Motor machine shell water channel structure and motor

A water channel and casing technology, applied in the field of heat dissipation of new energy vehicle motors, can solve the problems of high outlet temperature, low inlet temperature rise, and low water pump efficiency, so as to improve convective heat transfer capacity, increase turbulent flow, and reduce temperature poor effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

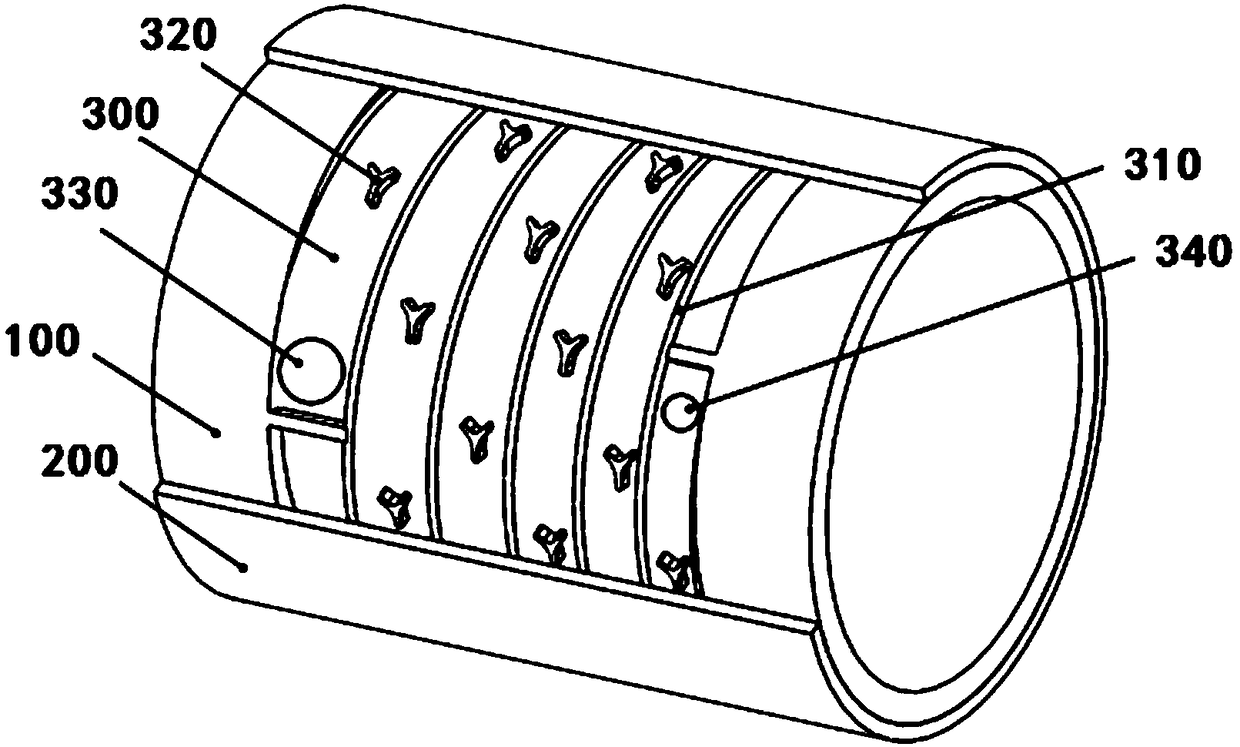

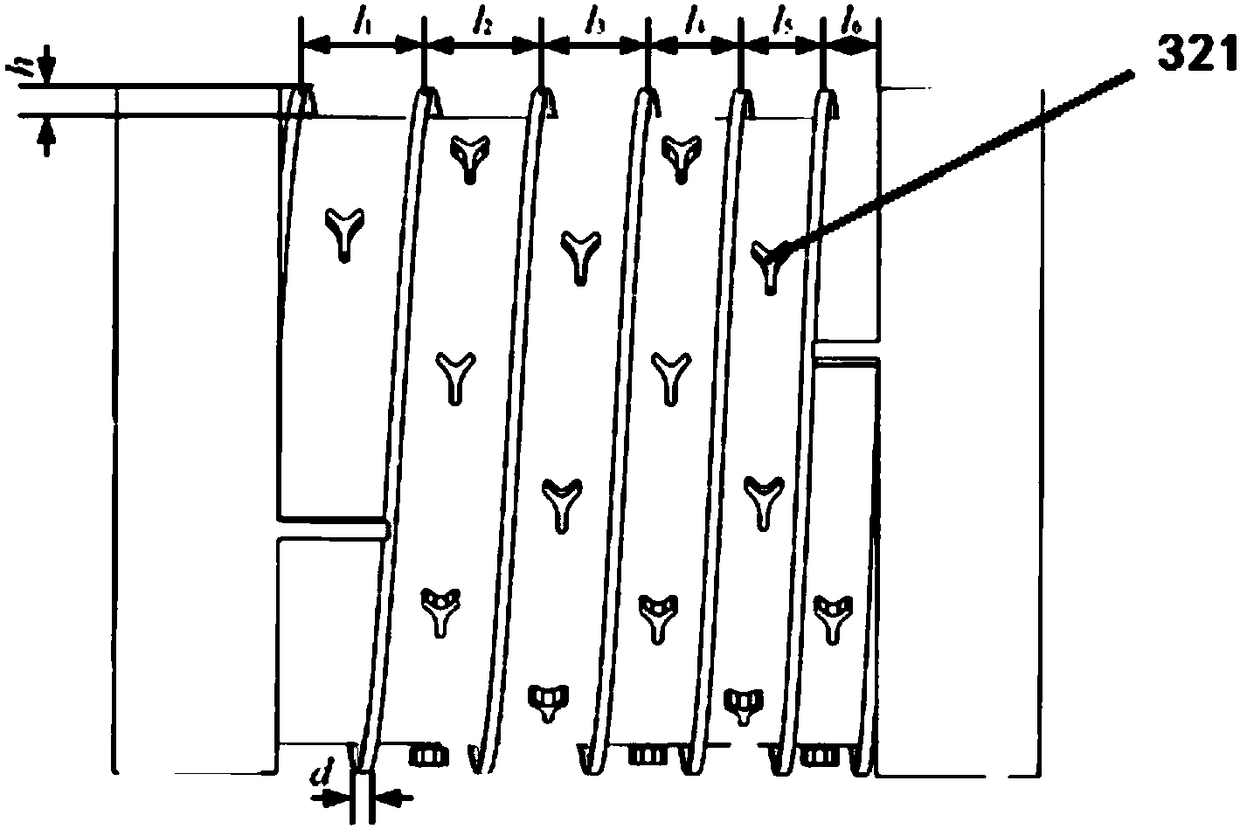

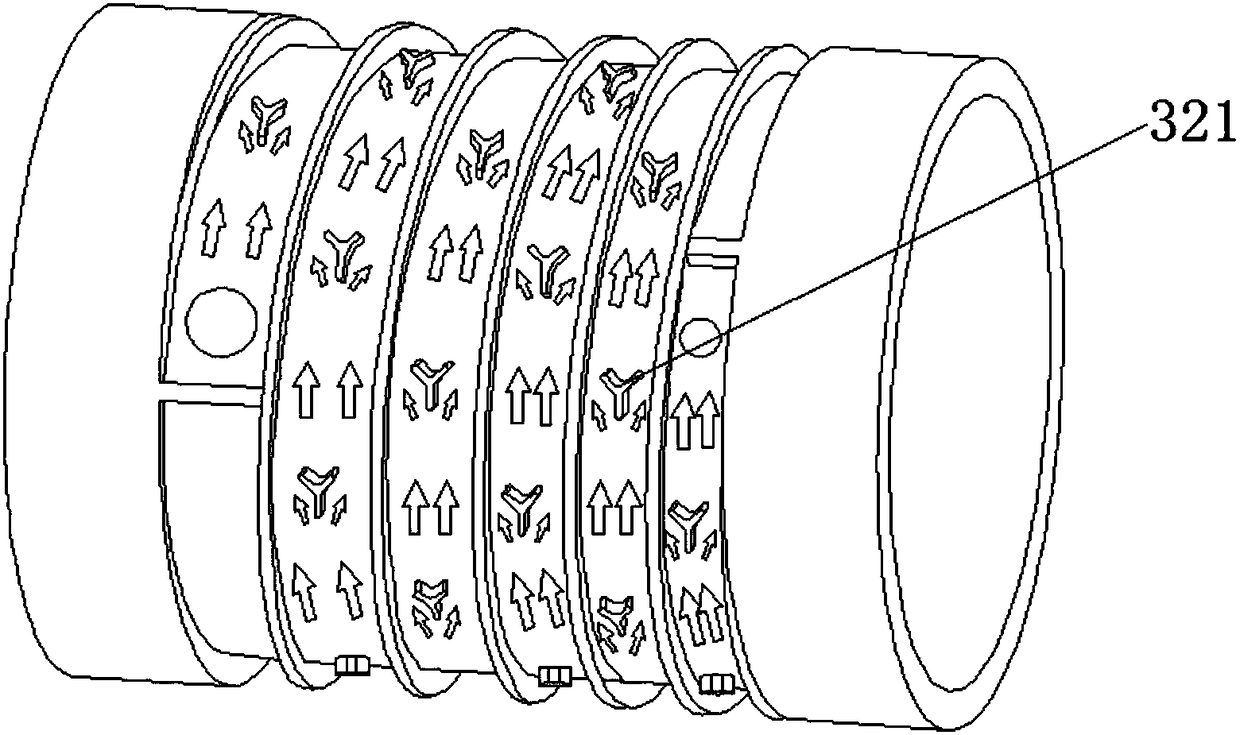

[0038] On the one hand, if figure 1 As shown in -3, the water channel structure of the motor casing provided by this embodiment includes: an inner casing 100 and an outer casing 200; the outer casing 200 is installed outside the inner casing 100, and the inner casing 100 A cavity for cooling medium is formed between the casing 100 and the outer casing 200; the outer surface of the inner casing 100 is provided with a water channel 300, and the width of the water channel 300 from the water inlet 330 to the water outlet 340 is gradually Decrease to increase the convective heat transfer capacity of the cooling medium at the water outlet 340 to ensure the temperature uniformity of the motor.

[0039] to combine figure 1 As shown, when working, the waterway structure of the motor casing is mainly composed of two parts: the outer casing 200 and the inner casing 100. After the outer casing 200 and the inner casing 100 are assembled, the connection between the outer casing 200 and the...

Embodiment 2

[0055] On the basis of Embodiment 1, the motor provided in this embodiment includes the motor casing water passage structure, which has all the advantages of the above motor casing water passage structure, and will not be repeated here.

[0056] It should be pointed out that the motor also includes other structures, but all of them have been disclosed as prior art, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com