Firework firecracker with two fuze and manufacturing method therefor

A technology for fireworks and firecrackers and a manufacturing method, which is applied in the directions of fireworks, offensive equipment, weapon types, etc., can solve the problems of many unsafe factors and inconvenient operation, and achieves the effects of high ignition success rate, convenient and safe discharge, and increased safety factor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 2

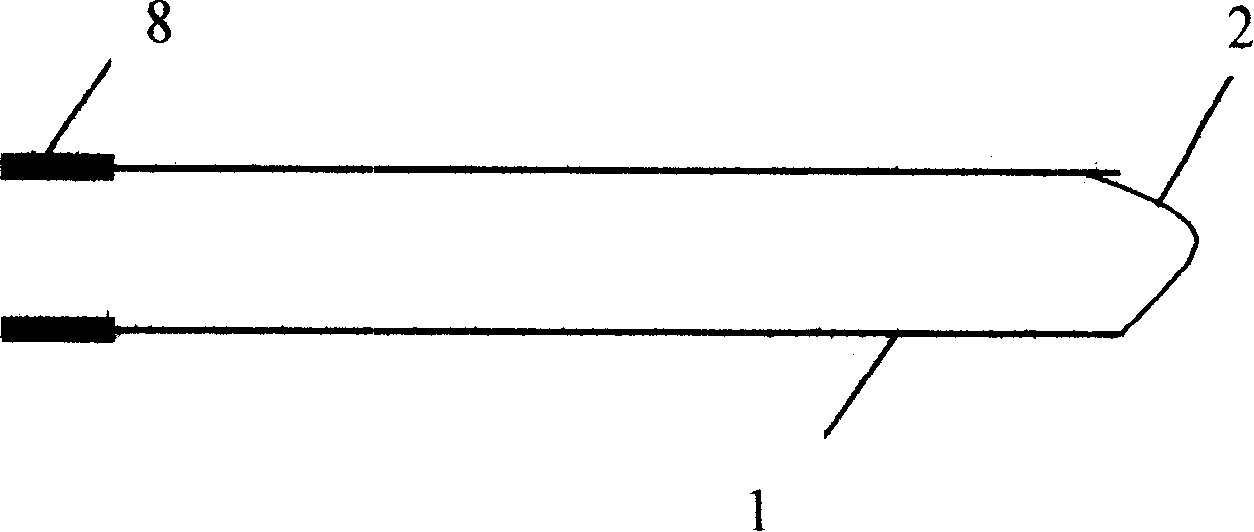

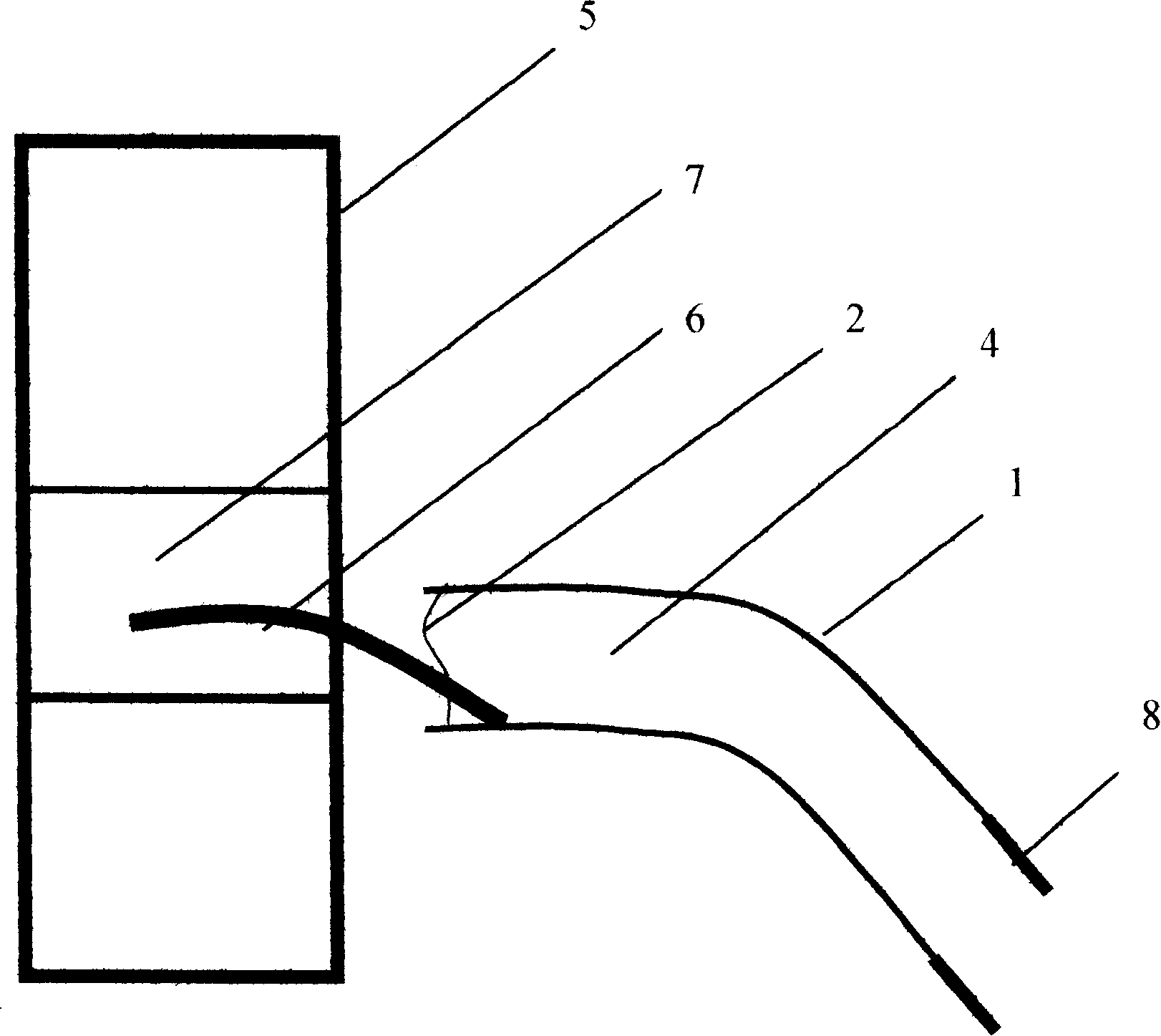

[0018] The gunpowder fuze (6) and the heating fuze (4) of fireworks and firecrackers (5) are as image 3 Connected together as shown, the heating wire (2) of the heating fuze (4) is connected on the middle section of the gunpowder fuze (6), and the heating fuze (4) and the gunpowder fuze (6) form a connection point (10), at the connection point (9) also has a section of gunpowder outer fuze (3) remaining outside, and when setting off, both can choose to directly ignite the gunpowder outer fuze (3) by open flame and can choose to ignite by heating fuze (4).

