Self-sinking type deep foundation pit barrier wall structure and construction method for underground space structure

A deep foundation pit and self-sinking technology, which is applied in the direction of infrastructure engineering, excavation, caisson, etc., can solve the problems of different frictional resistance, high construction noise, long construction period, etc., to achieve resistance, less construction procedures, and low construction noise Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

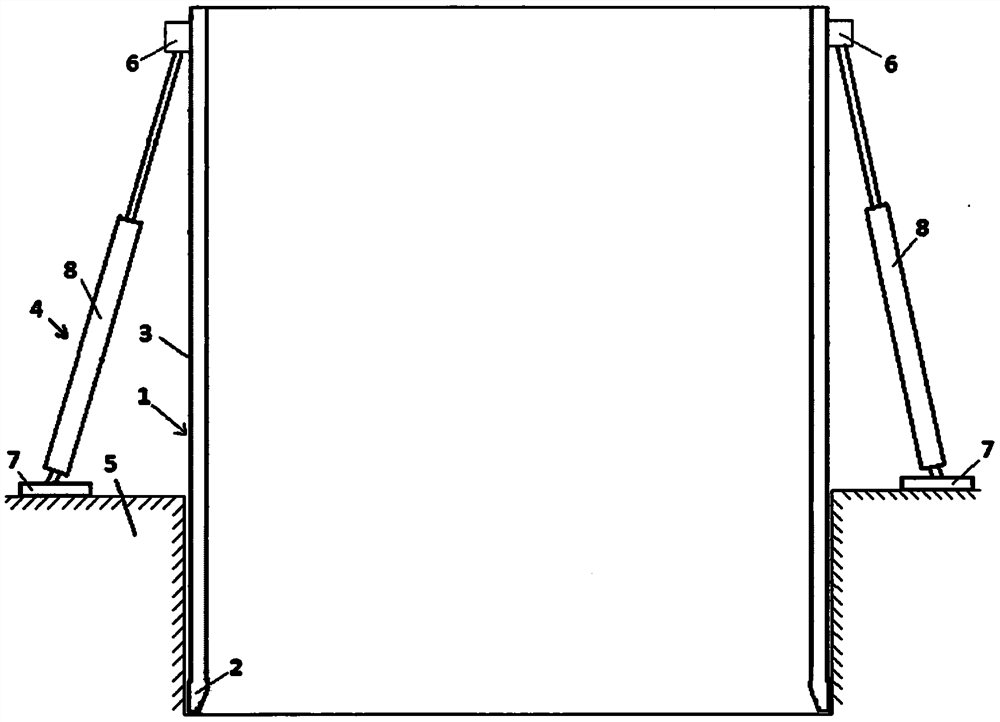

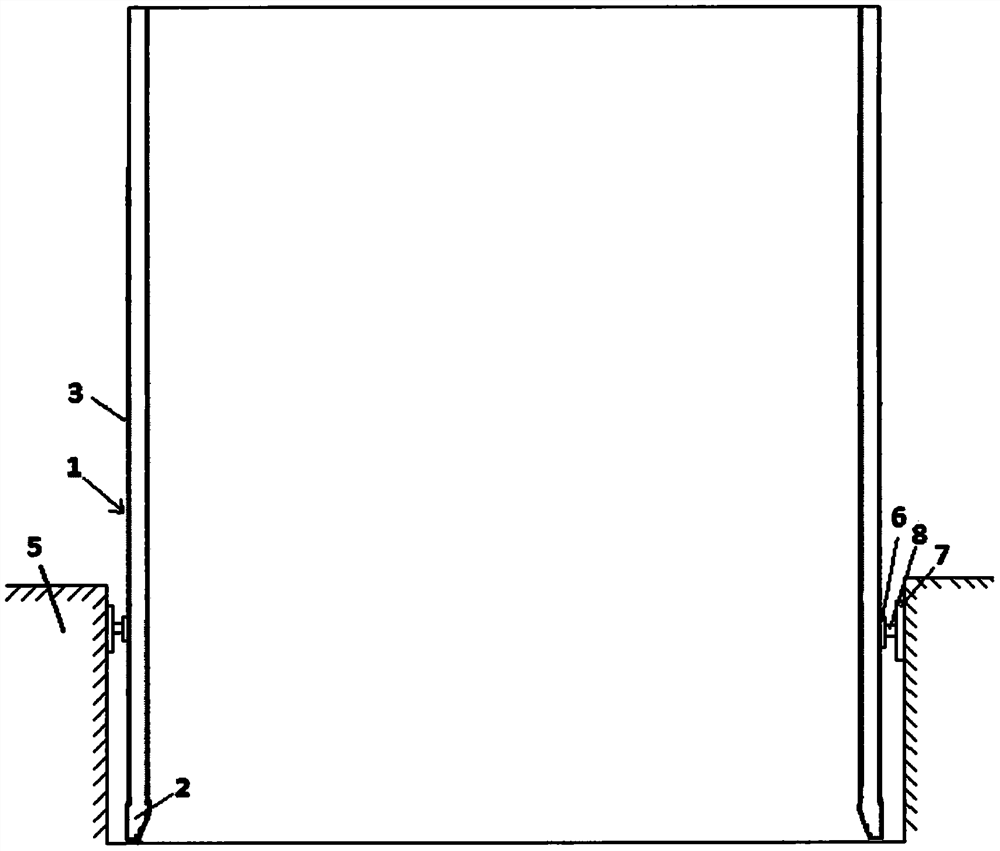

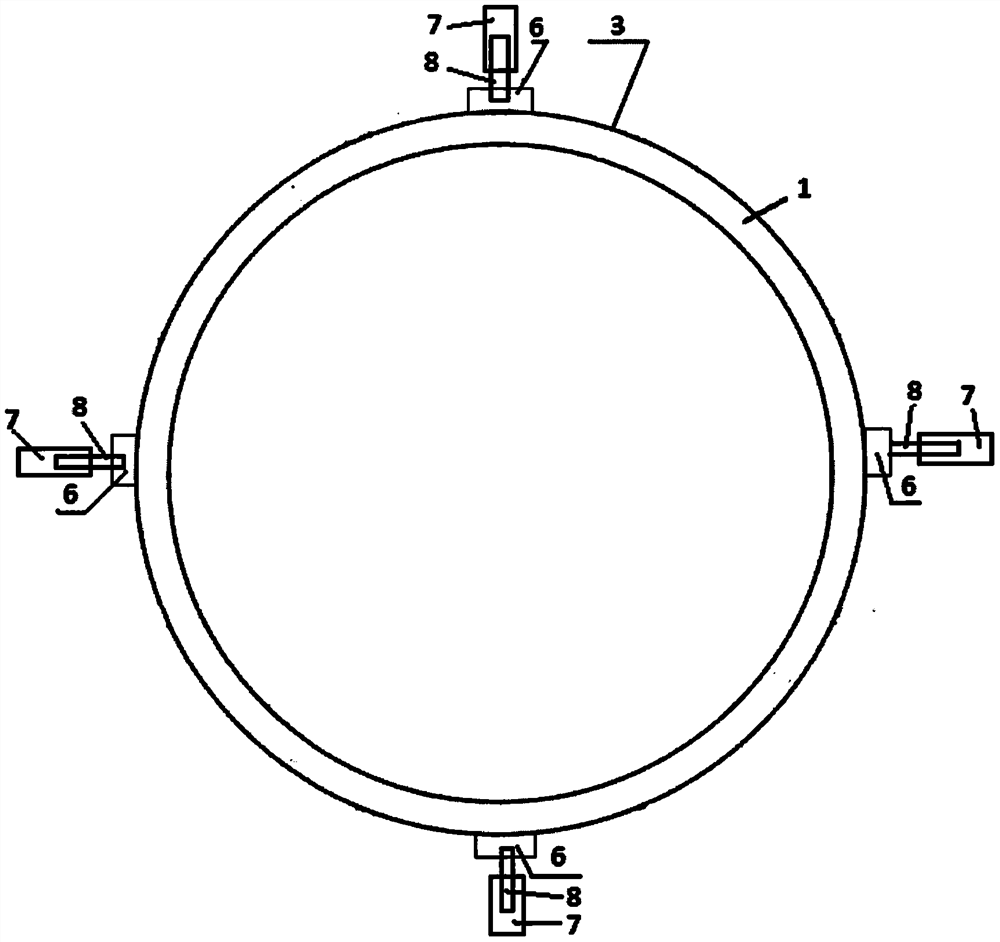

[0043] This embodiment provides a self-sinking deep foundation pit retaining wall structure, such as figure 1 As shown, it includes: a cylindrical retaining wall body 1, wherein a ground-breaking structure 2 is formed on the bottom of the cylindrical retaining wall body 1, and the cylindrical retaining wall body 1 is suitable for passing through the soil-breaking structure 2 and the cylinder The gravity cooperation of the type retaining wall body itself realizes breaking down and sinking; it also includes a resistance increasing device 4 arranged on the outer wall 3 of the cylindrical retaining wall body 1, and the resistance increasing device 4 is used for connecting with the foundation 5 Cooperate to adjust the upward resistance of the foundation 5 to the cylindrical retaining wall body 1 . Wherein, the earth-breaking structure is preferably formed on the inner side of the bottom of the cylindrical retaining wall body with a wedge-shaped edge structure, or a blade foot struc...

Embodiment 2

[0049] Such as Figure 4 As shown, the present invention also provides a construction method for an underground space, comprising the following steps: a. Shallow foundation treatment; b. Installing the first mold body; c. Installing steel bars in the first mold body, and Pour concrete into the first mold to make the first cylinder; the bottom of the first cylinder is formed with a soil-breaking structure (such as figure 1 shown); also includes the following steps: d. setting a resistance increasing device on the outer wall of the first cylinder, wherein the resistance increasing device is used to cooperate with the foundation and adjust the foundation to the first cylinder body upward resistance; e. Excavating soil from the inside of the first cylinder, so that the ground-breaking structure cooperates with the gravity of the first cylinder to break the soil downward, so that the first cylinder The body sinks under the action of its own gravity; at the same time, the resistanc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com