Flash welding process of large-sized mooring chain

A welding process and mooring chain technology, applied in the field of mooring chains, can solve the problems of reduced temperature uniformity, non-penetration of welding, cracks, etc., and achieve the effects of good mechanics, easy operation and simple welding process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the purpose of the invention, technical solutions and beneficial technical effects of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific implementation methods;

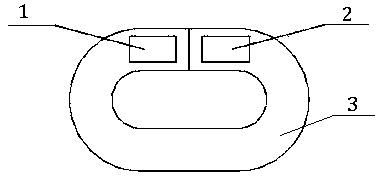

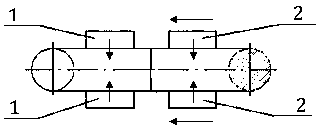

[0019] In the attached drawing: a flash welding process of a large-scale mooring chain, the chain link 3 is placed between the four electrodes during welding, of which the two left electrodes are fixed electrodes 1, and the two right electrodes are movable electrodes 2 ; It is characterized in that: welding process comprises the following steps:

[0020] Step 1: Fix the chain link: Fix the chain link 3 on the welding machine through the joint action of the two fixed electrodes 1 on the left and the two movable electrodes 2 on the right, and correct the up and down misalignment of the ring body;

[0021] Step 2: Flash preheating: the left electrode and the right electrode are connected to the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com