Composite thermal insulation steel skeleton concrete integration construction structure and construction process thereof

A steel-reinforced concrete and composite thermal insulation technology, which is applied to building components, building structures, and on-site preparation of building components, etc., can solve problems such as performance to be improved, complex processes, and many processes, and achieves significant energy-saving effects. The effect of high rate and quiet living environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] Examples see Figure 1-18 , The construction steps of the present invention and the involved building structure:

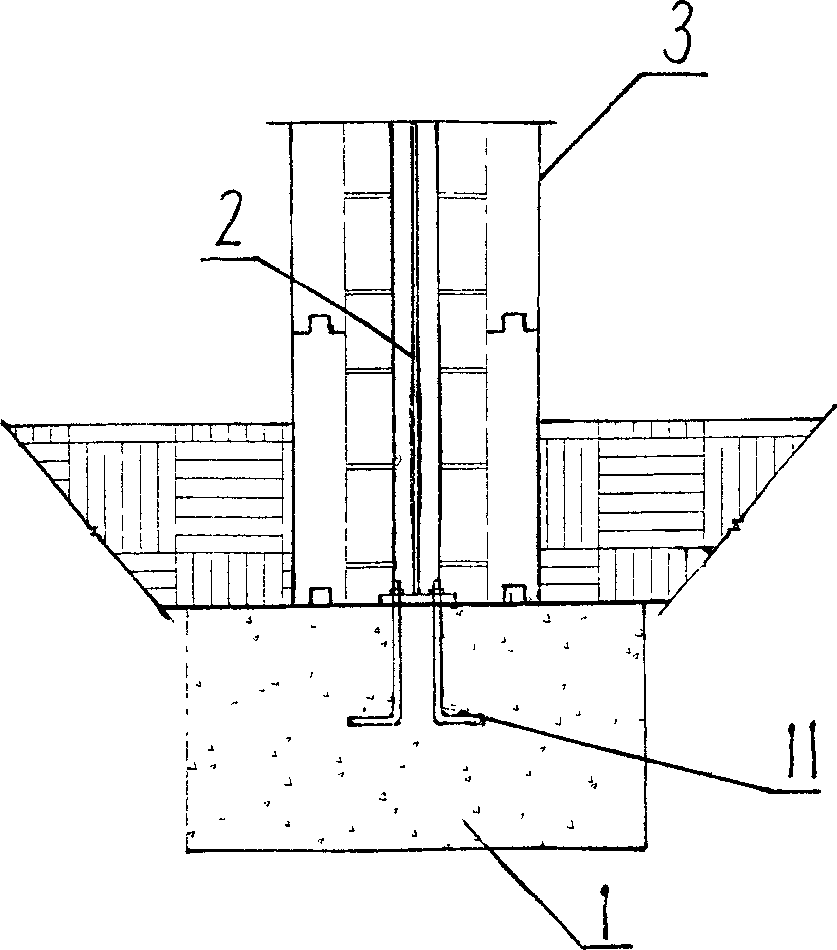

[0059] (1). See figure 1 , The foundation 1 of the present invention should be in the form of a strip foundation, and the width of the foundation surface should be 8 to 10 cm larger than the wall. The steel frame embedded anchor bolts 11 are placed at regular intervals and fixedly connected with the section steel frame 2 in the wall 3.