specific Embodiment approach 3

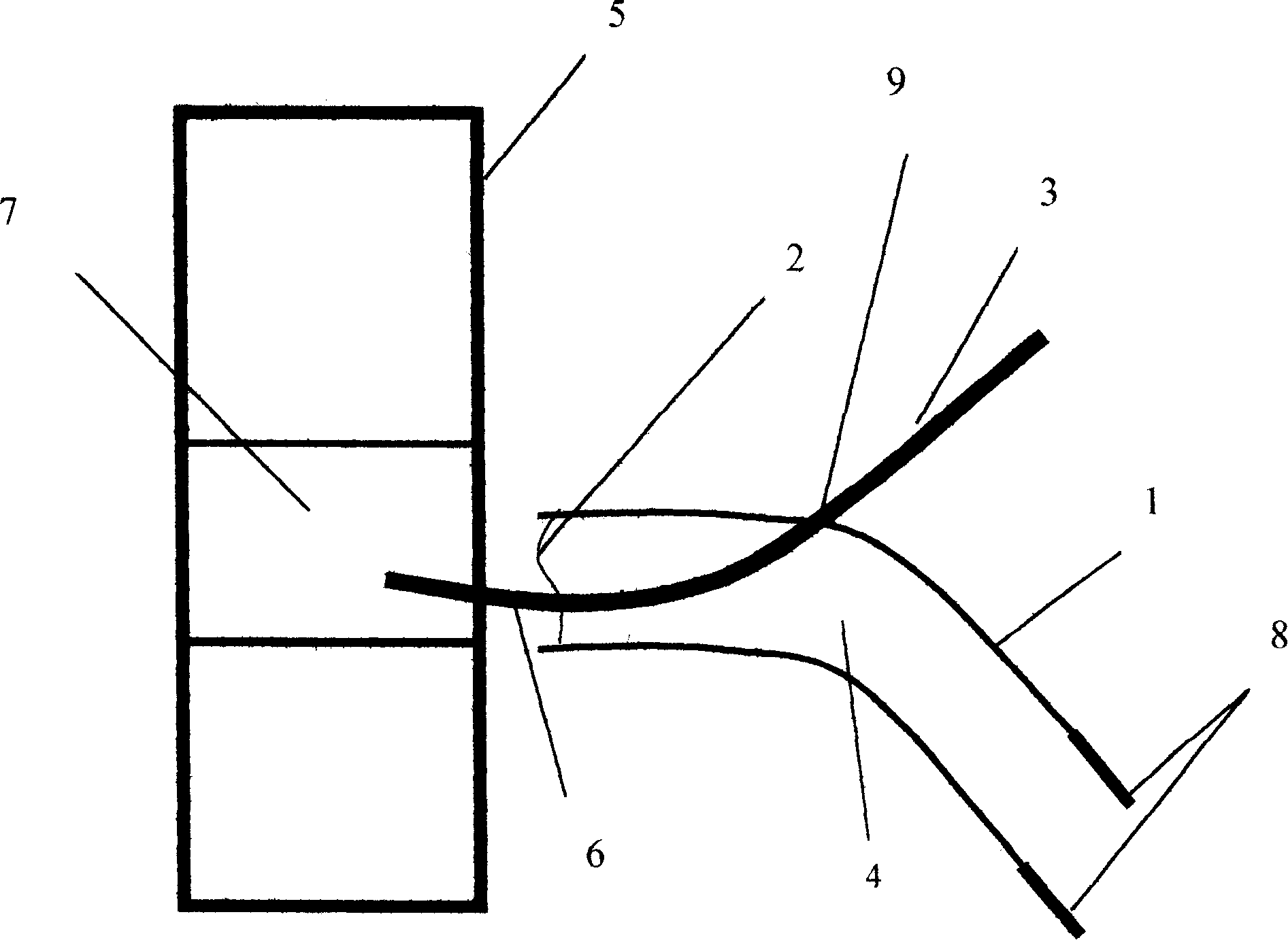

[0019] Such as Figure 4 As shown, the heating fuze (4) is directly connected with the internal propellant (7) of the fireworks (5) to form a double-fuze fireworks and firecracker with both an electric heating fuze (4) and a gunpowder fuze (6). , and then respectively weave the powder fuzes (6) of a plurality of double-fuze fireworks and firecrackers together to form the powder fuze combustion connection ignition end, and electrically connect the electric heating fuze power supply terminals (8) of the double-fuze fireworks and firecrackers together to form a common power supply terminal Leads to the power supply control box. When lighting fireworks and firecrackers, both the gunpowder fuze can be ignited by an open flame and the internal pyrotechnic fuze (7) can be ignited to set off by the heating fuze (4).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com