Method for optimizing complicated member gas-quenching system based on CFD software

An optimization method and component technology, applied in design optimization/simulation, special data processing applications, instruments, etc., can solve problems such as difficult quantitative analysis, poor universality, backward technology, etc., to achieve the effect of ensuring temperature uniformity and reducing losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0032] A method for optimizing the gas quenching system of complex components based on CFD software, comprising the following steps:

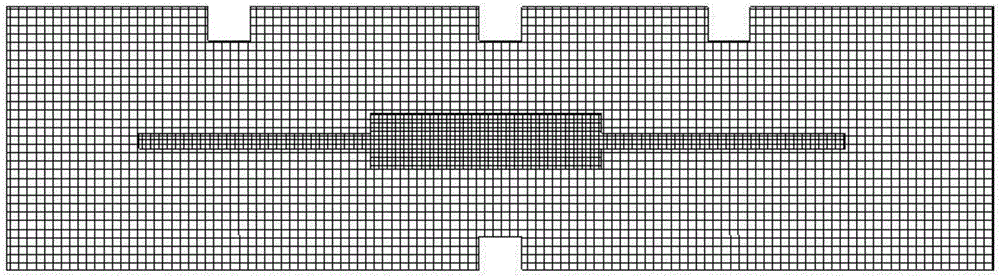

[0033] 1) Establish geometric model: According to the basic size parameters of the gas quenching system, establish the geometric model of the gas quenching system, including defining the solid calculation domain and the fluid calculation domain; use modeling software to establish the solid calculation domain according to the basic size parameters of the components and select 220 *310mm 2 The space is the fluid calculation domain, and the component gas quenching model is obtained;

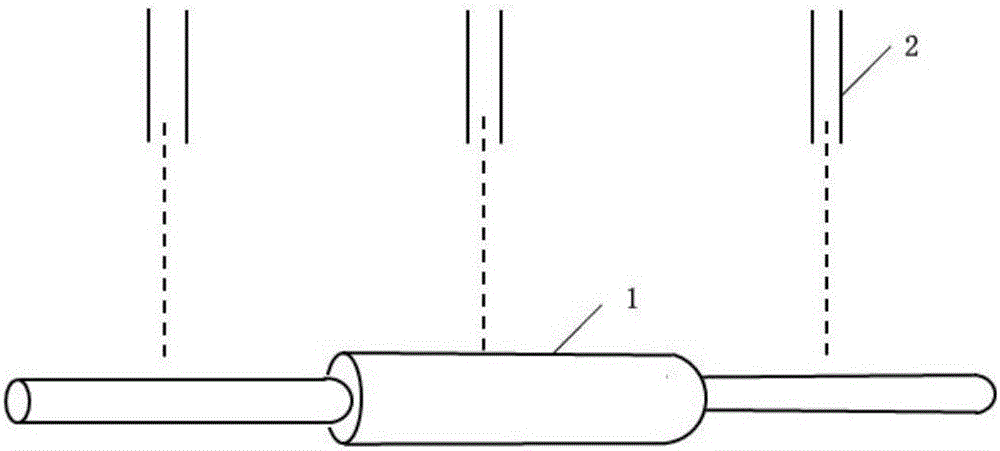

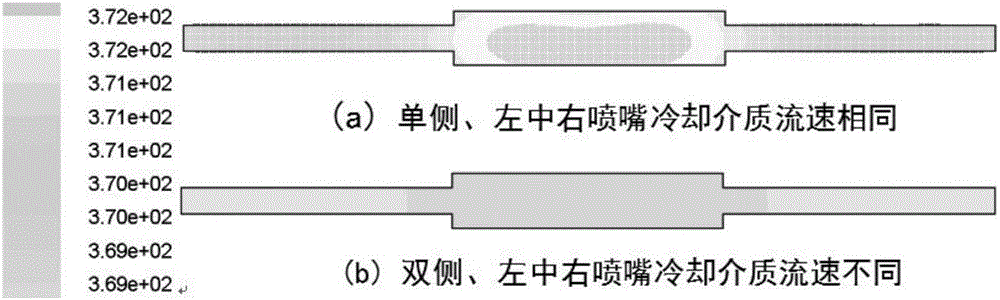

[0034] Such as figure 1 As shown, component 1 is composed of three sections, the two ends are Φ10×100mm cylinders, the middle is Φ20×100mm cylinder, the nozzle 2 is a Φ10mm round hole, the number is 3, and it is located above compon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com