In-line type multicavity laminated parallel processing vacuum equipment and use method thereof

A vacuum equipment, parallel processing technology, applied in coating, metal material coating process, gaseous chemical plating, etc., can solve the problems of manipulator not being too fast, increasing manipulator manufacturing cost, inaccurate substrate positioning, etc. The effect of improving equipment intensification, reducing the number of handling, increasing productivity and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] In order to make the above objects, features and advantages of the present invention more comprehensible, specific implementations of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0046] In the following description, many specific details are set forth in order to fully understand the present invention, but the present invention can also be implemented by other methods different from those described here, so the present invention is not limited by the specific embodiments disclosed below.

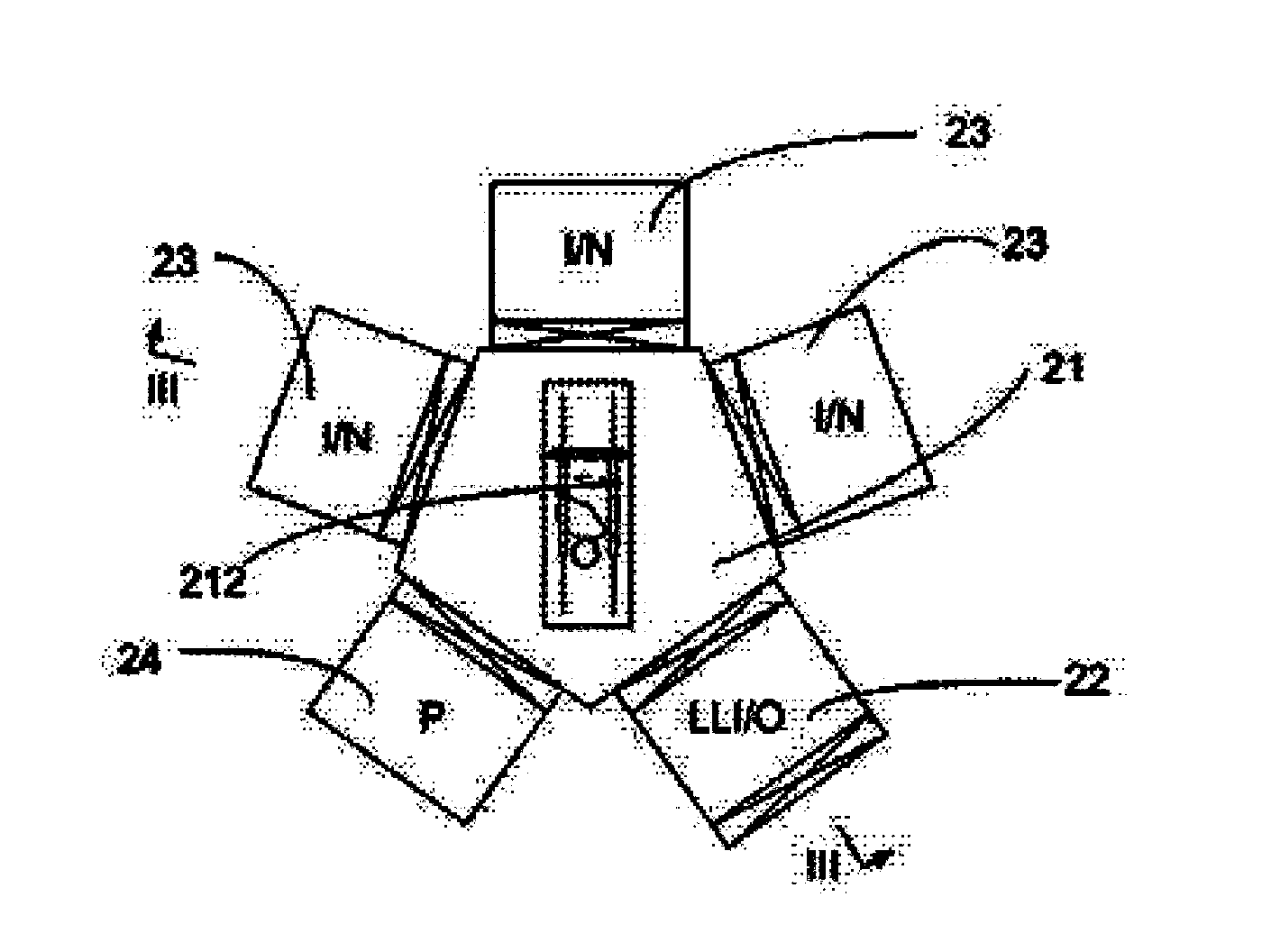

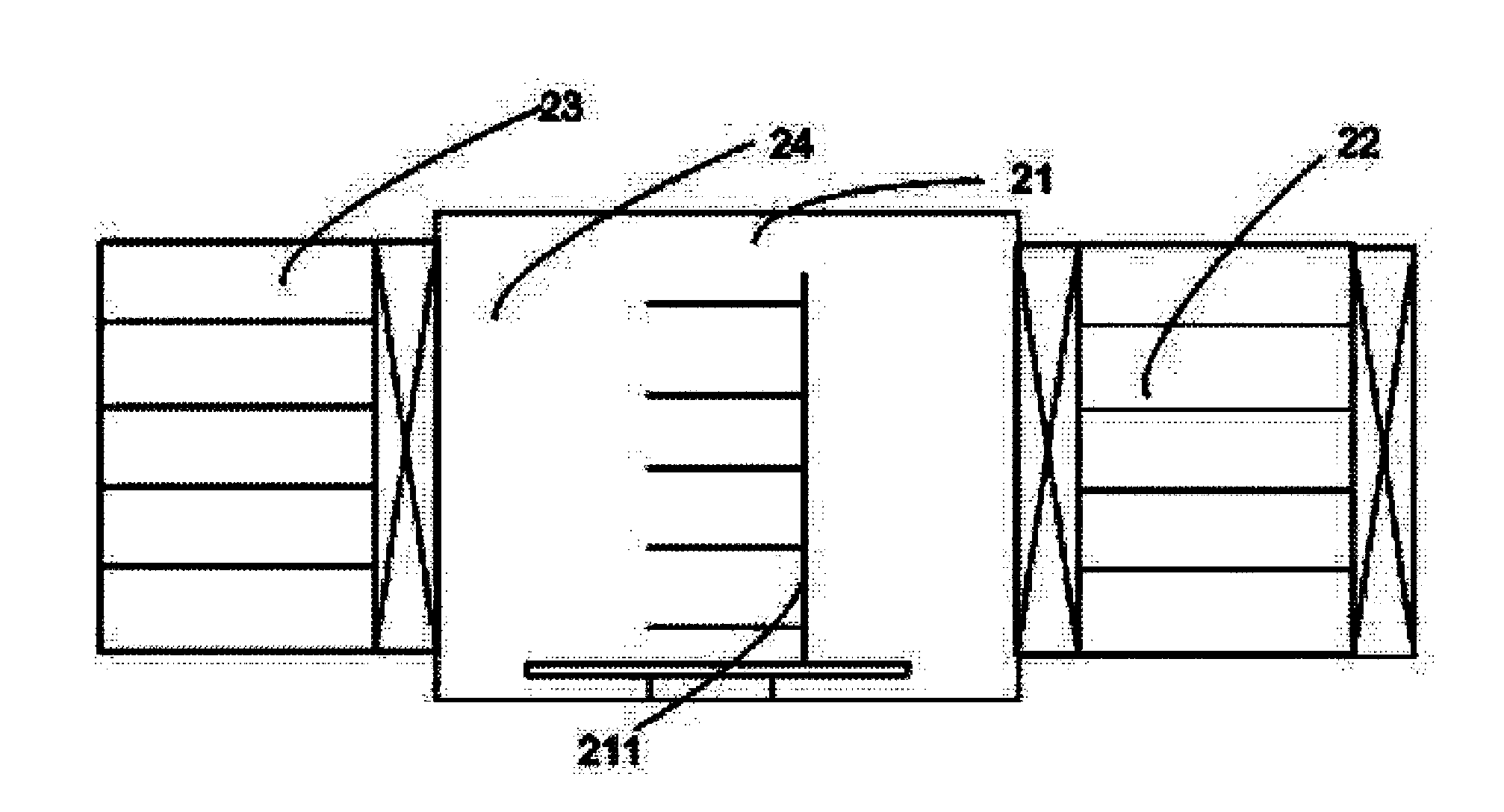

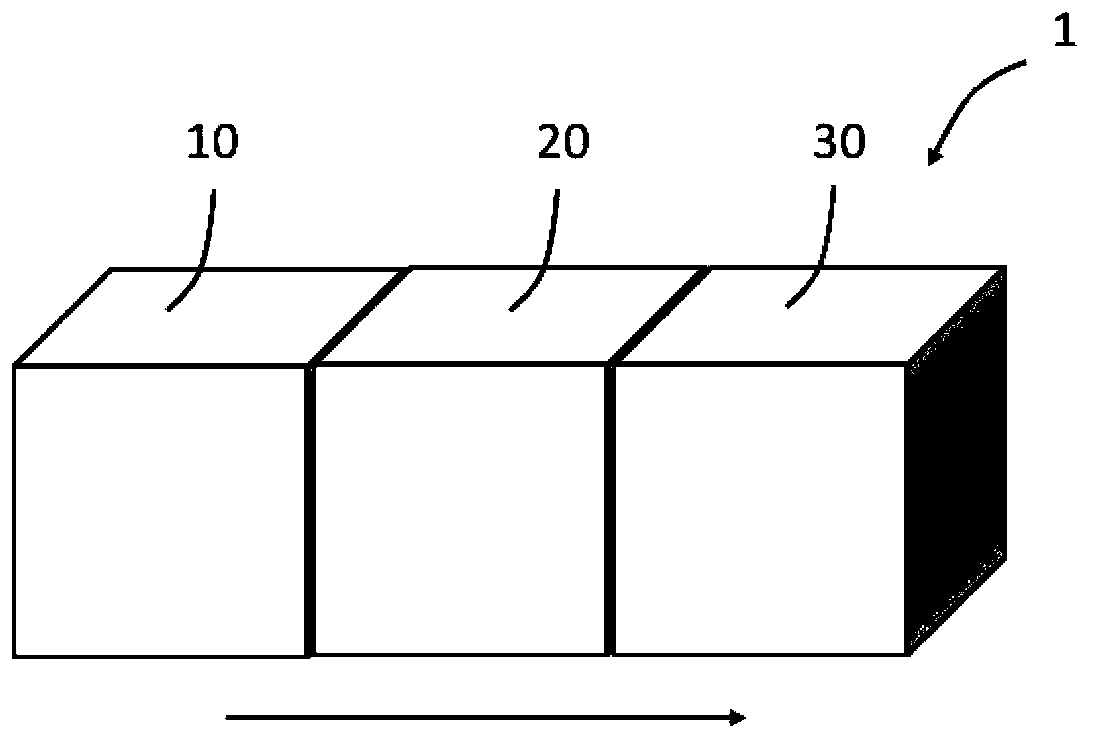

[0047] As described in the background technology, in the cluster vacuum equipment commonly used in industrial production, since the manipulator is installed in the transmission chamber in the center of the cluster equipment, corresponding to each film forming process in the PECVD equipment, the transmission chamber The manipulator inside has to move 10 times. For some chemical vapor deposition processes with short film forming...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com