Test device for minimum ignition energy and quenching distance of gas mixture

A technology of gas mixture and quenching distance, which is applied in the direction of material explosion, can solve the problems of minimum ignition energy and quenching distance of test gas, insufficient test accuracy, and high error, so as to reduce error, improve test accuracy, and realize reliable The effect of centering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

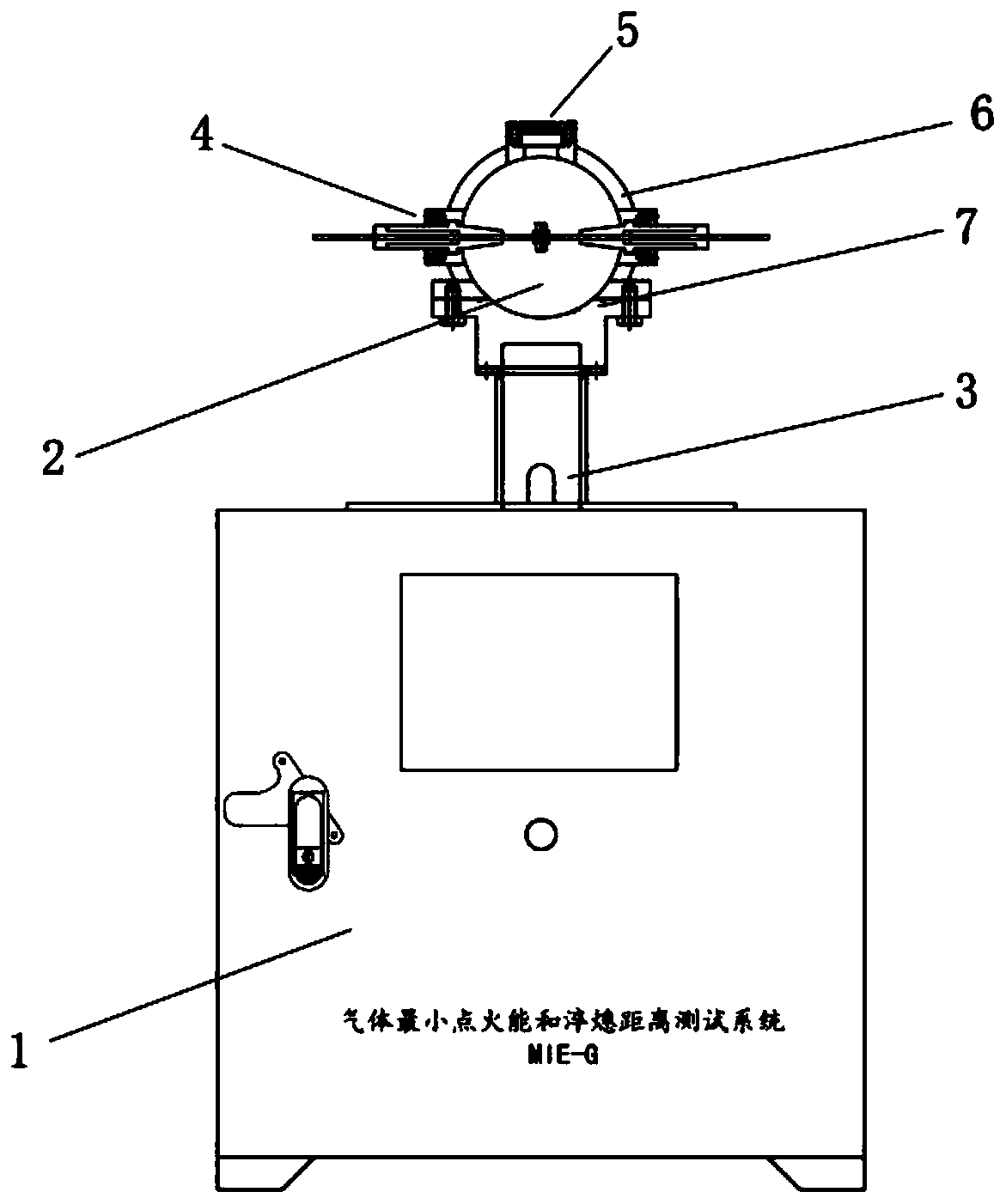

[0040] Such as figure 1As shown, the gas mixture minimum ignition energy and quenching distance testing device of the present invention includes a control box 1, a spherical reaction vessel 2, a support frame 3, an electric spark generating system 4, and a gas distribution system.

