Vehicle pneumatic tyre

A technology for pneumatic tires and vehicles, applied in vehicle parts, tire parts, tire treads/tread patterns, etc., can solve problems such as movable instability, avoid edge involvement effect, large edge length, reduce noise The effect of emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

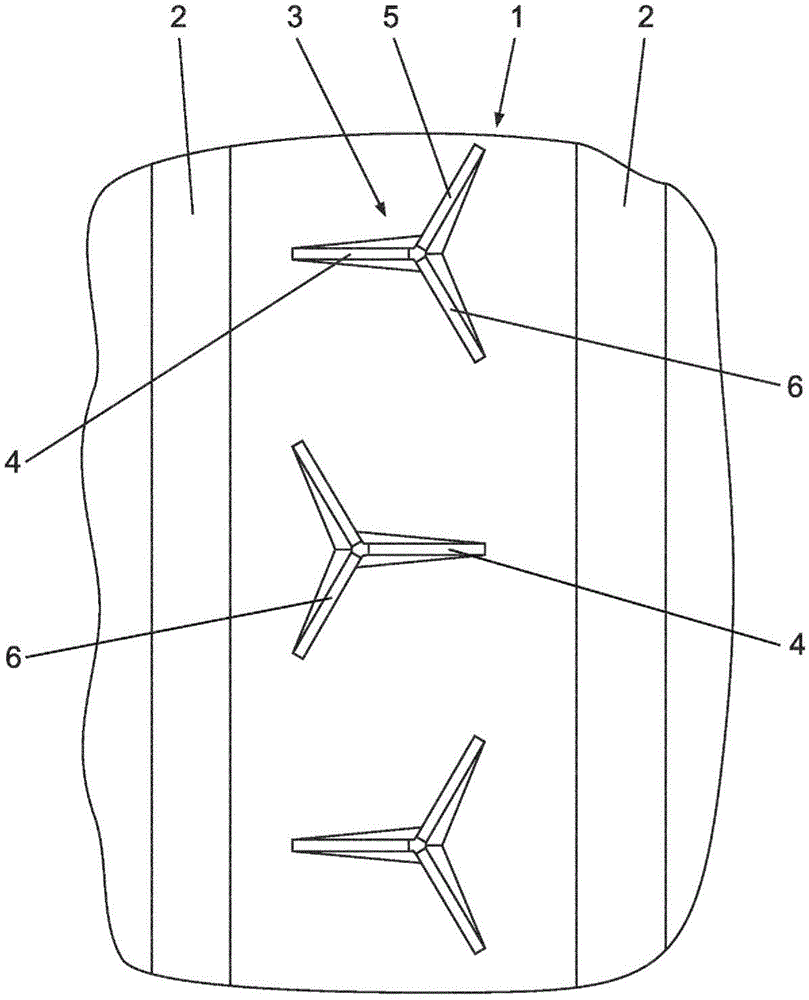

[0027] figure 1 A tread band 1 of a tread pattern of a pneumatic vehicle tire for passenger cars is schematically shown in a radial configuration. exist figure 1 The tread strips 1 shown in may have the usual widths for tread strips in the tread of passenger car tires in the order of 18 mm to 36 mm and each have a wide circumferential groove running straight around in the circumferential direction 2 defines that further ribs, not shown and indicated in detail and which may be, for example, tread bands and / or rows of blocks, are connected laterally or axially to the circumferential groove . In the following description, "depth", "tread depth" and similar expressions are respectively understood as the distance measured in radial direction between the surface of the tread 1 and the mentioned position (e.g. a groove base). distance between. The deepest position of these circumferential grooves 2 lies in the maximum tread depth set for the tread in question, which is usually ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com