In-site prestressed concrete sandwiched composite beamless floor structure system and construction method

A beamless floor and concrete technology, applied in the direction of floor, building, building components, etc., to achieve the effect of balanced force, low cost and low construction noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

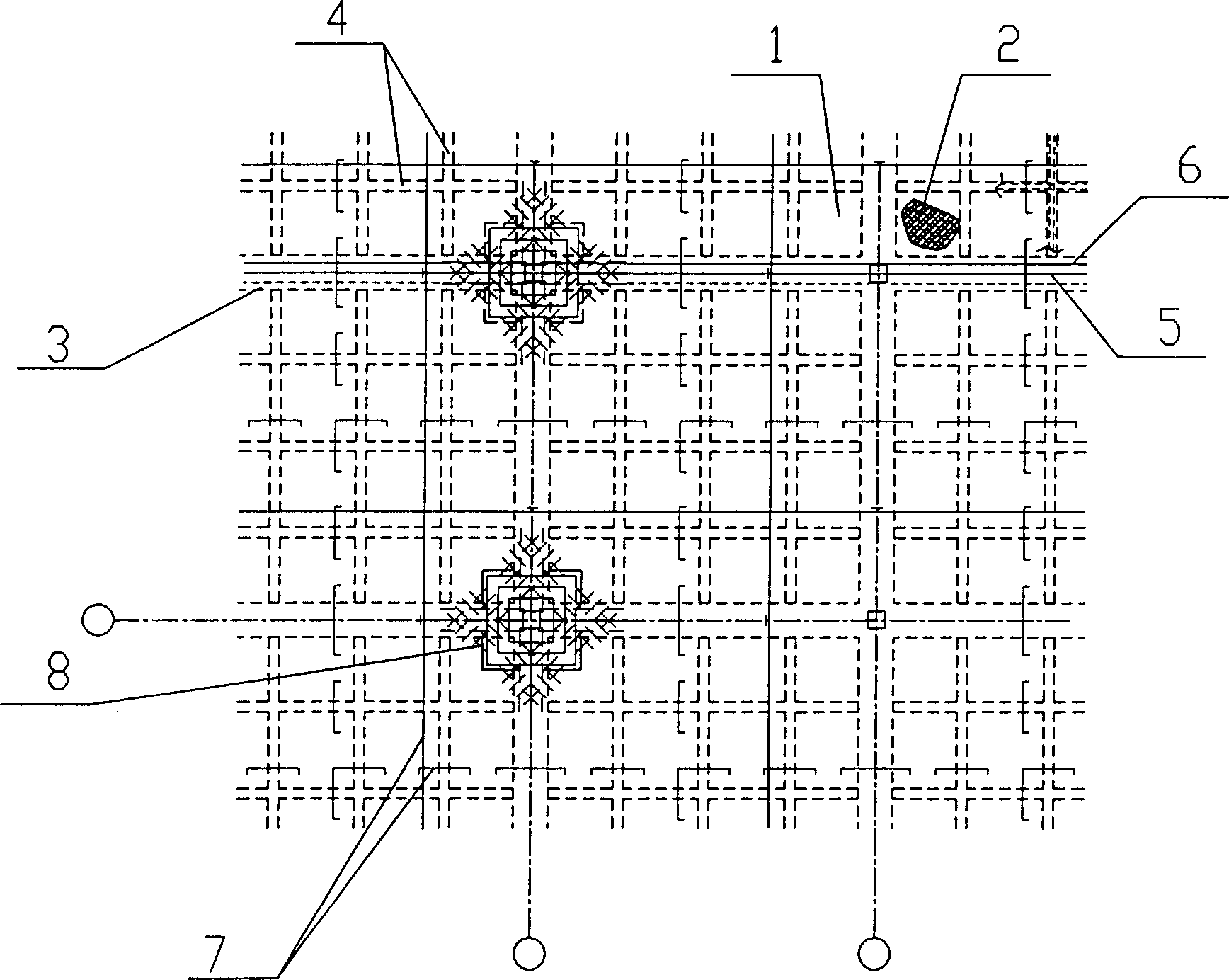

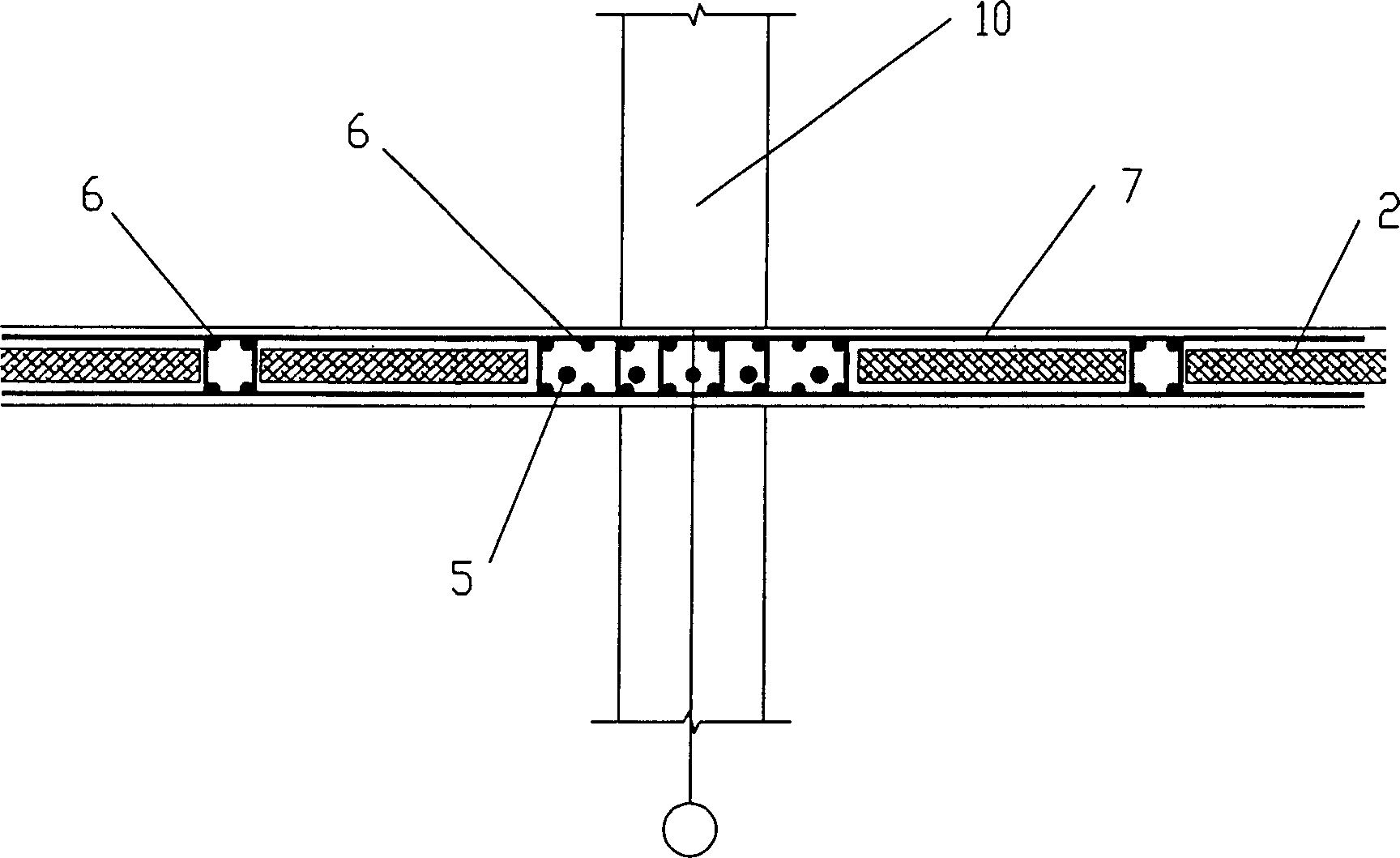

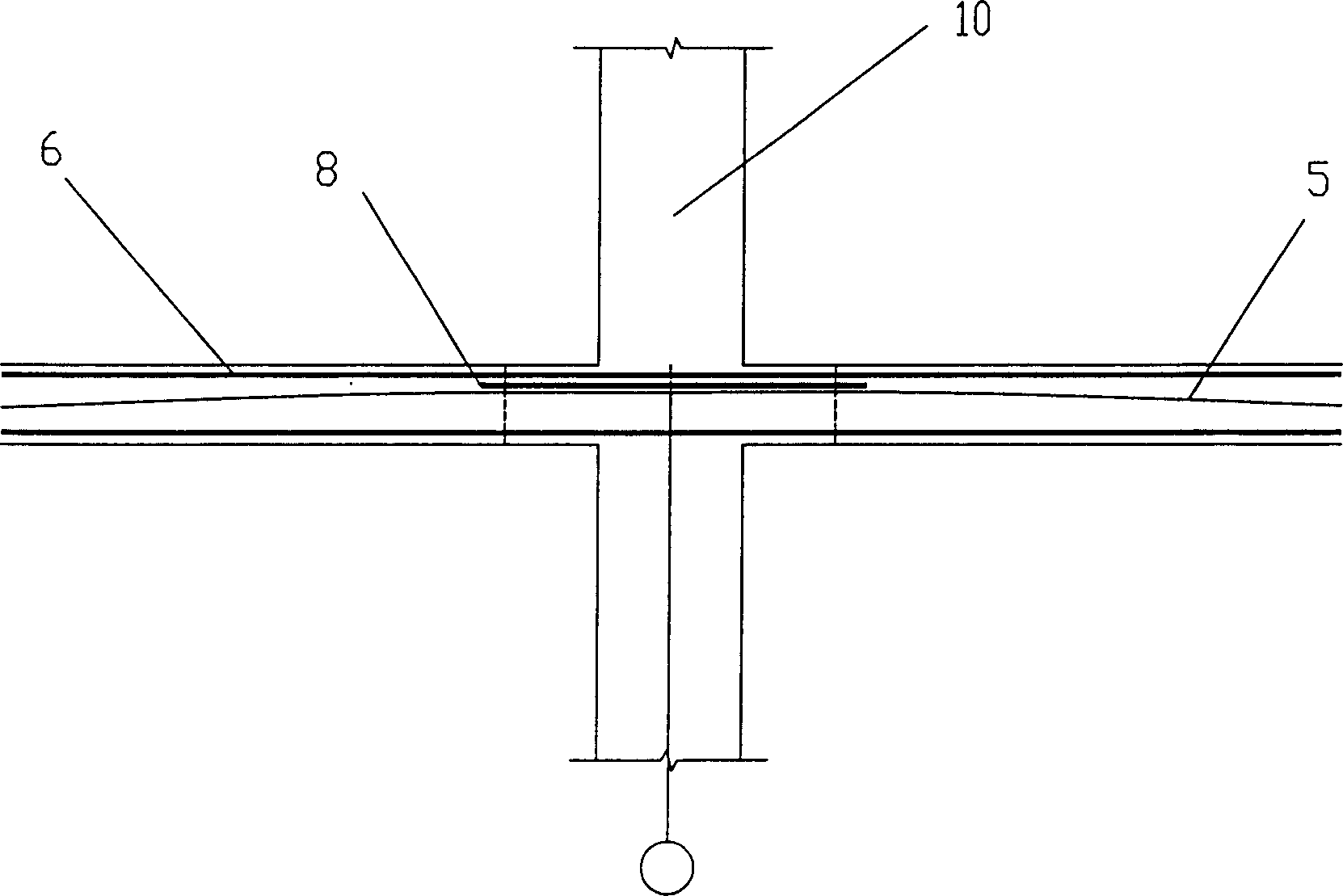

[0018] Such as figure 1 , 2 , 3, the cast-in-situ prestressed concrete sandwich composite beamless floor structure of the present invention includes a beamless floor slab body 1 without exposed beams. The beamless floor slab body 1 is provided with the main dark plate rib 3 in the slab and the secondary dark plate rib 4 arranged in a well-shaped pattern, and the main dark plate rib 3 in the slab is equipped with prestressed steel bars 5 and stressed steel bars 6 , in the upper and lower slab shells of the beamless floor slab body 1 and the secondary dark slab ribs 4 in the slab arranged in a well-shaped pattern, there are reinforced steel bars 7 in the slab, and the main dark slab in the slab of the beamless floor slab body 1 The inner space formed by the plate ribs 3 and the secondary dark plate ribs 4 in the slab arranged in a well-shaped pattern is filled with a lightweight solid plate core 2 . The prestressed steel bar 5 and the stressed steel bar 6 are equipped in the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com