Integrated automatic ignition eternal flame lamp

An automatic ignition and integrated technology, which is applied in the field of permanent lights, achieves the effects of simple structure, improved ignition success rate, and low gas consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

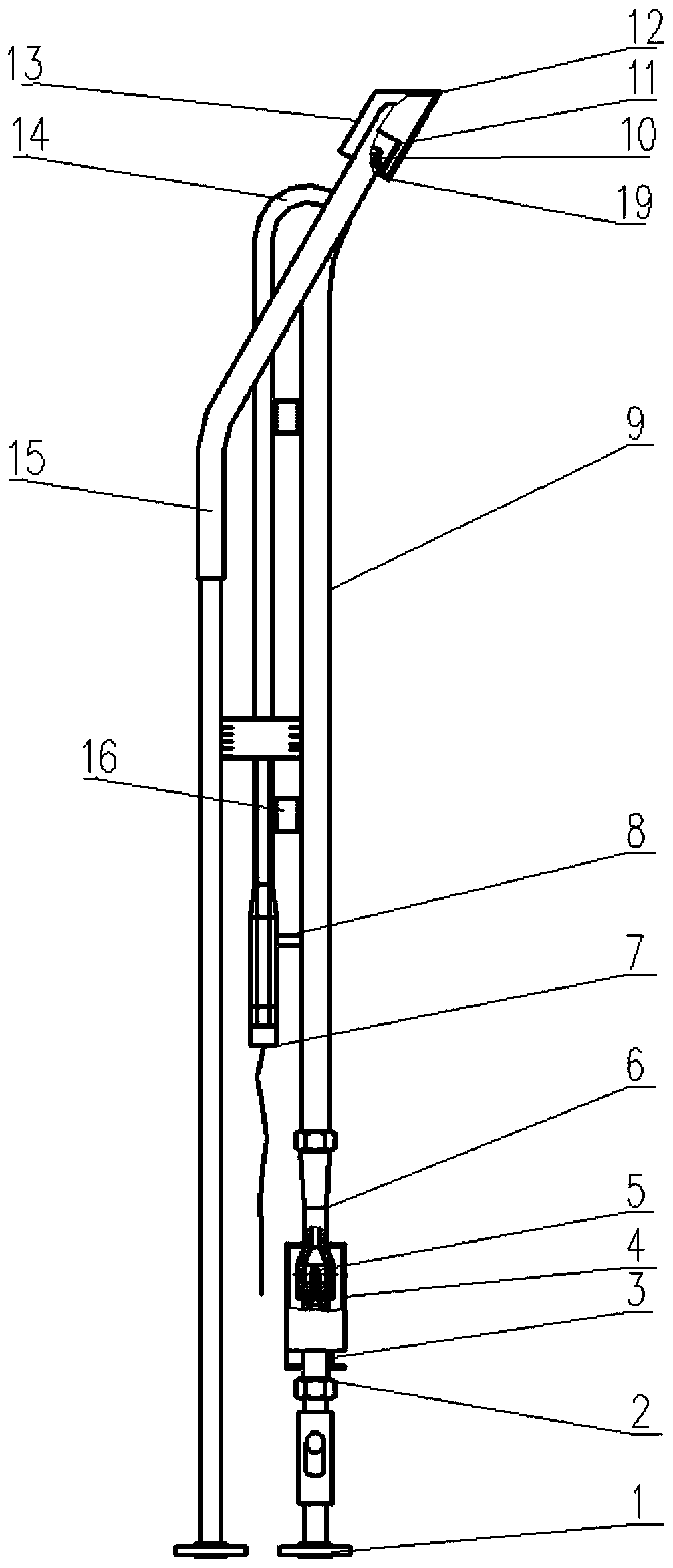

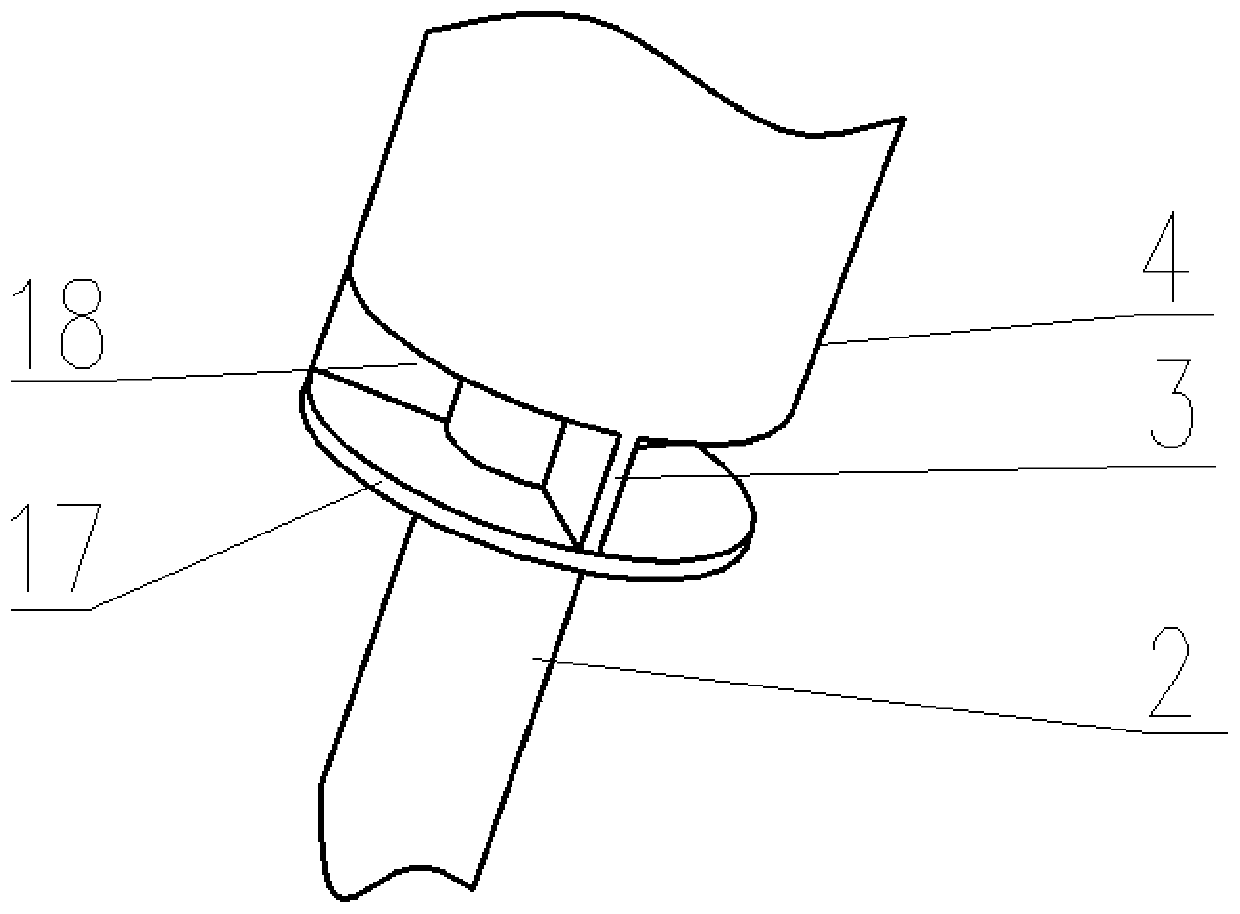

[0030] like Figure 1-Figure 3 As shown, the integrated automatic ignition permanent lamp includes a mixed fuel gas pipe 9, an ignition pipe 14, and a deflagration flame transfer pipe 15; the ignition pipe 14 