Automatic ignition system of chlorine hydride synthesis furnace and control method of automatic ignition system

An automatic ignition and synthesis furnace technology, applied in chlorine/hydrogen chloride, combustion ignition, combustion method and other directions, can solve the problems of complex hydrogen chloride synthesis conditions, erosion, strong corrosiveness, etc., to improve the ignition success rate and improve safety performance , compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

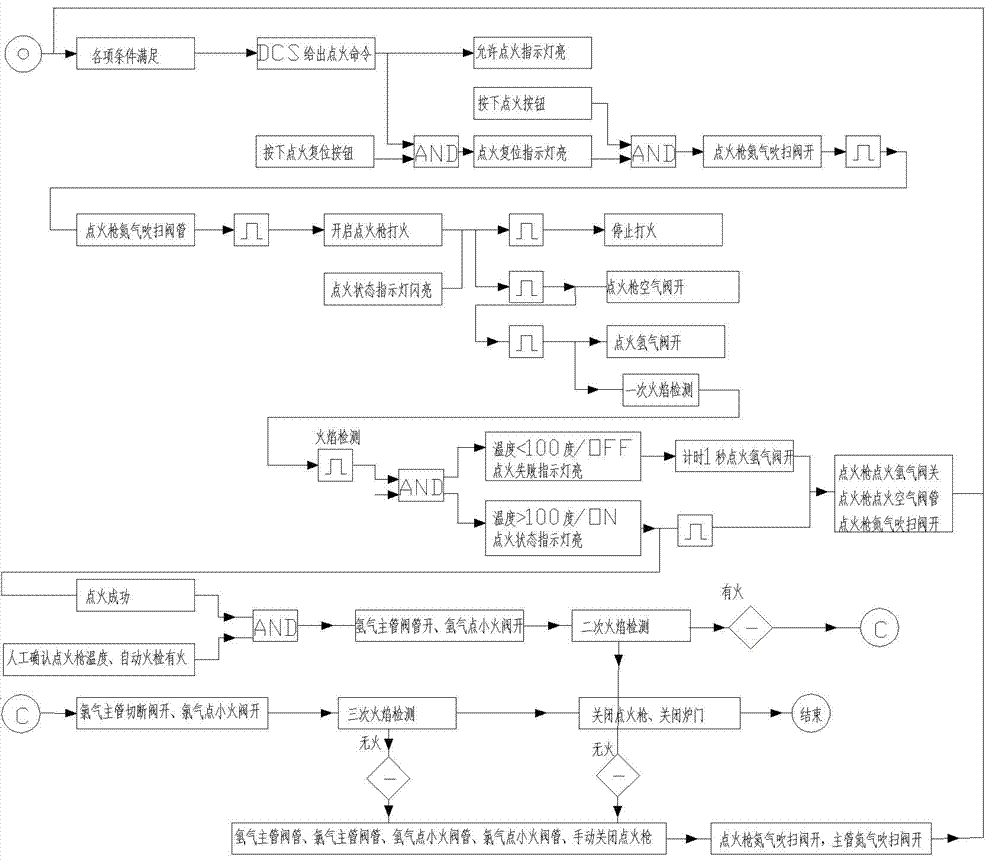

[0022] Such as figure 1 As shown, the present invention discloses an automatic ignition system for a hydrogen chloride synthesis furnace, which includes an ignition gun 1 and a flame monitor 2 arranged on the side of the furnace mouth of the hydrogen chloride synthesis furnace and a chlorine gas inlet connected in parallel and in series at the bottom of the hydrogen chloride synthesis furnace mouth. Gas pipeline 3, hydrogen inlet pipeline 4 and nitrogen pipeline 5, the air inlet of ignition gun 1 is connected in series with ignition air pipeline 6, the hydrogen inlet of ignition gun is connected in series with ignition hydrogen pipeline 7, the input end of the ignition hydrogen pipeline Simultaneously link to each other with the input end of hydrogen gas inlet line 4 and the input end of nitrogen gas inlet line 5;

[0023] A chlorine point small fire valve 8 and a chlorine main shut-off valve 9 are arranged on the chlorine gas inlet line 3; a hydrogen point small fire valve 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com