Minimum ignition energy testing device

A test device and ignition energy technology, applied in the direction of fuel oil testing, material inspection products, etc., can solve the problems of low test accuracy and narrow test temperature range, and achieve the effect of improved test accuracy and good technical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

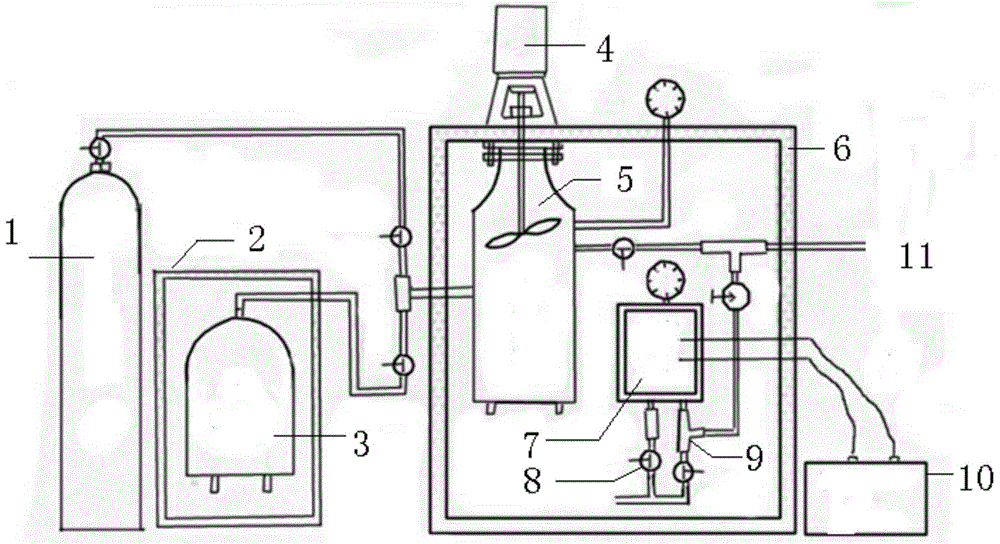

Embodiment 1

[0021] exist figure 1 On the test device shown, clean air with a relative humidity lower than 30% is contained in an air bottle with a volume of 50L and a pressure of 196×10 2 KPa. The steam generator 3 is welded with a 5mm thick alloy aluminum plate and should be strictly sealed. Its volume is 45±5L and it is placed in the thermostat 2. The thermostat 2 adopts a heat conduction oil heating box, the temperature control range is 25-150°C, and the temperature measurement error is ±2°C. The temperature control range of the thermostat 6 is 25-150°C, and the temperature control error is ±2°C. The mixer 5 is made of steel plate, the pressure is not lower than 980KPa, the volume is 40±5L, and it is placed in the thermostat 6. Agitator rod size is 10×250mm; the length of the propeller is 100mm; the dynamic sealing strength of the connecting rod shall not be less than 490kPa. The digital vacuum pressure gauge adopts a measuring range of 0-600KPa and a resolution of 1KPa to test th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com