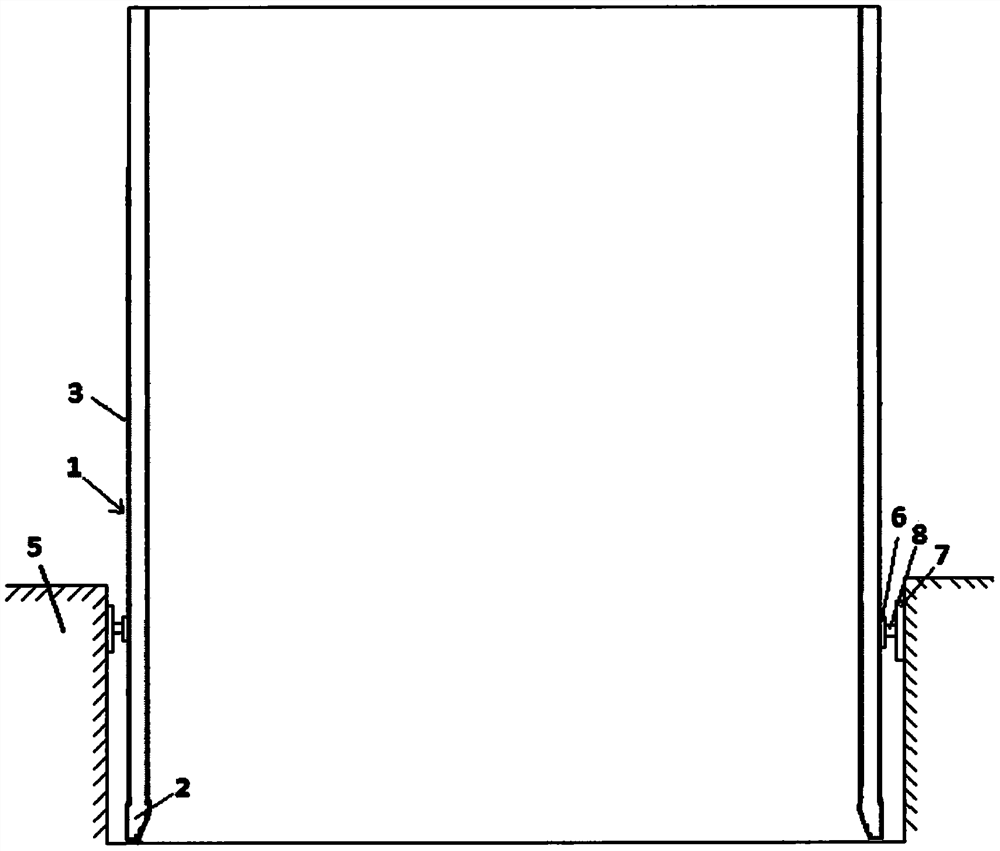

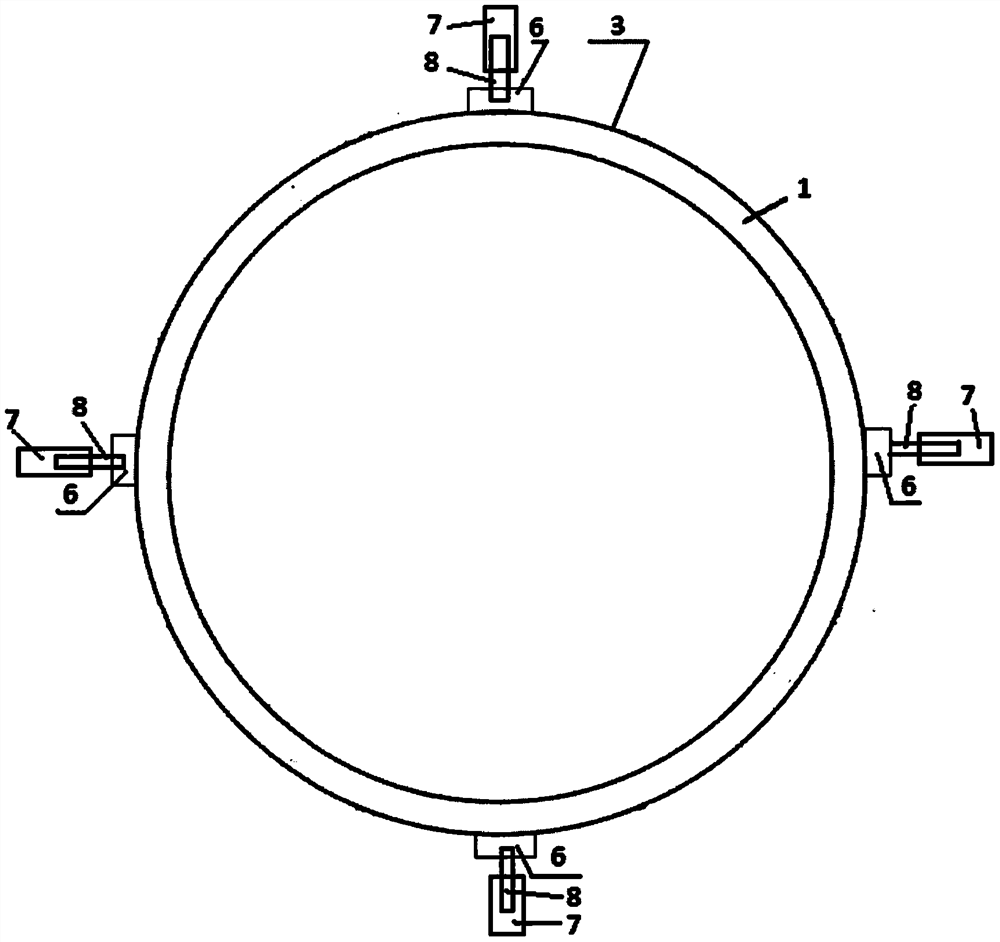

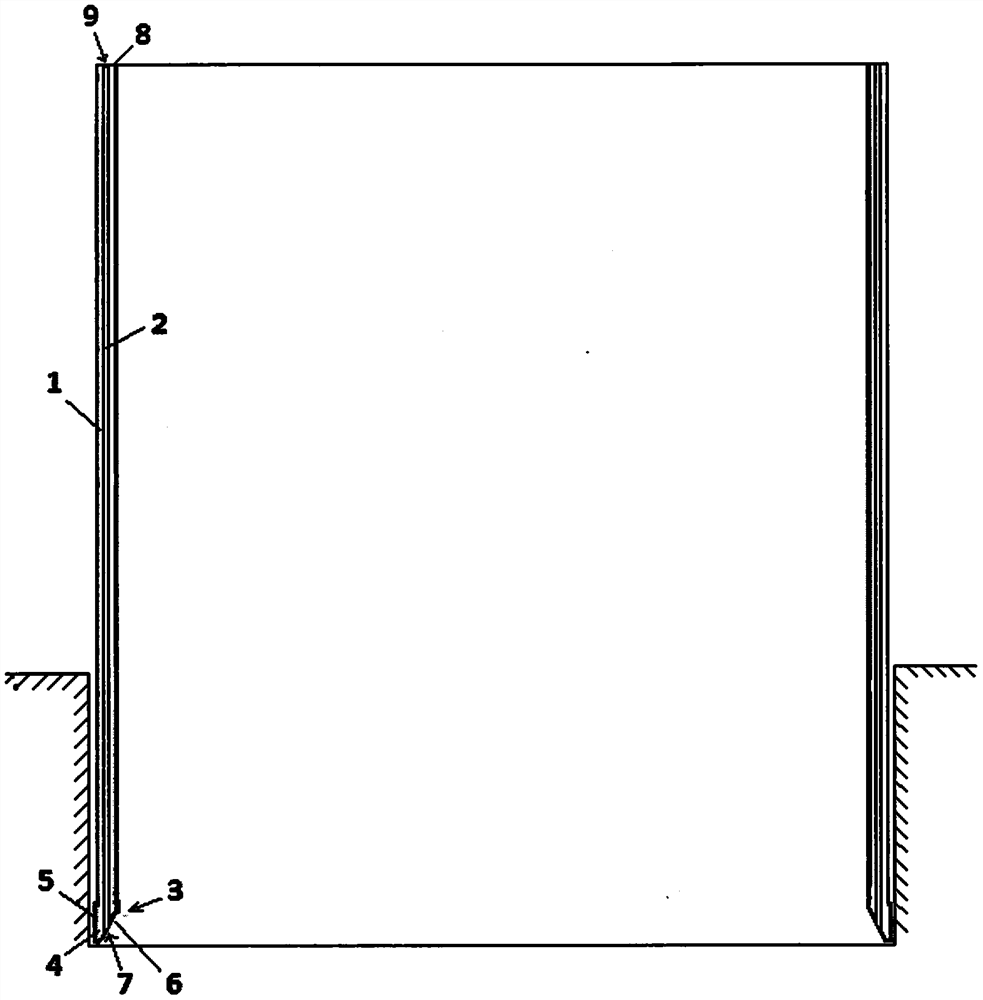

Self-sinking type deep foundation pit barrier wall structure and construction method for underground space structure

