Deep foundation pit retaining wall structure and construction method of underground space structure

A technology for deep foundation pits and retaining walls, which is applied in basic structure engineering, underwater structures, excavation, etc., can solve the problems of surrounding environmental pollution, large construction noise, and many construction procedures, shortening the construction period and reducing construction noise. , the effect of reducing the construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

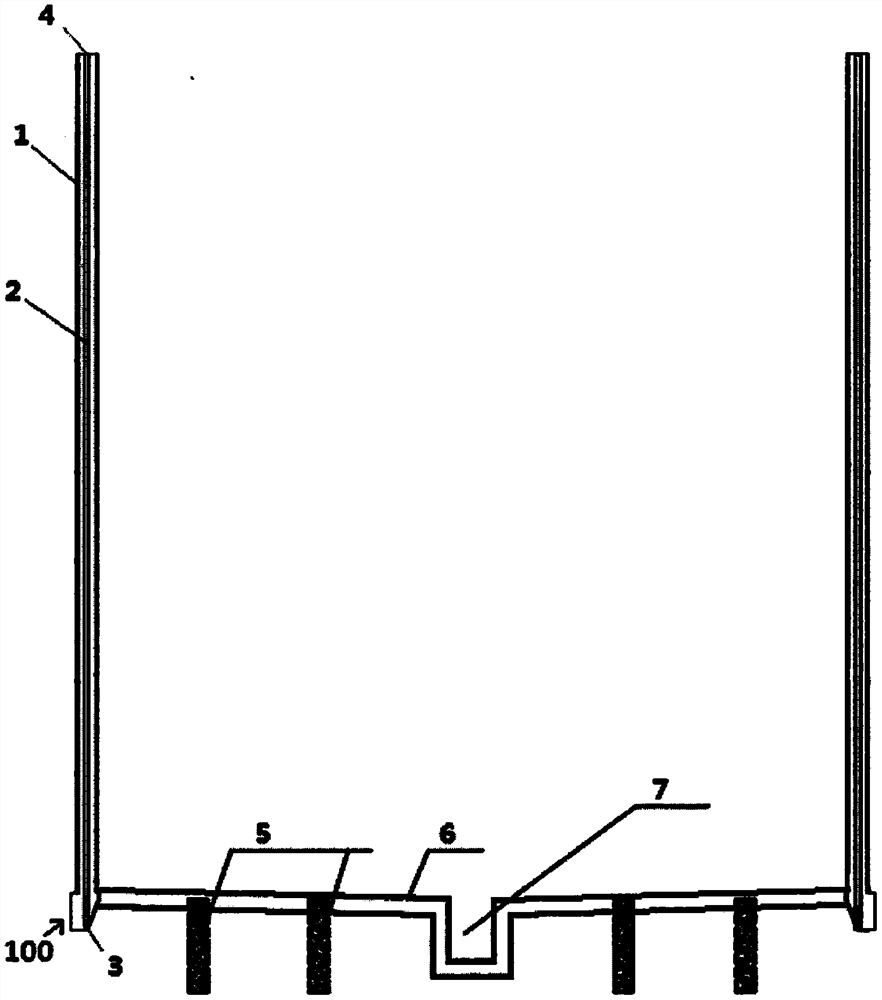

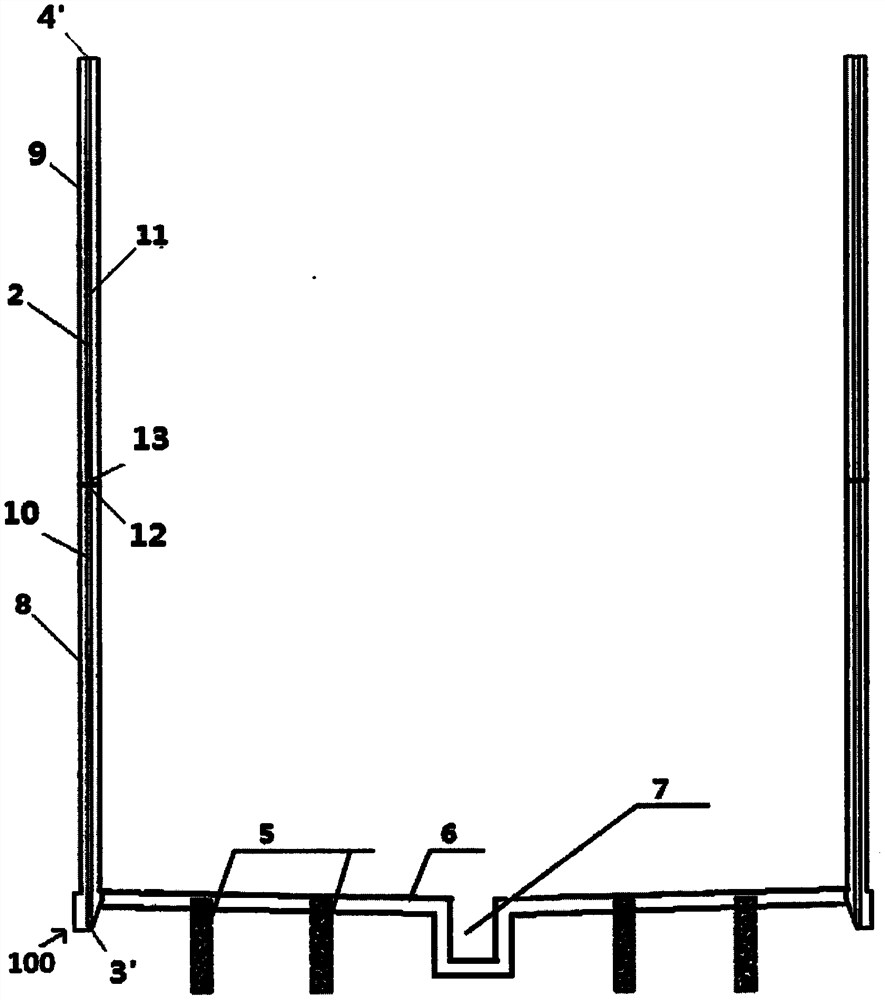

[0045] This embodiment provides a deep foundation pit retaining wall structure, as one of the implementation methods, such as figure 1 As shown, it specifically includes: a cylindrical retaining wall body 1, wherein a ground-breaking structure 100 is formed on the bottom of the cylindrical retaining wall body, and the cylindrical retaining wall body 1 is suitable for passing through the soil-breaking structure 100 and its own gravity. Cooperate to realize downward breaking and sinking; the cylindrical retaining wall body 1 is poured with a water pipe 2 that penetrates up and down, and the water pipe has a water outlet 3 located on the lower end surface of the cylindrical retaining wall body, and a The water inlet 4 on the upper end surface of the cylindrical retaining wall body 1 . In addition, it also includes a base plate 6 poured at the bottom of the retaining wall structure of the deep foundation pit and connected to the cylindrical retaining wall body. The base plate 6 ca...

Embodiment 2

[0052] The present invention also provides a construction method for an underground space, comprising the following steps:

[0053] a. Shallow foundation treatment;

[0054] b. Install the first phantom;

[0055] Among them, also include:

[0056] c. Install steel bars and first water pipes in the first mold, and pour concrete into the first mold to make the first cylinder; the bottom of the first cylinder is formed with a broken earth structure; the first cylinder A water pipe has a first water outlet located on the lower end surface of the first cylinder, and a first water inlet located on the upper end surface of the first cylinder;

[0057] d. Excavate the soil from the inside of the first cylinder, so that the gravity of the ground-breaking structure and the first cylinder cooperates to break the soil downwards, and pass through the first pipe of the first water pipe. The water inlet injects high-pressure water into the first cylinder, so that the high-pressure water j...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com