Boiler of circulating fluid bed for burning household garbage

A technology of circulating fluidized bed and domestic waste, which is applied in the direction of incinerators, fluidized bed combustion equipment, and fuel burned in a molten state. Effects of garbage pretreatment and exhaust gas purification, reduced floor space and compact equipment structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

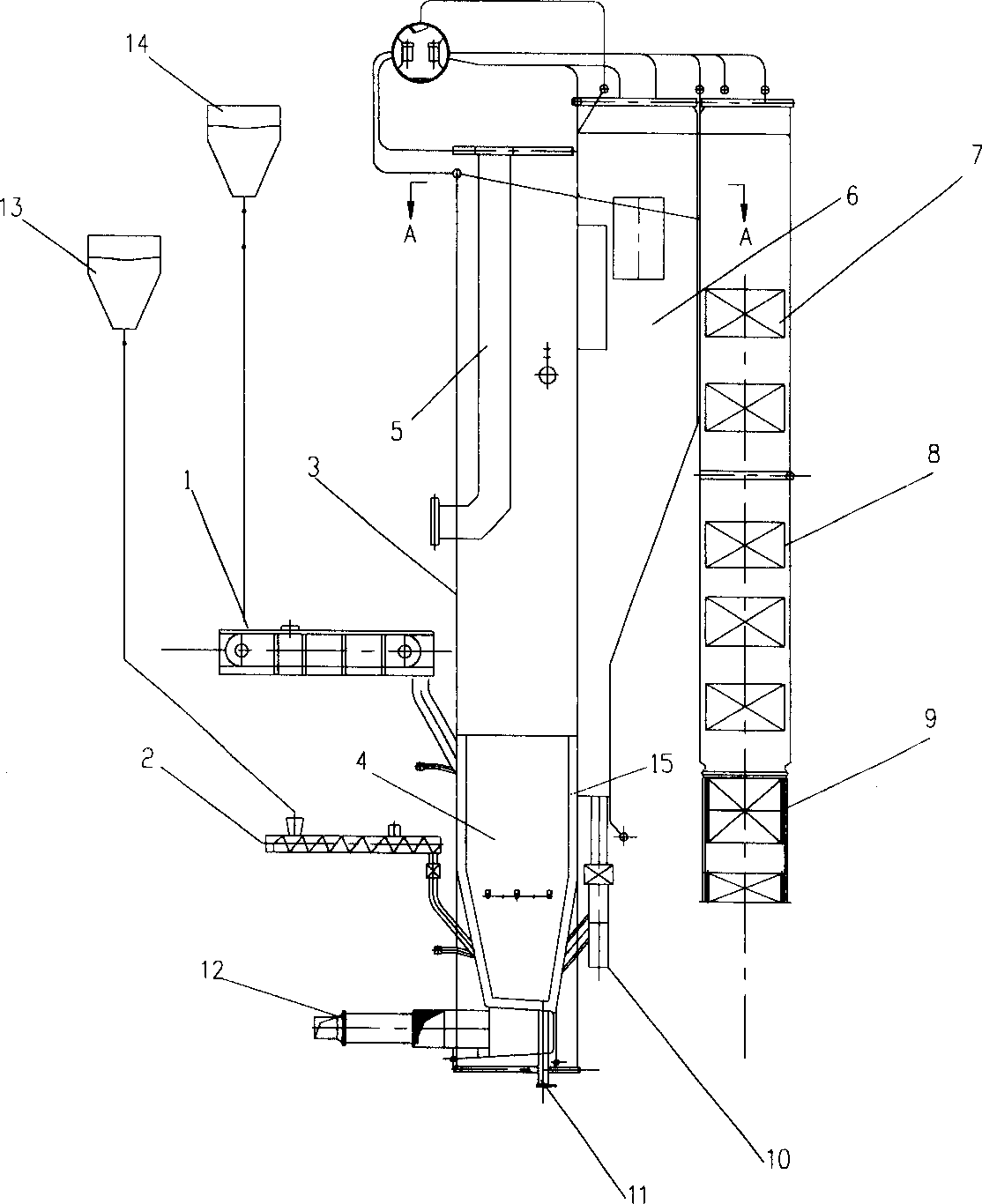

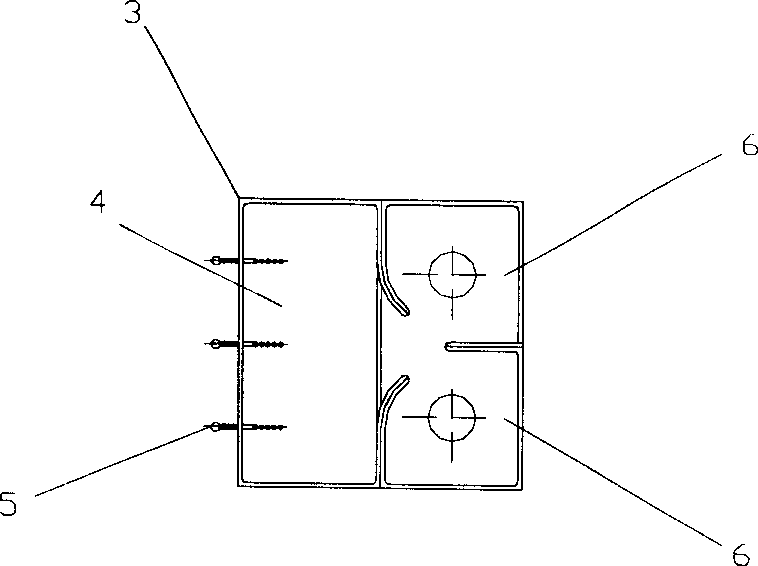

[0014] see figure 1 and figure 2 , the present invention comprises a feeder one 1 communicated with the garbage bin 14, a feeder two 2 communicated with the fuel / auxiliary material bin 13, a body of furnace 3 and a combustion chamber 4 placed in the body of furnace 3, an air chamber, Air distribution plate, air duct, ignition burner 12 installed under combustion chamber 4, double-row water-cooled separator 6 and superheater 7, economizer 8, air preheater connected in series in the shaft flue behind water-cooled separator 6 9. The feeder one 1 is placed on the feeder two 2 and communicates with the combustion chamber 4 respectively, and the front end of the turning chamber of the furnace body 3 is provided with a water cooling screen 5 . The water-cooled separator 6 is connected to the combustion chamber 4 in the furnace body 3 as an integral structure, and the water-cooled separator 6 with a membrane-type water-cooled wall structure is provided with an inclined shrinking wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com