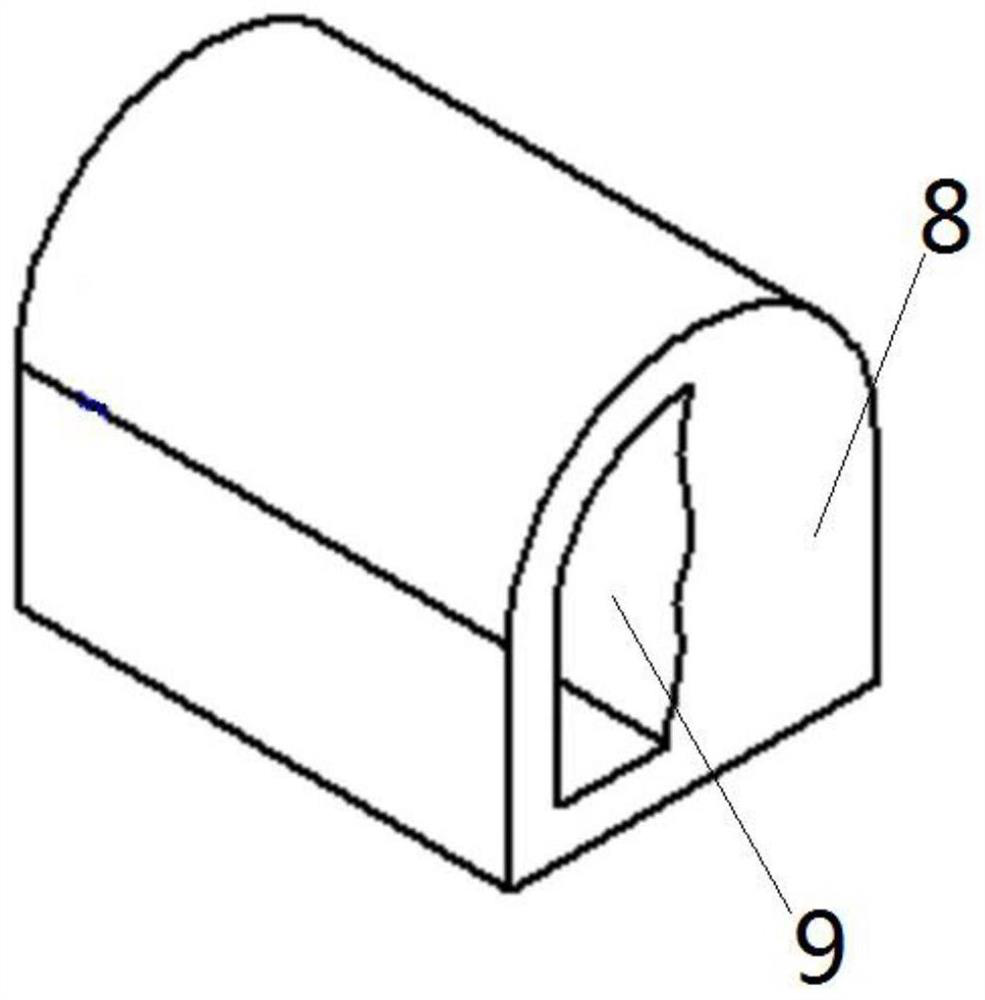

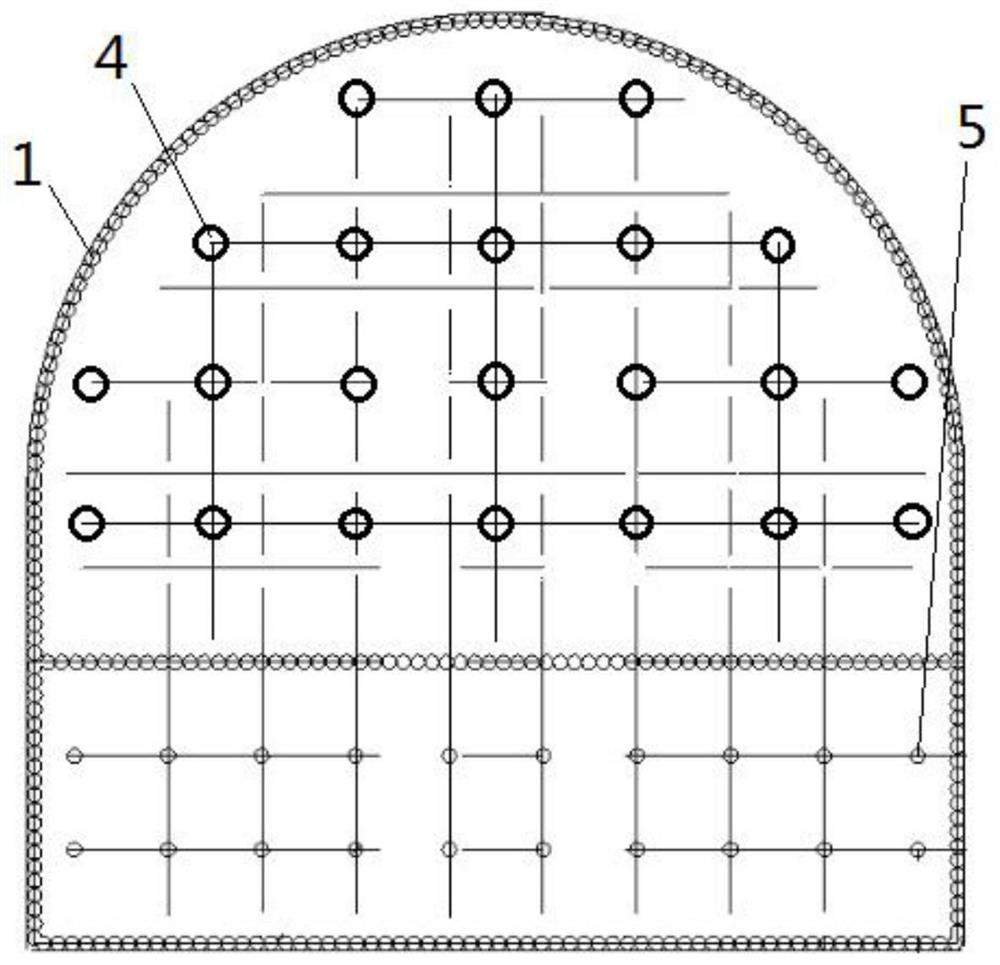

PendingCN111851506AReduce construction proceduresConstruction noise is smallExcavationsCaissonsUnderground spaceEngineering

The invention provides a self-sinking type deep foundation pit barrier wall structure. The self-sinking type deep foundation pit barrier wall structure comprises a barrel type barrier wall body, wherein the bottom of the barrel type barrier wall body is provided with a ground breaking structure, and the ground breaking structure and the barrel type barrier wall body are in gravity matching to achieve downward ground breaking. The self-sinking type deep foundation pit barrier wall structure further comprises resistance enhancement devices, wherein the resistance enhancement devices are arrangedon the outer side wall of the barrel type barrier wall body and used for cooperating with a foundation to adjust the upward resistance applied by the foundation to the barrel type barrier wall body.The bottom of the barrel type barrier wall body is provided with the ground breaking structure, hammering operation is avoided, self-sinking can be achieved, and construction procedures are decreased;generated construction noise is low, the construction duration is short, and pollution to the surrounding environment is small; and the resistance enhancement devices are arranged to adjust the upward resistance applied by the foundation to the barrel type barrier wall body, and thus, the sinking speed and / or perpendicularity of the self-sinking type deep foundation pit barrier wall structure canbe controlled according to different soil body conditions. The invention further provides a construction method for an underground space.

