Method for making special PVC (polyvinyl chloride) floor

A floor and workbench technology, which is applied in the field of making PVC special floors, can solve the problems of unsafe boilers, large energy consumption, failure to achieve environmental protection and energy saving, and achieve the effects of improving work efficiency and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

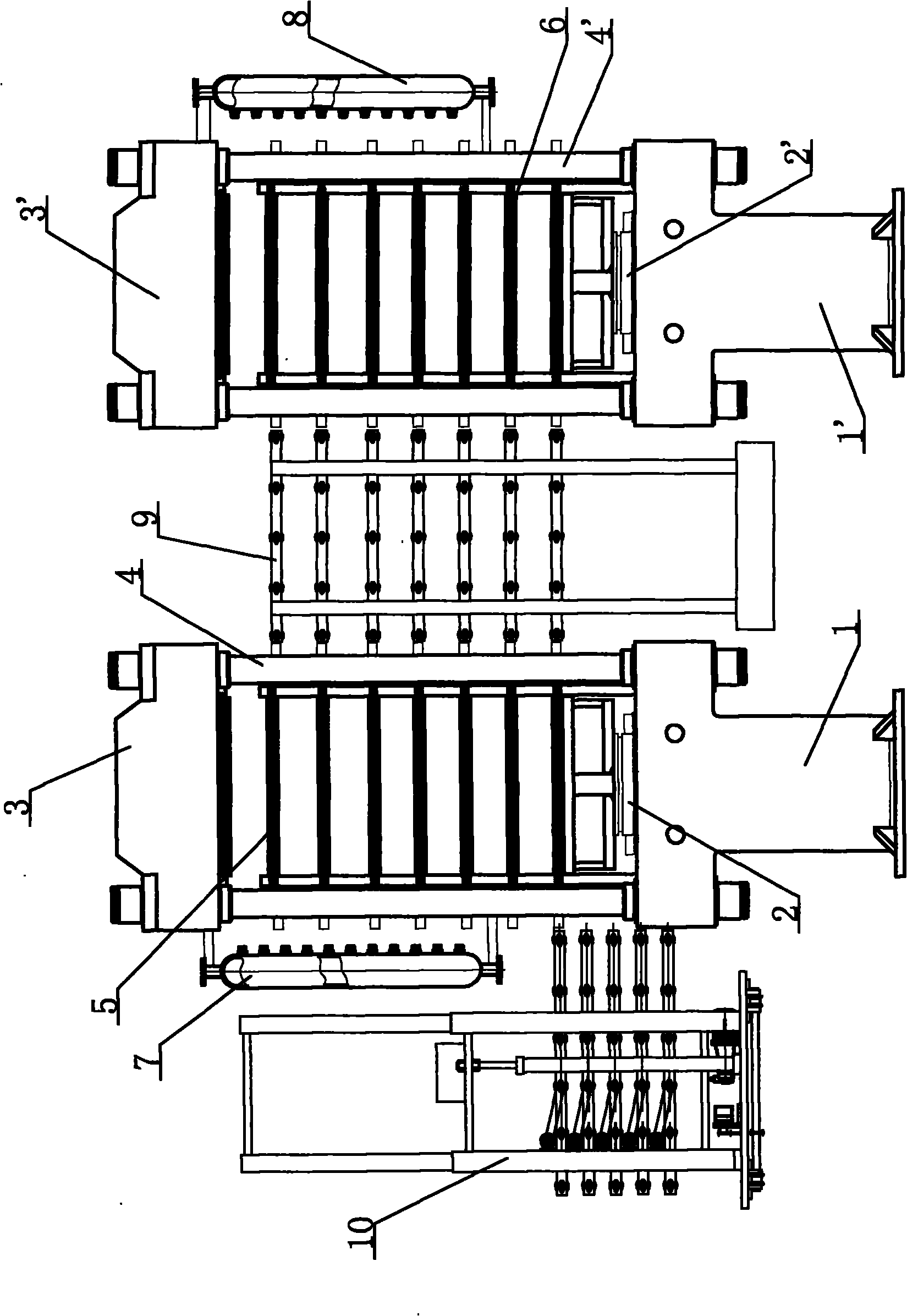

Image

Examples

Embodiment 1

[0024] The present invention discloses a method for making a special floor for PVC, which includes the following steps: first step, heat conduction oil enters the heating plate of the hot press, and makes the temperature of the heating plate constant, and the temperature is set at 150°C; second step, the The mold, PVC floor material and mold clamp are automatically fed to the workbench; the third step is to increase the pressure of the main cylinder in the heat press machine, and the pressure is 8mpa; the fourth step is to replenish pressure; the fifth step is to keep the pressure; In the sixth step, the main cylinder in the hot press machine is lowered, and the main cylinder’s lowering time is 9 minutes; in the seventh step, the mold and materials are automatically fed to the working table of another cold press; in the eighth step, The worktable of the cold press is kept at constant temperature with a water chiller, and the temperature is set at 20°C; in the ninth step, the ma...

Embodiment 2

[0027] The present invention discloses a method for making a special floor for PVC, which includes the following steps: first step, heat conduction oil enters the heating plate of the hot press, so that the temperature of the heating plate is set at 180°C; The mold, PVC floor material and mold clamp are automatically fed to the workbench; the third step is to increase the pressure of the main cylinder in the heat press machine, and the pressure is 16mpa; the fourth step is to replenish pressure; the fifth step is to keep the pressure; The sixth step, the main cylinder in the hot press machine is lowered, and the lowering time of the main cylinder is 12 minutes; the seventh step, the mold and the material are automatically fed to the worktable of another cold press; the eighth step, The worktable of the cold press is kept at a constant temperature with a water chiller, and the temperature is set at 29°C; in the ninth step, the main cylinder in the cold press rises and pressurize...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com