Processing technology for white carbon black with low water content

A technology of moisture content and processing technology, applied in the chemical industry, can solve the problems of damaging the processing performance of finished products, high moisture content of finished products, poor drying effect, etc., achieve uniform particle size distribution of finished products, short reaction cycle, and shorten combustion time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

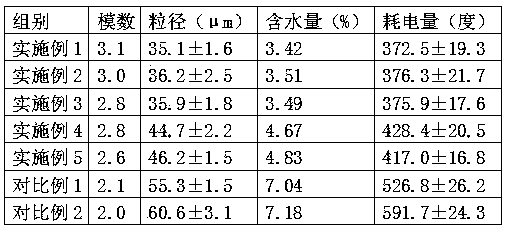

Examples

Embodiment 1

[0039] The processing technology of silica with low moisture content, the specific process steps are as follows:

[0040] A, the preparation of rice husk ash:

[0041] After removing impurities from the rice husk, add 11 times the mass fraction of the rice husk and soak in hydrochloric acid with a mass fraction of 3.5% for 2.5 hours, then wash with water to remove acid, spray dry the washed rice husk, and put the dried rice husk in a muffle furnace Combustion at 530°C for 1.4h, then send the combustion products into the suspension combustion furnace, and burn at 580°C for 45min to obtain rice husk ash for later use;

[0042] B, the preparation of water glass:

[0043] Mix rice husk ash and NaOH solution with a mass fraction of 45% in an autoclave at a mass ratio of 1:5. The agitator and steam pipe are respectively passed into the autoclave. Steam holes are evenly distributed on the steam pipe, and the stirring speed is controlled at 240r / min, the steam temperature is 190°C, t...

Embodiment 2

[0055] The processing technology of silica with low moisture content, the specific process steps are as follows:

[0056] A, the preparation of rice husk ash:

[0057] After removing impurities from the rice husk, add 9 times the weight of the rice husk and soak in 3% hydrochloric acid for 2 hours, then wash with water to remove the acid, spray dry the washed rice husk, and place the dried rice husk in a muffle furnace Combustion at 500°C for 1 hour, then send the combustion product into the suspension combustion furnace, and burn at 550°C for 30 minutes to obtain rice husk ash for later use;

[0058] B, the preparation of water glass:

[0059] Mix rice husk ash and NaOH solution with a mass fraction of 40% in the autoclave at a mass ratio of 1:4. The stirrer and steam pipe are respectively passed into the autoclave. Steam holes are evenly distributed on the steam pipe, and the stirring speed is controlled at 200r / min, steam temperature 170°C, pressure inside the kettle 0.6...

Embodiment 3

[0071] The processing technology of silica with low moisture content, the specific process steps are as follows:

[0072] A, the preparation of rice husk ash:

[0073] After removing impurities from the rice husks, add 12 times the weight of the rice husks and soak in 4% hydrochloric acid for 3 hours, then wash with water to remove the acid, spray dry the washed rice husks, and place the dried rice husks in a muffle furnace Combustion at 550°C for 2 hours, then send the combustion products into the suspension combustion furnace, and burn at 650°C for 60 minutes to obtain rice husk ash for later use;

[0074] B, the preparation of water glass:

[0075] Rice husk ash and NaOH solution with a mass fraction of 55% were mixed in an autoclave at a mass ratio of 1:6, the stirrer and steam pipe were respectively passed into the autoclave, steam holes were evenly distributed on the steam pipe, and the stirring speed was controlled at 300r / min, steam temperature 220°C, pressure insid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com