Owner:JIANGXI JIYE SCI & TECH

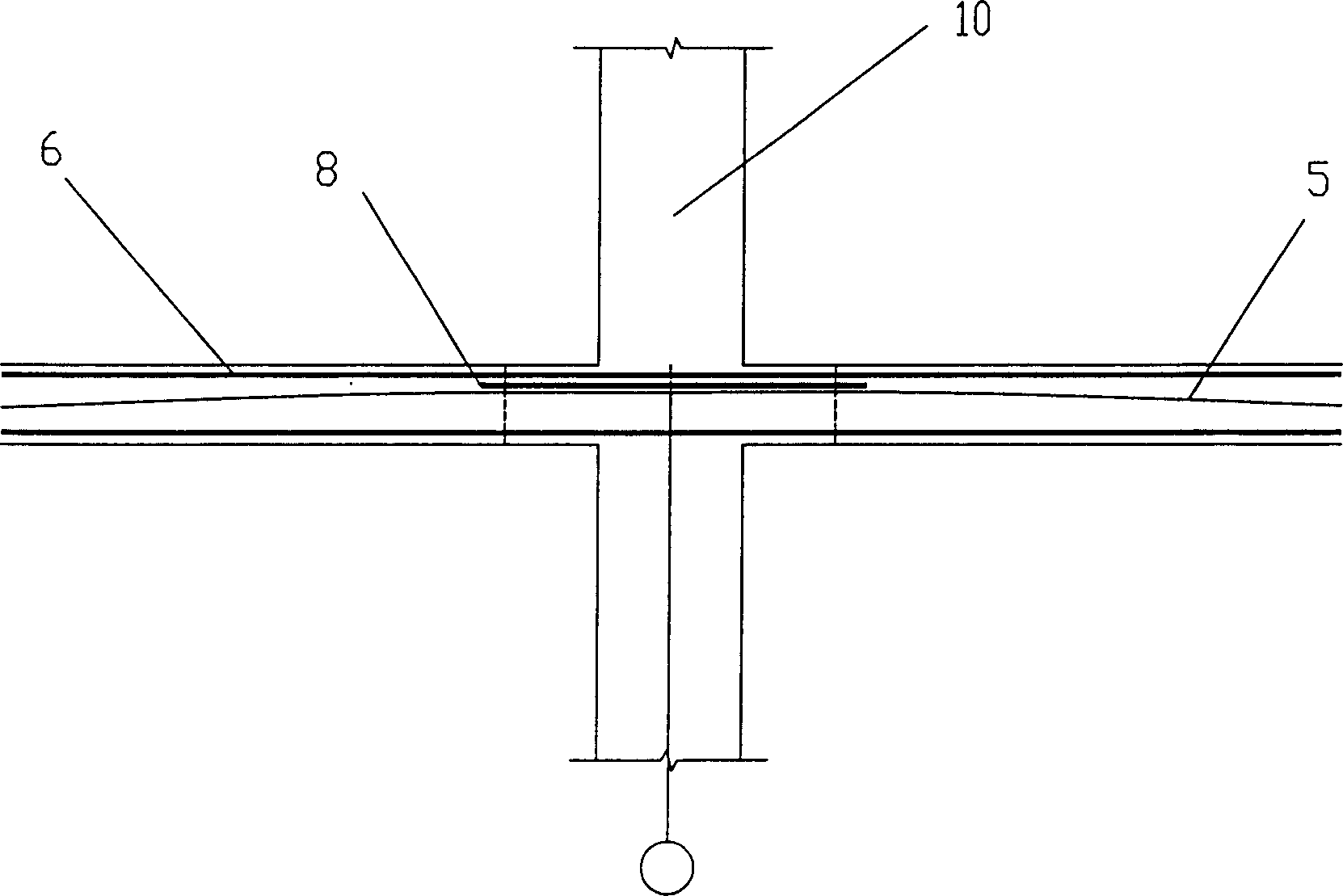

Deep foundation pit retaining wall structure and construction method of underground space structure

The invention provides a deep foundation pit retaining wall structure. The deep foundation pit retaining wall structure comprises a barrel-shaped retaining wall body, a water pipe through from top tobottom is arranged in the barrel-shaped retaining wall body in a poured mode, and the water pipe is provided with a water outlet which is located in the lower end face of the barrel-shaped retaining wall body and a water inlet which is located in the upper end face of the barrel-shaped retaining wall body. By means of the design, on one hand, water can be injected into a soil body located on the lower end face of the barrel-shaped retaining wall body through the water pipe to soften the soil body, so that the purpose of reducing the end resistance of the barrel-shaped retaining wall body is achieved, and then sinking of the barrel-shaped retaining wall body is facilitated; on the other hand, the softened soil body can further facilitate excavation, and the construction progress is improved; moreover, scouring can be carried out on the soil body located below the lower end face by using a method of injecting high-pressure water flow, so that the barrel-shaped retaining wall body sinks by virtue of gravity; and in this way, the purposes of reducing construction procedures, reducing construction noise, shortening the construction period and then reducing pollution to the surrounding environment can be finally achieved. The invention further discloses a construction method of an underground space.

Owner:JIANGXI JIYE SCI & TECH

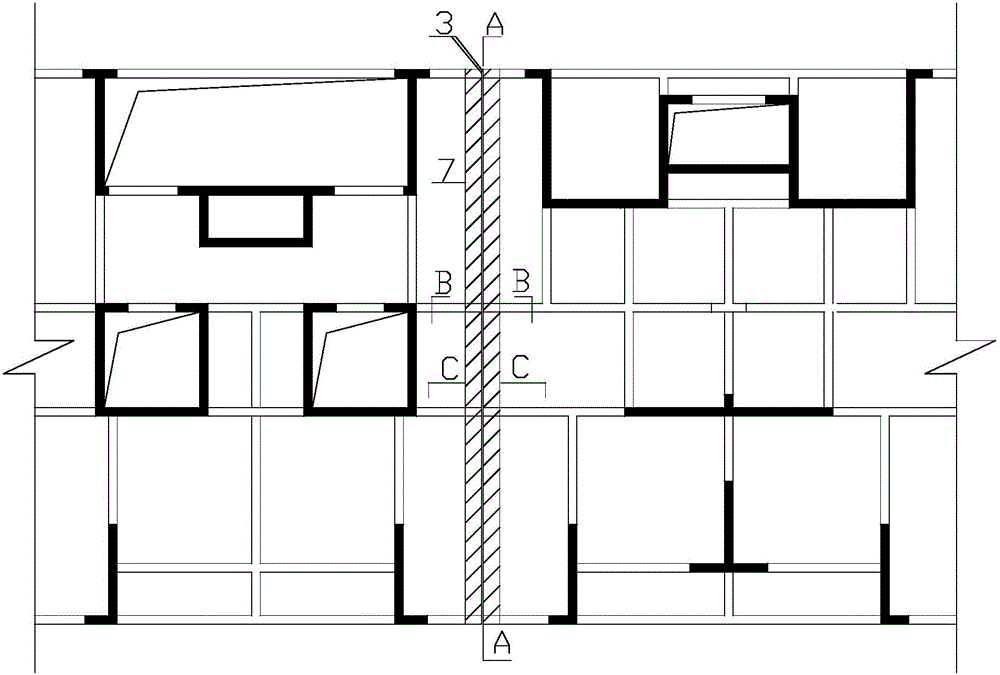

Metro-adjacent complex geological environment supporting system construction method

InactiveCN106592601AAddressing Security ImpactsGuaranteed uptimeExcavationsBasementSupporting system

The invention discloses a metro-adjacent complex geological environment supporting system construction method which comprises the following steps: (1) determining foundation pit positions of a 1# plot basement and a 2# plot basement 2, which are to be established, adjacent to the front side and the back side of a metro test line rail respectively, and then carrying out poured long screw drill pile construction on each pit sideline position every two holes respectively; and (2) symmetrically and simultaneously excavating the 1# plot basement foundation pit and the 2# plot basement foundation pit adjacent to the front side and the back side of the metro test line rail according to layers and sections respectively, and then carrying out prestressed anchor rod construction of corresponding layers, wherein at the depth of a first layer, tops of piles in the same foundation pit are connected together through a top beam, and a circle of brick wall is built on the top of the top beam. With adoption of the method, running safety of a metro is guaranteed to the maximum.

