Vibration damper for a motor vehicle and a method for producing a press fit between a damper inner tube and at least one separating plate

A vibration damper, motor vehicle technology, applied in shock absorbers, vehicle components, liquid shock absorbers, etc., can solve problems such as noise emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

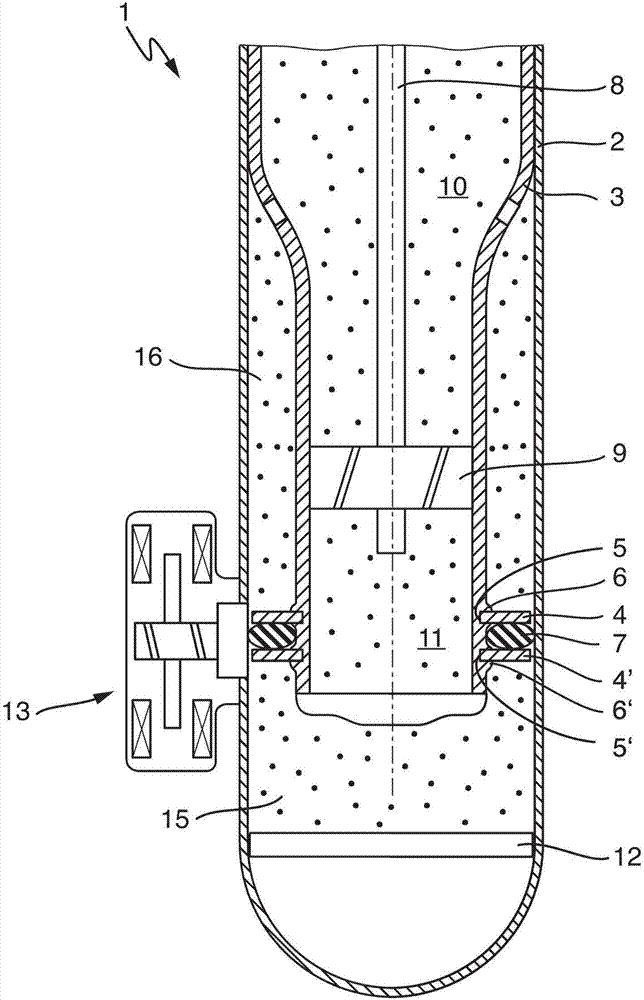

[0035] exist figure 1 , schematically shows a longitudinal section of a vibration damper according to the prior art. The vibration damper 1 has an outer damper tube 2 in which an inner damper tube 3 is arranged. A piston rod 8 capable of reciprocating axial movement is arranged in the damper inner tube 3 , and a working piston 9 is arranged on the piston rod 8 . The working piston 9 separates a working chamber 10 on the piston rod side from a working chamber 11 remote from the piston rod. A release piston 12 is arranged at the end in the damper outer tube 2 . The damper inner tube 3 has at one end a segmentally reduced outer diameter of which the outer diameter of the damper inner tube is reduced. In the region of the segmental reduction of the outer diameter, the two retaining rings 14 , 14 ′ are arranged coaxially in two grooves provided for this purpose on the damper inner tube side of the damper inner tube 3 . In the region between the recesses two separating plates 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com