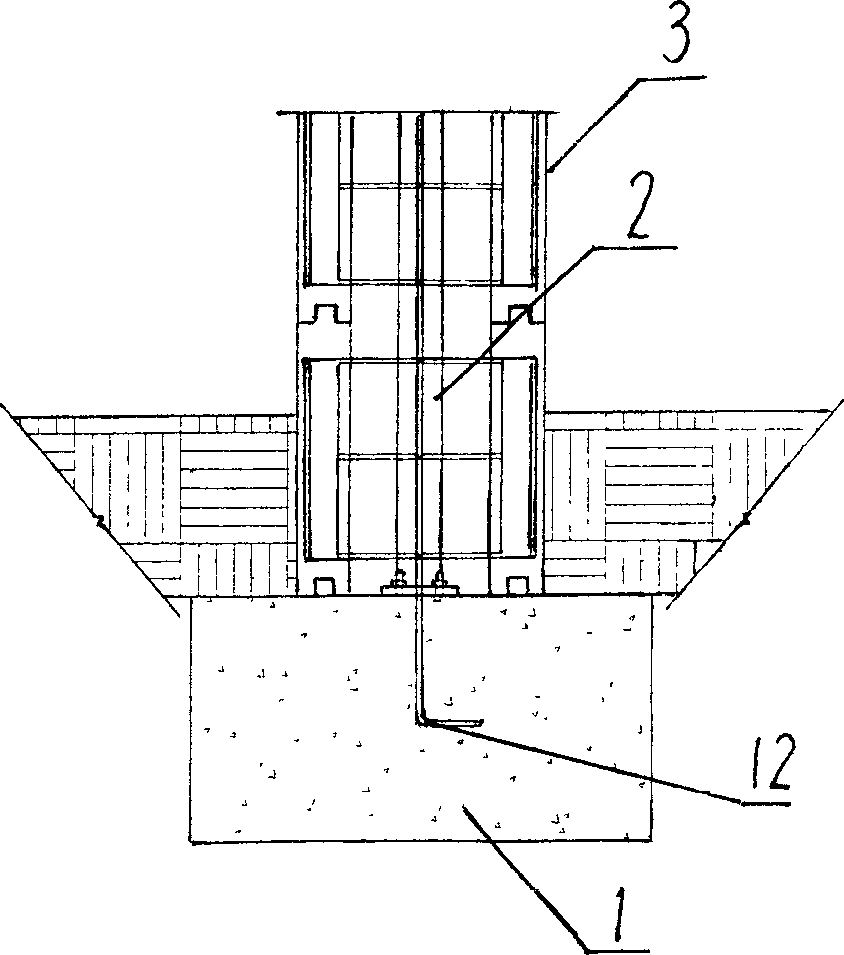

[0060] See figure 2 , The insert bars 12 in the wall 3 can be partially inserted into the foundation 1 and fixedly connected with the foundation 1.

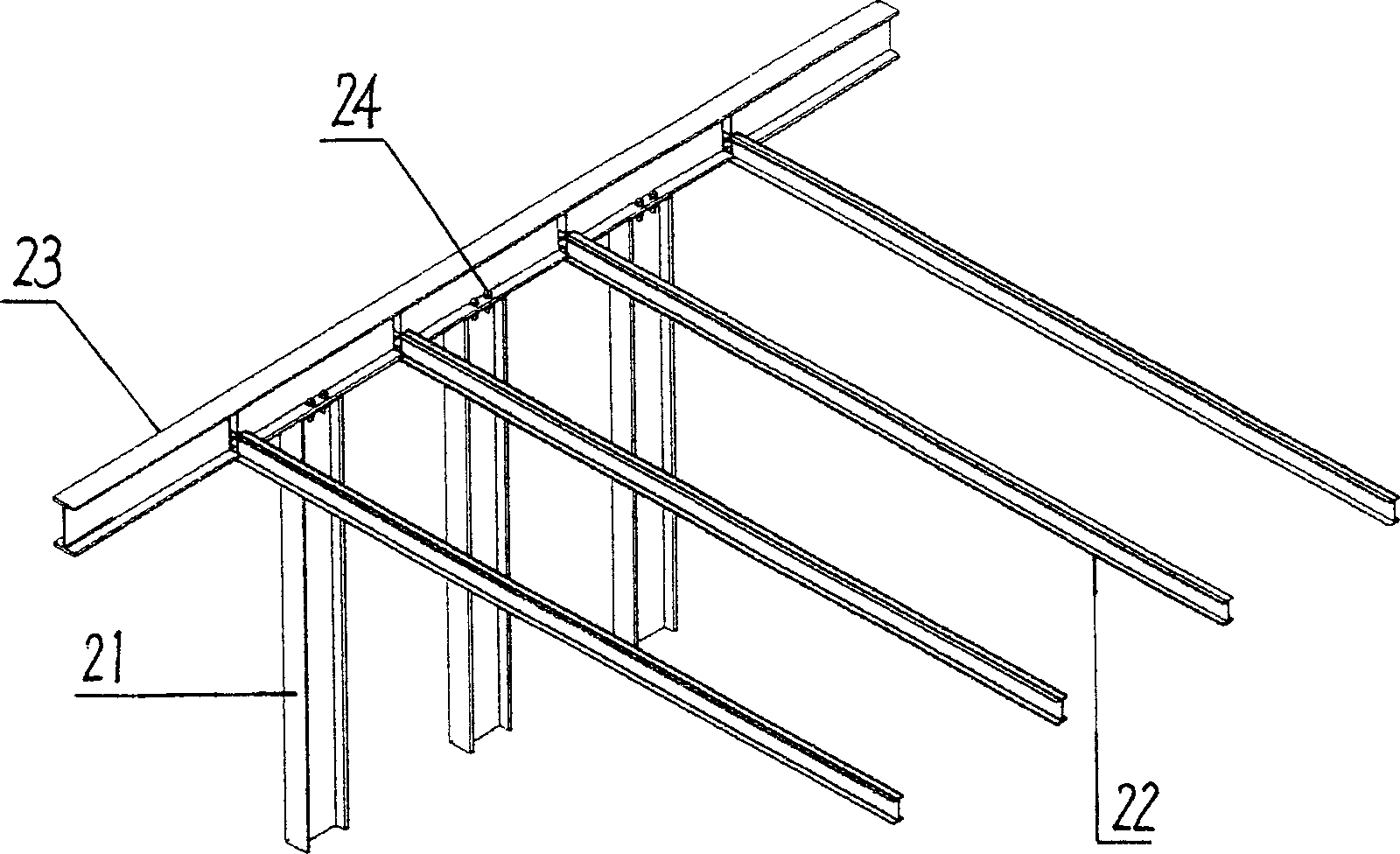

[0061] (2). See image 3 , Assemble the section steel skeleton 2 in the wall and the floor. The section steel skeleton consists of a group of shear wall steel frames 21 distributed longitudinally and consolidated in the concrete wall and a group of floor steel frames distributed horizontally and consolidated in the concrete floor. The bone 22 is fixedly connected to the steel fram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com