Owner:CHINA CONSTR SIXTH ENG BUREAU CIVILENG +1

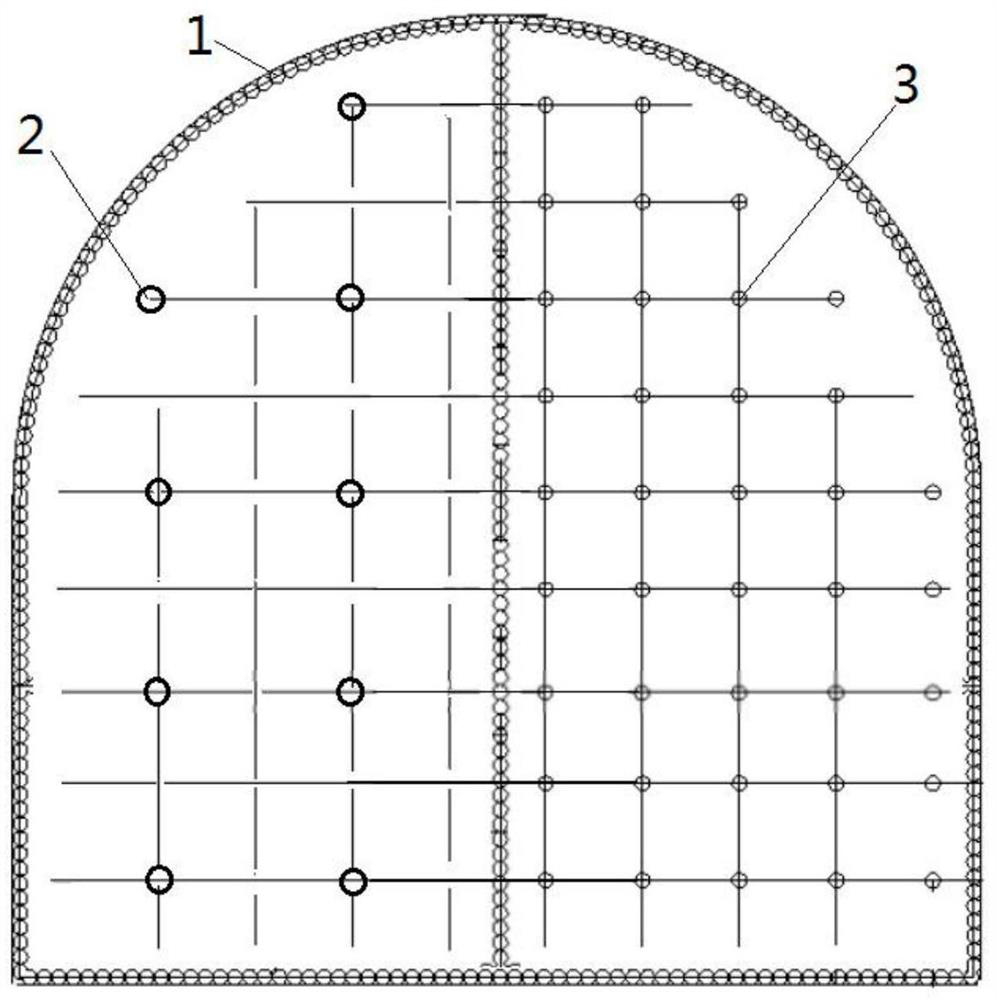

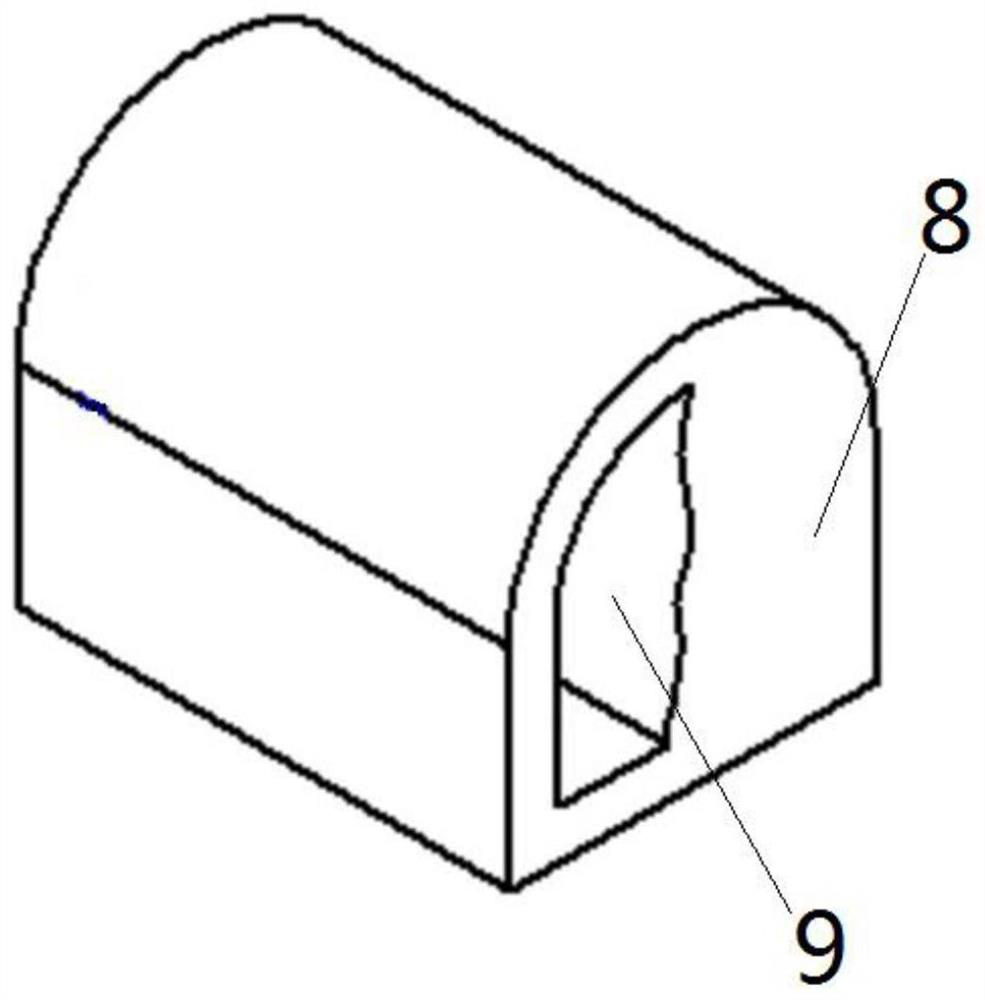

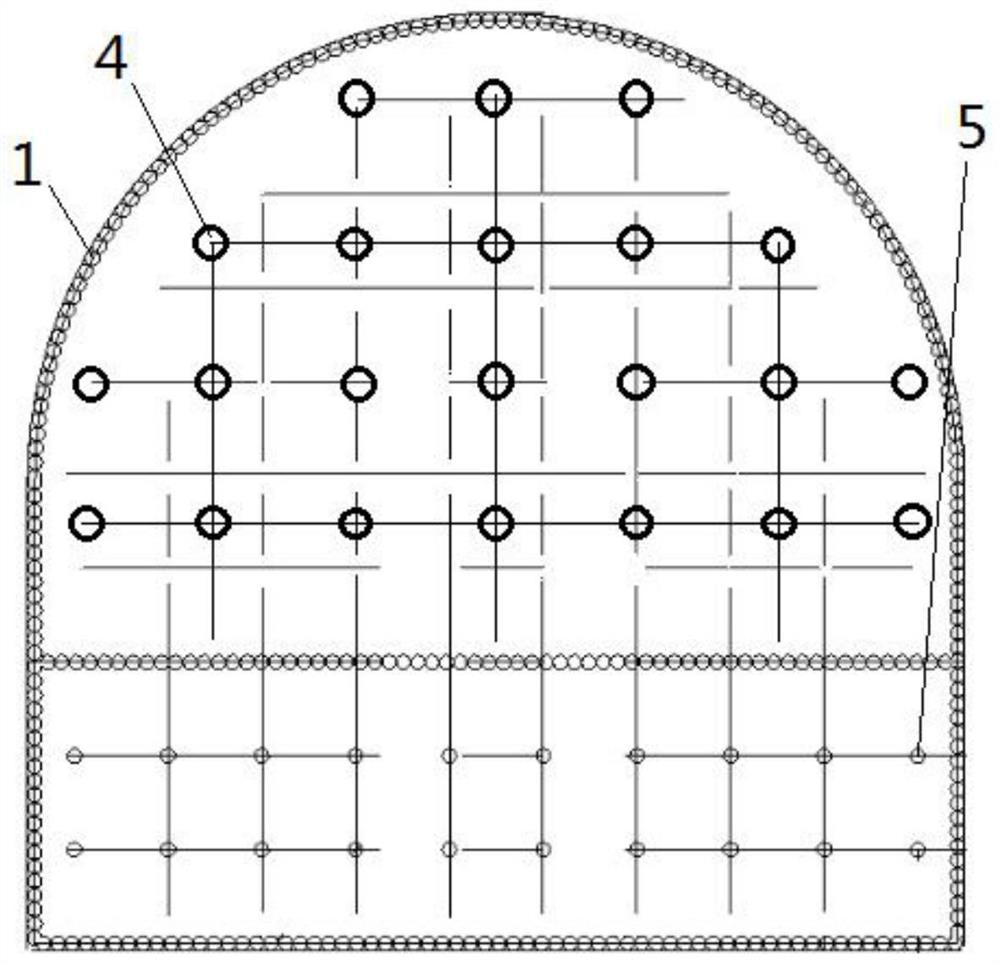

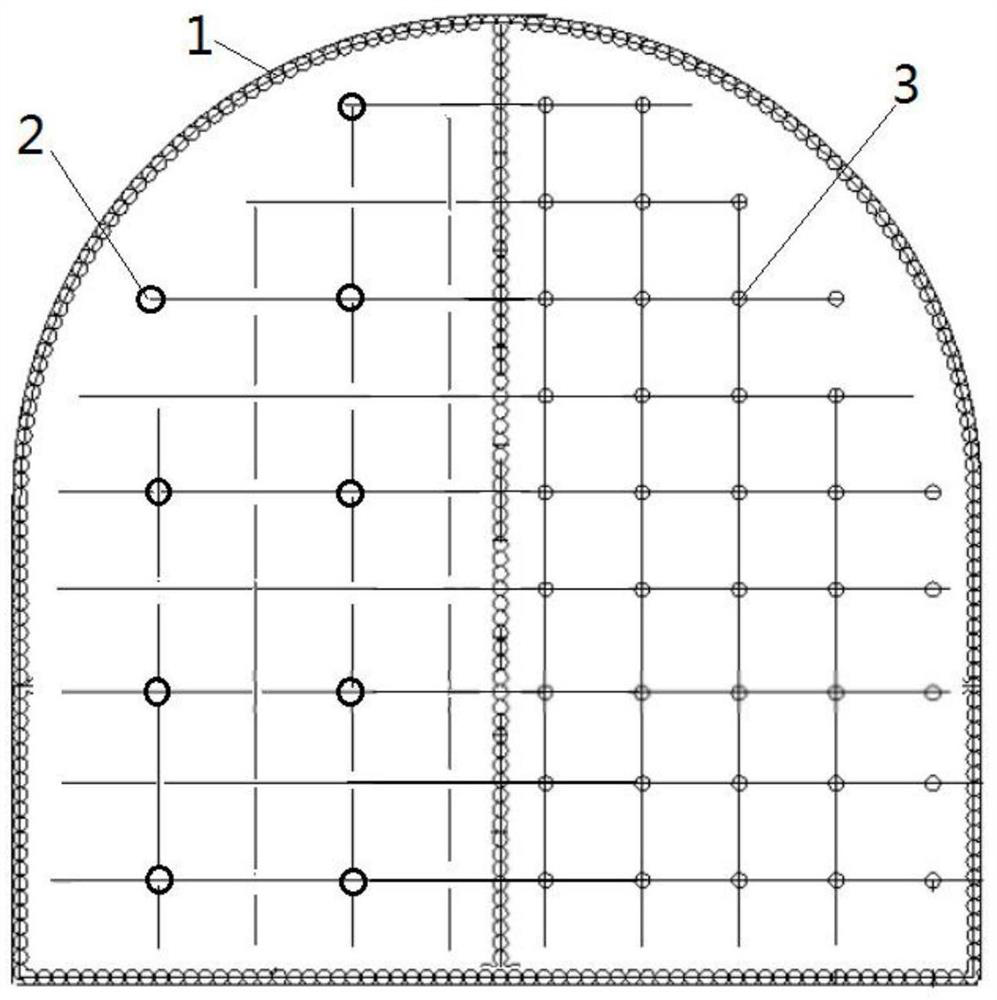

Drilling and splitting excavation construction method

ActiveCN111734421AReduce harmConstruction noise is smallTunnelsStructural engineeringDrilling and blasting

The invention provides a drilling and splitting excavation construction method. The method comprises the steps of drilling an adjacent empty layer hole along the contour line of a tunnel; selecting ahorizontal drilling and splitting excavation scheme or a vertical drilling and splitting excavation scheme or an annular drilling and splitting excavation scheme according to the rock grade differencedistribution condition of a tunnel face, and determining an initial excavation area; making a hole distribution scheme of corresponding split holes according to the rock grade of the drilling and splitting area of the tunnel face; splitting the adjacent empty layer hole and the split holes in the initial excavation area by using a drilling and splitting machine; tunneling the split initial excavation area; and drilling, splitting and tunneling the tunnel face except for the initial excavation area. According to the method drilling and blasting construction is replaced by drilling and splitting construction, so that the construction noise is reduced, the damage to construction personnel is reduced, the construction safety is guaranteed, meanwhile, a reasonable construction sequence is setaccording to the rock grade difference of the tunnel face, and the construction efficiency of drilling and splitting excavation is improved.

