Method and device for calibrating eclectic arc discharge energy correction factor

A correction factor and arc discharge technology, which is applied to measuring devices, measuring electrical variables, instruments, etc., can solve problems such as explosion, unsafe direct test method, and inability to obtain quantitative data, and achieve high accuracy and convenient use and setup. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

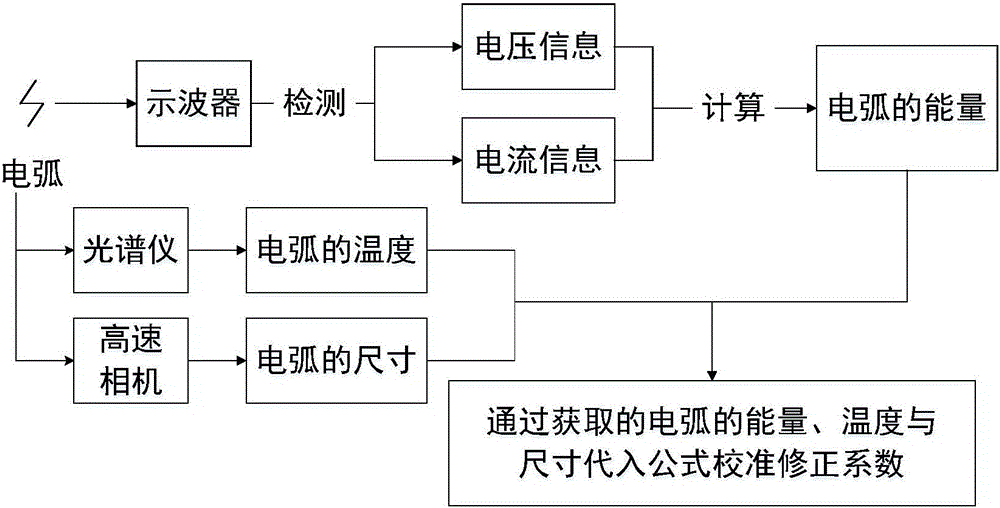

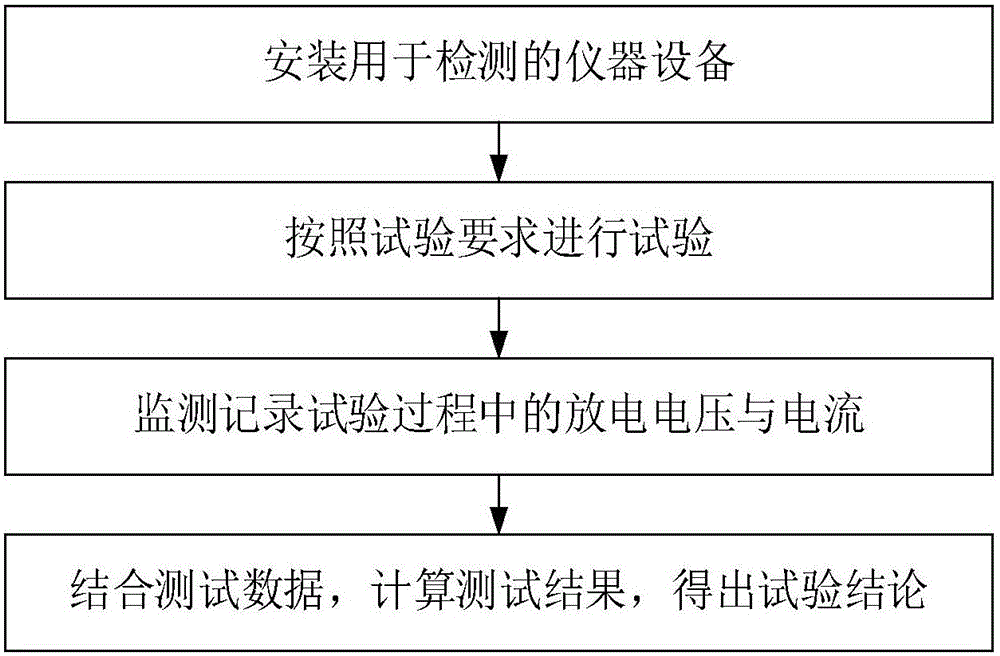

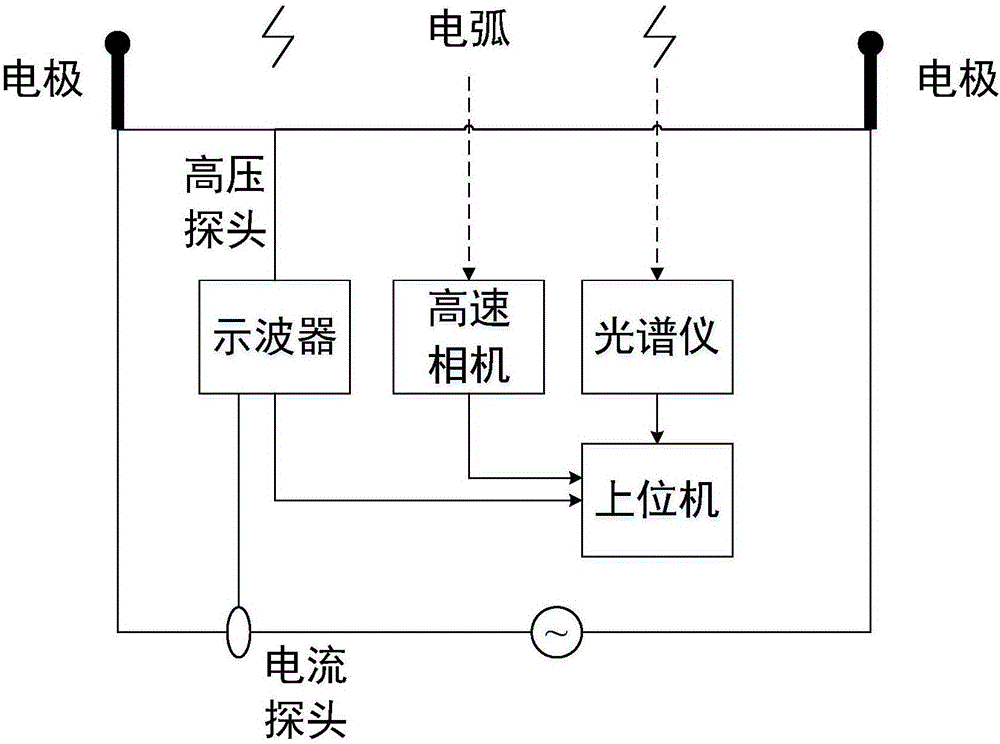

[0027] Such as figure 1 As shown, the discharge energy of the arc can be measured by an oscilloscope. The arc generated by gas discharge has obvious voltage and current characteristics. The voltage curve of the arc during the discharge period can be measured by using the high-voltage probe of the oscilloscope, and the current curve of the circuit during the discharge period can be measured by using the current probe, and the measured curve is stored and recorded. The relationship between energy, voltage and current can be accurately calculated to obtain the discharge energy of the arc. Arc discharge energy calculation formula: The temperature of the arc can be measured by a spectrometer. The gas discharge forms an arc with a distinctly bright light and releases corresponding spectral information. The spectral information of the arc can be collect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com