Combustible gas minimum ignition energy analysis method

An analysis method and ignition energy technology, which can be used in the analysis of materials, fuel oil testing, material inspection products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

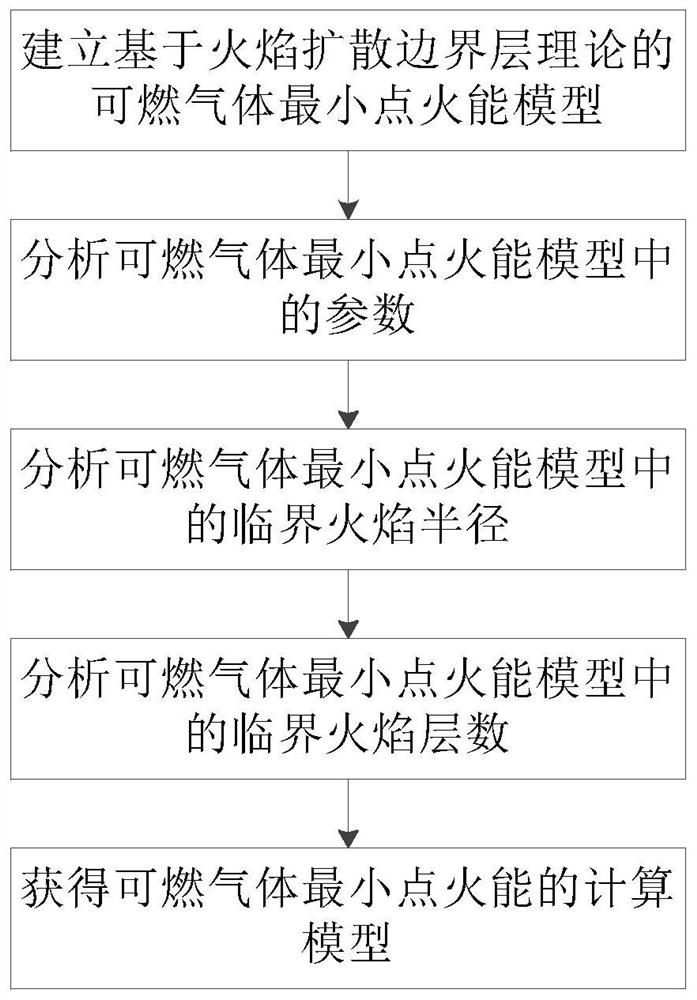

[0064] Such as figure 1 Shown, combustible gas minimum ignition energy analysis method of the present invention comprises the following steps:

[0065] Step 1, establishing the minimum ignition energy model of combustible gas based on the flame diffusion boundary layer theory;

[0066] Step 2, analyzing the parameters in the combustible gas minimum ignition energy model;

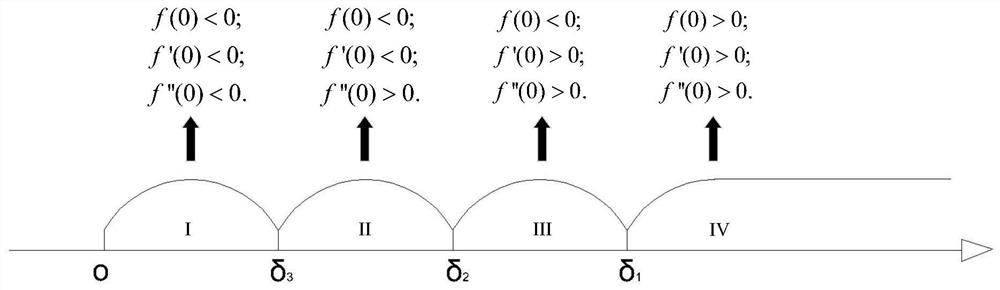

[0067] Step 3, analyzing the critical flame radius in the combustible gas minimum ignition energy model;

[0068] Step 4, analyzing the critical number of flame layers in the combustible gas minimum ignition energy model;

[0069] Step five, obtaining the calculation model of the minimum ignition energy of combustible gas.

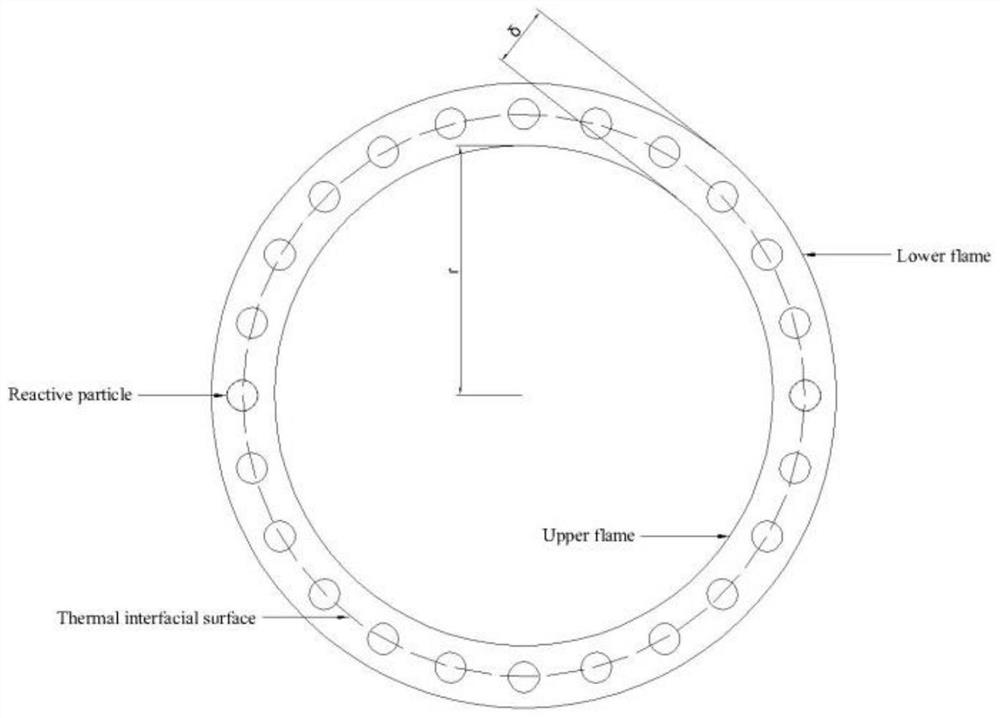

[0070] In this embodiment, the specific process of establishing the combustible gas minimum ignition energy model based on the flame diffusion boundary layer theory described in step 1 includes:

[0071] Step 101. Obtain the heat release E of the particles in the upper layer of the f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductivity | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com