Owner:CHINA RAILWAY CONSTR HEAVY IND

A Rapid Construction Method for Embedded Track System

ActiveCN103362036BNovel construction methodReasonable construction methodRailway tracksHardnessPlastic film

The invention discloses a quick construction method of an embedded rail system. The quick construction method comprises the following construction steps: performing construction preparation; paving a template; paving rail plates; casting a mortar layer; performing rail bearing groove pretreatment; welding a steel rail; adjusting the steel rail finely; performing antipollution protection and partitioning the rail bearing groove; casting the rail bearing groove; uniformly stirring high polymer material; casting material to the partitioned rail bearing groove with special equipment; clearing plastic films or adhesive tapes after the high polymer material achieves required hardness; and paving on the surfaces of the top surfaces of the rail plates according to construction requirements. Through being combined with prefabricated rail plates, the quick construction method has the characteristics of being quick in construction, high in efficiency and little in influence on surrounding environment, and is a green and environment-friendly construction method.

Owner:CHENGDU XINZHU ROAD & BRIDGE MASCH CO LTD

A construction method of drilling, splitting and digging

ActiveCN111734421BReduce harmConstruction noise is smallTunnelsArchitectural engineeringStructural engineering

Owner:CHINA RAILWAY CONSTR HEAVY IND

In-site prestressed concrete sandwiched composite beamless floor structure system and construction method

This invention discloses a kind of sandwich and compound beamless slab construction of watering prestress concrete and its constructing method. This construction includes beamless slab body, ribs of inner main and dark slabs and ribs of inner secondary dark slabs with cross arranged. The prestess and stress concrete reinforced bars are arranged in the ribs of main and dark slabs, and the stress concrete reinforced bars are laid out in the upper and lower crust of beamless slab body and in the inner secondary dark slabs with cross arranged. The inner space of the body is stuffed with polystyrene foam sandwich boards. In the job site, first, the form board is propped up and the prestress bars are arranged and stretched and drawn; second, the polystyrene foam sandwich boards should be laid out and fastened and the stress bars are arranged; then the concrete is poured and shaped into the construction, which can satisfy the constructing load-bearing requirements like fireproofing, sound insulation, heat insulation, high-intensity and light quality. Such beamless slab can be used in civilian and various industries construction.

