Super-long floor concrete post-pouring seam design and construction process

A construction technology, concrete technology, applied in building components, building insulation materials, etc., can solve the problems of weakening the bearing capacity of the floor, seismic performance and temperature stress release function, restraining the temperature stress of the floor concrete, and corrosion of post-cast steel bars , to achieve the effect of shortening the construction period, reducing construction waste and improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The present invention will be further described below in conjunction with accompanying drawing:

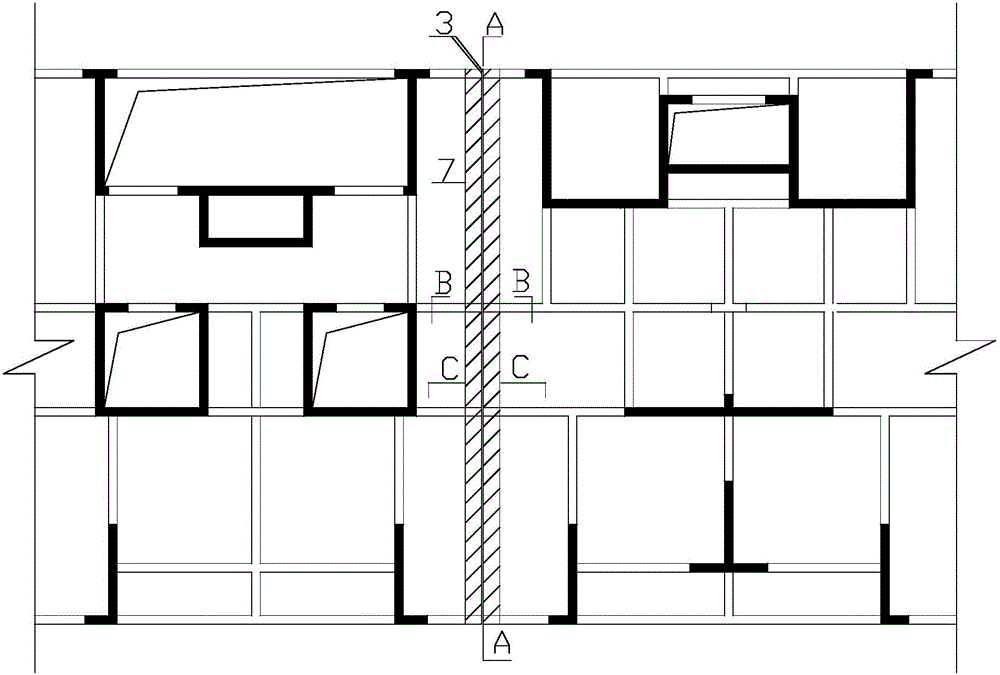

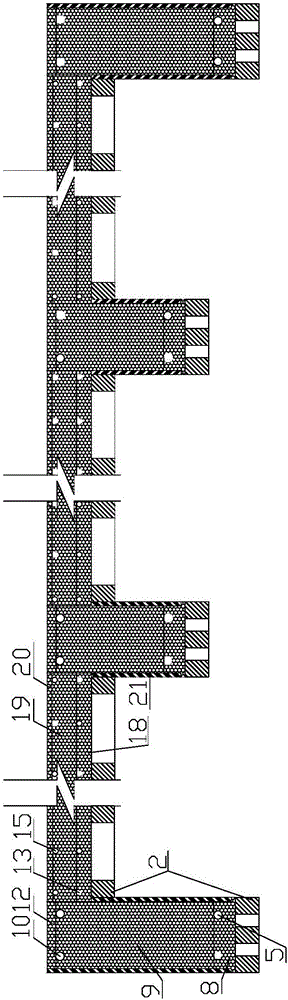

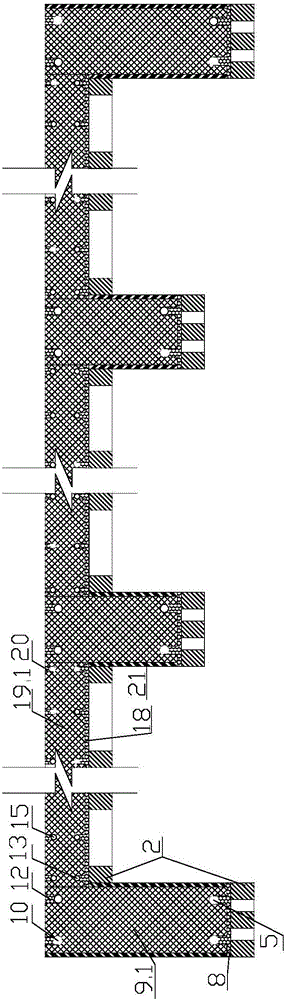

[0053] like Figure 1 to Figure 7 Shown, super long floor concrete post pouring joint design and construction technology of the present invention, take the following steps:

[0054] 1) Determining the edge line of post-pouring joints of beams and slabs: Measured at intervals of 30m to 40m from the edge of the floor, on the square wooden corrugation 2 at the bottom of the beams and slabs within 1 / 3 of the span range close to the beams and slab supports Determine the center line of the post-casting joint 3.1 of the beam and slab with the spring line, and then move parallelly from the center line to both sides by 10mm~15mm respectively to determine the edge line of the post-cast joint of the beam and slab 3;

[0055] 2) Install the beam slab face plate: install the beam slab bottom panel 4 on the beam slab bottom square wood second corrugation 2, and align the edge of the bea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com