Fuel injector with built-in positive temperature coefficient ceramic heating material

A positive temperature coefficient, ceramic heating technology, used in charging systems, machines/engines, fuel injection devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

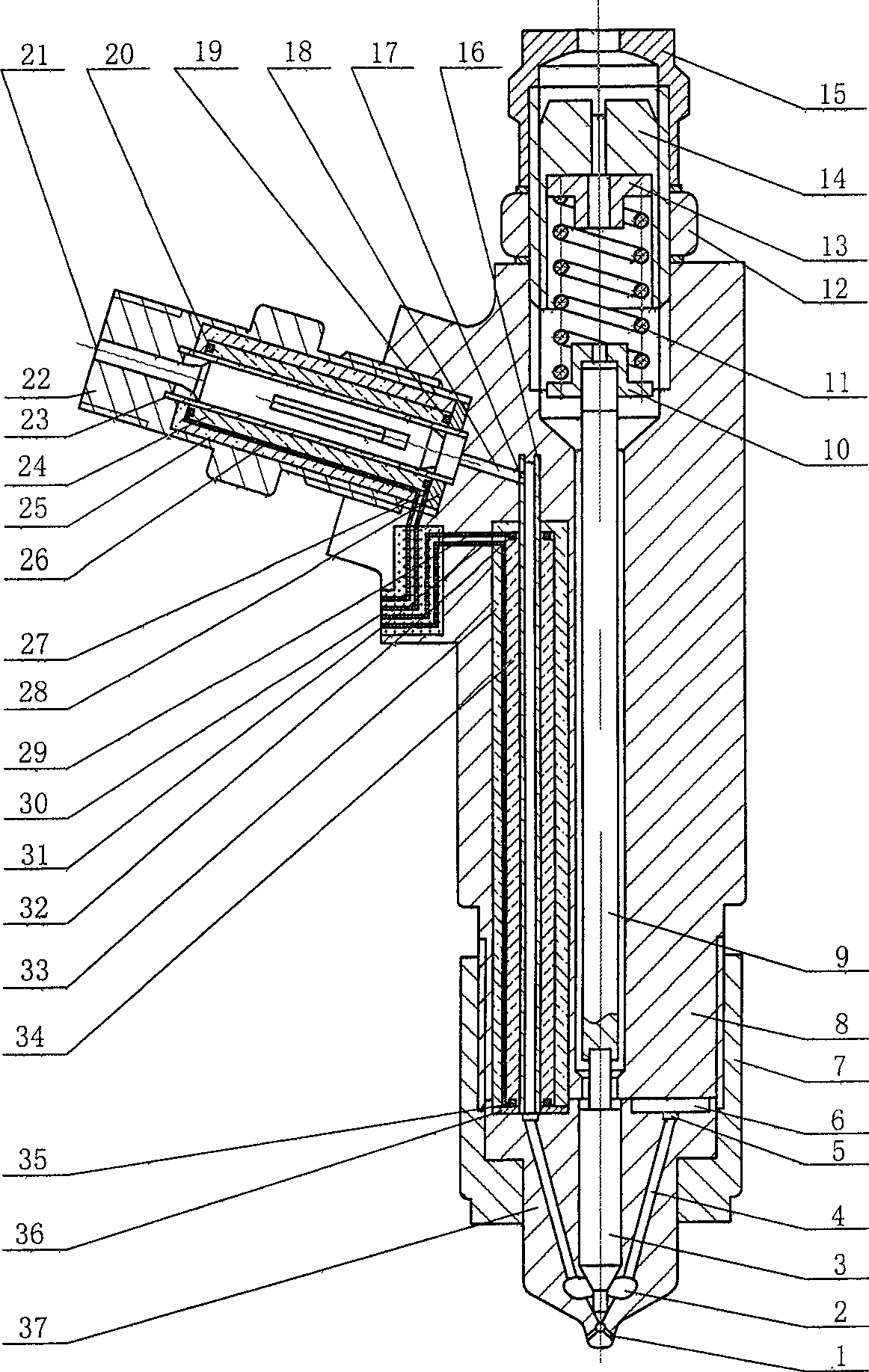

[0007] The specific implementation of the present invention will be further described below in conjunction with the accompanying drawings.

[0008] Such as figure 1 As shown, the present invention mainly includes: nozzle hole 1, fuel injector oil tank 2, fuel injector needle valve 3, fuel injector needle valve body oil inlet hole 4, fuel injector needle valve body oil inlet lower spin groove 5, Fuel injector needle valve body oil inlet upper spin groove 6, fuel injector tight cap 7, fuel injector body 8, fuel injector tappet 9, fuel injector pressure regulating spring lower seat 10, fuel injector pressure regulating spring 11 , Fuel injector pressure regulating nut 12, Fuel injector pressure regulating spring upper seat 13, Fuel injector pressure regulating screw 14, Fuel injector protective cap 15, Injector body heat conduction round tube 16, Fuel injector body heat conduction round tube inlet Oil hole 17, injector body oil inlet hole 18, heating electrode negative electrode...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com