Owner:胡战波

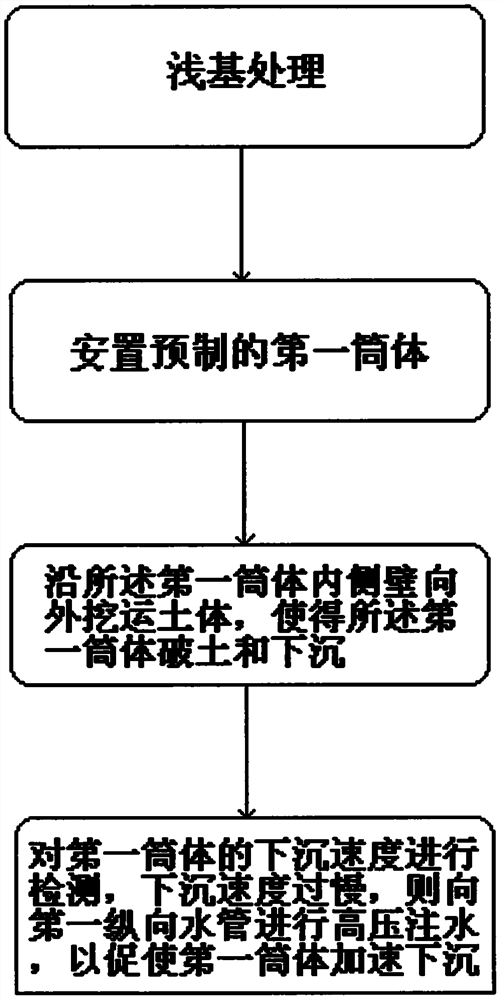

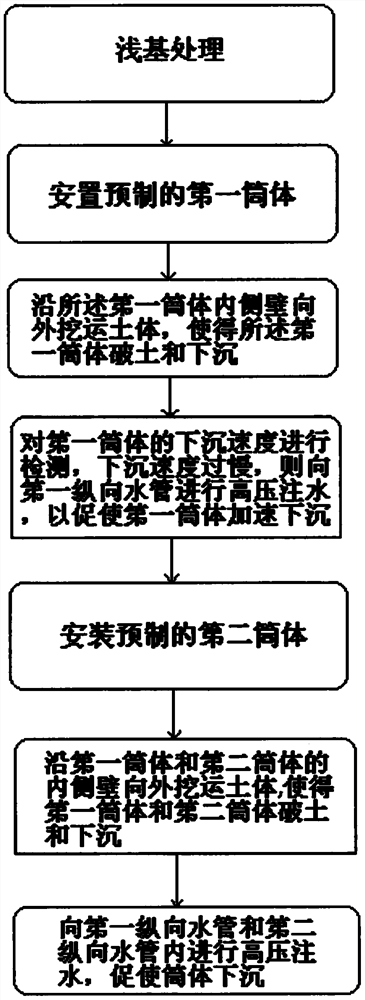

Construction method of cylindrical self-sinking underground space structure

The invention discloses a construction method of a cylindrical self-sinking underground space structure. The construction method comprises the following steps that a, shallow foundation treatment is conducted; b, a prefabricated first cylinder body is longitudinally arranged in place; and c, soil bodies are dug and conveyed outwards from the interior of the first cylinder body along the inner sidewall of the first cylinder body, so that through cooperation of a soil breaking structure and the gravity of the first cylinder body, soil breaking and sinking of the first cylinder body are realized; and a first longitudinal water pipe is provided with a first water outlet located in the bevel edge of the soil breaking structure and a first water inlet located in the upper end face of the firstcylinder body, and the water outlet direction of the first water outlet is vertically downward or downward along the bevel edge. In the execution process of step c, the construction method further comprises the following steps that d, the sinking speed of the first cylinder body is detected, and if the current sinking speed of the first cylinder body is lower than the preset sinking speed, high-pressure water injection is conducted in the first cylinder body, so that high-pressure water flow scours the soil body located at the lower end of the first cylinder body into the first cylinder body,and then the first cylinder body is promoted to sink.

Owner:JIANGXI JIYE SCI & TECH

Grooving tool

InactiveCN105350751AImprove construction efficiencyGrooving speed is fastBuilding constructionsTool bitChisel

The invention discloses a grooving tool which comprises a handle rod and a corresponding tool bit. The tool bit comprises a groove type chisel head connected to the handle rod, and the groove type chisel head is bent towards one side by one angle relative to the axis of the handle rod. The grooving tool is simple and reasonable in structure, convenient to use and high in construction efficiency and construction quality, and the influence on and the damage degree of constructed objects are small.

Owner:张建平

Method of replacing and repairing sewage pipes without excavation

ActiveCN110565779BPrevent collapsePrevent subsidenceSewer pipelinesArchitectural engineeringStructural engineering

The invention relates to a method for non-excavation replacement and repair of sewage pipelines, which includes excavating a well to the depth of the pipeline to be connected, removing the soil at the missing pipeline, leaving a transport space from the well to the pipeline to be connected, and preparing more The section has an inner support with a hollow channel, and the inner support is pushed through the delivery space to the position of the pipe to be connected in turn, the hollow channels of two adjacent inner supports are butted, and the hollow channel of the inner support extends from the shaft to the pipeline to be connected. The new pipeline is transported to the pipeline to be connected through the hollow channel of the inner support, the new pipeline is connected to the pipeline to be connected, the soil is backfilled, the shaft is repaired, and the repair is completed. The invention completes non-excavation repairing of pipelines under the condition of limited road surface space. Compared with large-scale equipment, the construction noise is small, the impact on the surrounding environment is small, and road collapse and settlement are effectively avoided; the damage to the foundation of surrounding buildings is reduced. It solves the interference of traditional excavation construction on residents' lives, and has high social and economic effects.

Owner:苏州市平海排水服务有限公司

A kind of preparation method of lightweight concrete prefabricated slab

ActiveCN105906371BOptimize mix ratioExcellent preparation strengthCeramicwareFoaming agentStone dust

The invention discloses a production method of lightweight concrete prefabricated big panels. The method comprises the following steps: 1, selecting raw materials according to a case that every cubic meter of lightweight concrete prefabricated big panels contains 450-550kg of cement, 65-195kg of stone flour, 3.25-9.75kg of a water reducer and 0.01-0.05kg of a foaming agent, foaming the foaming agent, uniformly mixing cement, the stone flour and the water reducer to prepare a cement mortar, adding the foamed foaming agent to the cement mortar, and uniformly stirring the foamed foaming agent and the cement mortar to prepare lightweight concrete; and 2, pouring the lightweight concrete in a die, and carrying out demolding treatment and curing to produce the lightweight concrete prefabricated big panels. The method solves the problem of adverseness of too large weight of common prefabricated big panels to transportation and hoisting installation, the weight of the lightweight concrete prefabricated big panels produced in the invention is about 50% lower than that of common concrete prefabricated big panels, and the construction efficiency of prefabricated wallboards is effectively increased.

Owner:GUANGDONG PROVINCIAL ACAD OF BUILDING RES GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com