[0041] The inner cavity of the spherical reaction vessel 2 is spherical, and the spherical reaction vessel 2 includes a spherical reaction part 6 and a base 7 . The volume of the spherical reaction vessel 2 is 1 L, and the material of the spherical reaction vessel 2 is stainless steel.

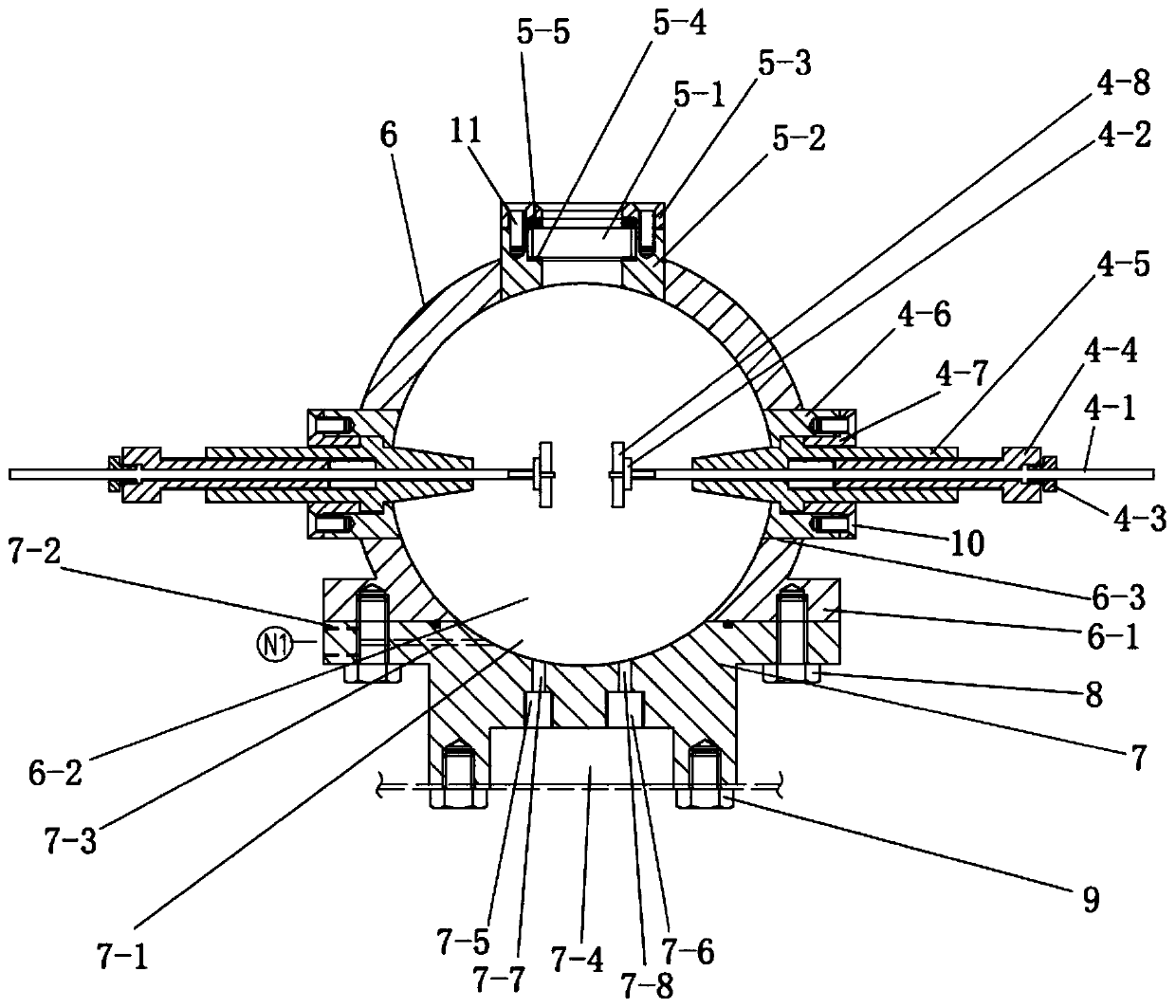

[0042] Such as figure 2 As shown, after the lower part of the spherical reaction part 6 is cut by the first horizontal plane, the mounting edge 6-1 extends outward from the bottom of the outer wall and forms the inner cavity 6-2 of the spherical reaction part. Two first circular...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com