A closed-loop control method for a low-voltage direct current cdi igniter

A closed-loop control, low-voltage DC technology, used in ignition controllers, spark ignition controllers, engine ignition, etc., can solve problems such as the inability to meet the requirements of engine operating conditions, improve integration and efficiency, improve adaptability, reduce cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

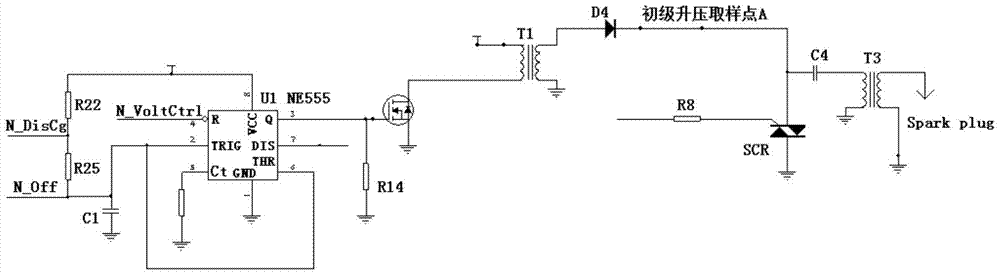

[0035] Such as Figure 5 as shown in Figure 5 (Product Example IGD0414) shows a closed-loop control method for a low-voltage DC CDI (Loop locked CDI, LLCDI) igniter according to the present invention, which specifically includes the following steps:

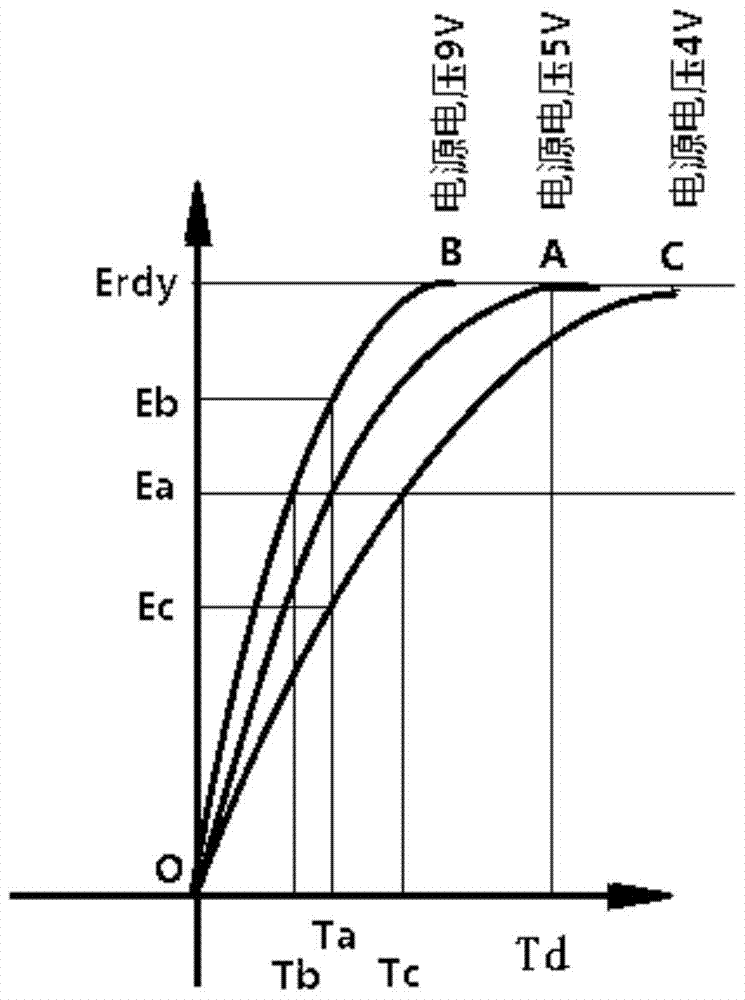

[0036] Step 1: Power on, CPU measures Td time to obtain preliminary duty ratio parameters;

[0037] Step 2: Measure the time Tp of the energy storage capacitor (C3) from the start of the booster circuit to the lowest energy point voltage, and the booster circuit continues to work until its voltage reaches the maximum limit point voltage;

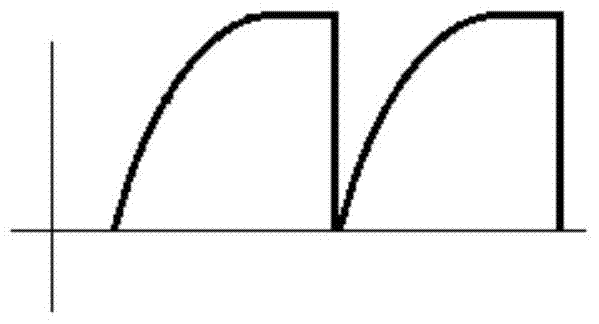

[0038] Step 3: The CPU compares the measured Tp time with the predetermined standard Ts time, adjusts the duty cycle of the boos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com