and the mixed fuel gas pipe 9 are welded and fixed by a connecting plate 16; the upper end of the mixed fuel gas pipe 9 is connected with The burner 10 is arranged with a flame-stabilizing cover 11 and a windshield 13 along the outer ring of the burner 10. The bottom of the burner 10, the flame-stabilizing cover 11 and the windshield 13 are welded with a windshield bottom plate 19; The height of the cover 11 is about 2 times of the burner so that the upper end is higher than the burner to form an internal high temperature zone, and there is a small rain hole on the wall surface of the flame stabilization cover 11 lower than the outlet of the burner 10; the upper end of the windproof cover 13 is higher than the flame stabilization Cover 11, the top of the windshield 13 is ...

Embodiment 2

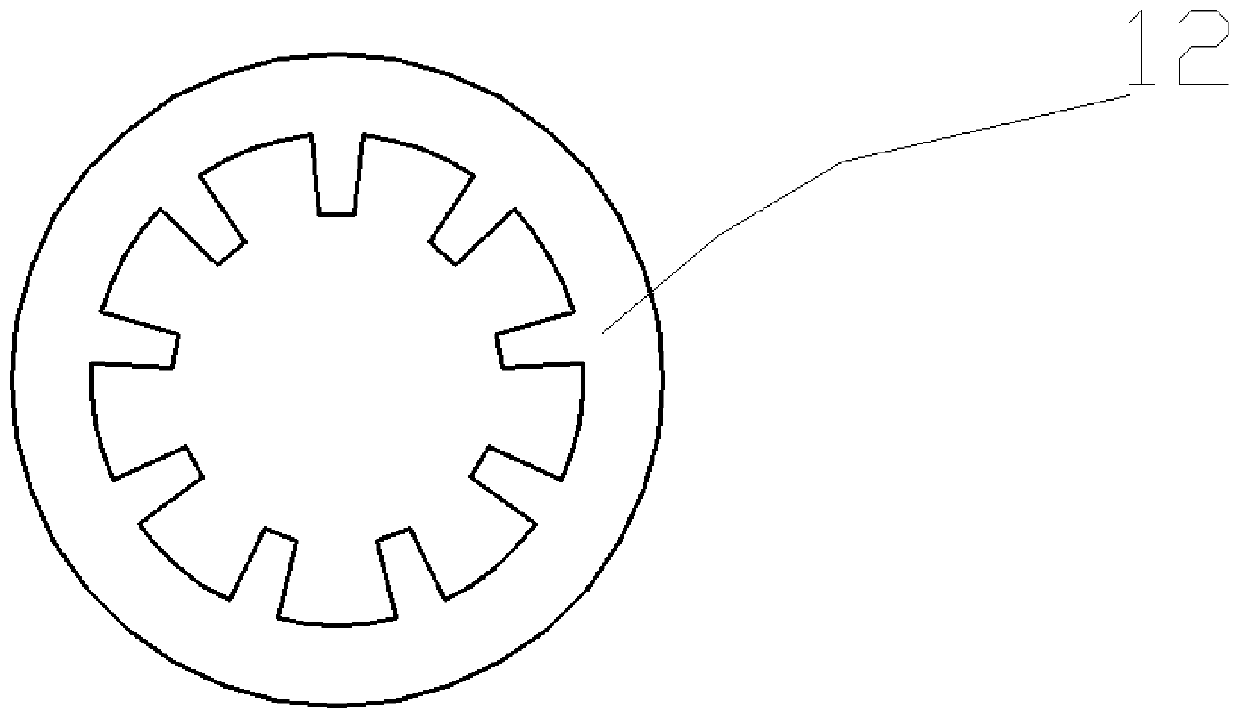

[0038] On the basis of Embodiment 1, the structure of the flame stabilizing sheet 12 is adjusted. In this embodiment, the flame stabilizing sheet 12 is an open cylinder with round holes on the side, and the flame stabilizing sheet 12 is fixed on the top of the windshield 13 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com