Guide rail type detachable floor

A guide rail type and floor technology, applied in the direction of floors, buildings, building structures, etc., can solve the problems of non-reusable, wood consumption, large and deep, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

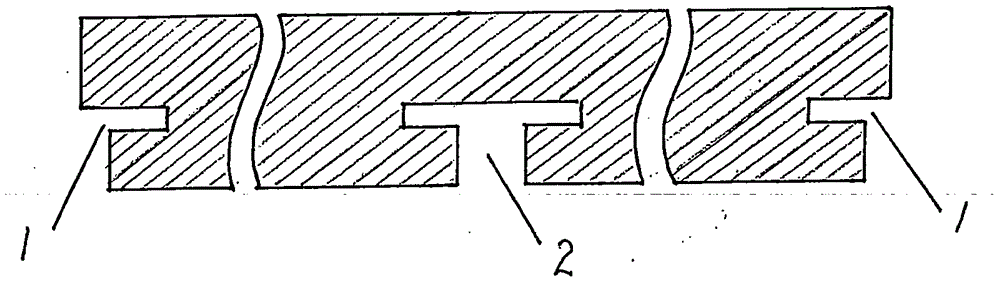

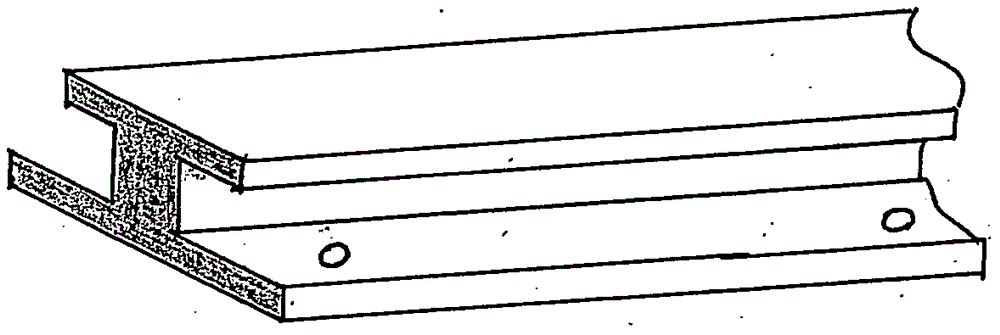

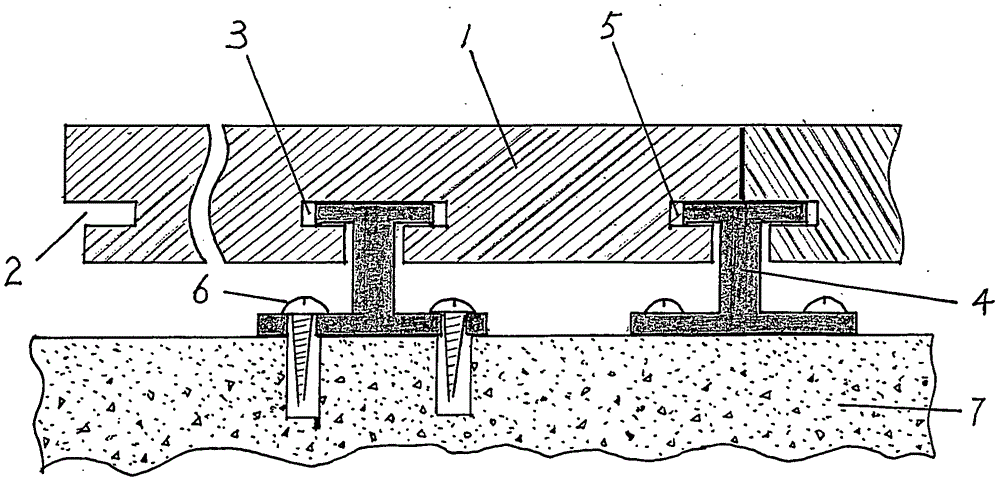

[0012] 1. When assembling, first fix the guide rail on the ground with screws according to the spacing of the floor grooves, and then put the floor into the guide rails in turn; because the spacing of each groove is equal, the floor can also be spliced in the same way as before .

[0013] 2. The length of the guide rail can be spliced, but the interface must be placed under the same floor, that is, it must be staggered with the floor.

[0014] 3. It is necessary to grind and remove the "I" shape at the end of the guide rail near the wall to make it into a "⊥" shape. The length of the grinding is the width of the floor, which is used as the entrance for the floor to enter the guide rail. ( Figure 5 )

[0015] 4. The last sealing floor (1) on the "⊥" shape is fixed by the groove of the adjacent floor and the skirting line (2) on the wall ( Figure 6 ).

[0016] 5. When disassembling, remove the skirting line on the above-mentioned sealed floor first, and then withdraw the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com