Impingement system in drying section of paper machine or like

A technology of impact system and paper machine, which is applied in the direction of paper machine, dryer department, paper making, etc., and can solve the problem that it cannot be installed on the base normally

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

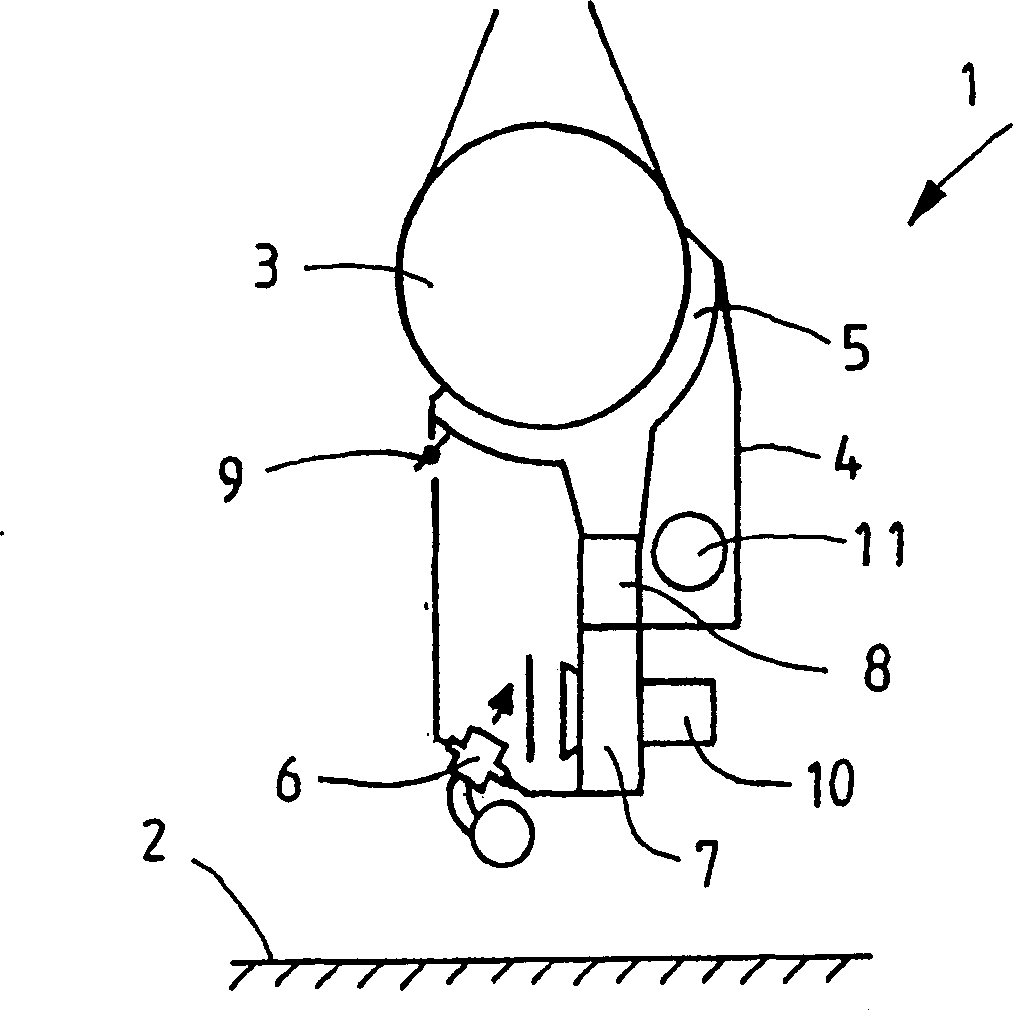

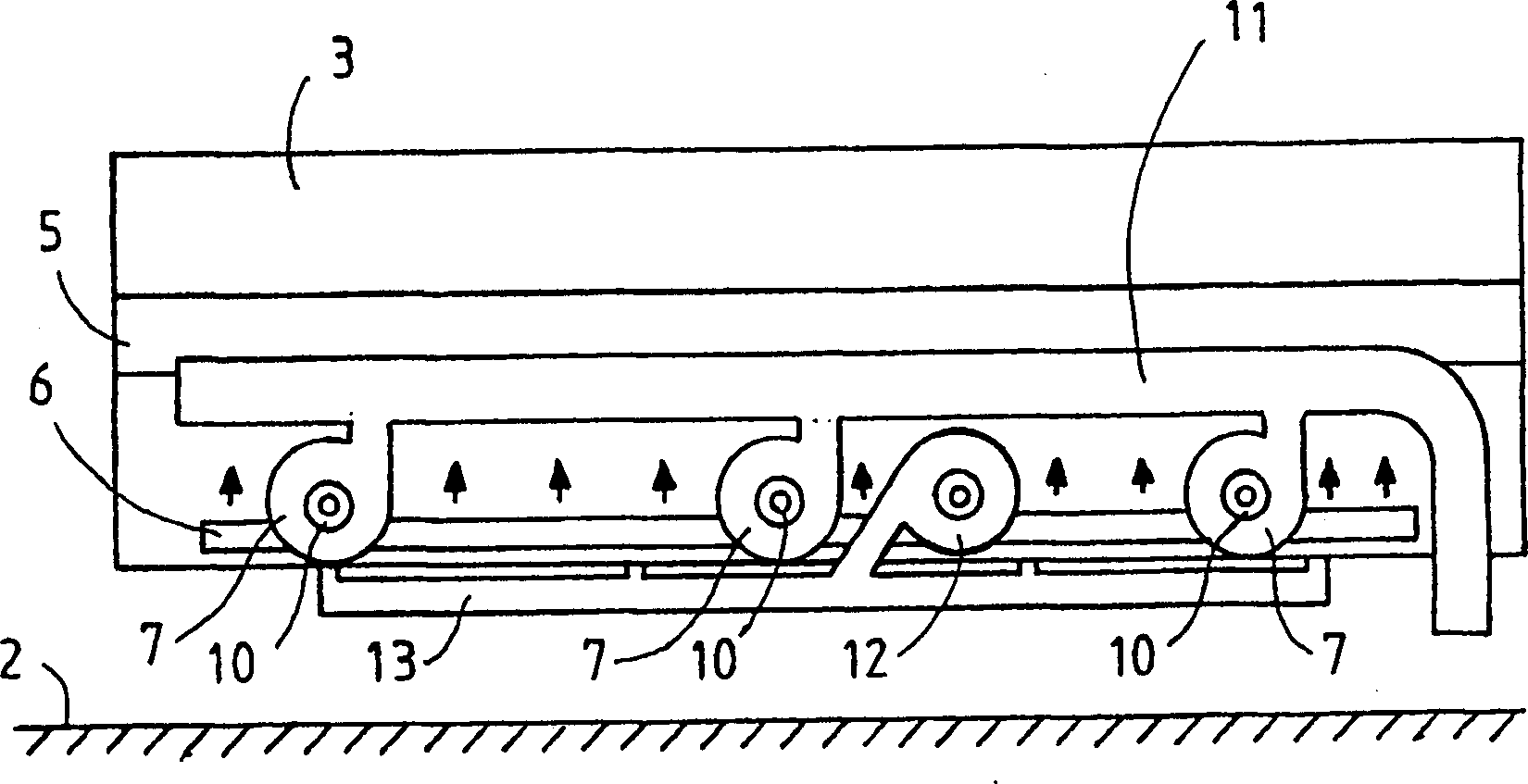

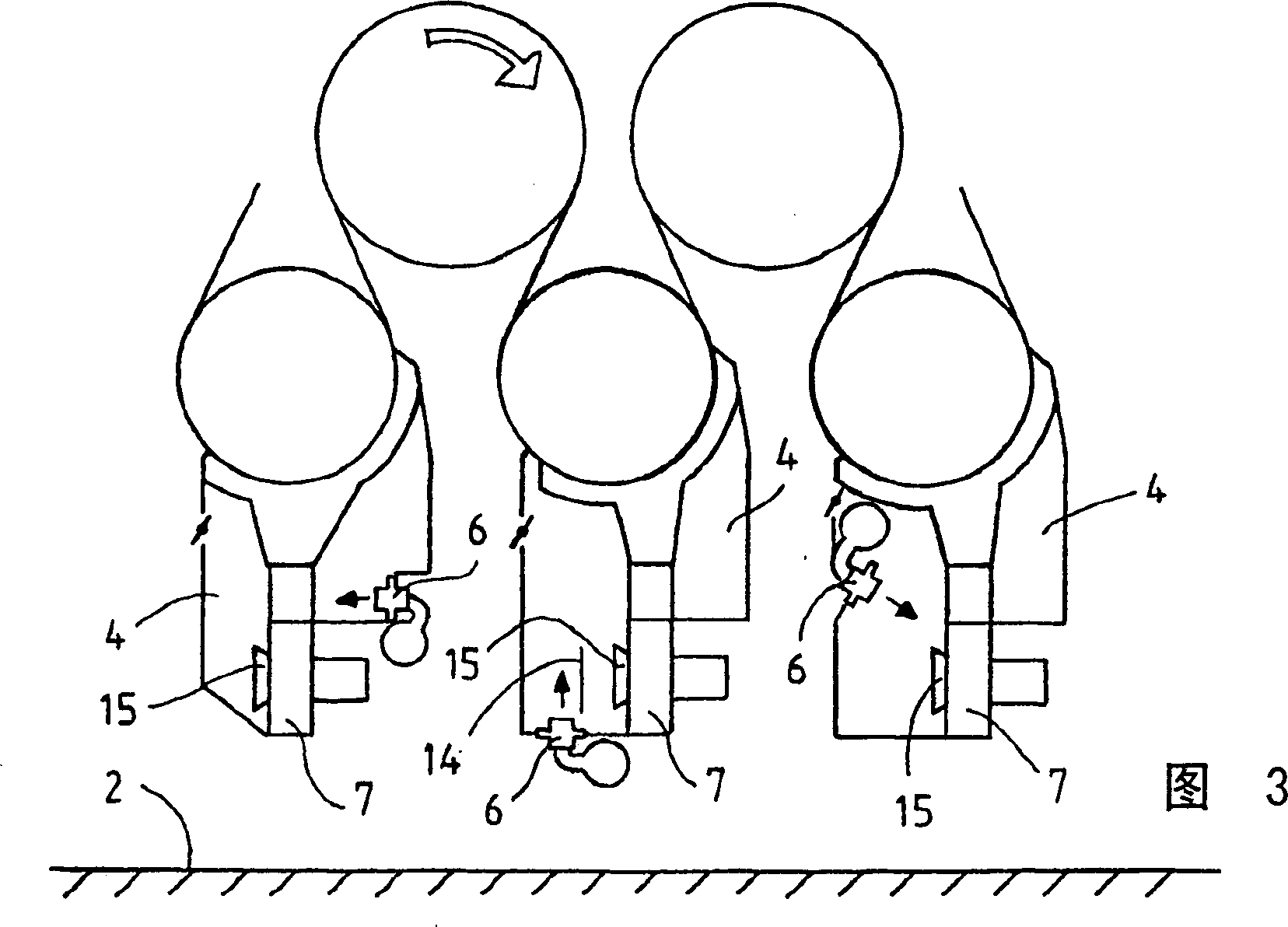

[0030] figure 1 The number 1 in the figure indicates the air impingement system of the present invention located in the bed space below a paper machine, and the floor of the bed space is indicated by the number 2 . The diameter of the drying roll 3 is in many cases about 1.5 m, ie about 1.5-2 m, and the height of the bed space below the paper machine is usually 5-8 m. The air impingement system comprises a hood 4 located mainly below the drying roll 3, but on the rear side of the drying roll 3, so that the shredded paper can fall freely. Shredding causes web interruptions, but usually it only causes quality deviations which are also harmful. The cover 4 is at most 5m high, preferably only 1.5-2.5m high. The area over which the cover covers the drying roller should be at least no greater than 180° so that the cover can be removed from its working position when required, in particular without using any troublesome mechanisms. This is why it is recommended that the maximum cov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com