Heat storage type burner used for radiant tube

A radiant tube and regenerative technology, applied in the direction of burner, combustion method, combustion type, etc., can solve the problems that the surface of the strip steel cannot reach the expected temperature, the spark plug affects the flame detection signal, and affects the coating effect of the strip steel product, etc. , to achieve high heat utilization rate, continuous and stable combustion state, and good heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The following will further illustrate the regenerative burner for radiant tubes according to the present invention according to specific embodiments and related drawings, but the specific embodiments and related descriptions do not constitute improper limitations to the technical solution of the present invention.

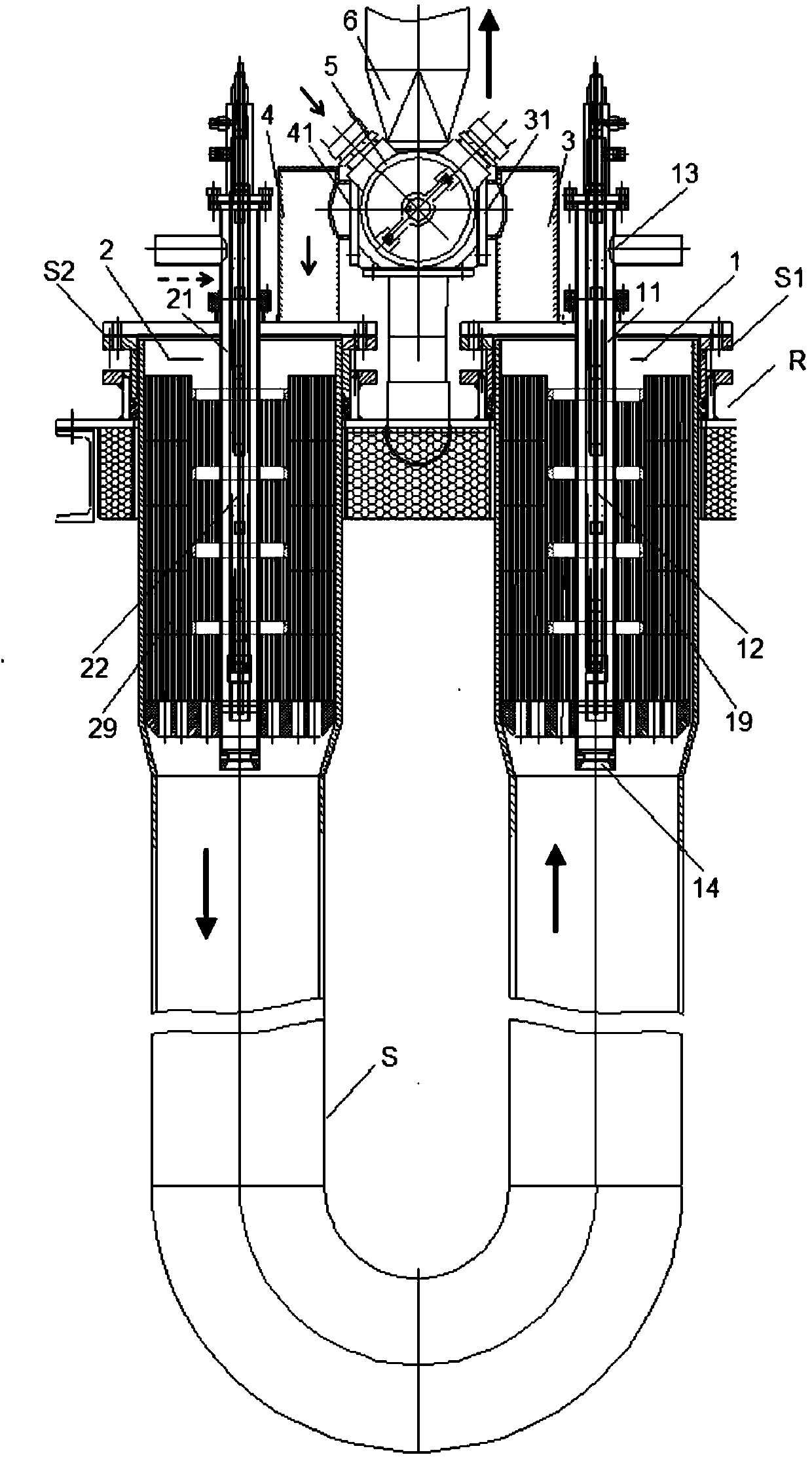

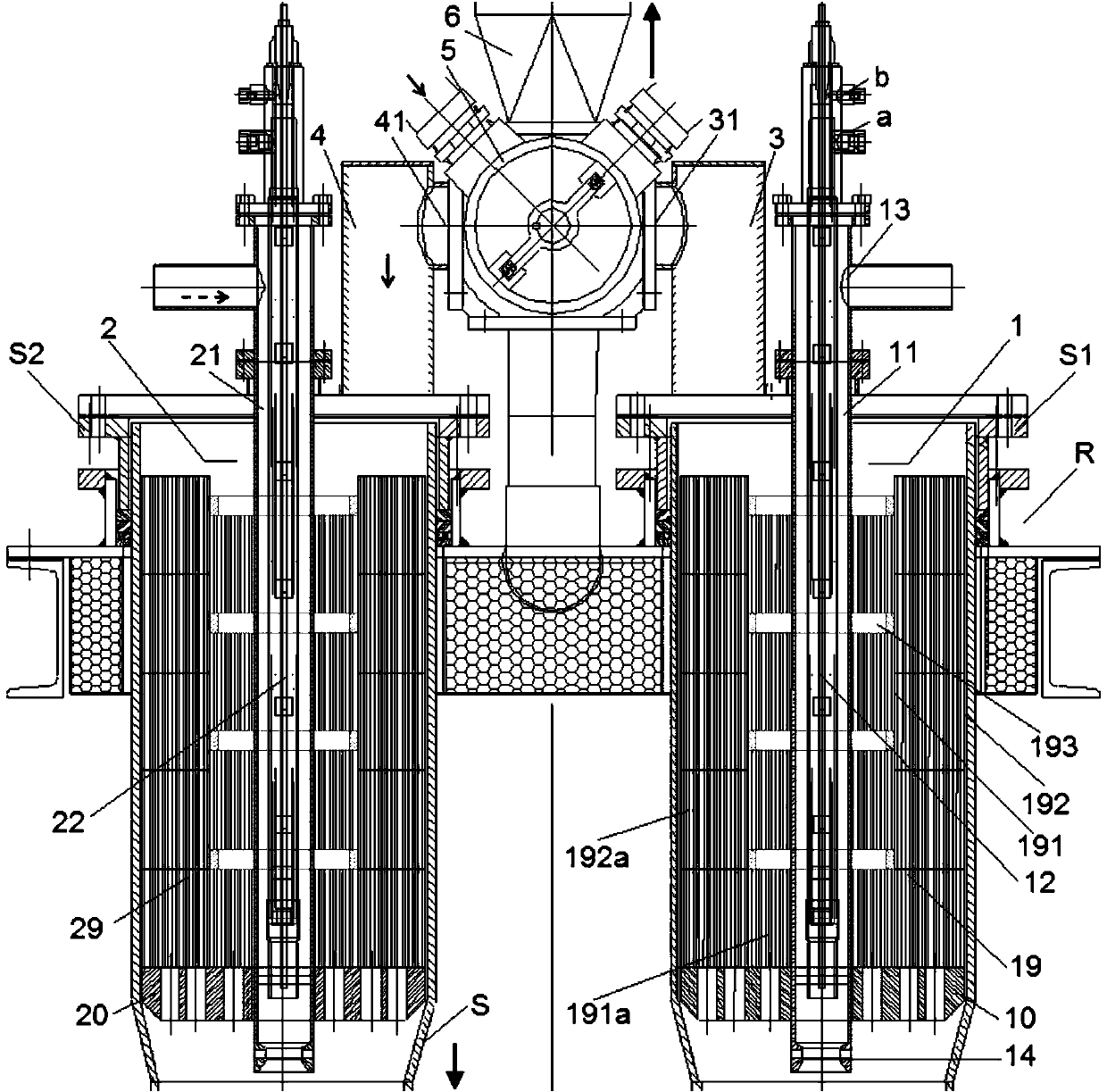

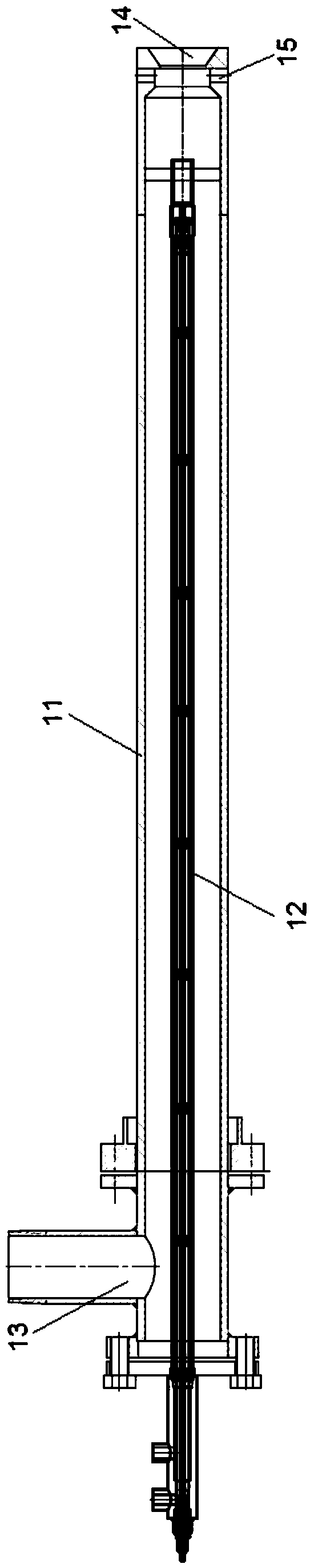

[0055] figure 1 and figure 2 The structures of the regenerative burners for radiant tubes according to the present invention in one embodiment are shown respectively.

[0056] In the following embodiments, the combustion-supporting gas is air, and the combustible gas is coal gas.

[0057] exist figure 1 The direction of the solid arrow in the figure represents the flow direction of air, the dashed arrow represents the flow direction of gas, and the bold arrow represents the flow direction of exhaust gas. figure 1 The reversing valve is shown in the first position.

[0058] like figure 1 and figure 2 As shown, the regenerative burner R for radiant tub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com