Testing device of minimum ignition energy of gas-solid two-phase combustible material

A test device and ignition energy technology, which is applied in the direction of chemical analysis using combustion, etc., to achieve simple operation, good technical effect, and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

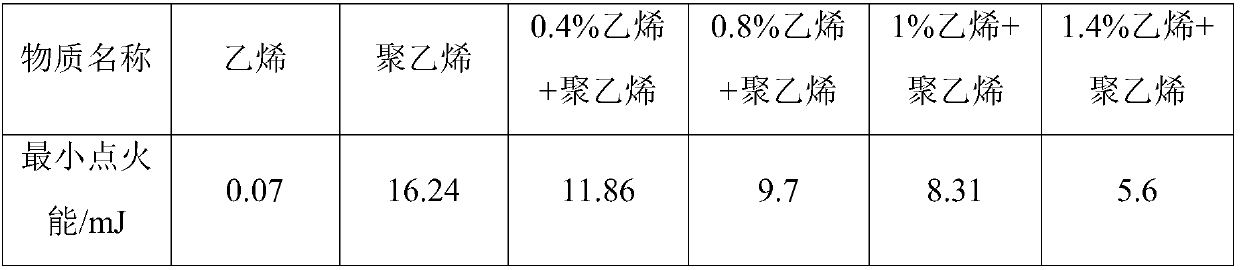

Embodiment 1

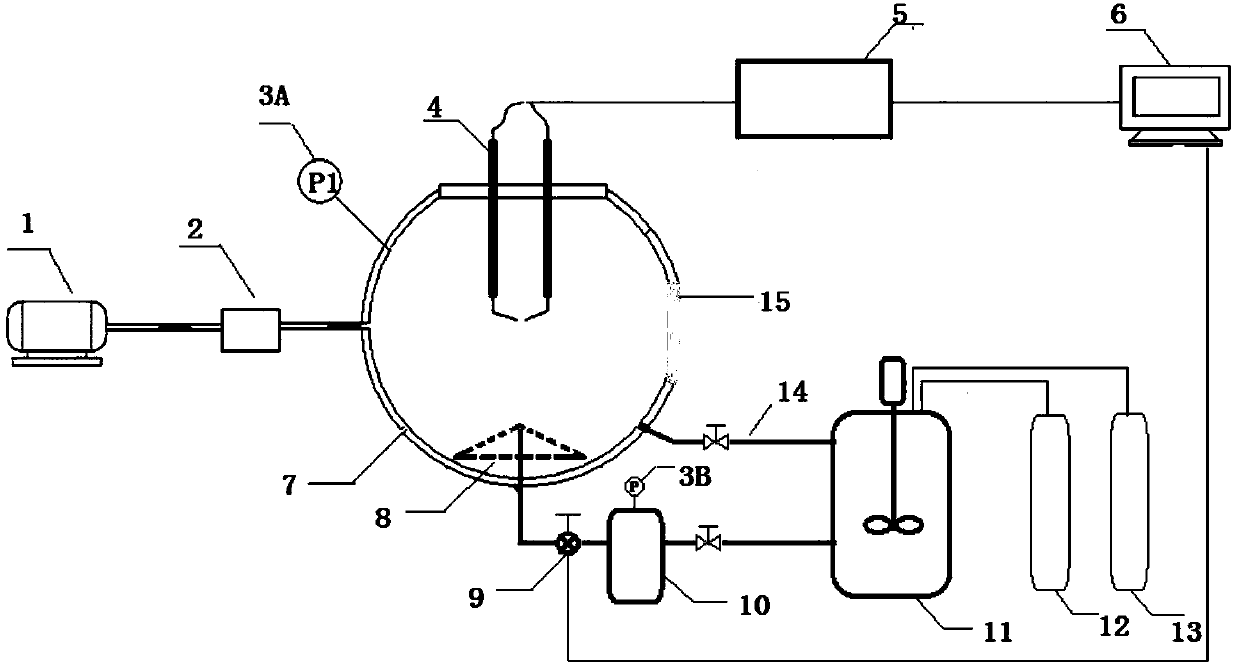

[0019] A test device for the minimum ignition energy of gas-solid two-phase combustible materials, such as figure 1 As shown, the minimum ignition energy test of gas-solid two-phase combustible materials is carried out. The main body of the device is a spherical test chamber, a vacuum pump and a buffer tank are connected to the chamber, and the ignition electrode is installed on the flange on the upper side of the chamber. One end of the spark generator is connected to the ignition electrode, and the other end is connected to the computer; during the test, the following steps are included: (1) Prepare a mixture of combustible gas cylinders and air cylinders according to the working conditions and enter the mixer; (2) Put combustible dust Place it on the dust blower, turn on the vacuum pump, and evacuate the test cavity. Part of the mixed gas in the mixer enters the cavity, and the other part enters the high-pressure gas storage tank. The gas in the high-pressure gas storage tan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com